Vibration dampened drilling tool

A technology of drill bit and drill body, which is applied in the direction of shock absorber, friction shock absorber, drill repairing, etc., and can solve the problem of not being able to give noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

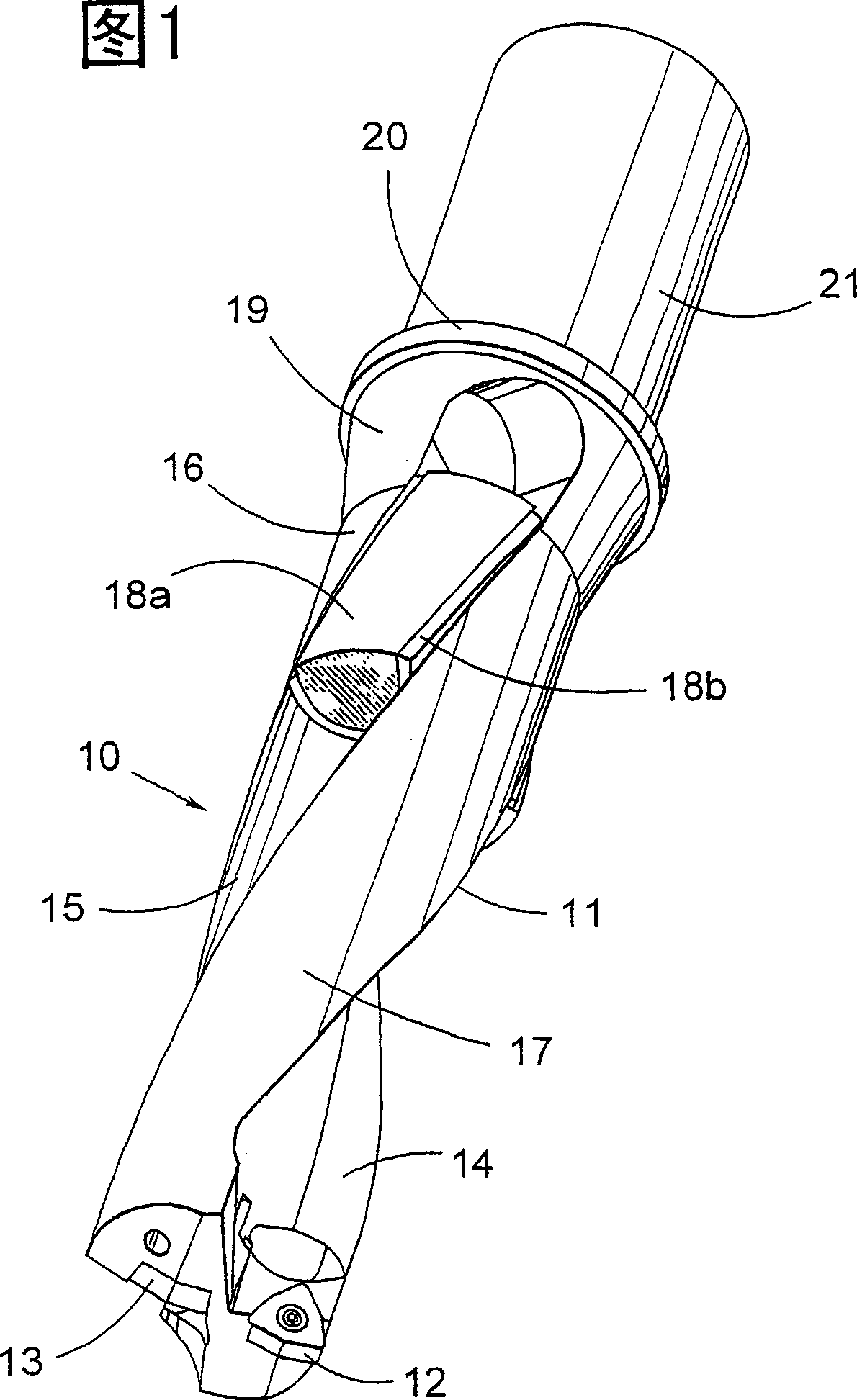

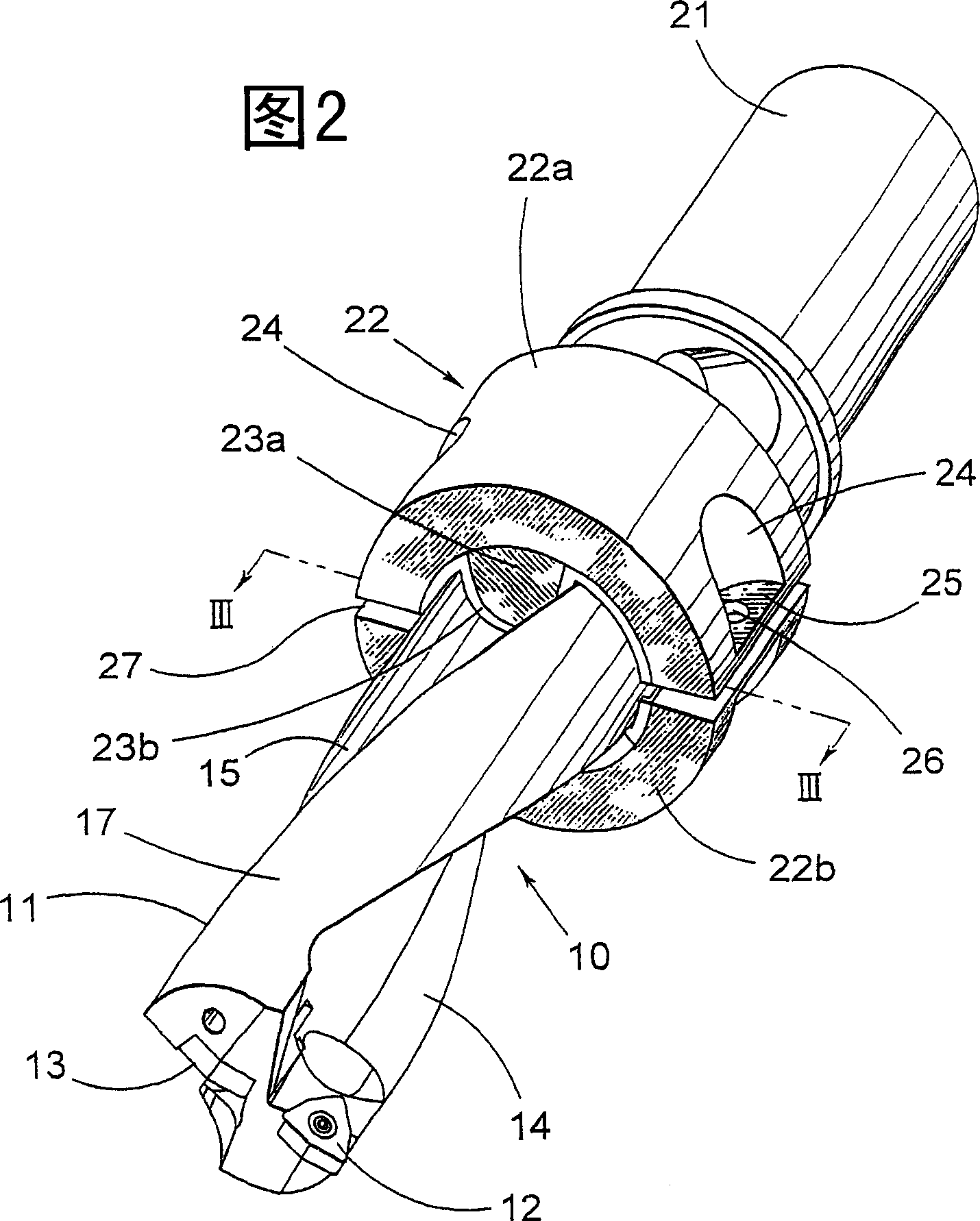

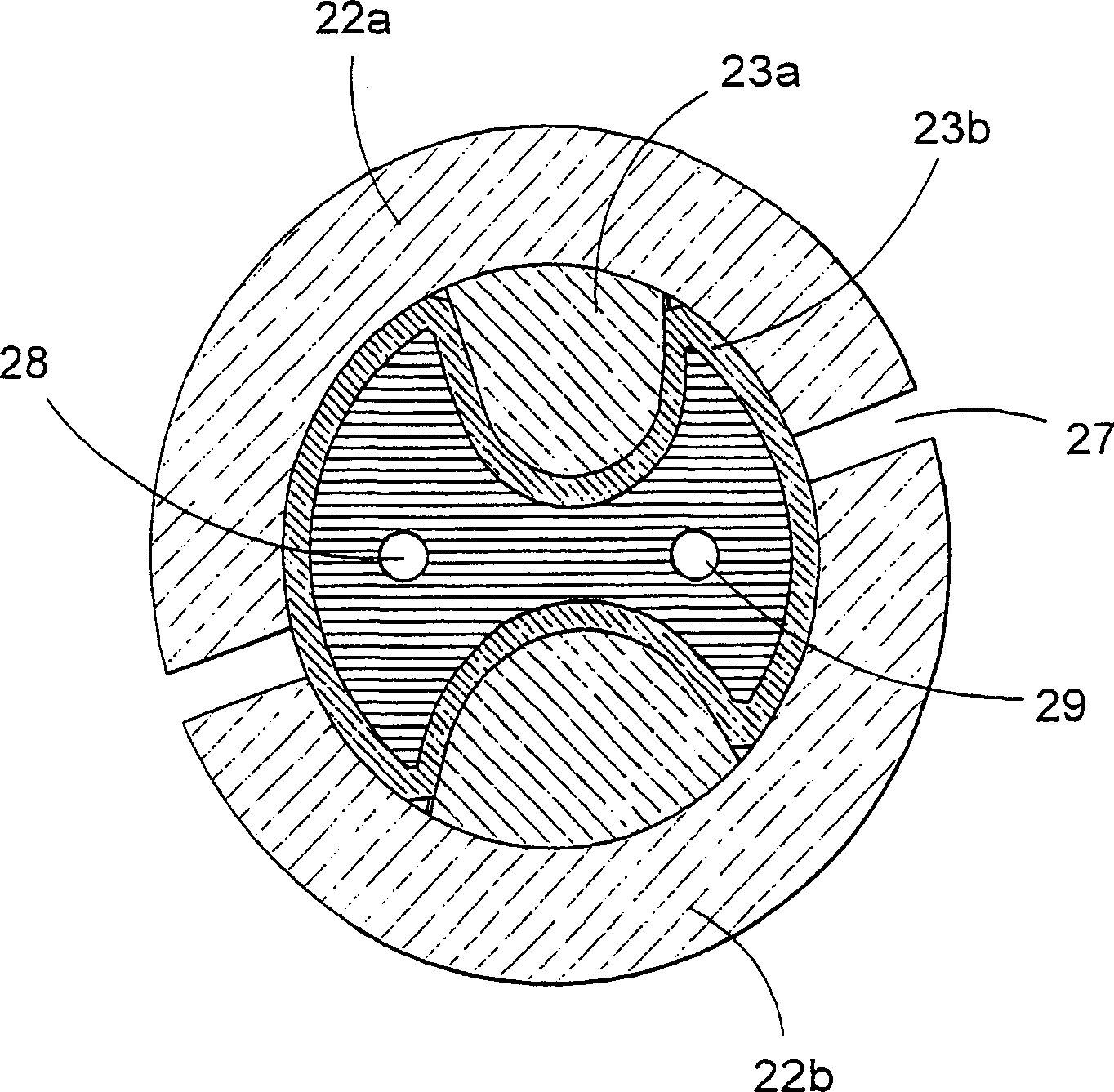

[0010] According to the invention shown in FIG. 1, the embodiment of the drill bit portion 10 containing the damping elements 18a and 18b includes a drill body 11, and an outer cutting insert 12 at the edge of the drill bit and an inner cutting insert 13 near the center of the drill bit. The cutting insert is preferably made of cemented carbide. The two cutting inserts are located at different radial distances from the drill axis A, and their operating areas overlap each other. At the same time, the two cutting blades are offset by about 180° in the circumferential direction of the drill. The cutting inserts 12, 13 are fastened in corresponding insert seats on the drill body 11 in a known manner, such as a threaded connection. The drill body 11 has a substantially cylindrical basic shape and is made of steel.

[0011] On the part of the drill body 11 located behind the cutting blade, there are provided grooves 14, 15 extending axially and opening radially outward. The cross sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com