Water-cooled brake hub and waterway system thereof

A brake grain, water-cooled technology, applied in the field of brake cooling devices, can solve the problems of non-concentricity of the sealing ring and the water storage cover, poor sealing effect of the sealing ring, lack of effective support for the water storage cover, etc., and achieves simple structure and improved use. Longevity, the effect of ensuring concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

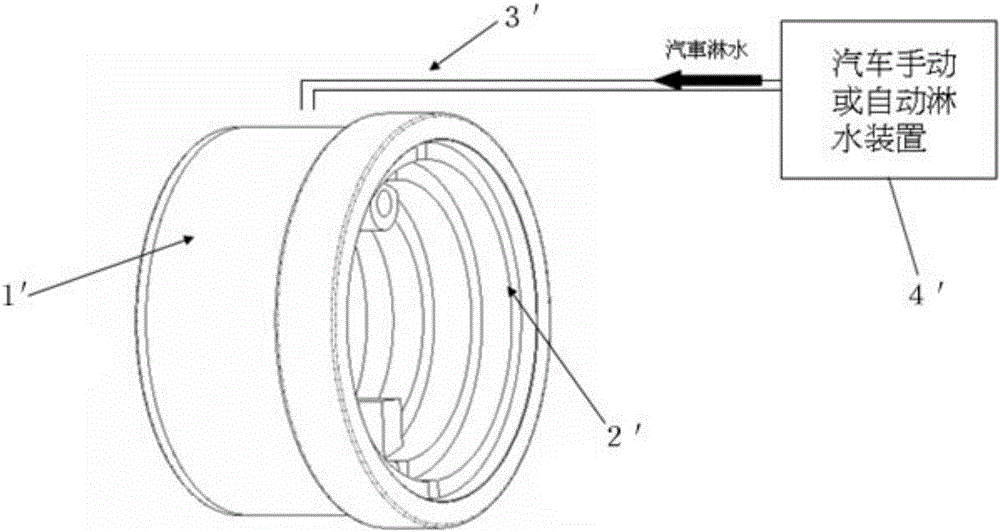

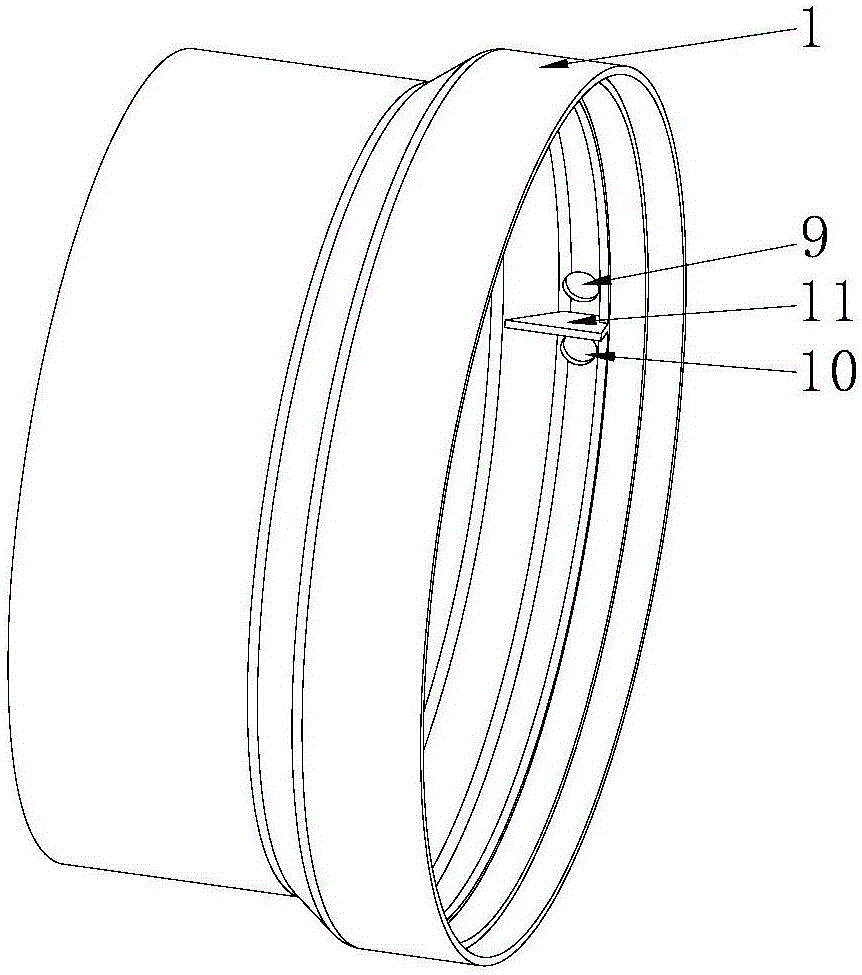

[0038] Such as figure 1 , 2 , 3, 4, and 5, the water cover 1 is installed outside the brake hub body 2, and two bearings are installed between the water cover 1 and the brake hub body 2, namely the first bearing 3 and the second bearing 4. The first bearing 3 is installed on the small end of the brake hub body 2 as the first bearing member, the brake hub body 2 is connected with the inner ring of the first bearing 3 , and the water cover 1 is connected with the outer ring of the first bearing 3 . The second bearing 4 is installed on the big end of the brake hub body 2 as the second bearing part, the brake hub body 2 is connected with the inner ring of the second bearing 4 , and the water cover 1 is connected with the outer ring of the second bearing 4 .

[0039] A first sealing ring 5 as a first sealing member and a second sealing ring 6 as a second sealing member are installed between the first bearing 3 and the second bearing 4 . If the first bearing 3 and the second bear...

Embodiment 2

[0044] Figure 6 , 7 Shown is the waterway system for constructing the cooling cycle using the brake hub of Embodiment 1. In the present embodiment 2, the temperature control system of the waterway system consists of a data processing control board, a water pump, a temperature sensor, a condenser, a water tank, a first solenoid valve 13, a second solenoid valve 14, a booster pump, a first filter device and a second filter. Wherein, the water tank is used as a liquid storage tank, and a certain amount of water can be stored in advance as a cooling liquid. The water pump draws the water in the water tank and sends it to the downstream condenser. The condenser acts as a condensing device to lower the water temperature. A filter, that is, the first filter, is generally installed between the water pump and the condenser to filter impurities in the water entering the condenser. As a data processing module, the data processing control board is electrically connected with the tem...

Embodiment 3

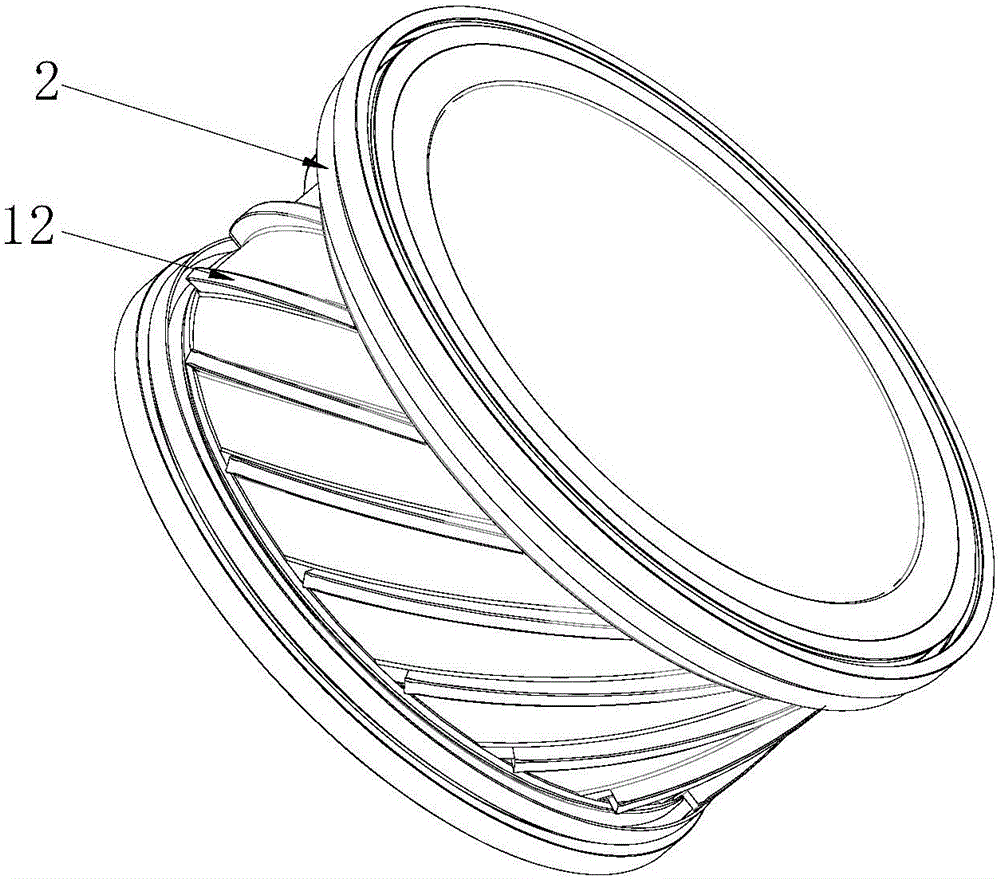

[0048] The difference between this embodiment 3 and embodiment 1 is that, as Figure 8 As shown, in the third embodiment, a plurality of cooling fins 12 are formed on the brake hub body 2, and these cooling fins 12 are arranged side by side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com