Planetary gear transmission gear-matching method

A technology of planetary gear transmission and planetary gear, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of difficult tooth matching, large vibration and noise, insufficient and reasonable basis, etc., and achieve simplified matching The tooth calculation and tooth matching process are simple and the operability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

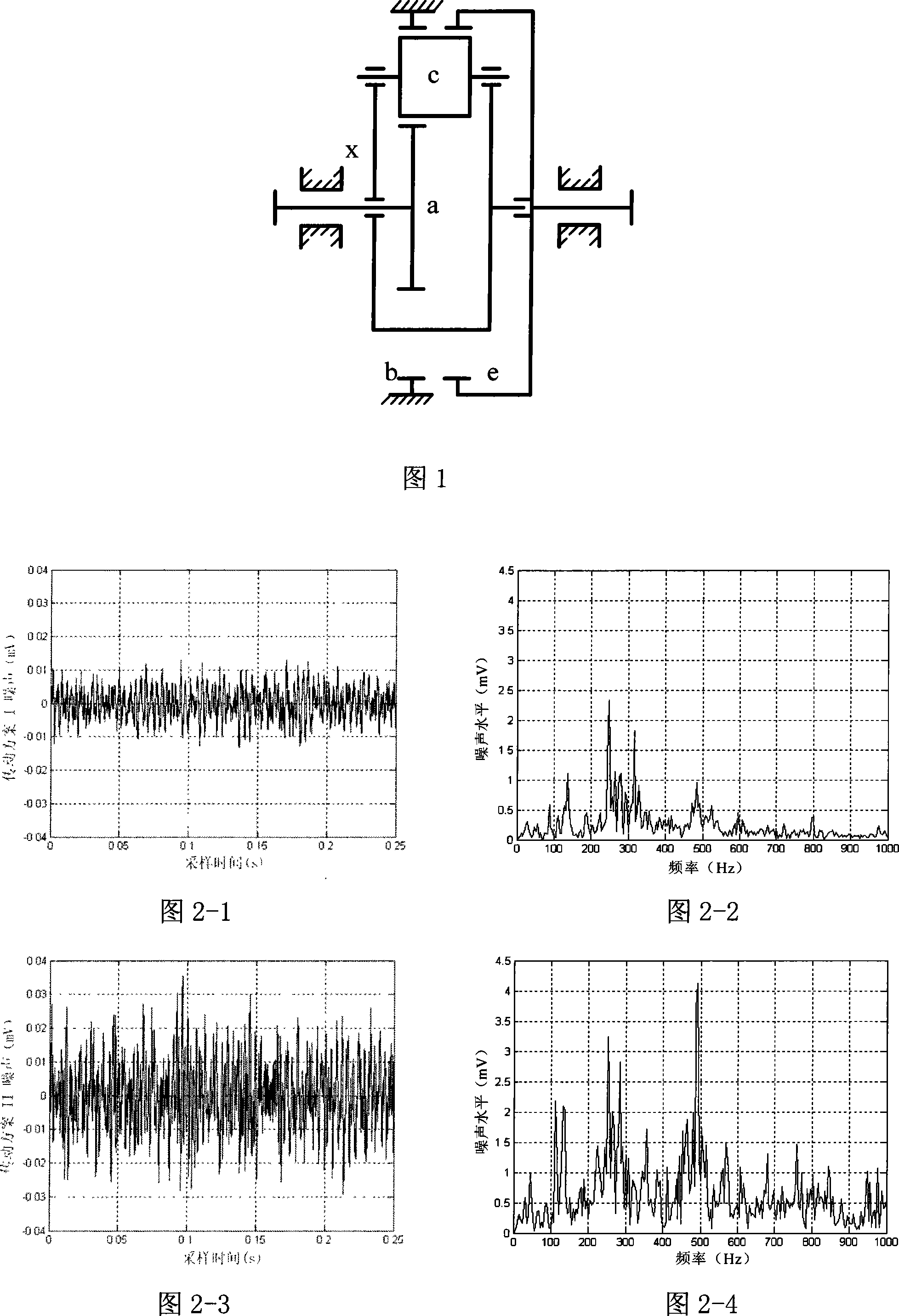

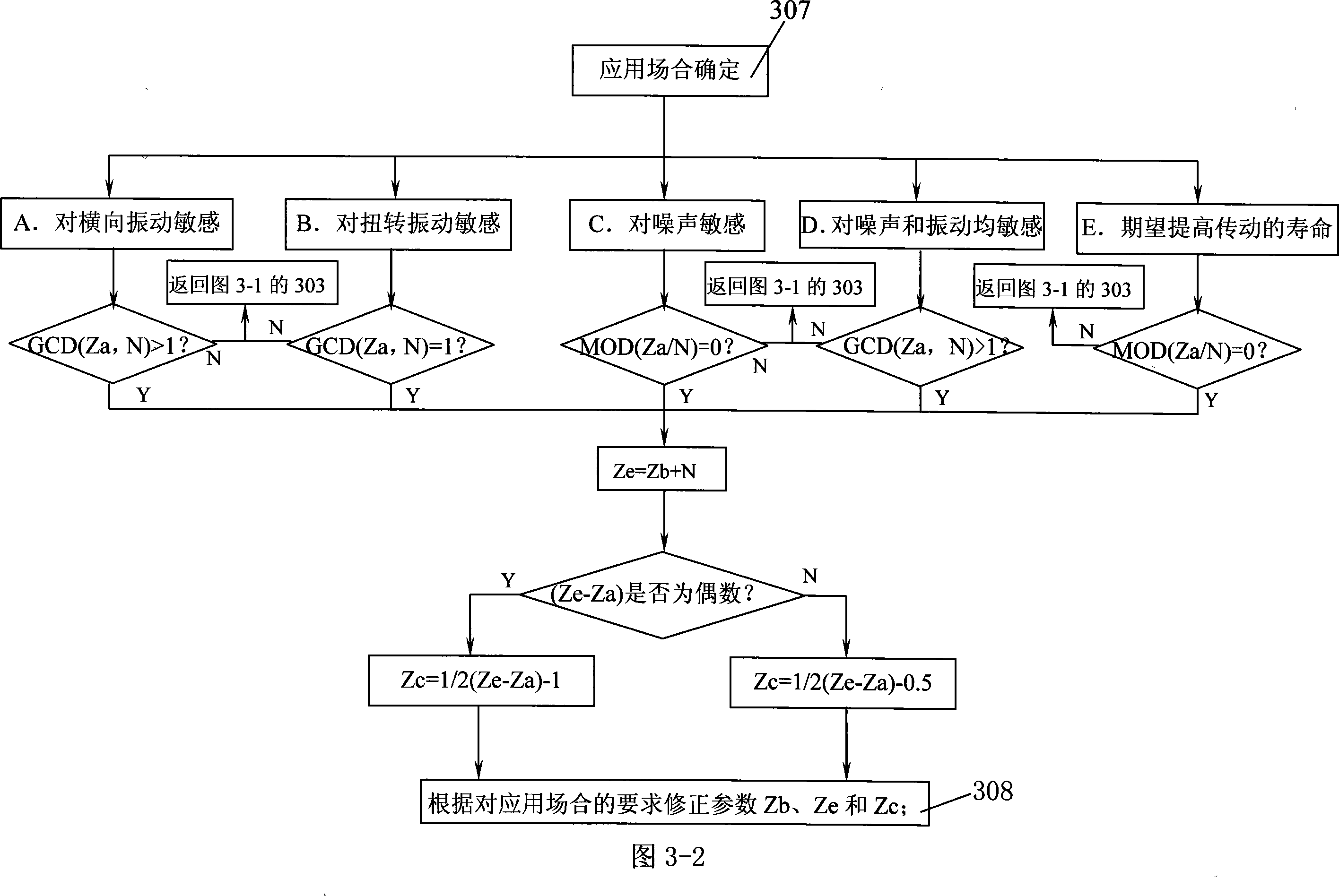

[0026] The implementation process of the tooth matching method of the present invention will be described in detail below with reference to Fig. 1, Fig. 3-1 and Fig. 3-2, taking the 3K (II)) type planetary gear transmission system as an example.

[0027] (301) start the system;

[0028] (302) According to the design requirements, formulate the theoretical transmission ratio i according to the formula (1) p ;

[0029] i p =(1+Z b / Z a )(Z e / (Z e -Z b )) (1)

[0030] (303) Formulate the number of gears N in the planetary transmission system and the number of teeth Z of the central external gear a a ;

[0031] (304) draw up the number of teeth Z of the center internal gear b according to the formula (2) b :

[0032] Z b = 1 2 [ ( Z a + N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com