Iron notch mud sleeve finishing tool

A technology for dressing tools and taphole mud sleeves, which is applied to blast furnace parts, furnaces, blast furnace details, etc., can solve the problems of slow trimming of taphole mud sleeves, multi-person operations, etc., so as to avoid plugging mud and reduce wind. The effect of blocking phenomenon, reducing labor intensity and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

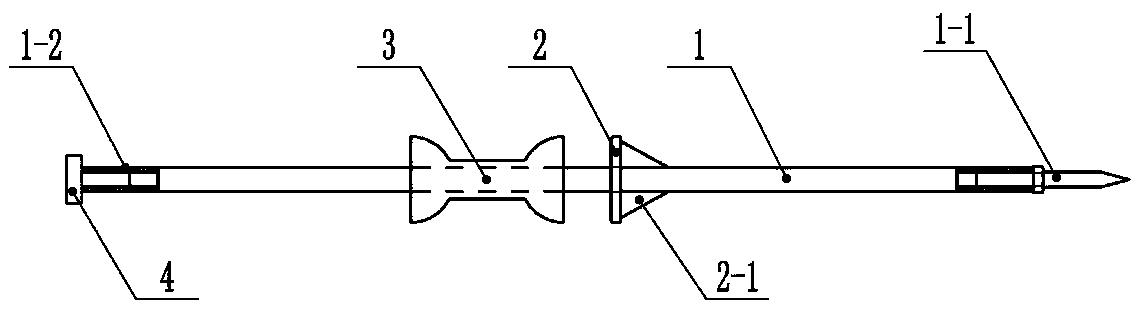

[0015] Such as figure 1 The trimming tool for the iron mouth mud sleeve shown includes a drill rod 1 provided with a drill head 1-1 and a drill tail 1-2. The middle section of the drill rod 1 is provided with a striking baffle 2. A striking slide hammer 3 is installed between the tails 1-2; the striking slide hammer 3 is set on the drill rod 1, and the tail baffle 4 is provided on the drill tail 1-2, which can prevent the striking slide hammer 3 from the drill tail 1-2. 2 slipping off, the tail baffle 4 is connected with the drill tail 1-2 through a screw, which can facilitate the disassembly and assembly of striking slide hammers 3 with different sizes and weights to obtain different striking strengths; between the striking baffle 2 and the drill bit 1-1 A triangular rib plate 2-1 is provided, and the triangular rib plate 2-1 is fixed on the drill rod 1 and the hitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com