Composite material composite sleeper

A composite material and sleeper technology, which is applied in the field of rail transit, can solve the problems of reducing the effect of foam base material shock absorption and noise reduction, increasing the vibration and wear of rails, wheels, and unsatisfactory shear resistance, so as to reduce wave wear and tear. , Improve the service life and ensure the effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

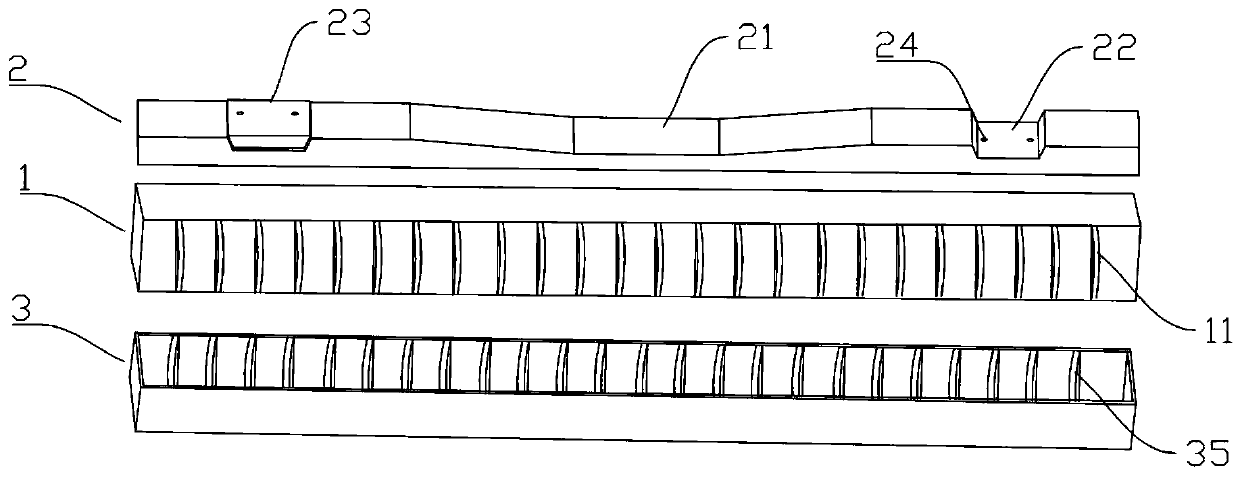

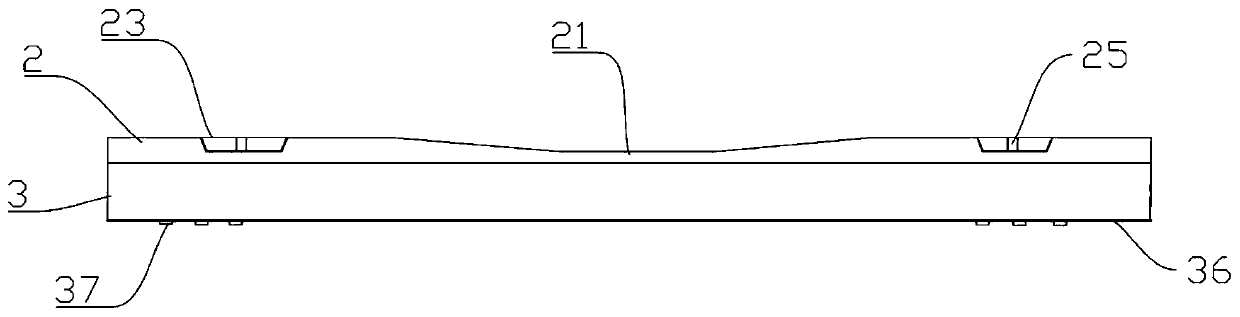

[0035] Such as figure 1 As shown, this embodiment provides a composite sleeper comprising a shell and a concrete core 1, the shell is made of composite material, the shell includes an upper shell 2 and a lower shell 3, the lower shell The body 3 is arranged as a trough structure, and the concrete core 1 is accommodated inside the lower shell 3 . The concrete core body 1 increases the dead weight of the sleeper, avoiding insufficient resistance due to small dead weight, and finally improves the stability of the railway system. When a train passes the rail on the upper part of the sleeper, a greater vibration force will be generated, and the upper shell of the sleeper can relieve the vibration force transmitted from the rail and increase the service life of the sleeper. And compared with conventional concrete sleepers, the arrangement of the shell can effectively reduce the noise generated when the train passes the rails.

[0036] The length, width and height of the concrete c...

Embodiment 2

[0045] Further, in order to increase the connection stability of the upper shell 2, the concrete pillow core 1 and the lower shell 3 in the synthetic sleeper, this embodiment sets a clip 4 outside the synthetic sleeper on the basis of the embodiment 1, for The upper shell 2, the concrete pillow core 1 and the lower shell 3 are fixed.

[0046] The clamp 4 includes a pair of elastic sheets 41, which are arranged oppositely. The upper ends of the two elastic sheets 41 are connected and fixed by locking bolts. The lower end of the shrapnel is fixed on the ballast bed through a connecting piece. The elastic piece is arranged in a curved structure, and the elastic piece is buckled with the top of the upper casing, the side wall of the lower casing and the ballast bed, thereby fixing and clamping the upper casing, the lower casing and the core inside the casing.

[0047] In the sleeper made of composite material provided in this embodiment, clips are installed on the outside of the ...

Embodiment 3

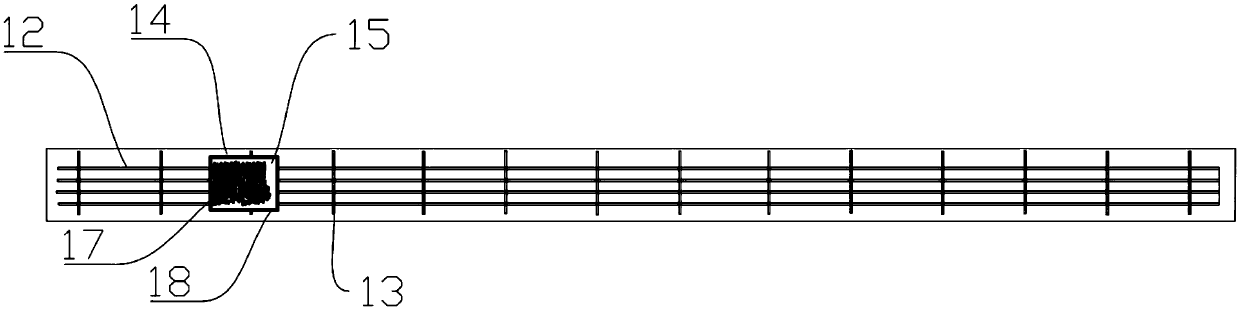

[0049] In this embodiment, on the basis of Embodiment 1, the vibration damping effect of the concrete core is further improved. Specifically, a damping element 14 is disposed inside the concrete core 1 , and the damping element 14 is disposed at a position corresponding to the lower part of the rail bearing groove 22 . Specifically, a cavity 15 is provided inside the concrete core 1 corresponding to the position of the rail bearing groove 22, and discrete particles 17 are added inside the cavity 15, and an opening 16 is provided on the top side of the cavity 15 to facilitate adding or taking out discrete particles. particles17. During the vibration process of the rail, the vibration is transmitted to the sleeper, and the sleeper drives the cavity 15 and the discrete particles 17 to move, and a large number of discrete particles impact and rub against each other, dissipating the vibration energy of the rail, thereby reducing the vibration of the rail. Moreover, the absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com