Vibration isolation lifting lug device with exhaust pipe and auxiliary frame connected

A sub-frame and exhaust pipe technology is applied in the direction of gas intake of power plant, power plant, vehicle components, etc., to achieve the effects of improving vibration isolation capability, reducing vibration transmission, and reducing exhaust noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

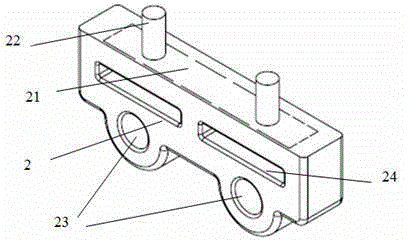

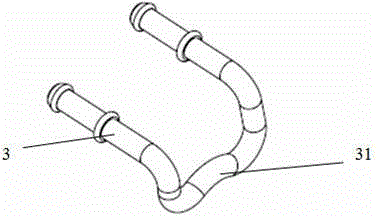

[0018] see Figure 4 , The vibration isolation lifting lug device is composed of a lifting lug mounting bracket 1, a rectangular composite double lifting lug 2 and a hook 3. It designs the traditional lifting lug hook form as a matching form of mounting bracket and bolts, which is convenient for general assembly with the sub-frame, and the special mounting bracket increases the rigidity of the mounting attachment point. The traditional lifting lug structure is designed as a rectangular composite double lifting lug structure, and the lateral vibration of the exhaust pipe can be effectively suppressed through the torsional deformation of the rectangular lifting lug.

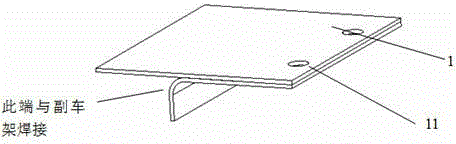

[0019] see figure 1 , the lifting lug mounting bracket 1 adopts a two-layer metal plate spot welding structure, one end of the lower metal plate is bent downward, and the edge of this end is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com