Boring device

A technology for processing equipment and objects to be processed, which can be used in feeding equipment, metal processing equipment, drilling/drilling equipment, etc., to solve the problems of short tool life and deterioration of the smoothness of the machined surface, and to prolong the life and suppress the temperature rise. , the effect of suppressing fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

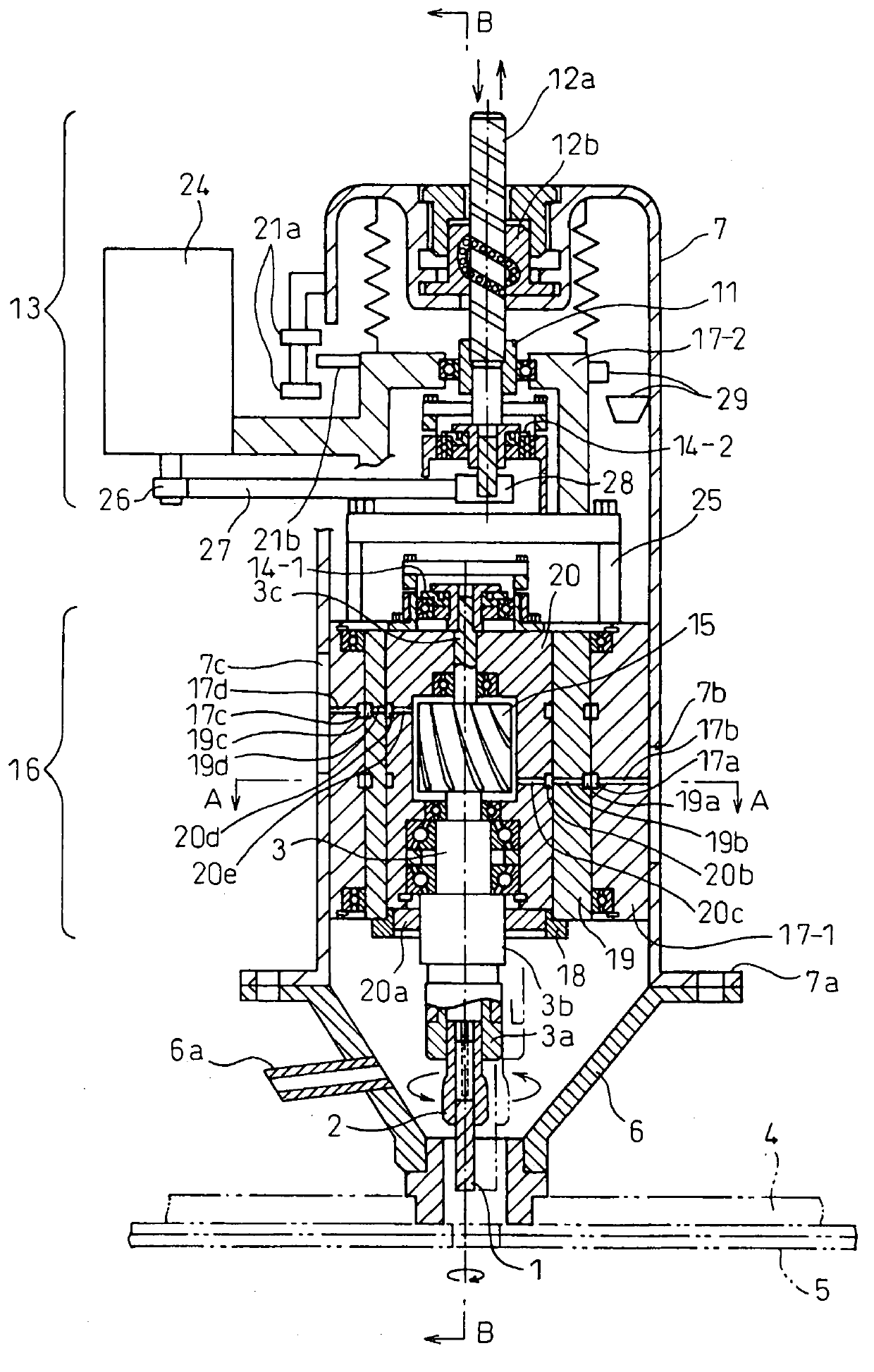

[0037] Next, a first embodiment of the present invention will be described in detail with reference to the drawings.

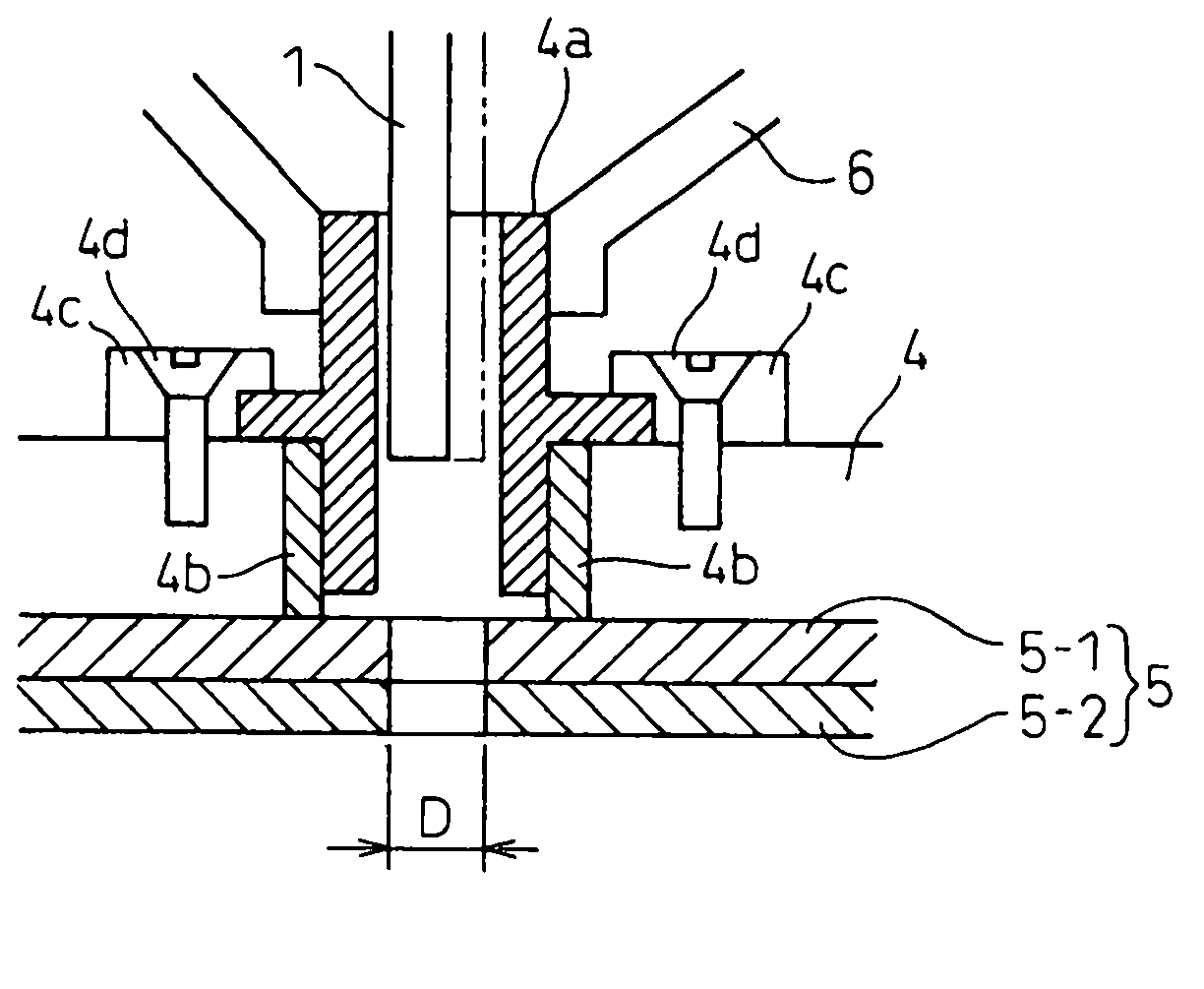

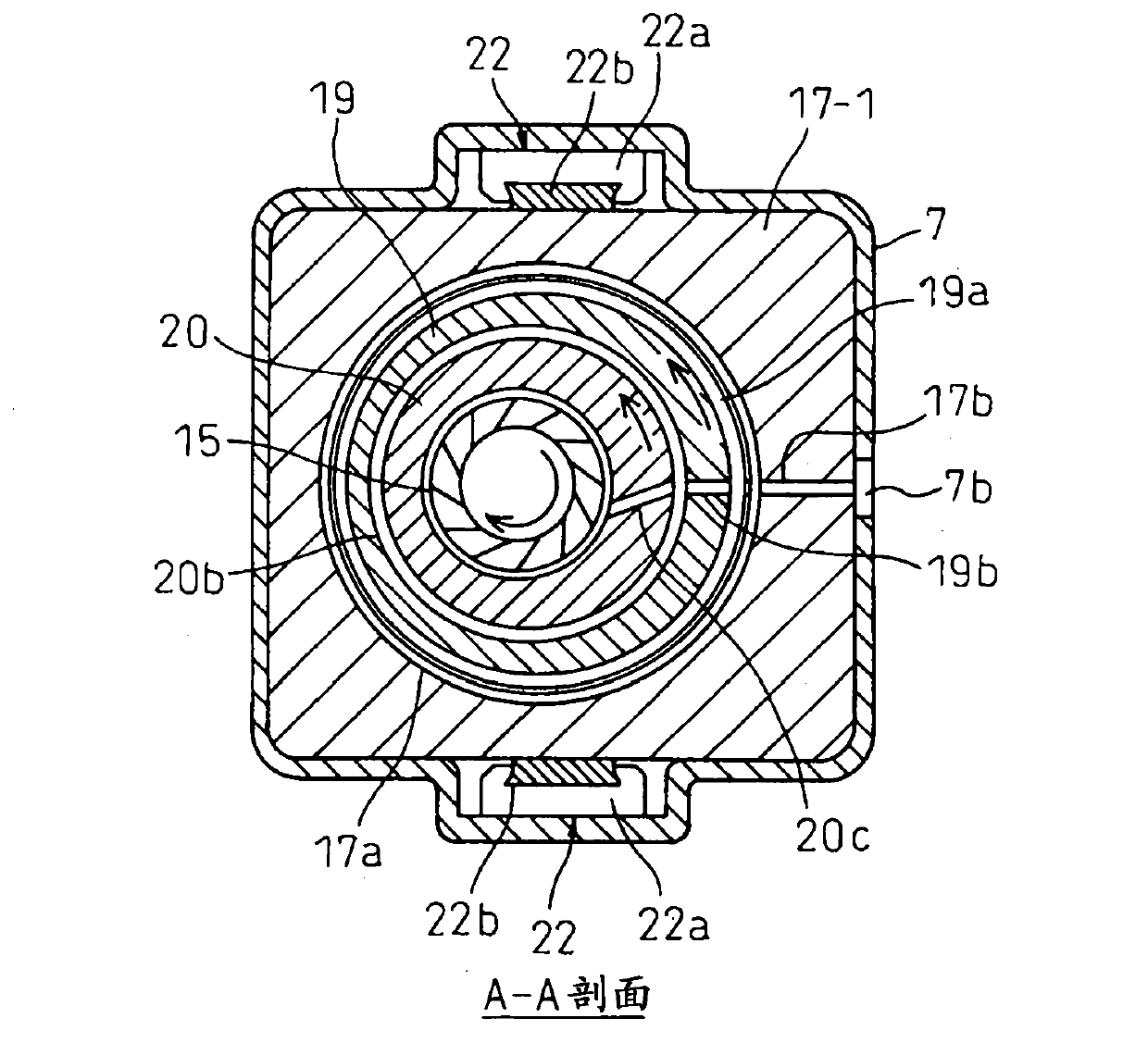

[0038] Such as figure 1 As shown, the main structure of the eccentric rotation drive mechanism 16 in the drilling device of this embodiment includes: a cylindrical body (hereinafter referred to as "inner cylinder") 20, which is built in by the first rotating shaft part 3 The air-driven part that air motor 15 (such as turbine etc.) constitutes, makes drilling such as end mill cutter 1 around the axis of rotation shaft part 3 ( Figure 5 C1) rotates on its own axis while around the axis of the eccentric cylinder ( Figure 5 C2) revolution; the first deceleration member 14-1 [such as a harmonic drive (registered trademark)], which is connected with the rotation shaft portion 3 extending from the holder 2 that holds the above-mentioned drilling tool; the eccentric cylindrical body (hereinafter referred to as "outer cylinder") 19, which is connected to the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com