1-3 type piezoelectric composite material based on self-similar photonic crystal structure, and preparation method thereof

A technology of piezoelectric composite materials and phononic crystals, which is applied in the selection of materials for piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials, etc., can solve structural problems. Problems such as unclear design can achieve the effects of reducing energy loss, suppressing lateral vibration, and widening the bandgap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

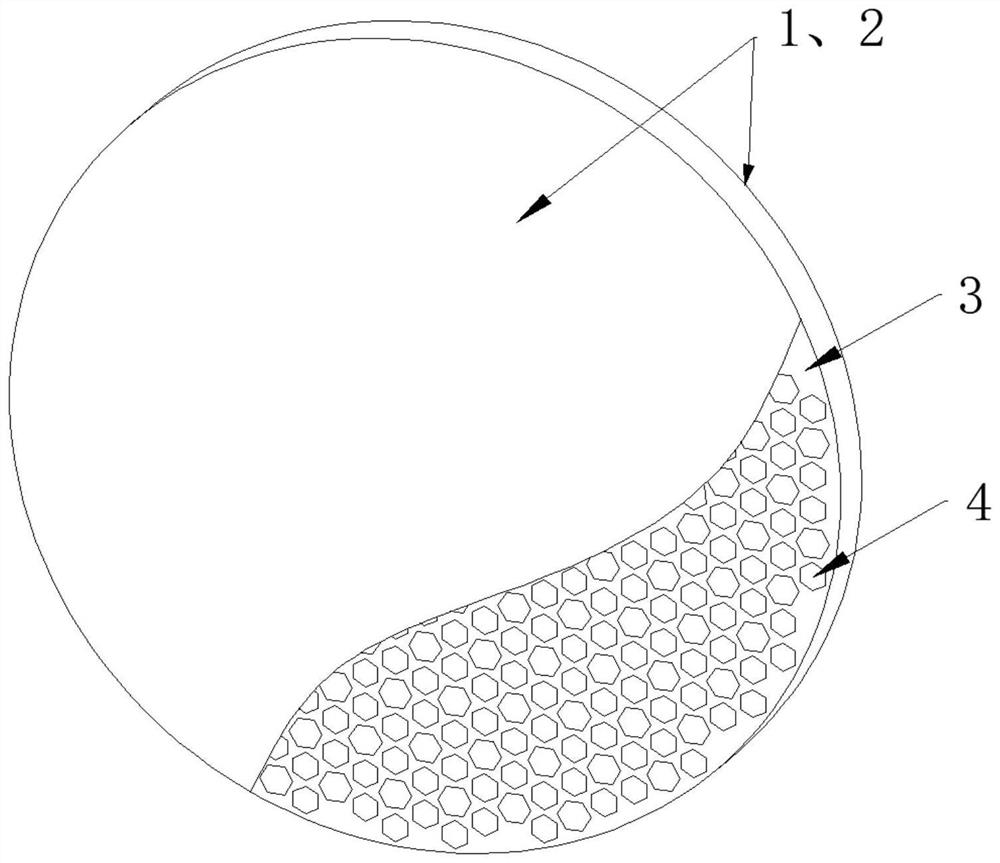

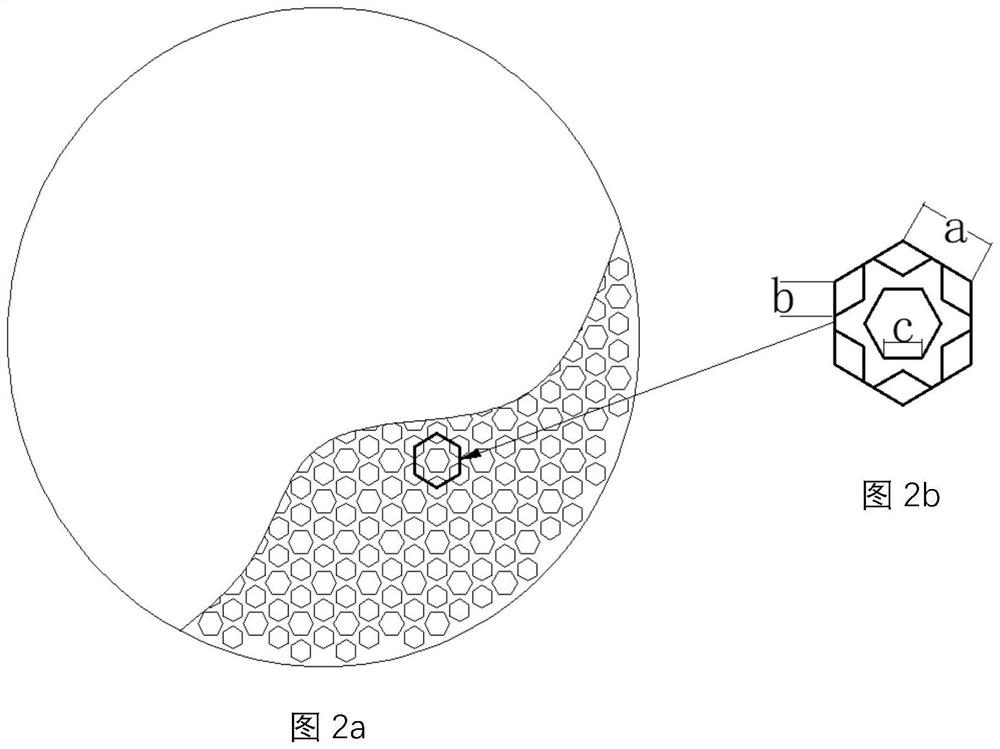

[0035] Such as figure 1 As shown, this embodiment provides a 1-3 type piezoelectric composite material based on a self-similar phonon crystal structure, including an upper electrode 1 , a lower electrode 2 , an epoxy resin 3 , and a piezoelectric ceramic column 4 .

[0036] The piezoelectric phase material is defined as PZT-5H, which is polarized along the thickness direction, the polymer phase material is defined as epoxy resin 3, and the upper electrode 1 and the lower electrode 2 are respectively located on the upper and lower surfaces of the piezoelectric composite material. Among them, the piezoelectric phase is piezoelectric ceramic columns 4 with a hexagonal cross-sectional shape, which are arranged periodically, and each PZT piezoelectric column 4 is rotated by a certain angle relative to the surrounding piezoelectric columns, so as to keep no gap between the piezoelectric columns. The generation of parallel sides is arranged in a hexagonal lattice type, epoxy resin 3 ...

Embodiment 2

[0043] This embodiment provides a method for preparing a 1-3 type piezoelectric composite material based on a self-similar phonon crystal structure, and the specific steps are as follows:

[0044] 1. Inject the prepared PZT powder into a hexagonal mold, and pre-press it into an embryo body under a press (100MPa to 200MPa);

[0045] 2. Use a high-temperature resistance furnace to sinter the green body at a temperature of 950°C to 1300°C, and keep it warm for 2 hours to 2.5 hours after sintering to obtain a PZT piezoelectric column, and then use an ultrasonic cleaner to clean the piezoelectric column;

[0046]3. After the PZT piezoelectric columns are arranged in the form of hexagonal lattice in the fixture, the epoxy resin is poured and vacuumized to avoid residual air bubbles from affecting the performance of the piezoelectric composite material. When arranging the PZT piezoelectric columns, each piezoelectric column forms a certain angle with respect to the surrounding piezoe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com