Compression-resistant type automobile hinge pin shaft and manufacturing technology thereof

A hinge pin and pin shaft technology, applied in the field of auto parts, can solve the problems of not being able to resist the impact force of the parts, affecting the overall quality of the car, and the pin shaft is easy to deform, etc., and achieve the effects of fast forming speed, prolonging the service life and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

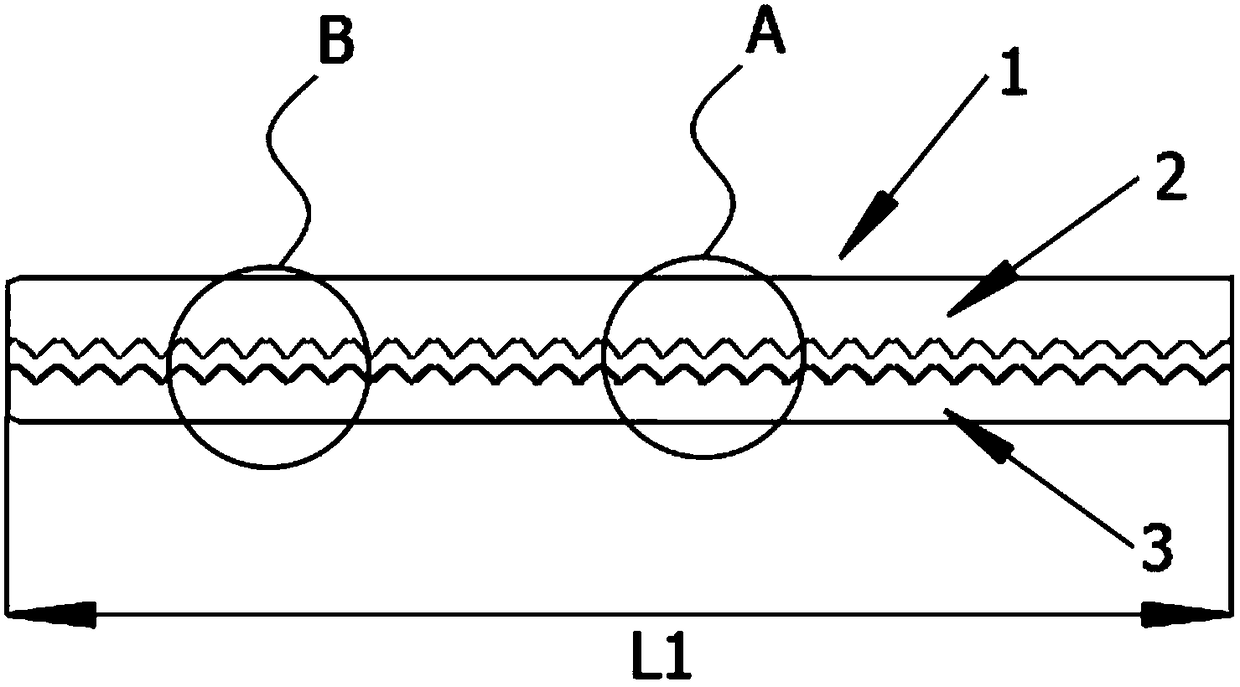

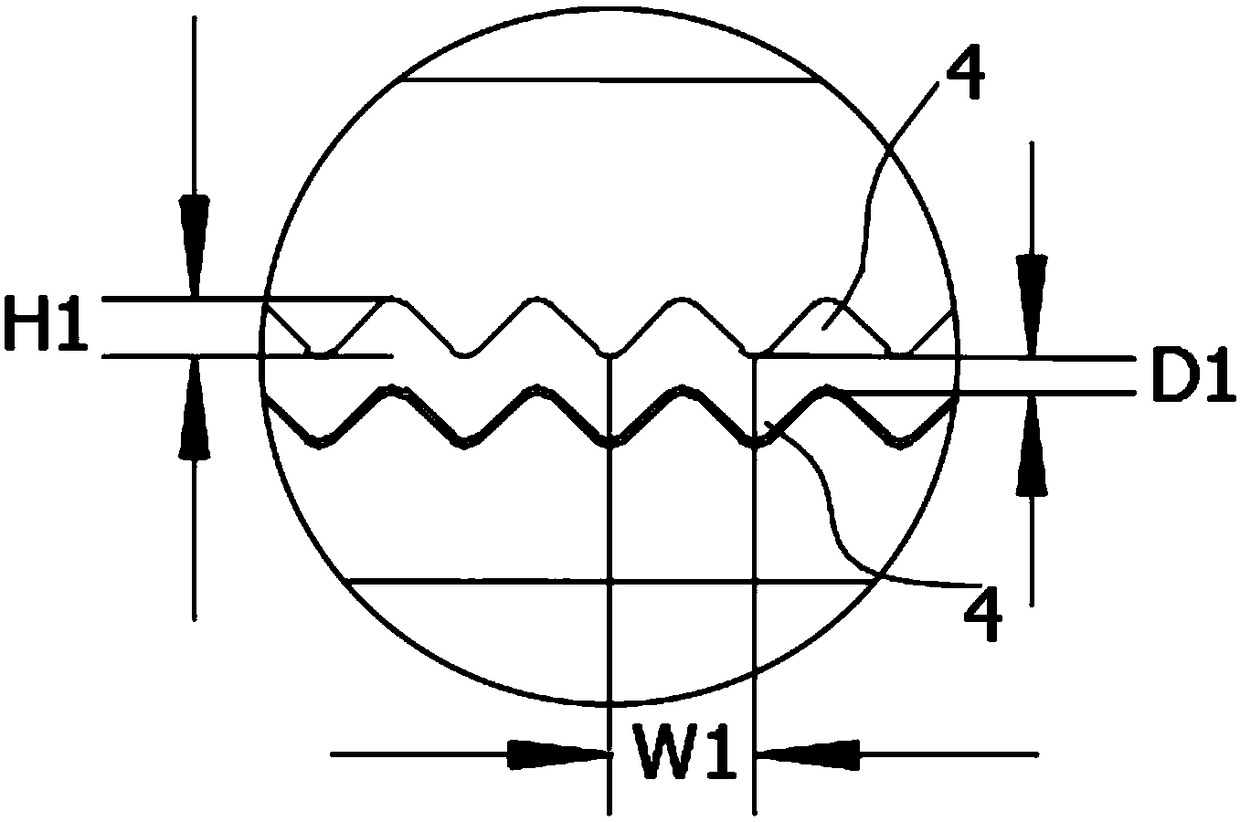

[0037] Embodiment: a kind of compression-resistant type automobile hinge pin and its manufacturing process, such as Figure 1-Figure 4 As shown, it includes a hollow pin shaft 1, the side wall of the pin shaft 1 is provided with an opening along the axial direction of the pin shaft, and the opening portion has opposite first side walls and second sides wall, the first side wall is formed with a first alveolar portion 2, and the second side wall is formed with a second alveolar portion 3, when the surface of the pin shaft is pressed radially, the first alveolar portion meshing with the second alveolar portion;

[0038] The first alveolar portion 2 and the second alveolar portion 3 respectively include several continuous alveoli 4;

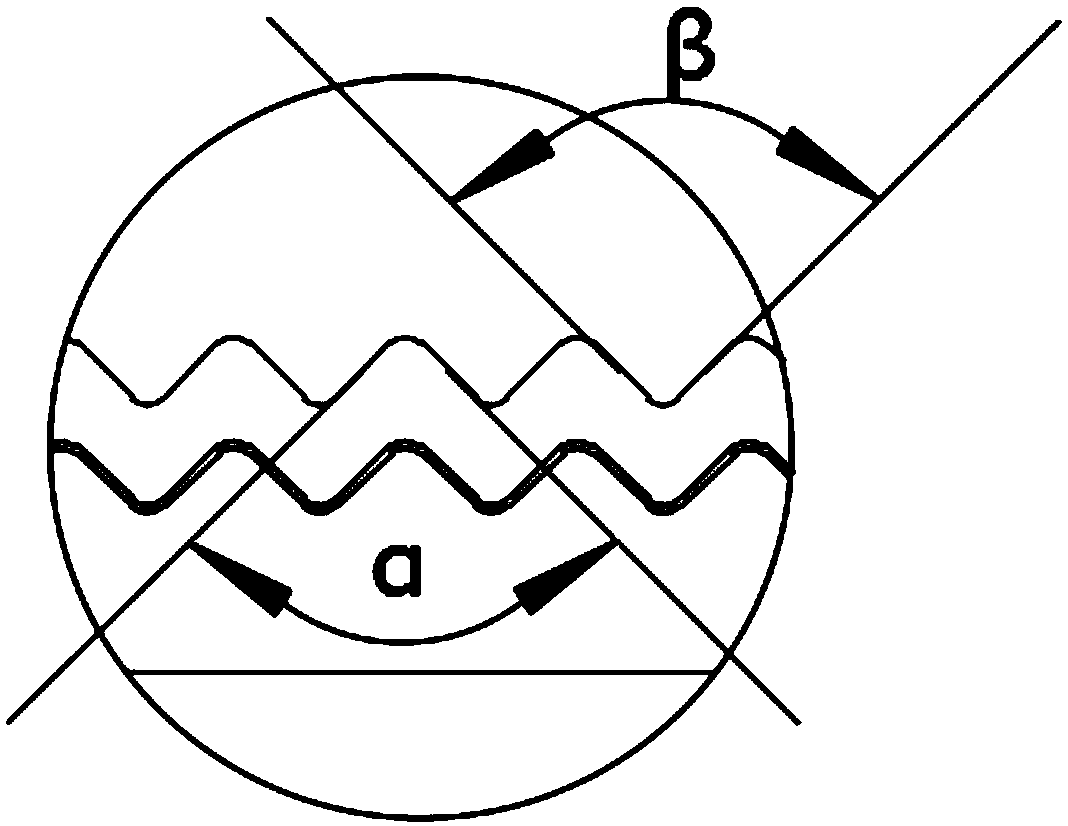

[0039] The opening width W1 of the tooth top of the tooth groove 4 is 1.4-1.6mm, the tooth depth H1 is 0.6-0.7mm, the tooth bottom of the tooth groove is arc-shaped, and the opening angle α of the tooth bottom is 90° ; The connection surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com