Surface finishing apparatus and related method

A surface finishing and workpiece technology, applied in the field of surface finishing devices, can solve problems such as troublesome implementation and expensive roller polishing tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

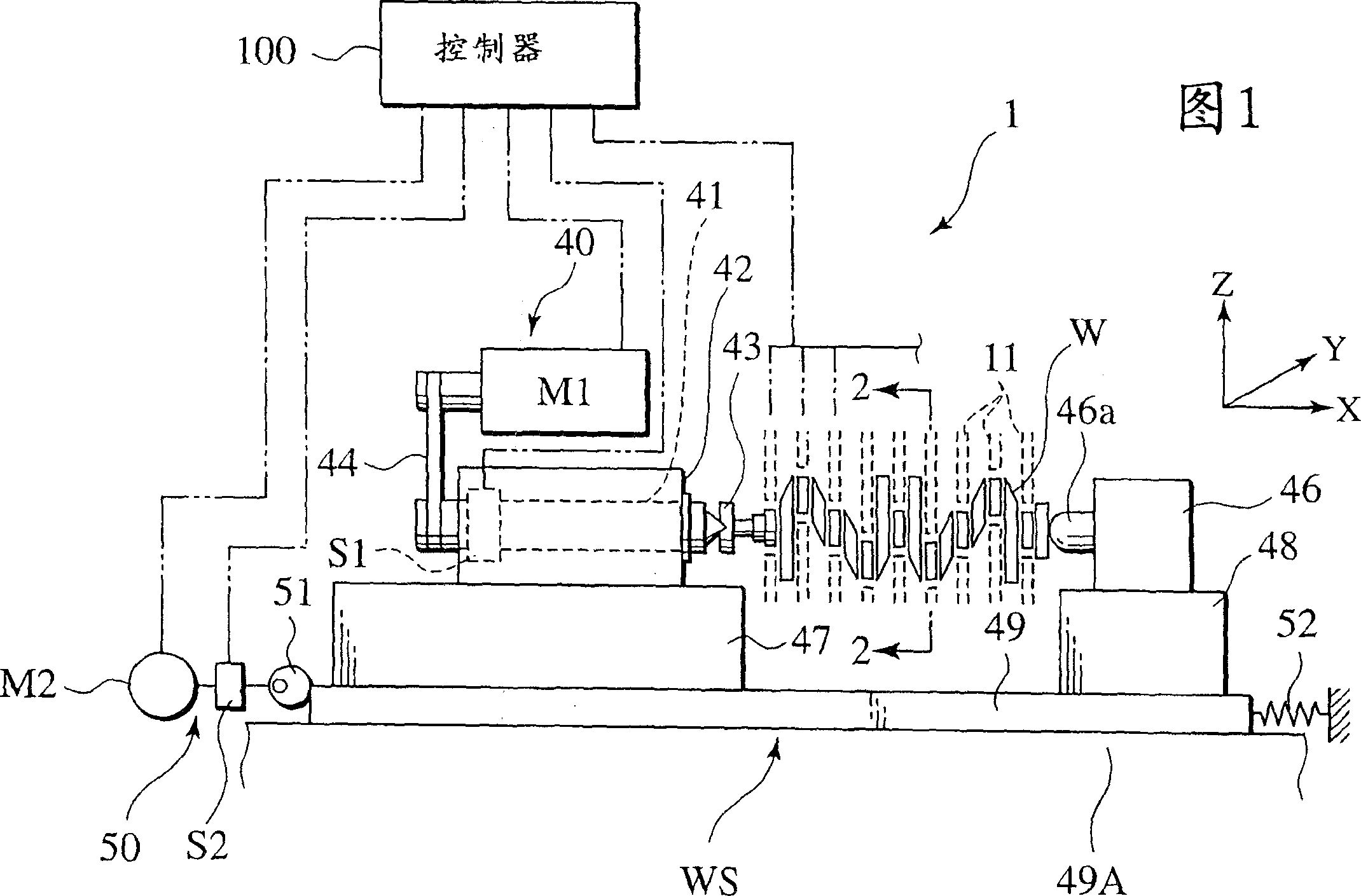

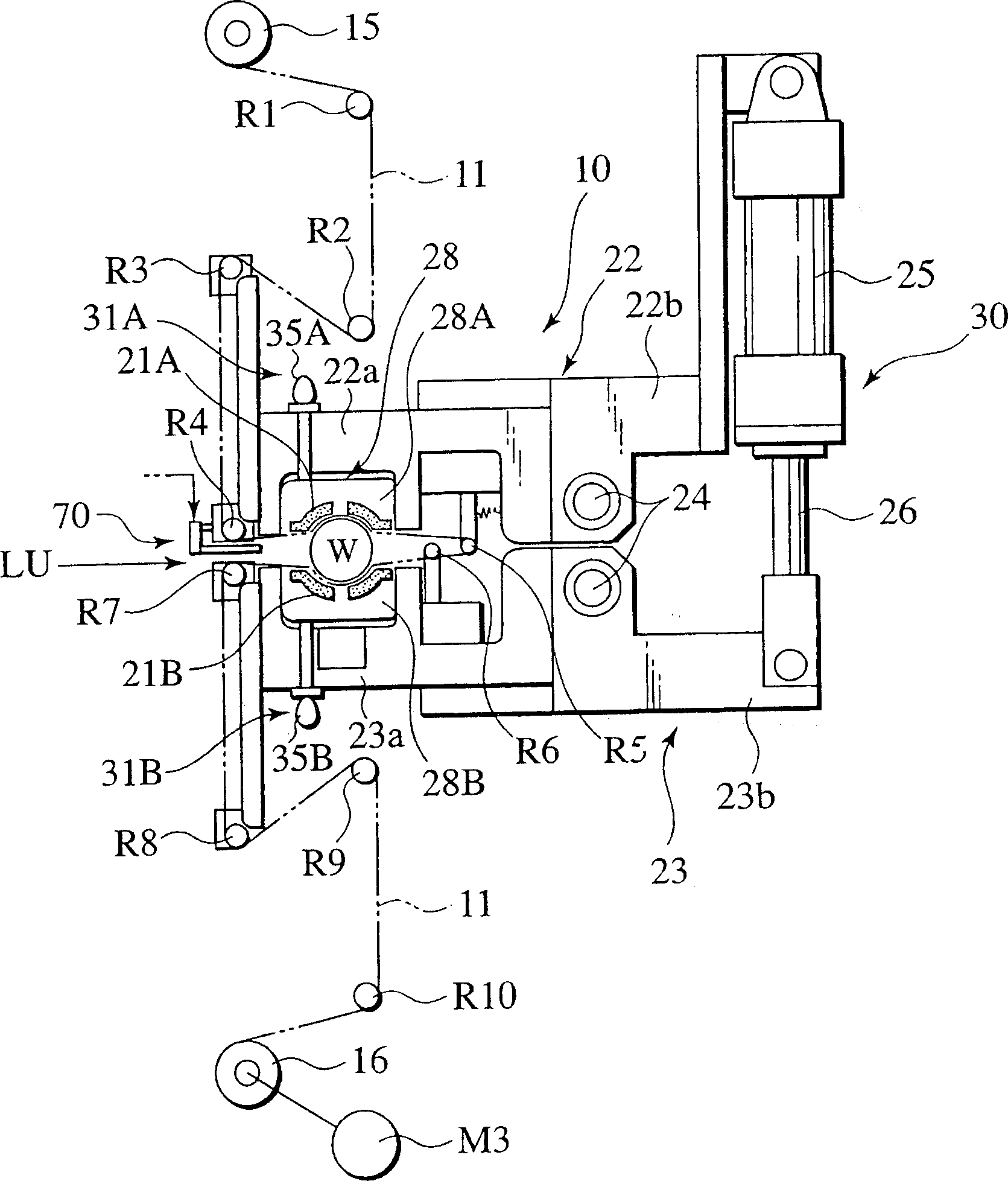

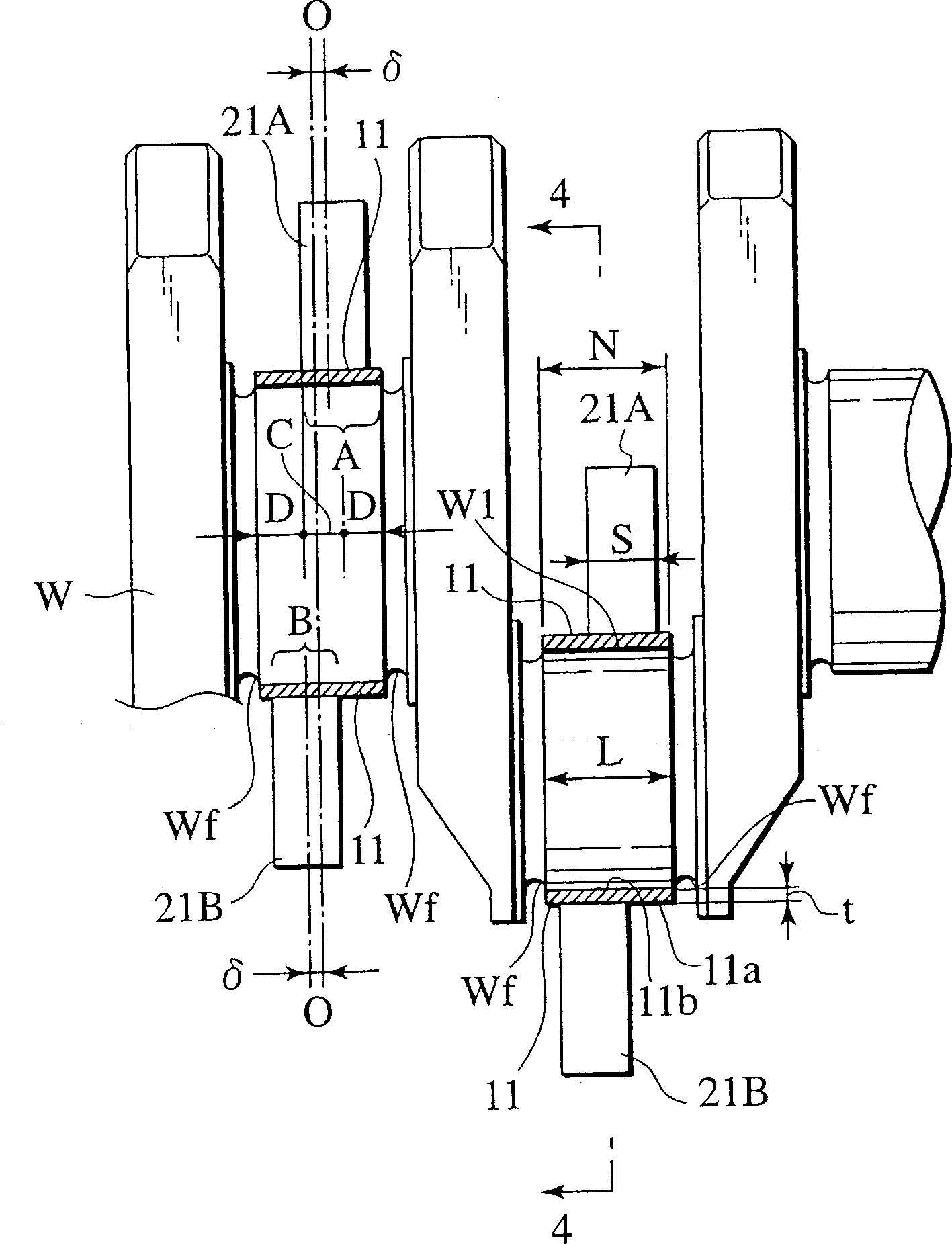

[0059] Referring now to FIGS. 1 and 2, there is shown a first embodiment of a surface finishing apparatus according to the present invention as a grinding apparatus 1. Referring to FIG. Figure 1 is a schematic front view of the grinding device, figure 2 is a schematic diagram corresponding to the cross-section of line 2-2 in Fig. 1 .

[0060] As shown in FIGS. 1 and 2, the grinding apparatus 1 in the presently described embodiment is used to finely grind a workpiece W in the form of a crankshaft in a surface finishing operation following a surface roughing operation such as : A cutting operation, a heat treatment operation, and a grinding operation are performed with one processing tool. That is, the grinding device 1 is used to grind a target shaped periphery of a workpiece W, such as a connecting portion or a pin portion of a crankshaft, to a desired surface quality having a concave surface profile. The shown grinding device 1 includes: a workpiece supporting mechanism WS...

no. 2 example

[0104] The following will refer to Figures 8 to 14 and Figure 15A with 15B A surface finishing apparatus 1A of a second embodiment of the present invention is described. FIG. 8 is a schematic diagram illustrating a surface finishing apparatus 1A of a second embodiment of the present invention. Figure 9 is the positional relationship corresponding to figure 2 is a schematic diagram showing a pressure applying mechanism 10A forming part of the surface finishing device 1A, the upper and lower pressing arms of the pressure applying mechanism 10A can be manipulated to assume an open state and a closed state, and in the Figure 9 , the upper and lower pressing arms are closed. Figure 10 The pressure applying mechanism 10A is schematically shown with the upper and lower pressing arms in the opened state. Figure 11 is a partially enlarged cross-sectional view showing the presser mechanism of the surface finishing apparatus 1A of the presently described embodiment, which consti...

no. 3 example

[0166] Figure 22 Schematically represents a surface finishing device according to a third embodiment of the present invention, Figure 23 yes Figure 22 A cross-sectional cutaway view of the surface finishing device shown, with the pin portion of the workpiece shown in slightly exaggerated form.

[0167] The surface finishing device of the third embodiment differs from the first embodiment in that the surface finishing device of the presently described embodiment takes the form of a roller polishing device which passes a surface in the form of a polishing roller under pressure. The finishing tool is brought into contact with the workpiece W by a pressure exhibiting a given distribution pattern according to the axial direction of the workpiece, which has been initially ground in surface finishing to have such Figure 5 A workpiece with a concave profile cross-section as shown is roll polished. Therefore, the same reference numerals are used for the same components as those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com