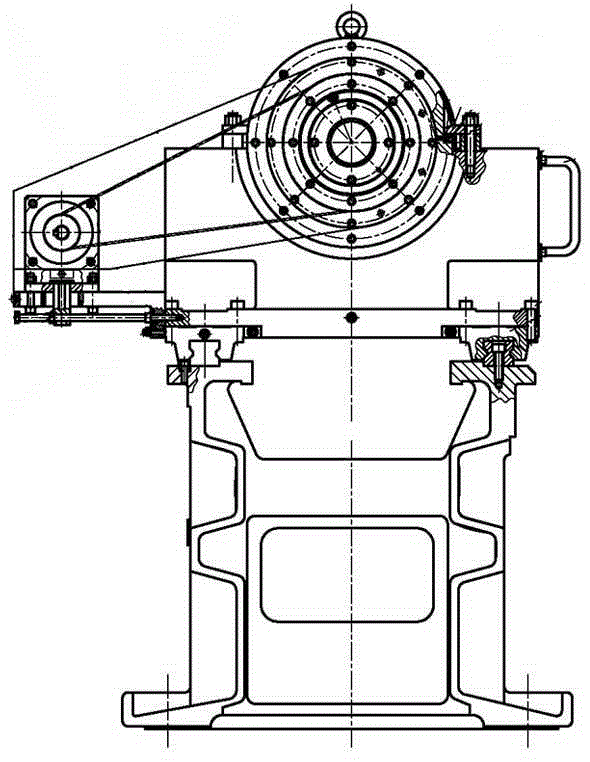

Vibration reducing supporter of deep hole machining cutter bar

A supporter and cutter bar technology, applied in metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of complex structure, unsatisfactory and unreasonable vibration reduction effect of the vibration-absorbing supporter, and achieve novel structural design, Safe to use and excellent vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

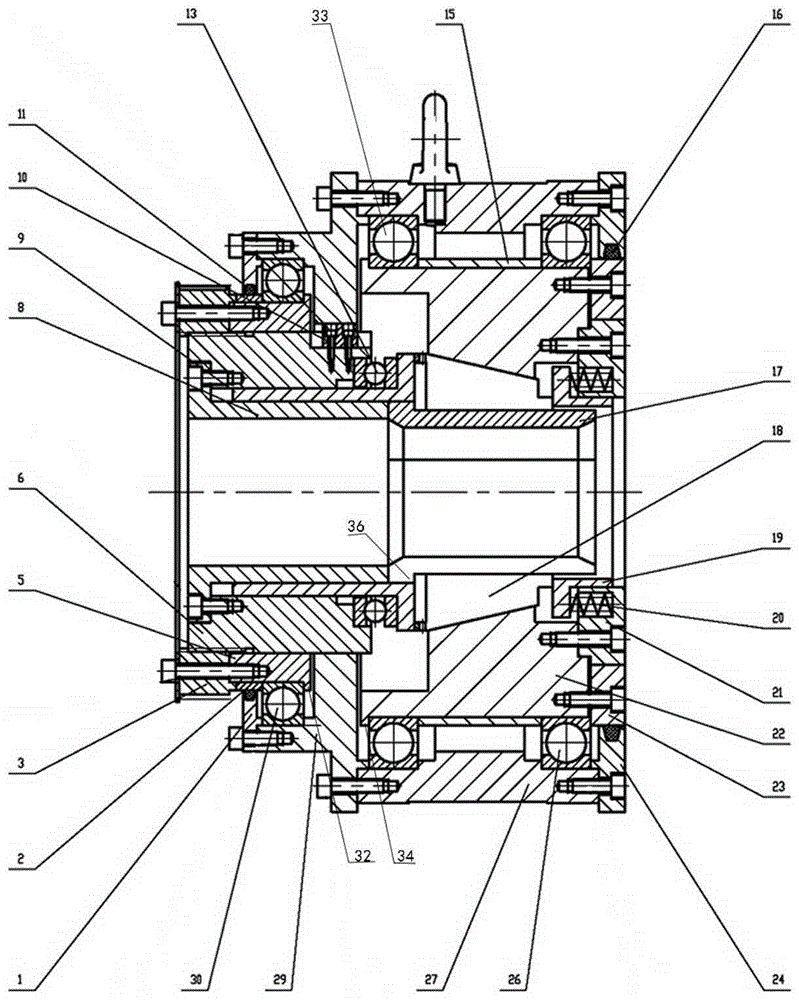

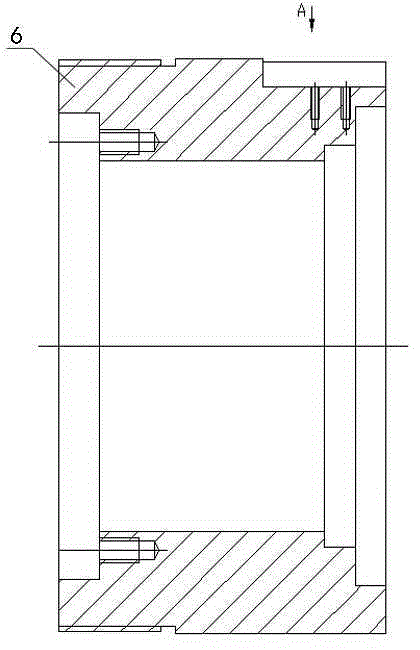

[0023] The deep hole processing cutter bar vibration damping supporter includes the front bearing seat 29, the outer contour of the front bearing seat 29 is cylindrical, one end is provided with a connecting flange, and the front bearing seat 29 has a three-stage stepped shaft hole. The first deep groove ball bearing 30 is embedded in the inner bottom of the large-diameter hole of the front bearing seat of the shaft hole, which is not connected to the flange end. The first deep groove ball bearing 30 is sleeved with a pulley connecting shaft 5, and the pulley connecting shaft 5 is provided with a shaft. The outer convex ring 32 is provided at one end of the hole, and the outer convex ring 32 extends to the lower part 30 of the first deep groove ball bearing (that is, in the middle diameter hole of the three-stage stepped shaft hole of the front bearing seat), and the pulley connecting shaft 5 The end face of the other end (that is, the non-external convex ring end) is fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com