Built-in floor of railway vehicle, floor structure and railway vehicle

A rail vehicle and floor technology, which is applied in the field of rail vehicle traffic, can solve the problems of not meeting the requirements of light weight and sound insulation and noise reduction of the floor installed in the train, unable to ensure passenger comfort, and poor sound insulation and noise reduction effect, etc. Achieve reliable connection, reduce weight and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

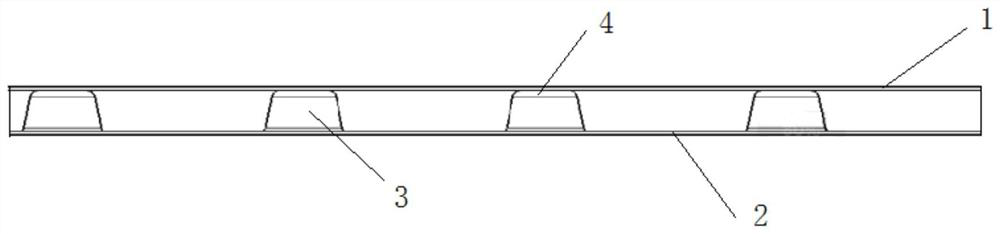

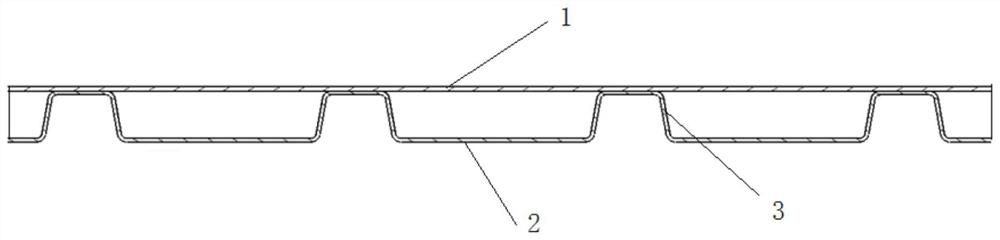

[0048] In a typical embodiment of the present invention, refer to figure 1As shown, a rail vehicle interior floor includes a first plate 1 and a second plate 2, the second plate 2 is arranged below the first plate 1, the first plate 1 is a flat plate, and the second plate 2 is stamped with a plurality of The boss 3, the second board 2 is fixedly connected with the first board through the boss 3;

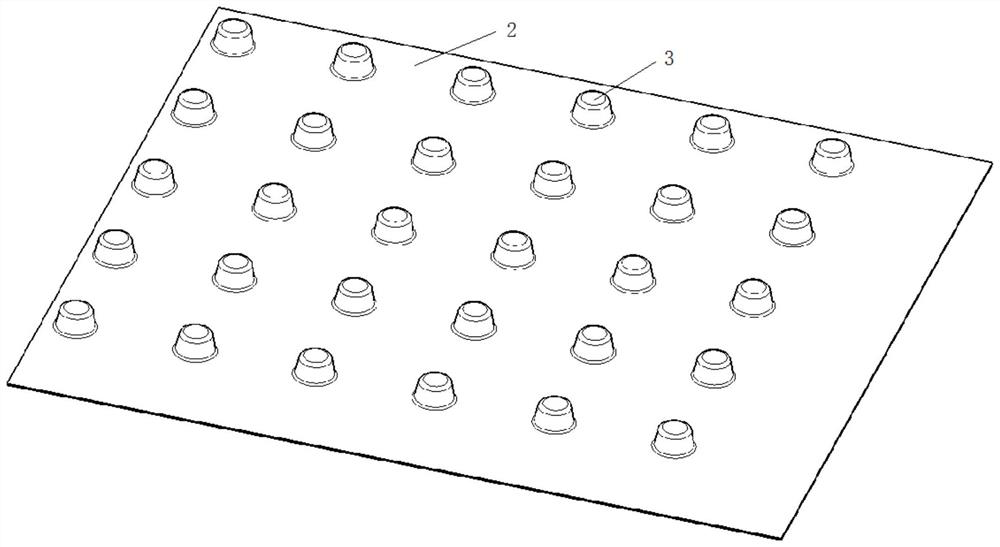

[0049] Such as figure 2 and image 3 As shown, the boss 3 is a circular platform structure, the diameter of one end of the boss 3 close to the first plate 1 is smaller than the diameter of the other end, and the end with a small diameter of the boss is fixed to the bottom of the first plate 1 by welding, in order to make full use of the space , the second plate 2 is provided with multiple rows and columns of bosses 3 , two adjacent bosses 3 are arranged at a predetermined distance apart, and the bosses 3 are evenly distributed on the second plate 2 .

[0050] It can be understood...

Embodiment 2

[0062] This embodiment provides a rail vehicle floor structure, including a car body floor and a rail vehicle interior floor (referred to as interior floor) described in Embodiment 1. The interior floor is connected to the car body floor, and the interior floor is connected to the car body floor. A vibration energy recovery device and a mounting seat are arranged between them, and the mounting seat and the boss are staggered. In some examples, the mounting seat is located below the space between two adjacent rows and / or two rows of bosses.

[0063] Such as Figure 5 and Figure 6 As shown, there are multiple rows of mounting seats 6 in this embodiment, and the mounting seats 6 are respectively arranged between the vehicle body floor 7 and the interior floor 5, and each row of mounting seats 6 is arranged along the width direction of the floor structure, and the mounting seats 6 The reliable connection between the interior floor 5 and the vehicle body floor 7 is effectively en...

Embodiment 3

[0078] This embodiment provides a rail vehicle, which adopts the rail vehicle interior floor of Embodiment 1 and the rail vehicle floor structure of Embodiment 2, and the interior floor 5 can also be called a den floor.

[0079] The vibration and noise generated when the train is running on the track are transmitted to the interior floor 5 through the car body floor, and the interior floor 5 vibrates to diffuse the noise to the passenger compartment of the car body. The amount of noise diffusion can be expressed by the following formula:

[0080] W = σ rad ρC2 >S

[0081] σ rad is the audio frequency diffusivity, which characterizes the efficiency of converting the vibration of the interior floor 5 into the vibration of air particles; ρ is the air density; C is the speed of sound; 2 > is the average value of the square of the vibration velocity of the interior floor in time-space; S is the area of the second plate, when the excitation source is constant, it can be reduced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com