Turning positioning fixture for thin-wall rotational parts and clamping method

A technology for positioning fixtures and revolving bodies, applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of high processing difficulty, loss, and high rejection rate of parts, improve processing accuracy, reduce human errors, and parts deformation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

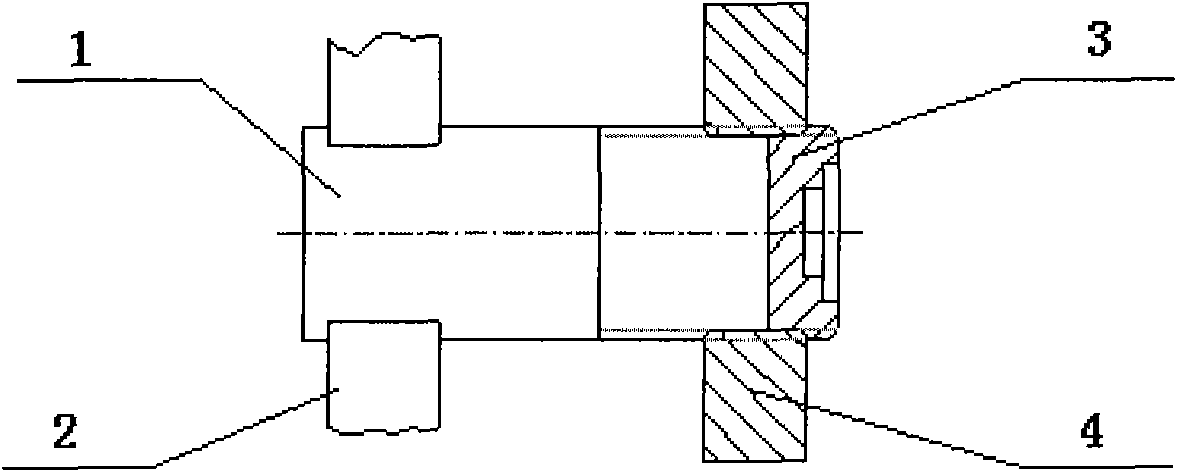

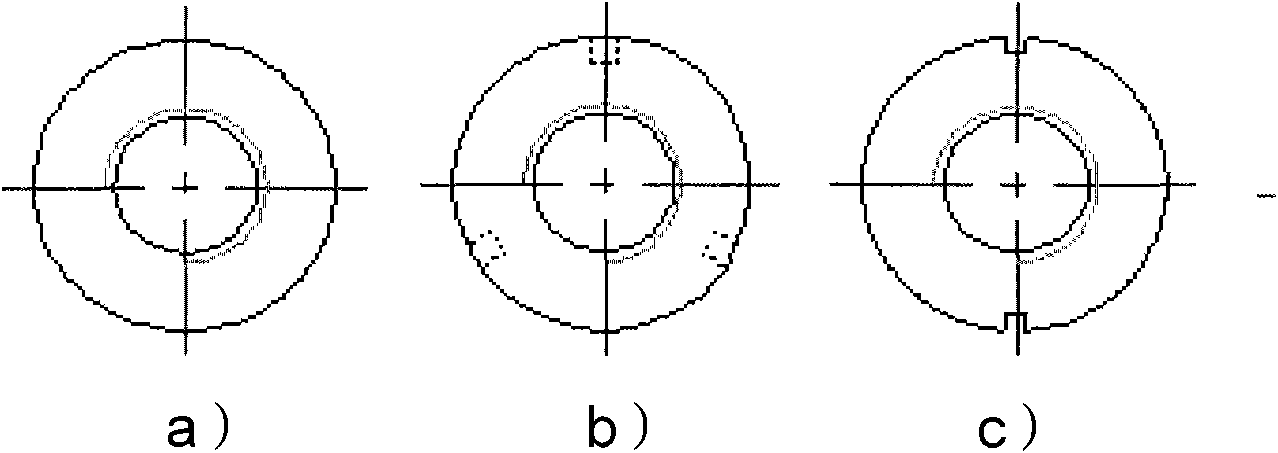

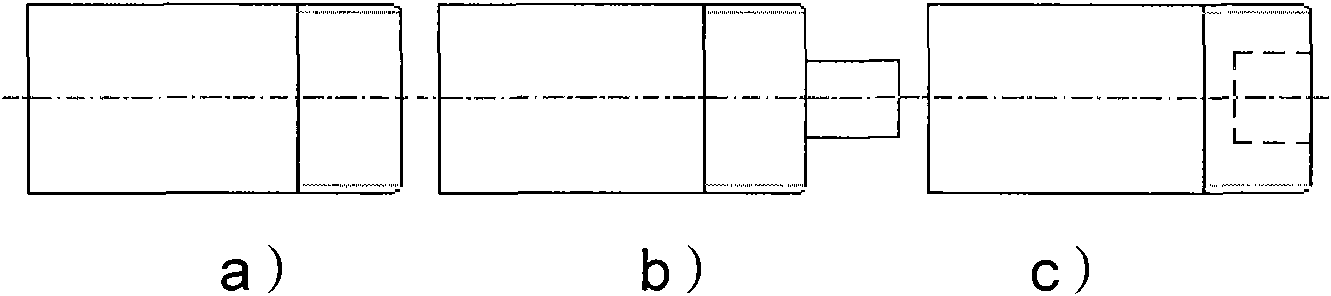

[0032] Such as Figure 4 Shown is the clamping schematic diagram of the first embodiment of the lathe positioning fixture of the present invention. This embodiment is used for processing thin-walled parts with strict tolerance requirements on parallelism, flatness, coaxiality and perpendicularity. With external threads, as in this embodiment, the part 3 to be processed is a sensor diaphragm. Figure 4 a) The middle positioning body 1 is an end face positioning body, which provides an end face positioning reference for the part 3 to be processed, so as to drill and bore the inner hole; Figure 4 b) The positioning body 1 is an axial positioning body, which provides an axial positioning reference for the part 3 to be processed after drilling and boring; 1 The external surface thread is matched with the internal thread.

[0033] The specific clamping and positioning process of the positioning fixture in this embodiment is as follows:

[0034] Step 1. Clamp the part 3 to be pro...

Embodiment 2

[0042] like Figure 5 Shown is the clamping schematic diagram of the second embodiment of the lathe positioning fixture of the present invention. This embodiment is used to process slender blind hole parts with high requirements on the coaxiality of the inner and outer circles. The outer surface has no external thread, as in this embodiment. The part 3 to be processed is an elongated shell part. like Figure 5 In the shown embodiment, the positioning body 1 is an axial positioning body, which provides an axial positioning reference for the parts after drilling and boring; 1 The external surface thread is matched with the internal thread.

[0043] The specific clamping and positioning process of the positioning fixture in this embodiment is as follows:

[0044] Step 1. Clamp the part 3 to be processed on the machine tool first, turn out the end face, blind hole and process external thread with a larger diameter than the designed outer circle, and cut off after leaving a marg...

Embodiment 3

[0049] like Figure 6 Shown is the clamping schematic diagram of the third embodiment of the lathe positioning furniture of the present invention, this embodiment is used for processing parts with high parallelism and perpendicularity requirements with external threads, such as the part 3 to be processed in this embodiment is Sensor base. like Figure 6 In the present embodiment shown, the positioning body 1 is an end face positioning body, and the central drilling 6 is used to accommodate the thin shaft of the part to be processed, and the end face of the positioning body 1 is in contact with the step of the part to be processed 3 to provide an end face positioning reference; the threaded ring 4 The outer surface is knurled, and the inner surface is machined with internal threads matching the outer surface threads of the part 3 to be processed and the positioning body 1; the part 3 to be processed is a multi-step base with a slender shaft, and the parallelism of each step su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com