Chain-type freight ropeway vibration attenuation device and method

A technology of freight cableway and vibration damping device, which is applied in the direction of cable railway, transportation and packaging, motor vehicles, etc., can solve the problems of motion instability, impact, and complex operation lines, and achieve the effect of reducing lateral vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

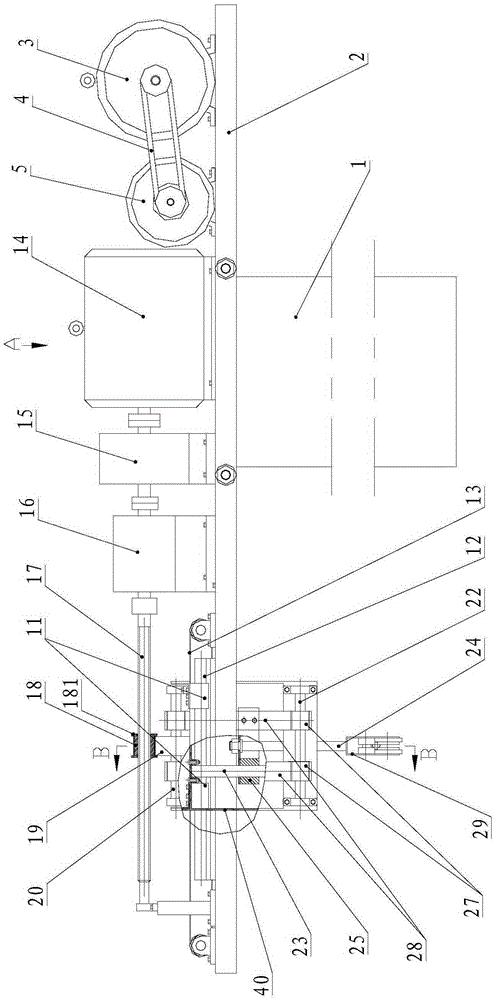

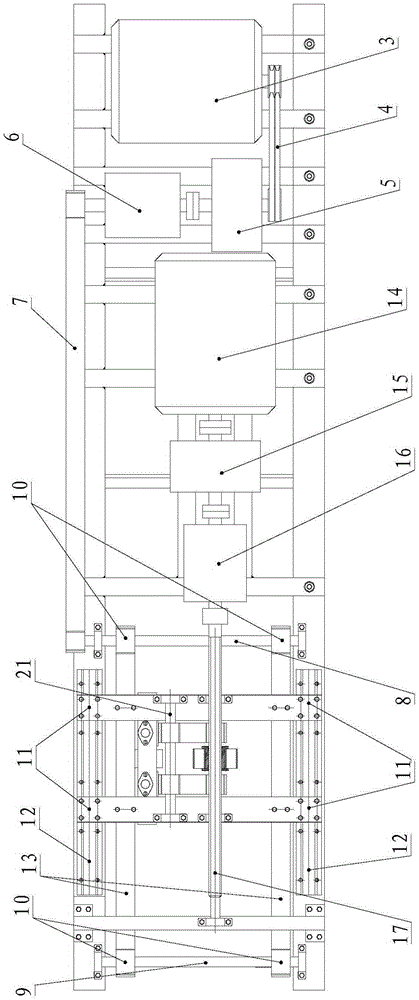

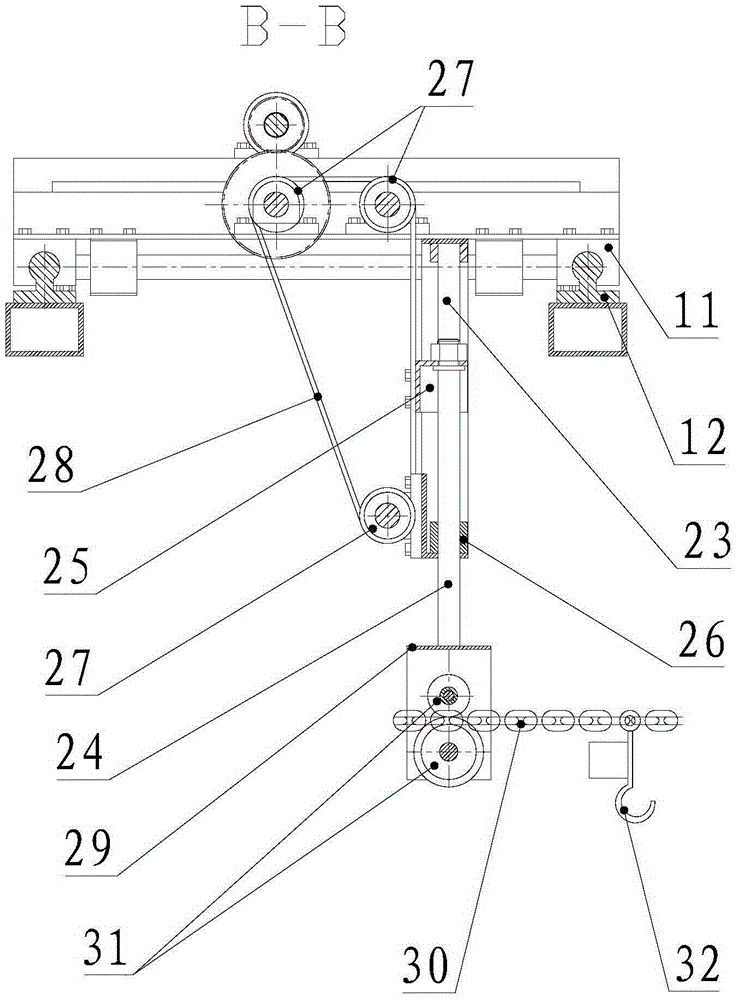

[0054] This embodiment discloses a chain-type freight ropeway vibration damping device, which includes a horizontal adjustment mechanism, a horizontal drive mechanism, a vertical adjustment mechanism, a vertical drive mechanism, a vibration signal collection module, and a vibration controller;

[0055] The vibration signal collection module is set on the tosso mechanism of the chain freight ropeway, and is used to collect the vibration signal of the chain freight ropeway toso mechanism;

[0056] The vibration signal acquisition module is connected to the vibration controller and sends the collected vibration signals to the vibration controller; the vibration controller is respectively connected to the horizontal drive mechanism and the vertical drive mechanism to receive the output torque signals of the horizontal drive mechanism and the vertical drive mechanism and Control the work of horizontal drive mechanism and vertical drive mechanism;

[0057] The power output end of the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com