Method for reducing undulatory wear of steel rails

A wave wear and rail technology, applied in the direction of rails, rails, instruments, etc., can solve the problems of severe vibration of rails and the environment, reduce the service life of rails and wheels, and increase the maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

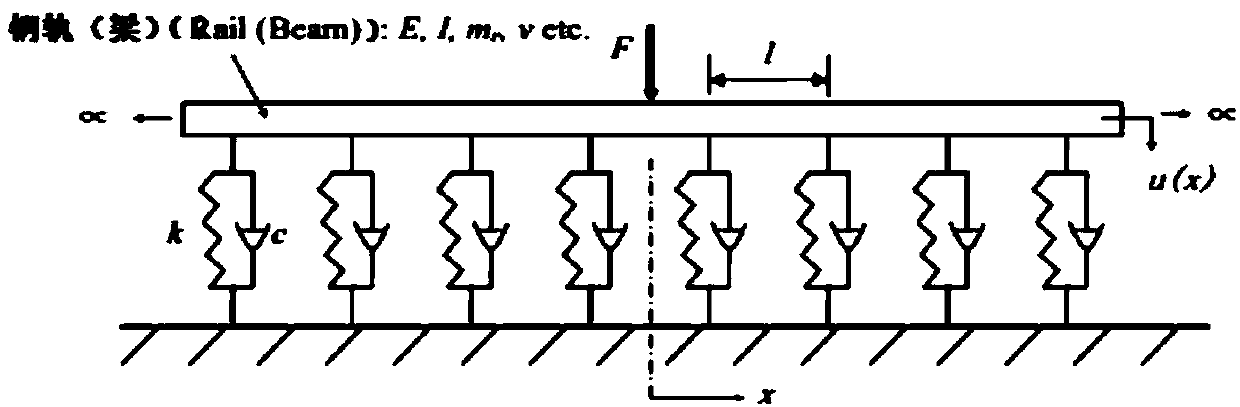

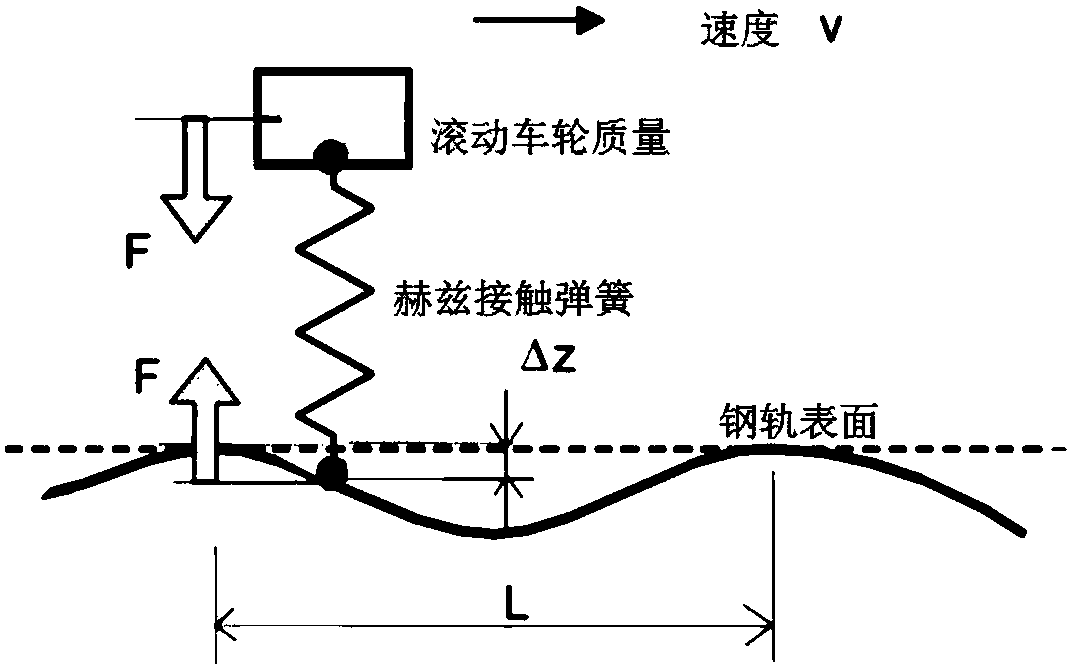

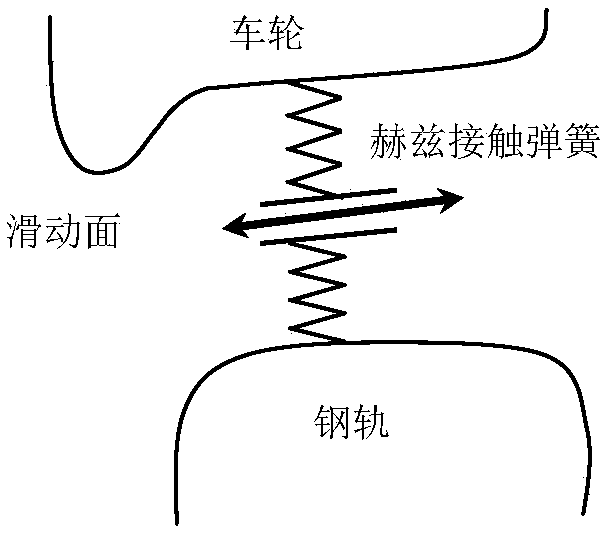

[0039]The formation and development of rail corrugation is a cyclic process in which the dynamic behavior of the vehicle track interacts with corrugation, that is, when the vehicle passes through an irregular (curved) track, the vehicle and the track vibrate, resulting in uneven wear of the rail contact surface And plastic deformation, when the vehicle passes next time, the irregularities of the track and the accumulated uneven wear and plastic deformation of the rail contact surface will aggravate the vibration of the vehicle track, which will accelerate the uneven wear of the rail and increase the cumulative amount of plastic deformation. After repeated cycles, it leads to the formation of wavy wear on the contact surface of the rail. The interaction between wheel and rail is very complex, which includes dynamic action, wheel-rail contact action, friction action and the mechanism of their mutual interaction. According to an analysis, the rail wave wear is caused by the quasi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com