A ball screw pair vibration damping structure

A ball screw pair and vibration-damping structure technology, which is applied in the field of damper vibration reduction, can solve problems such as difficult vibration control, and achieve the effects of simple structure, convenient adjustment, and simple vibration-damping structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

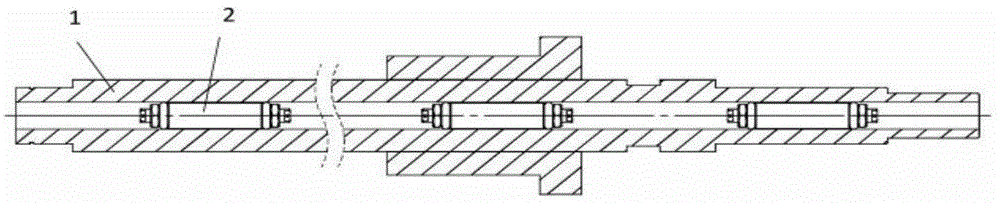

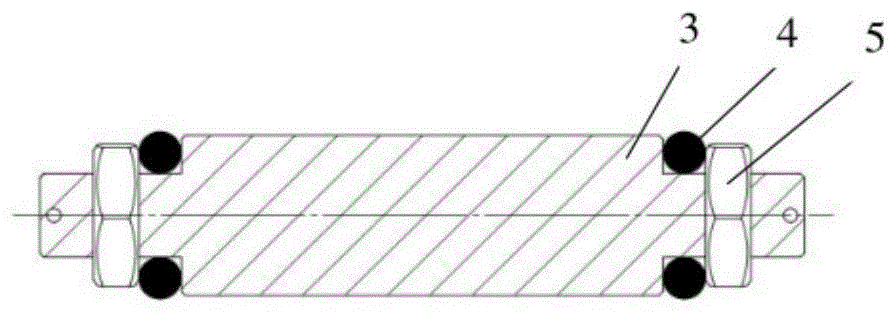

[0019] first as figure 1 , the present invention is a ball screw pair vibration damping structure, comprising: a ball screw pair 1 and a damper unit 2, the screw of the ball screw pair 1 is a hollow screw, and a plurality of Damper unit 2. The damper unit 2 is composed of a mass block 3 , a rubber ring 4 and an adjusting nut 5 . Rubber ring 4 is installed on mass block 3 two ends and is fastened with adjusting nut 5. The mass block 3 of the damper is supported and fixed in the inner hole of the hollow screw by the rubber rings 4 at both ends, and the supporting stiffness of the mass block 3 by the rubber ring 4 is changed by adjusting the nut 5, so that the natural frequency of each damper unit 2 is consistent with that of the ball wire The dynamic characteristics of the bars are matched to achieve the best vibration control effect.

[0020] The mass block 3 is cylindrical, with small-diameter steps at its two ends, the rubber ring 4 is set on the step, and the nut 5 is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com