A vertical adjustment vibration damping device and method for a chain freight ropeway

A technology for vertical adjustment and freight ropeway, which is used in cable railways, transportation and packaging, motor vehicles, etc., can solve the problems of unfavorable operation safety and reliability of ropeway systems, shortened service life, complicated operation lines, etc. The effect of amplitude lateral vibration, simple structure and principle, and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

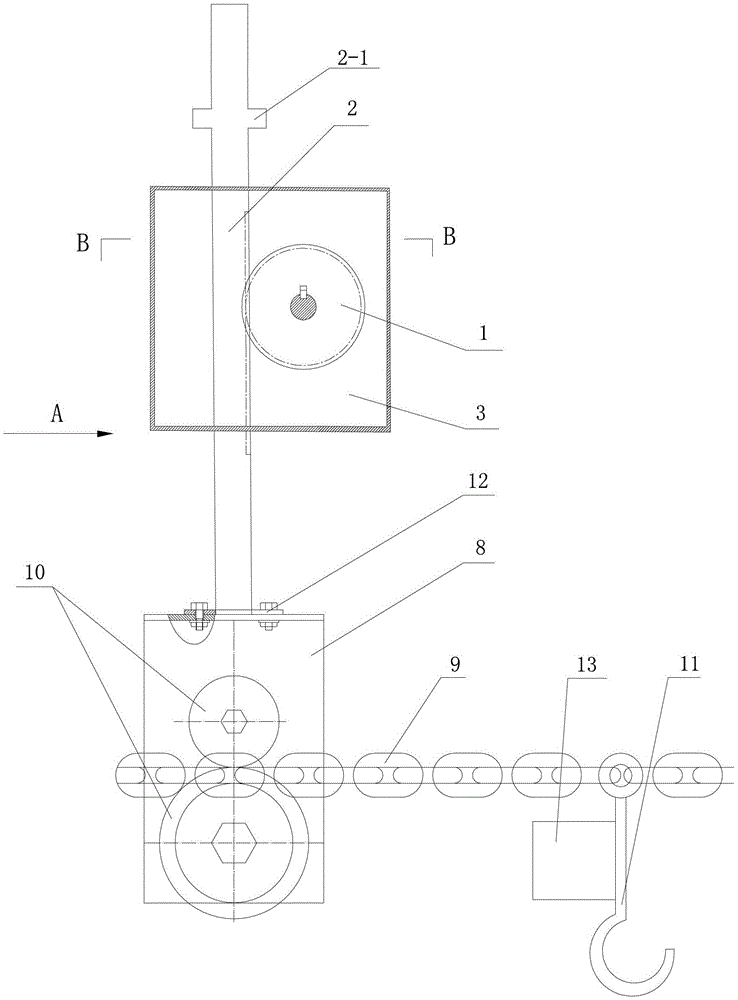

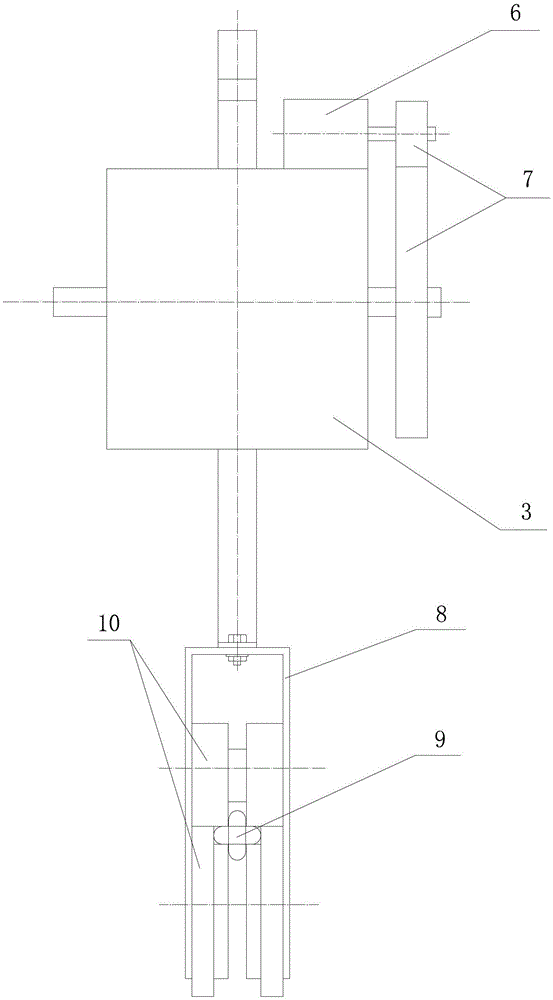

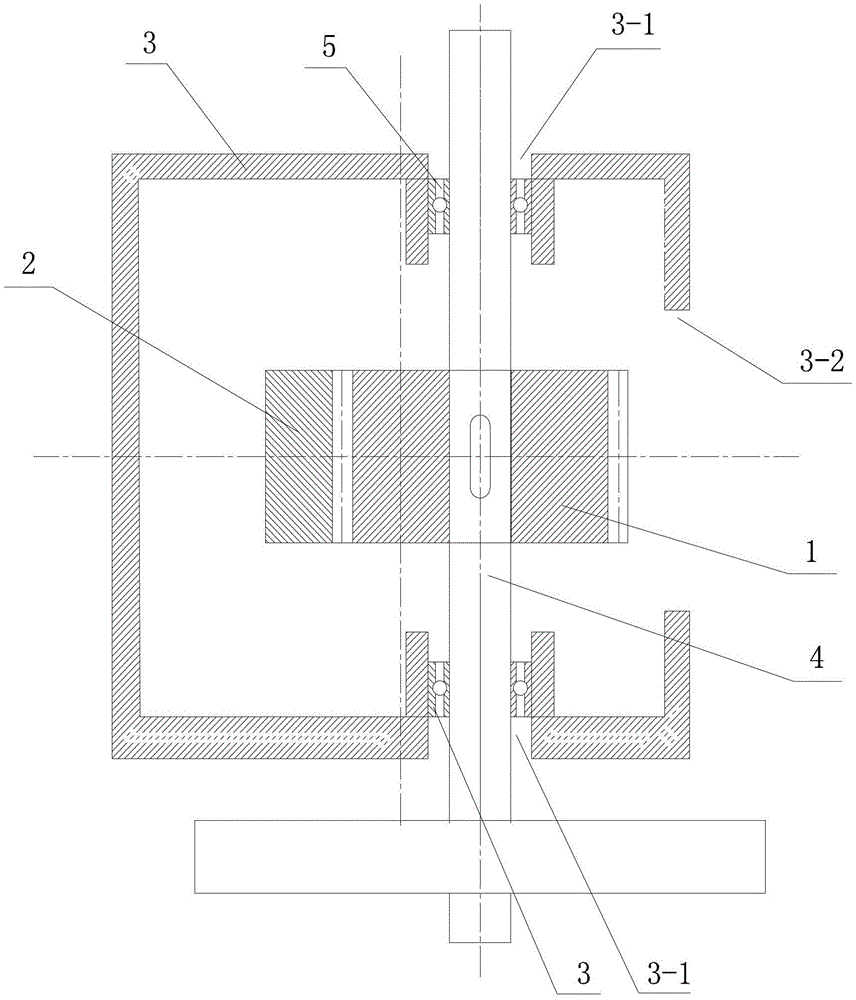

[0026] In this embodiment, a chain-type freight cableway vertical adjustment damping device, such as figure 1 As shown, it includes a vertical adjustment mechanism, a vertical drive mechanism, a cable mechanism, a vibration signal acquisition module and a vibration controller; the vertical adjustment mechanism includes an adjustment gear 1 and an adjustment rack 2 that are meshed and connected, and one end of the gear shaft of the adjustment gear is provided with a vertical drive mechanism, the adjusting rack is vertically arranged on the supporting mechanism, the bottom of the adjusting rack is fixedly connected with the supporting mechanism, the vibration signal acquisition module is arranged on the supporting mechanism, the vibration controller is arranged on the vertical driving mechanism, the vibration signal acquisition module and the vibration control signal connection.

[0027] The vertical adjustment mechanism is also provided with a support shell 3, the adjustment ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com