Ram and ram mechanism containing the ram

A ram and cavity technology, used in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve problems such as the difficulty of greatly improving the overall stiffness, the limited weight of the ram, and the limitation of the machining accuracy of the milling machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

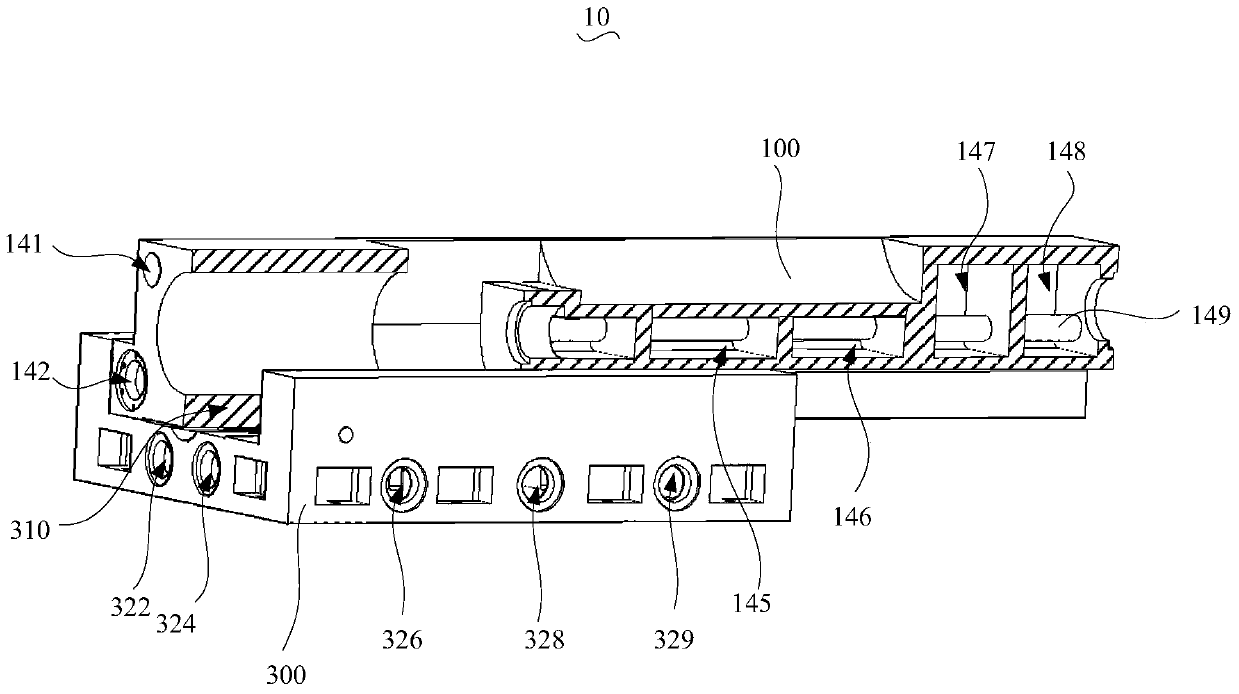

[0021] see figure 1 , the ram mechanism 10 of one embodiment includes a ram 100 and a ram seat 300 . The ram seat 300 is provided with a groove 310 , the outer periphery of the ram 100 matches with the groove 310 , the ram 100 is partly accommodated in the groove 310 , and the ram 100 can slide on the ram seat 300 .

[0022] The ram 100 defines a first cavity, and the first cavity is filled with damping particles.

[0023] There are at least two first cavities. In this embodiment, there are eight first cavities. The four first cavities are respectively arranged on four corners of the ram 100 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com