Patents

Literature

48results about How to "Non uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

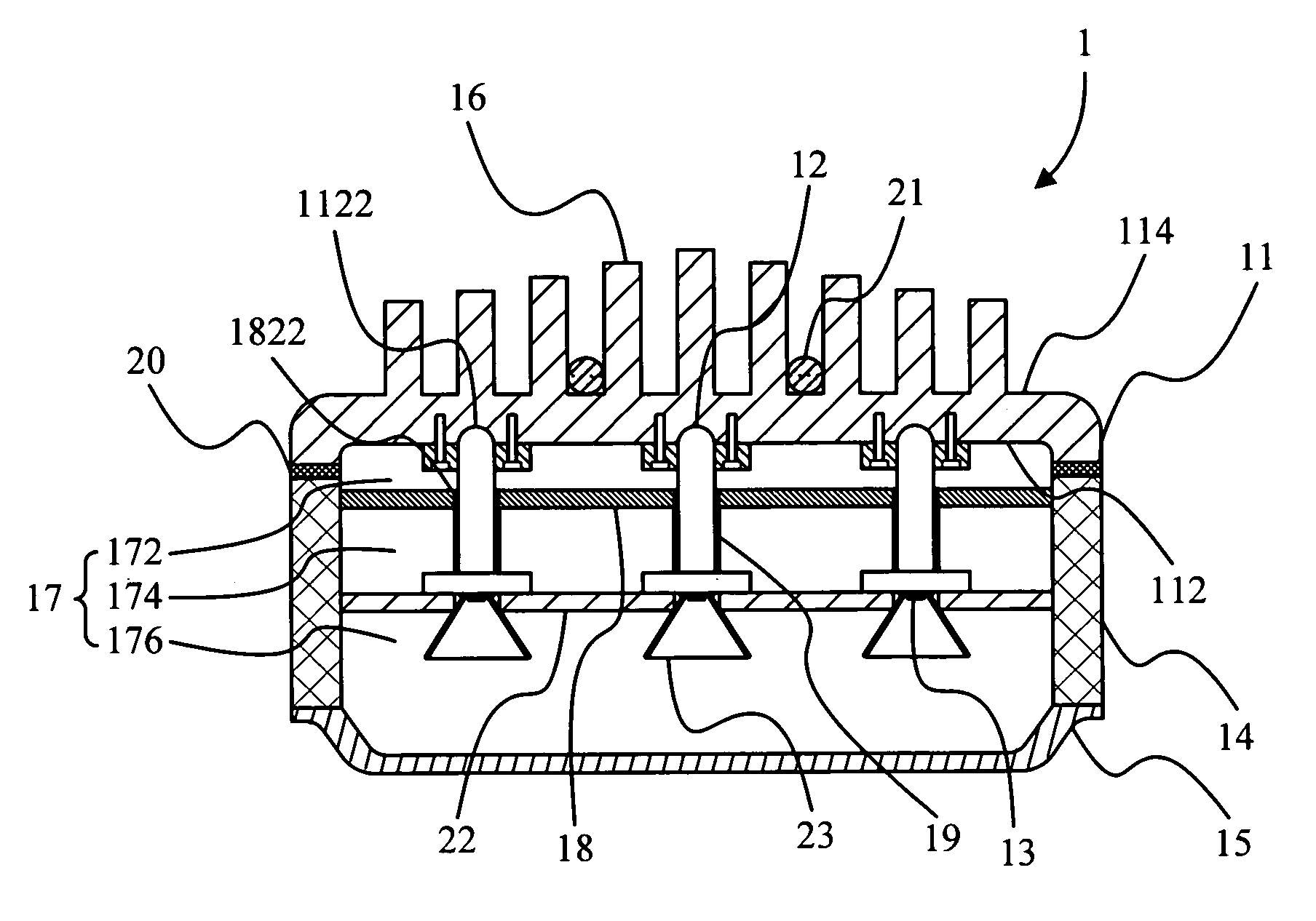

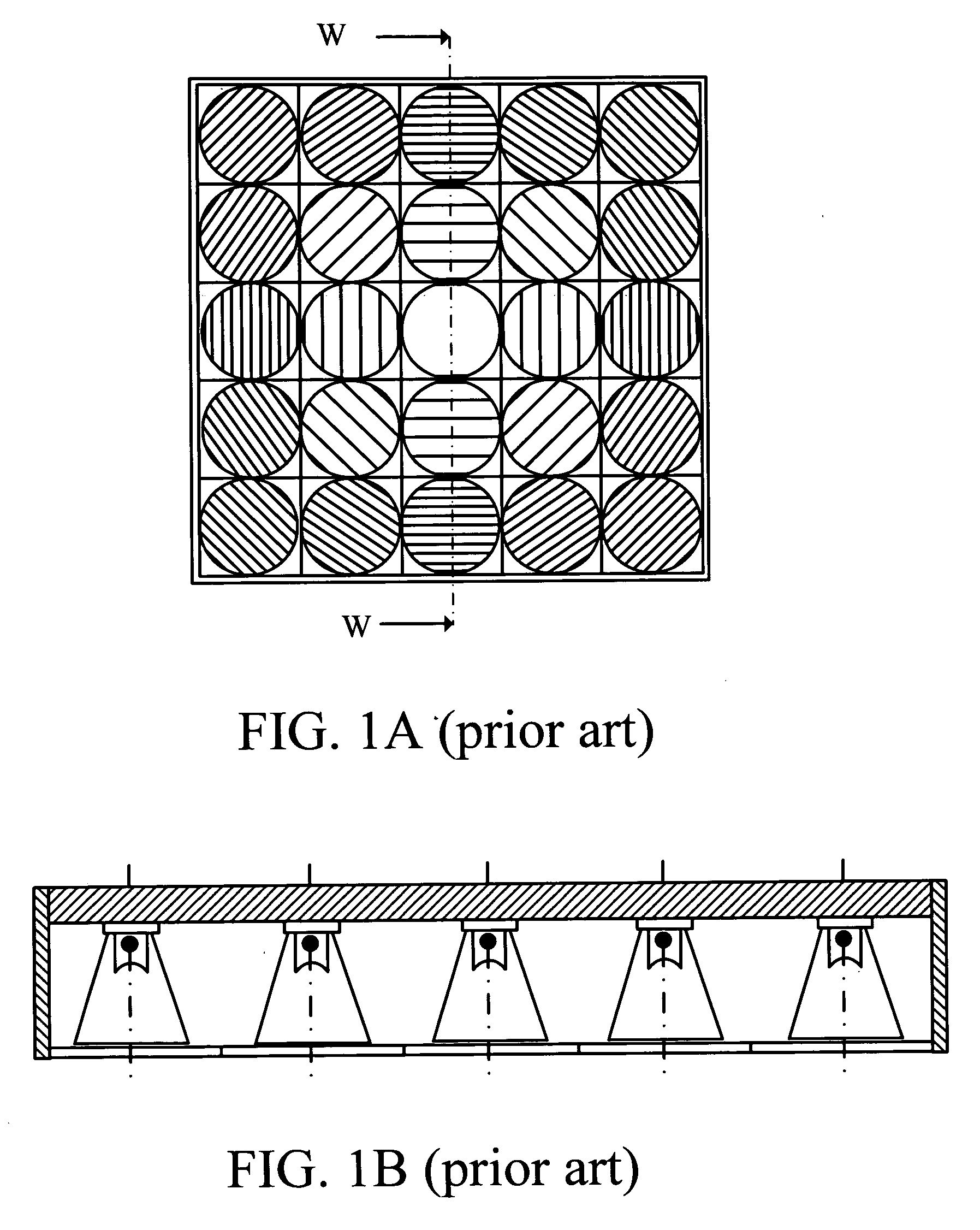

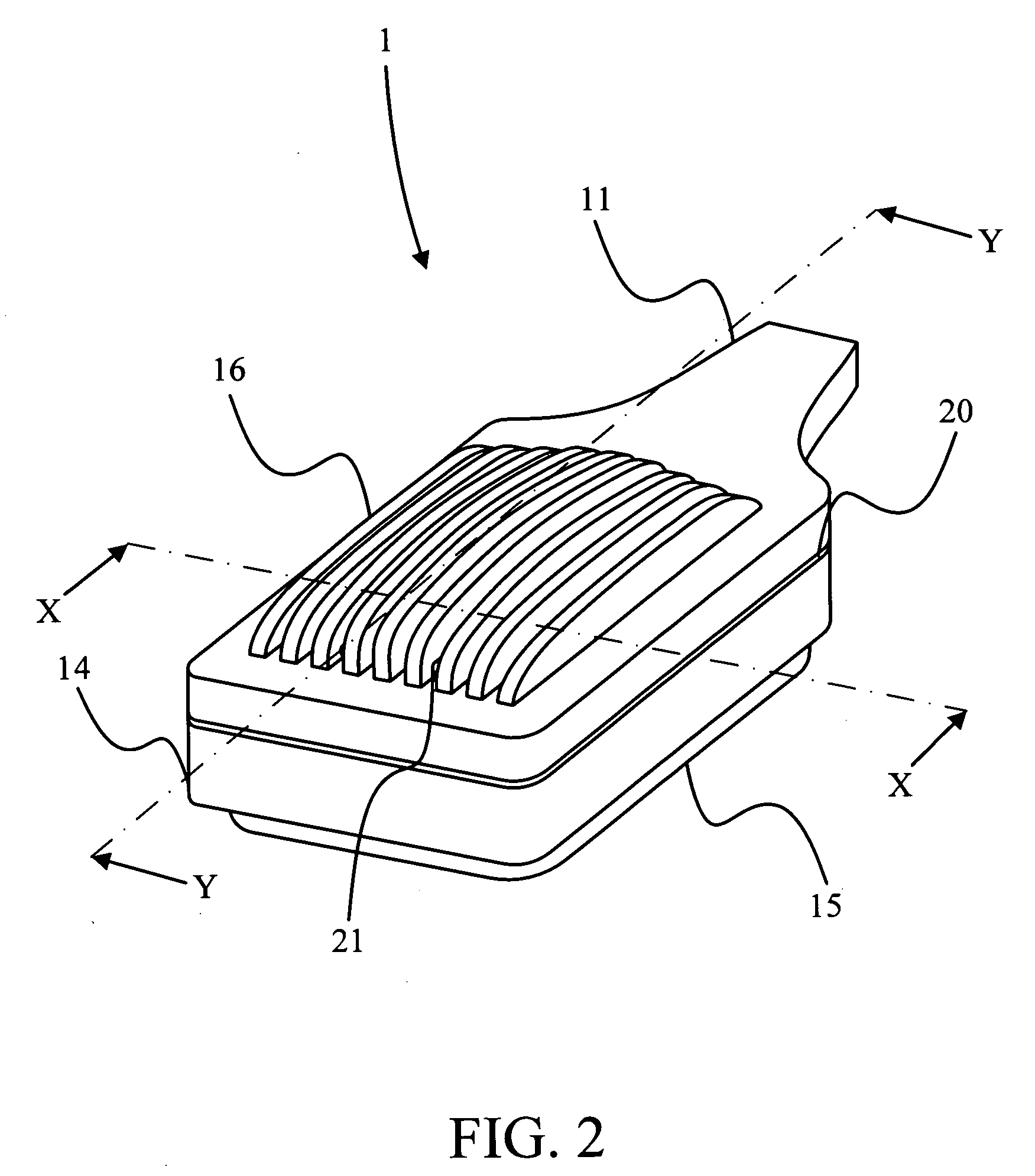

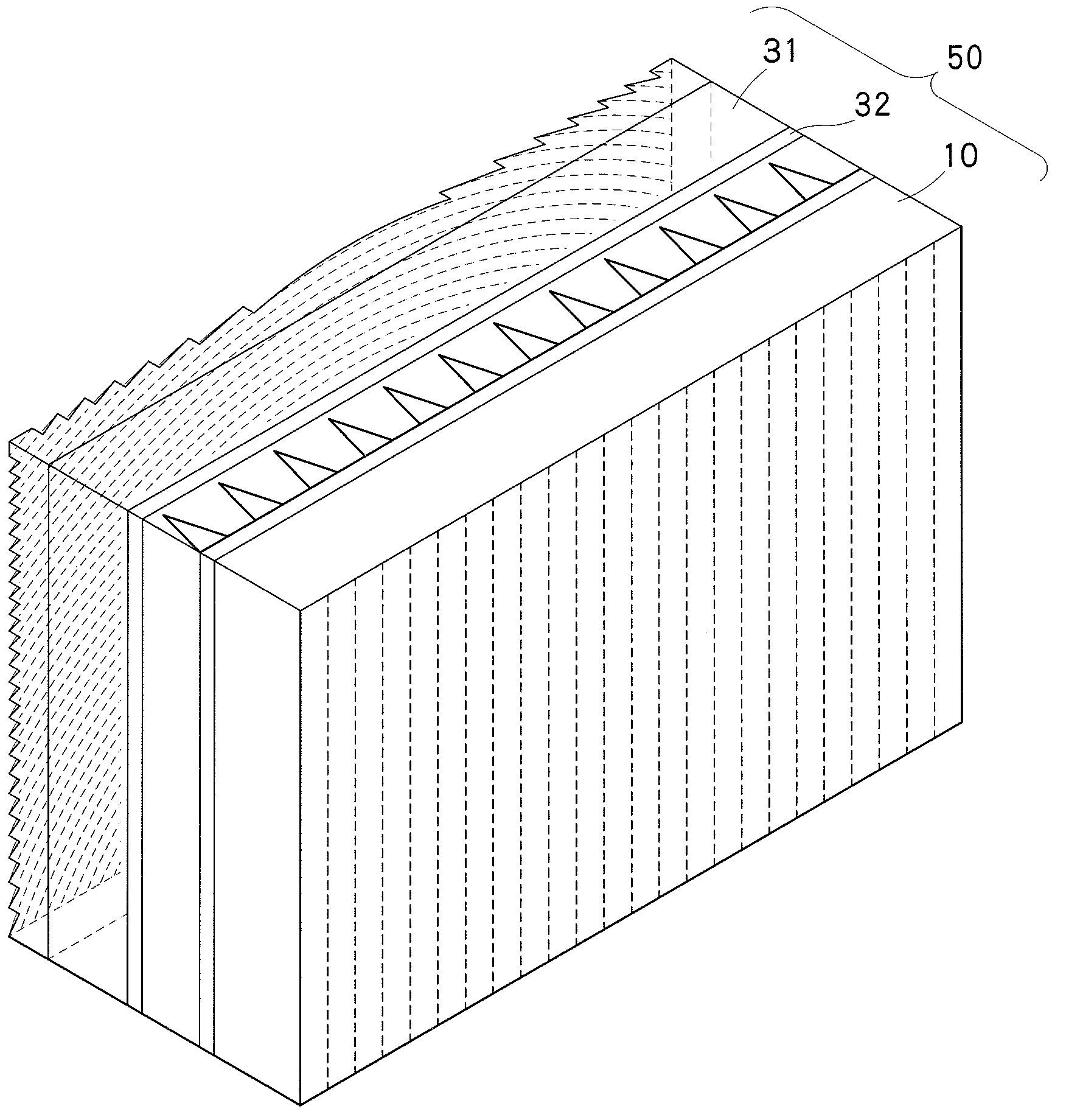

Light-Emitting Diode Illuminating Equipment with High Power and High Heat Dissipation Efficiency

InactiveUS20090244895A1Improve efficiencyAvoid conductionPlanar light sourcesMechanical apparatusEngineeringHigh heat

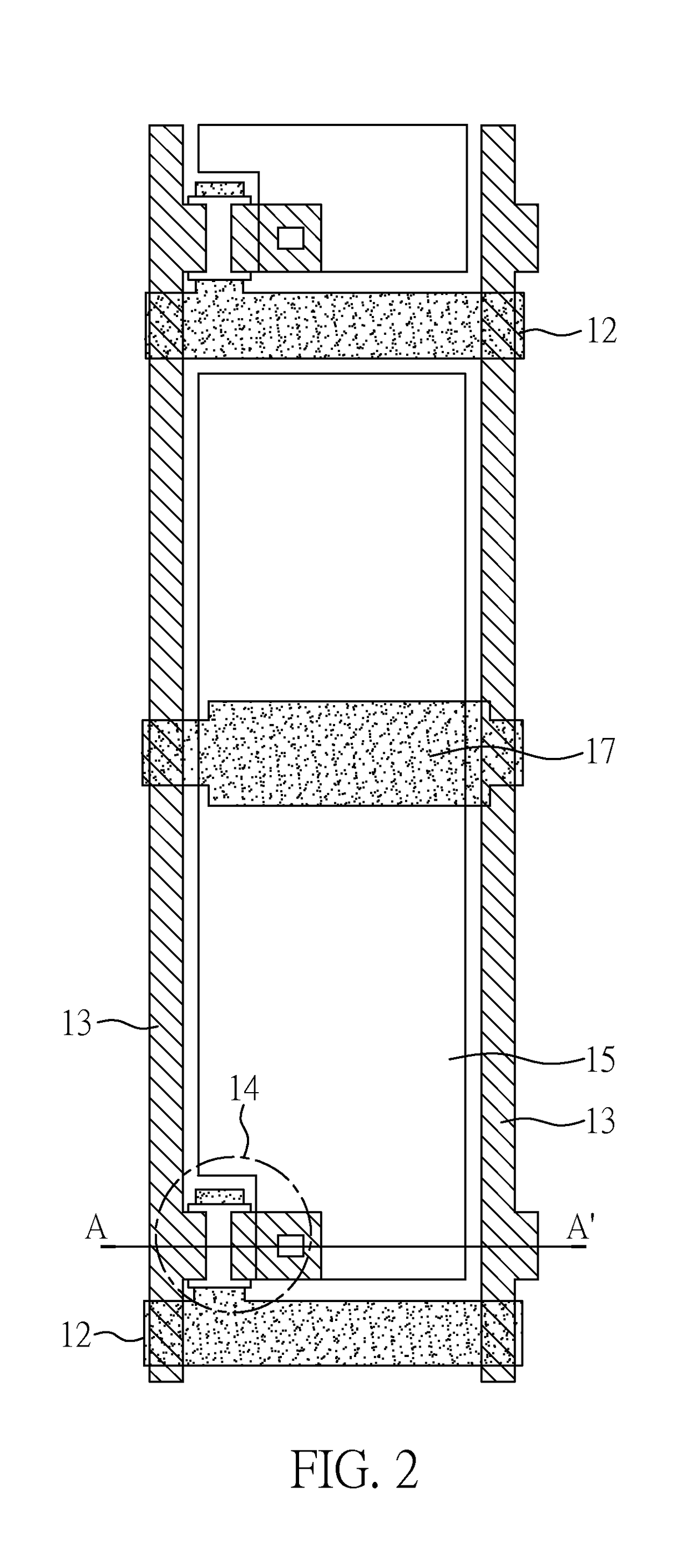

The invention provides a LED illuminating equipment with high power and high heat-dissipating efficiency. The LED illuminating equipment of the invention includes a plurality of diode light-emitting apparatuses. Particularly, the heat generated by the diode light-emitting apparatuses in operation is conducted to a heat-dissipating plate device and the heat-dissipating fins. Besides, the heat is uniformly distributed over the heat-dissipating plate device and further dissipated by the heat-dissipating plate device and the heat-dissipating fins extending thereon.

Owner:ENRAYTEK OPTOELECTRONICS

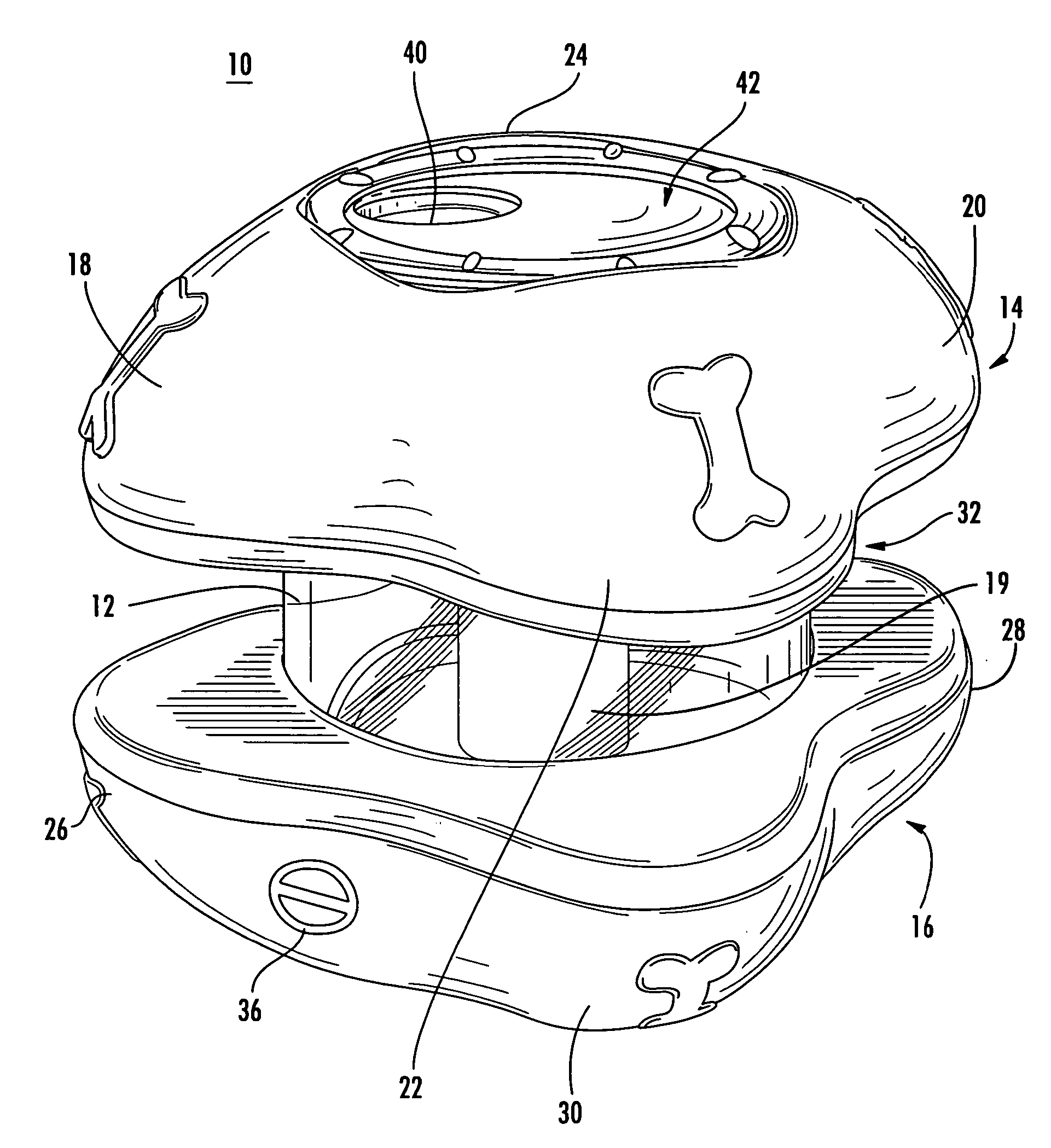

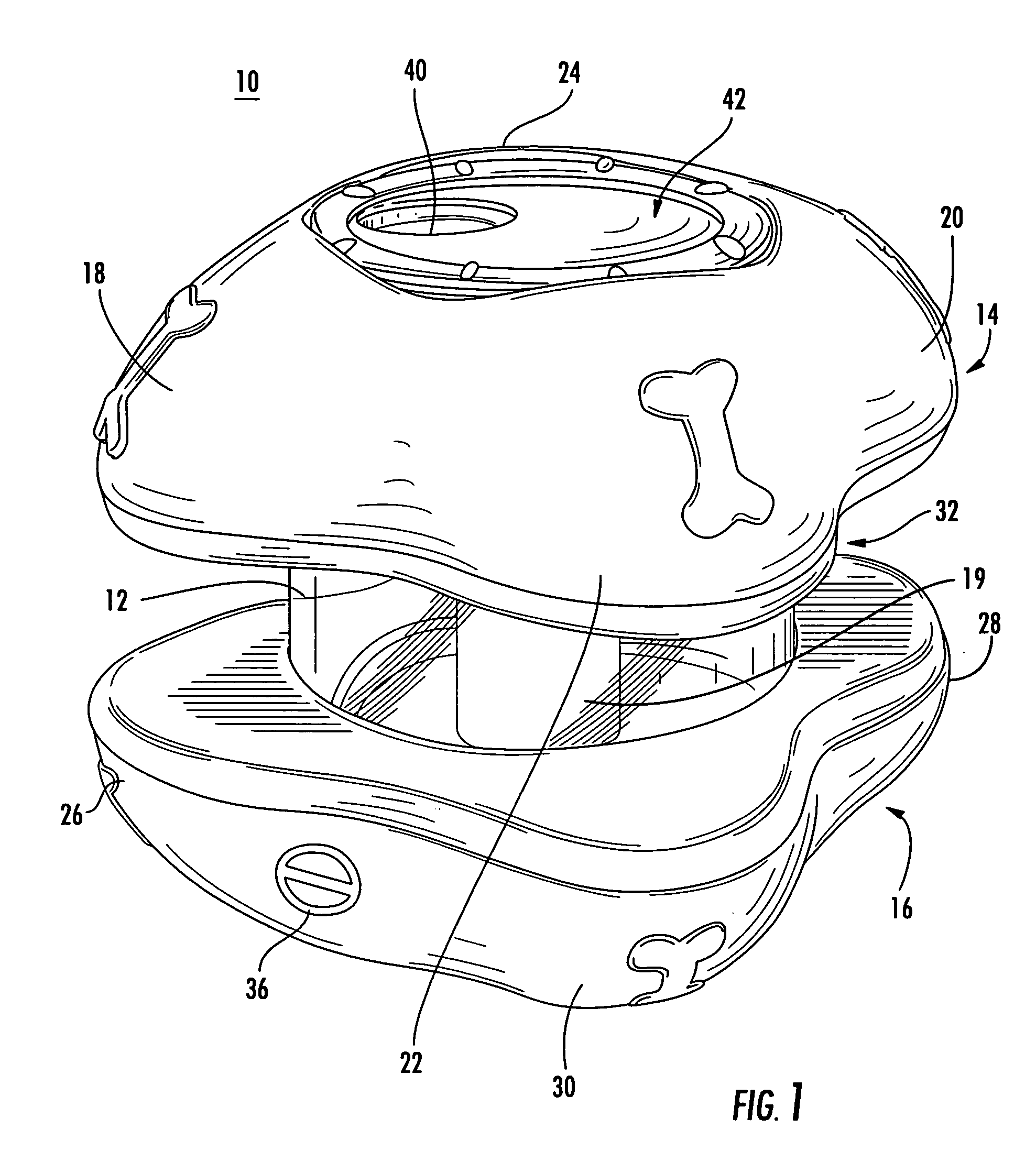

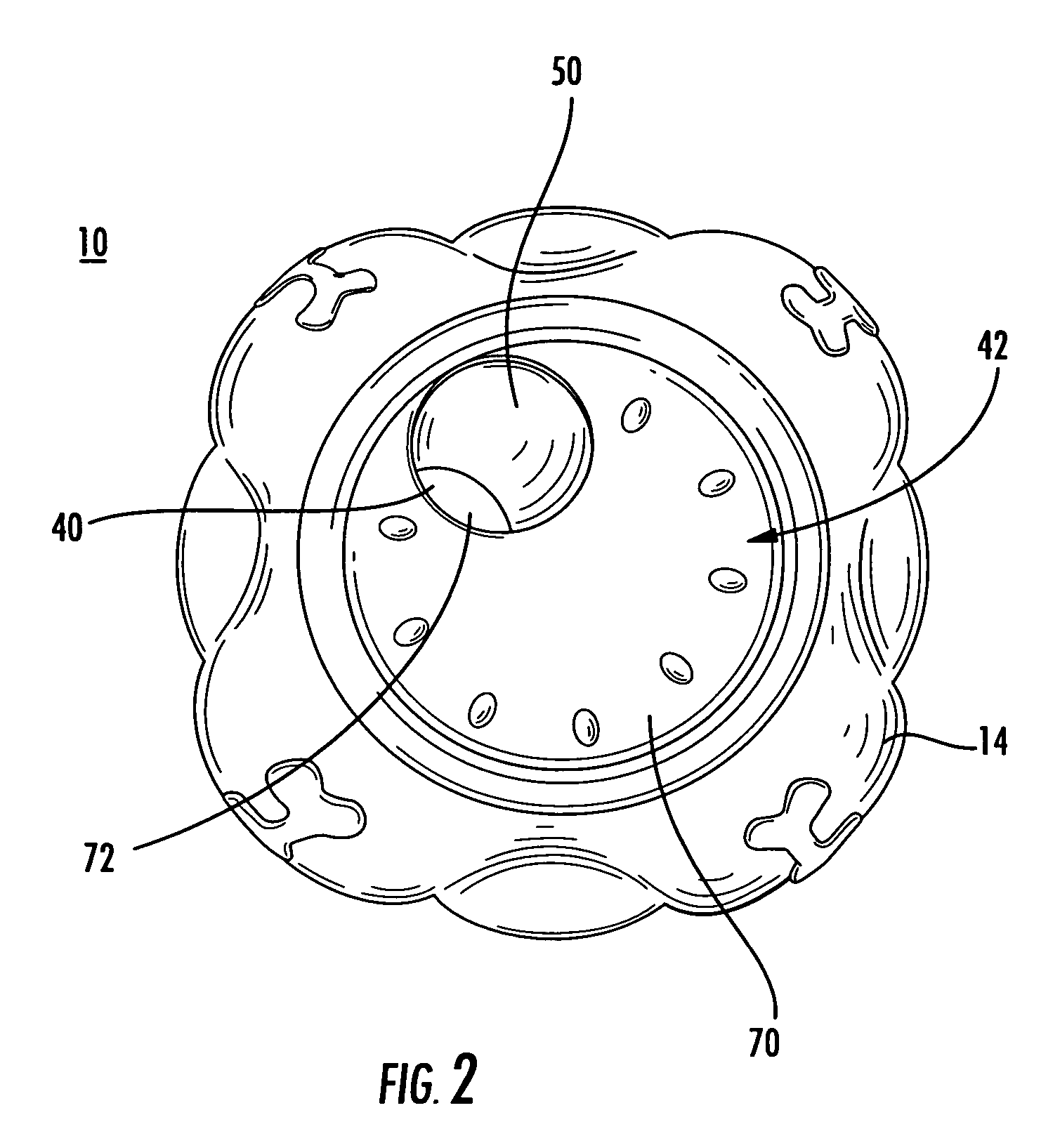

Treat ball

InactiveUS20070068464A1Non uniformIncreases challenge and excitement and stimulationOther apparatusTaming and training devicesMechanical engineeringEngineering

Owner:PETEDGE

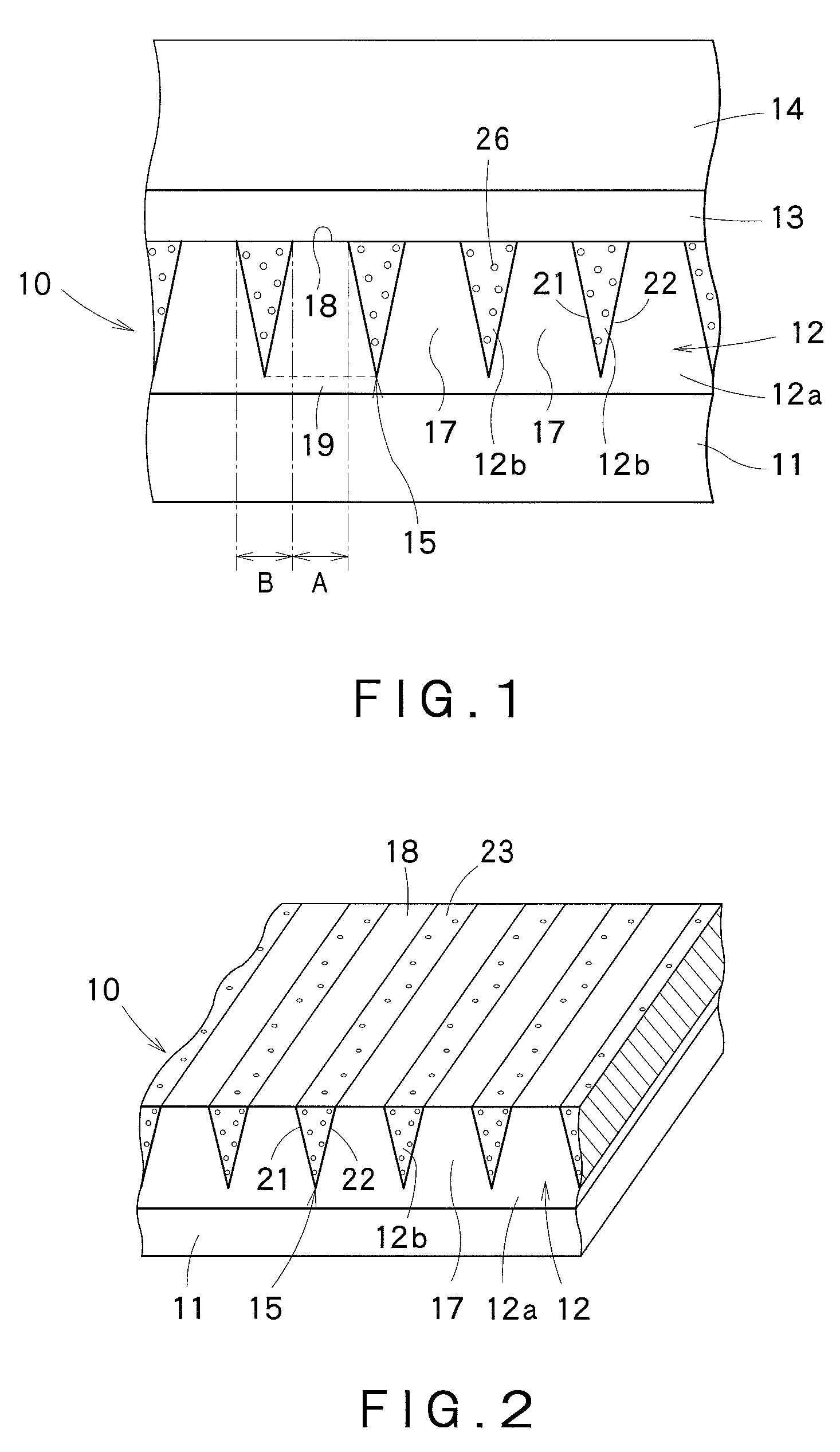

Light-Diffusing Member, Transmission Type Screen, Rear-Projection-Type Display, and Light-Absorbing-Part-Forming Resin Composition

ActiveUS20090091824A1Not easy to coverNon uniformDiffusing elementsBuilt-on/built-in screen projectorsEngineeringRadiation

The present invention provides a light-diffusing member having no non-uniformity in stripes. The light-diffusing member according to the present invention is for diffusing at least a part of transmitted light by totally reflecting the same. The light-diffusing member comprises a light-diffusing part that has a diffusing-part base having a plurality of grooves tapered down toward the incident side, formed on the light-outgoing side in juxtaposition with one another, and light-absorbing parts formed, in the grooves in the diffusing-part base, by a radiation-curing resin composition. The radiation-curing resin composition includes colored particles. The colored particles have a mean particle diameter of 3.5 μm or more and 20 μm or less.

Owner:DAI NIPPON PRINTING CO LTD +1

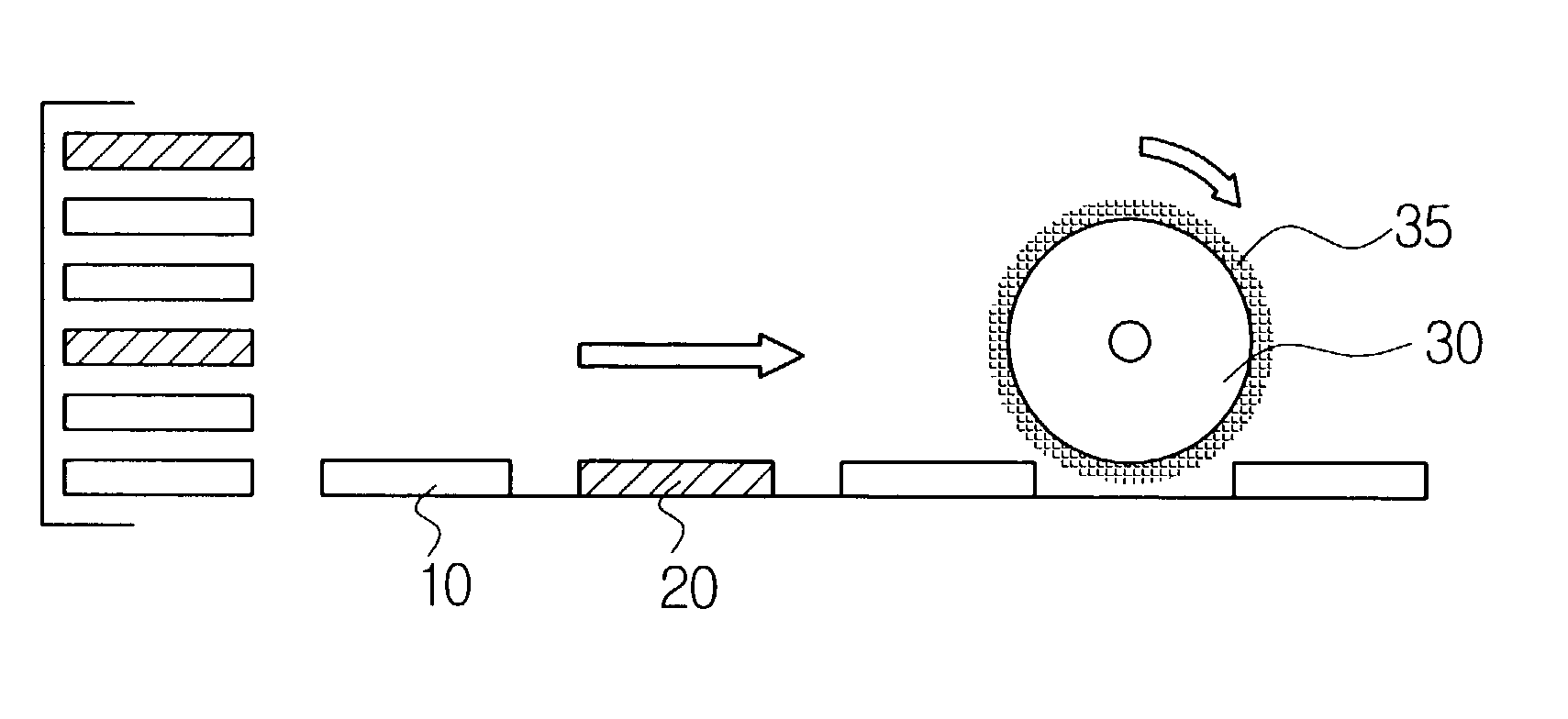

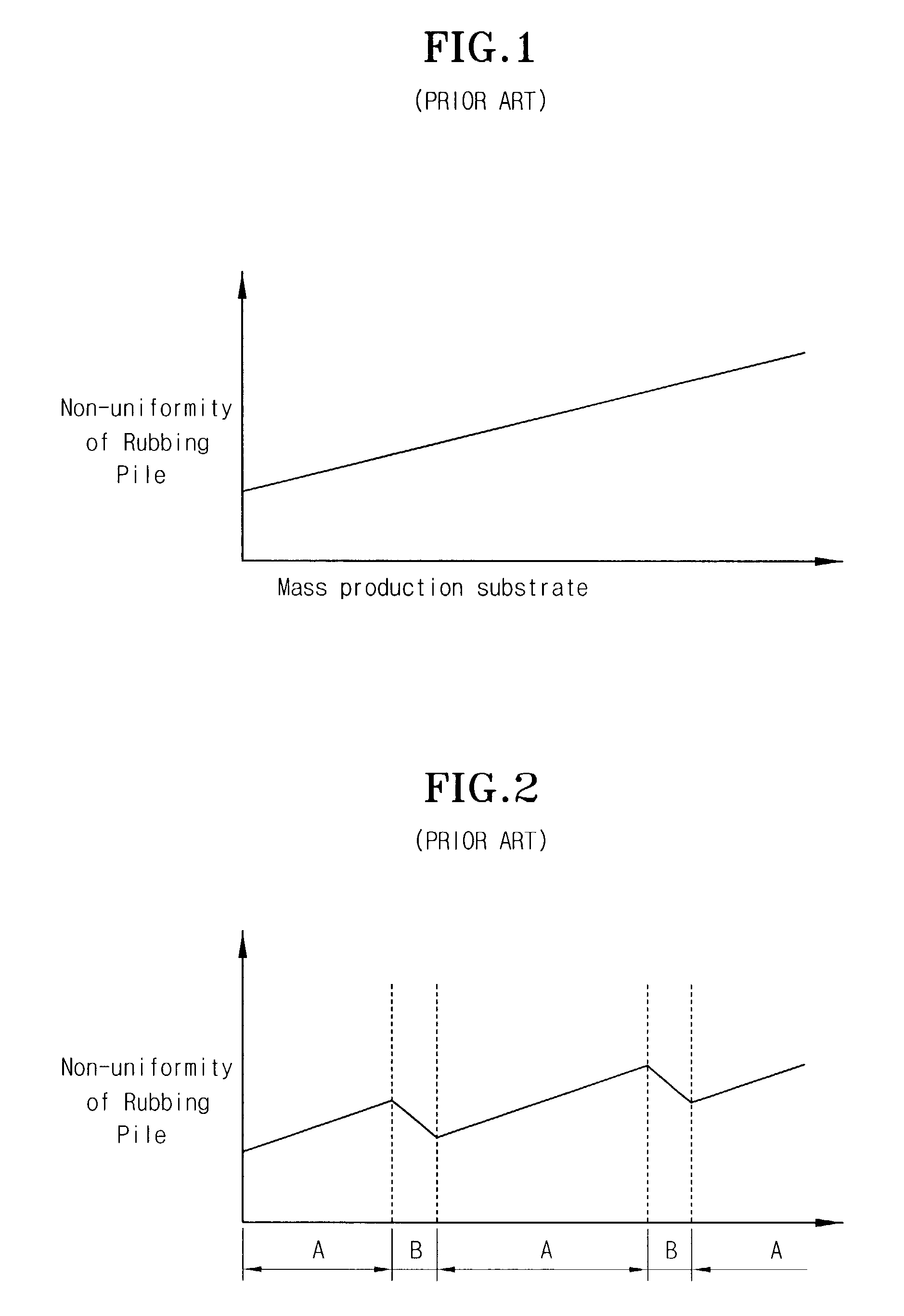

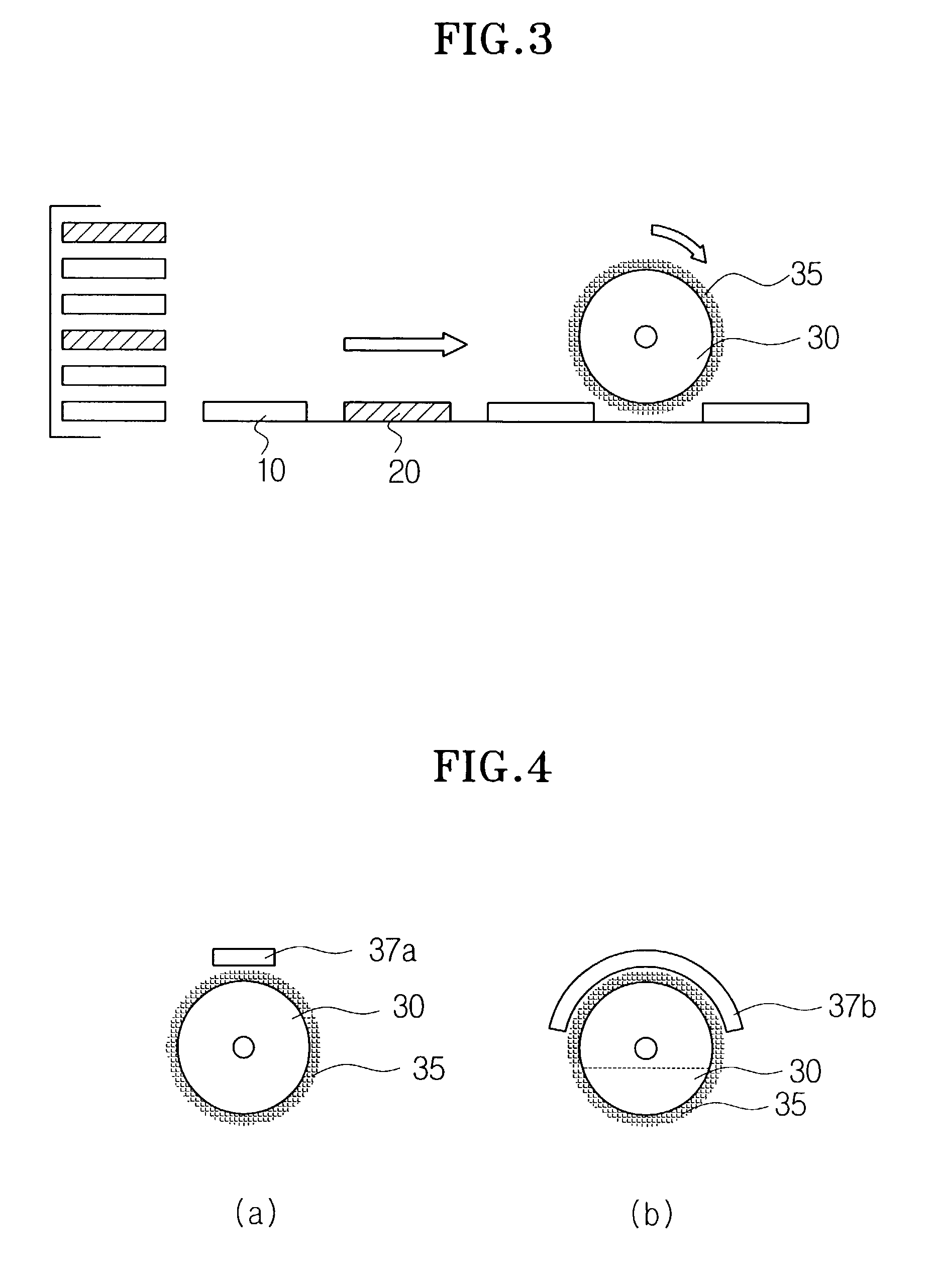

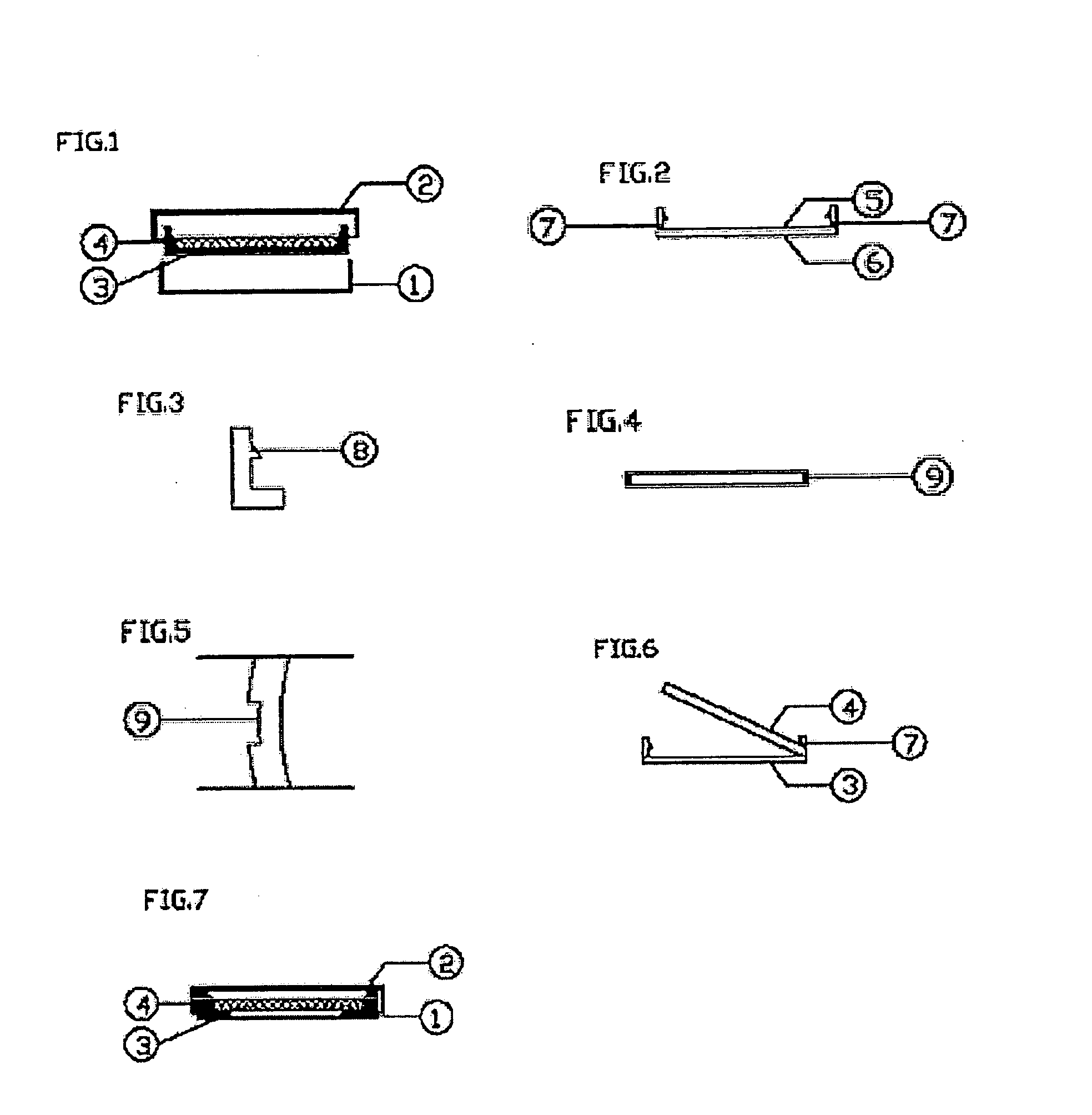

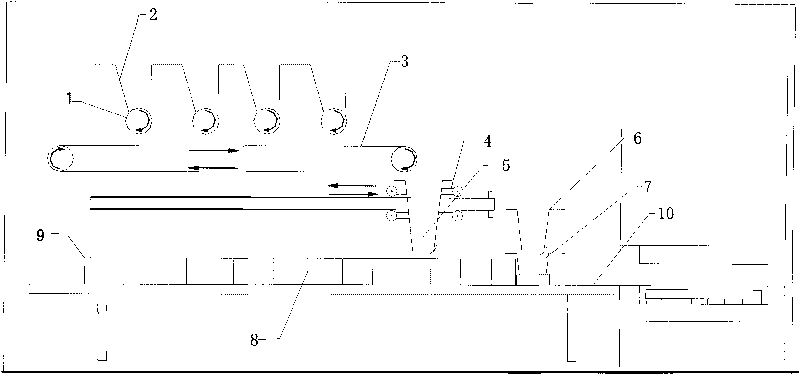

Rubbing machine with realigning functions of rubbing cloth for use in LCD manufacturing process and rubbing method using the same

ActiveUS7048619B2Quality improvementNon uniformEdge grinding machinesPolishing machinesEngineeringRubbing

The present invention relates to a rubbing machine with realigning functions for use in an LCD manufacturing process and also to a rubbing method which is conducted using the same. The rubbing machine is used to determine the direction of alignment by rubbing an alignment film coated on a substrate disposed on a stage. In this rubbing machine, an realigning section for realigning a rubbing cloth is disposed on the portion of a rubbing roll in such a manner that the realigning section be in contact with the rubbing cloth.

Owner:BOE HYDIS TECH

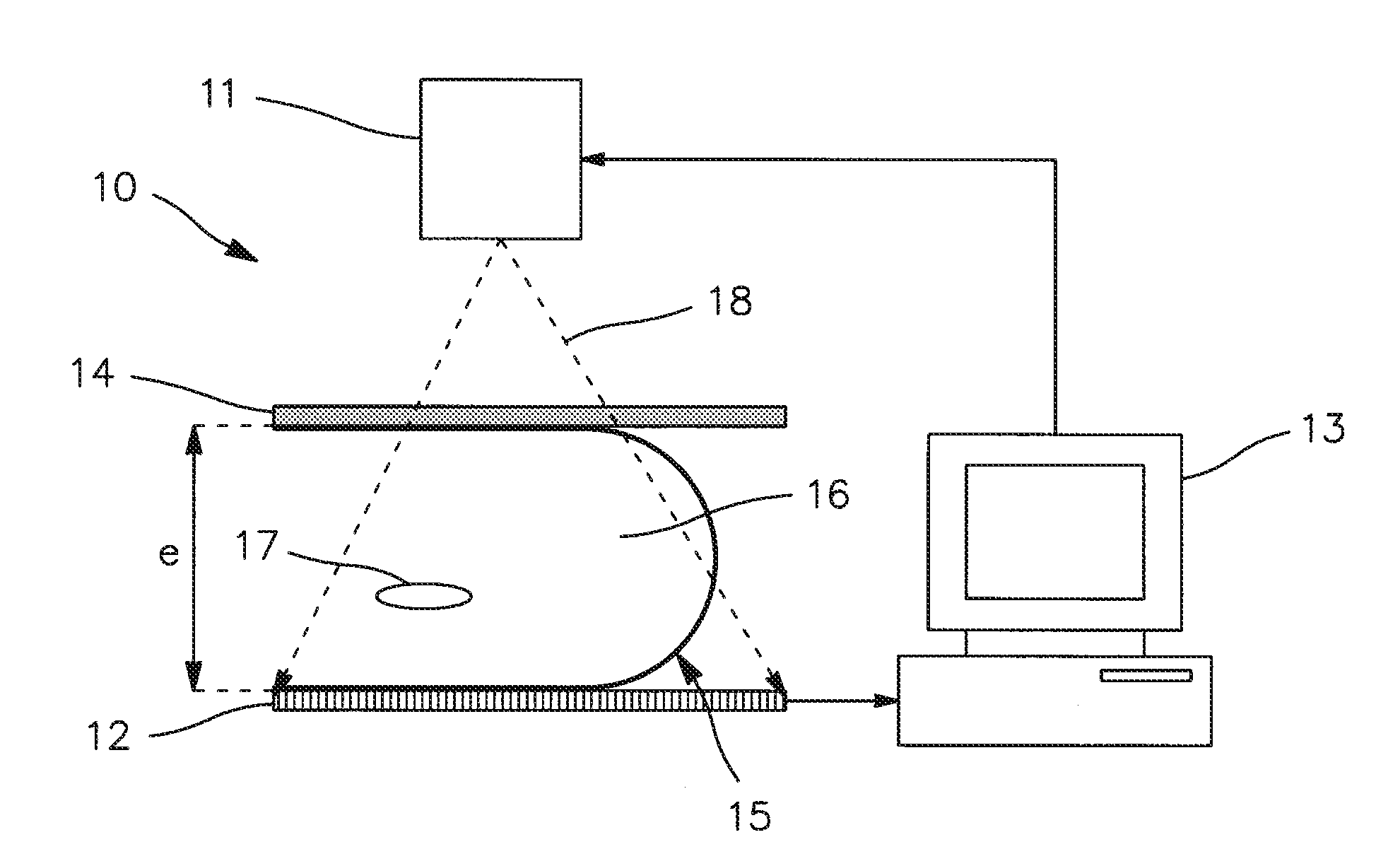

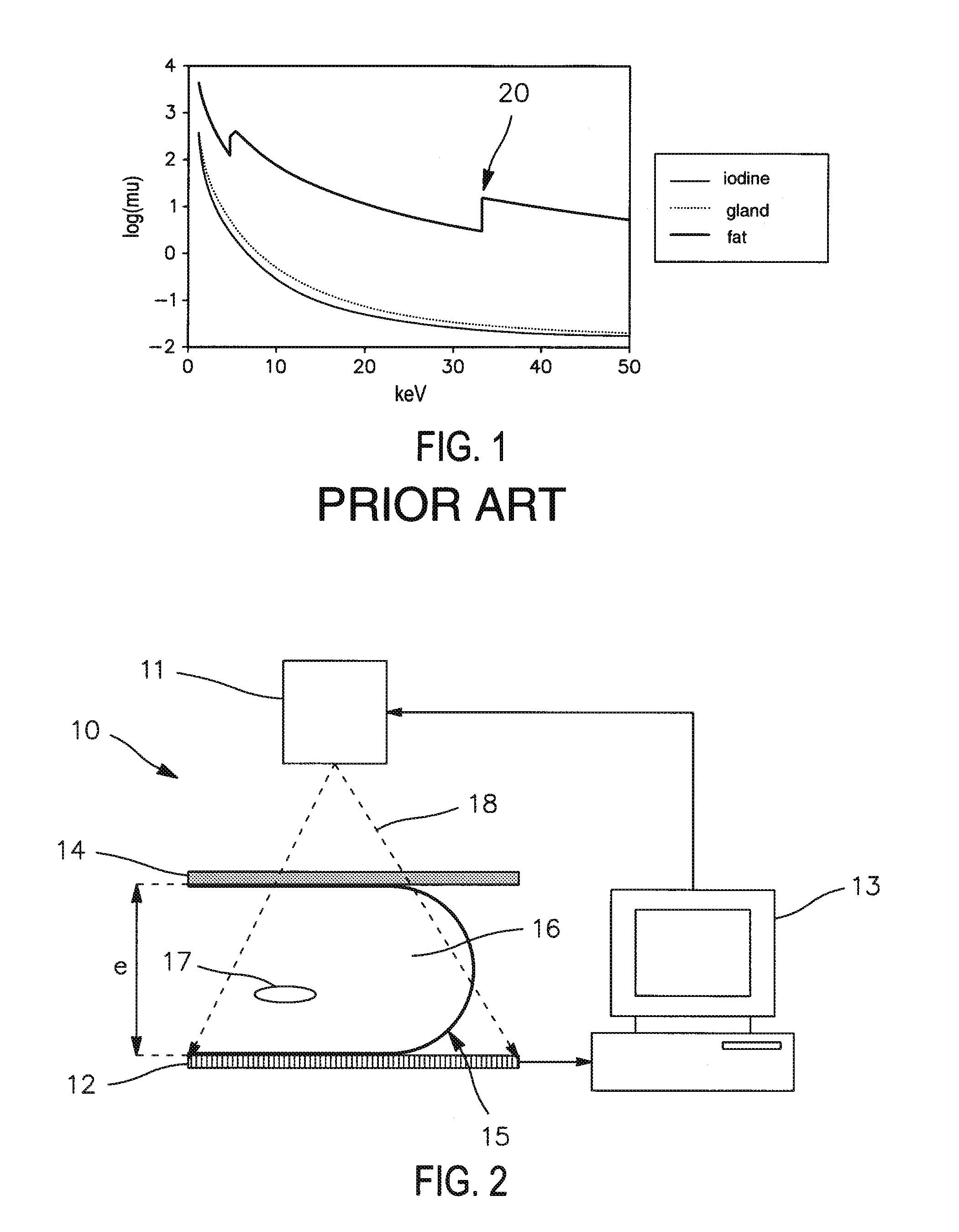

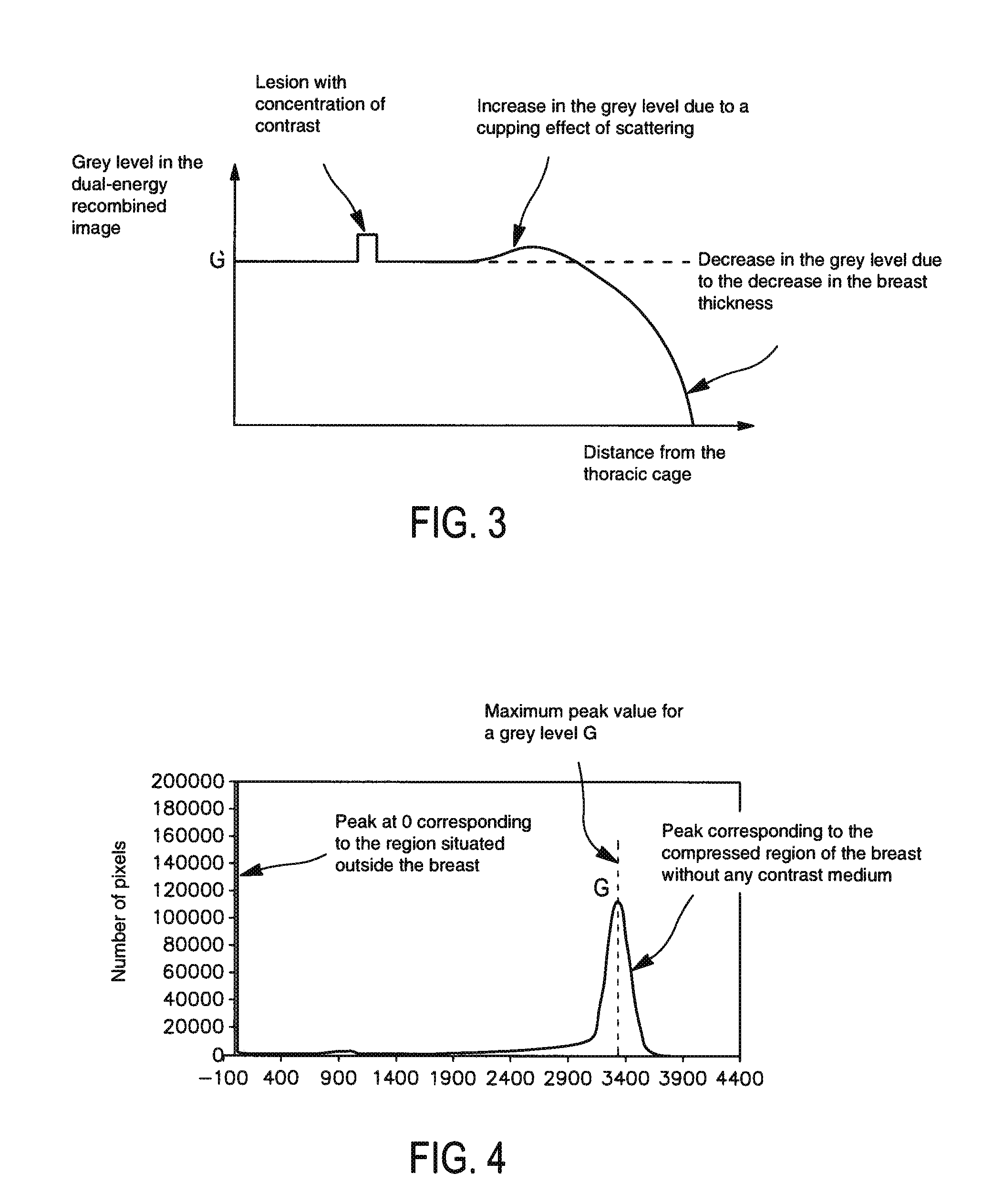

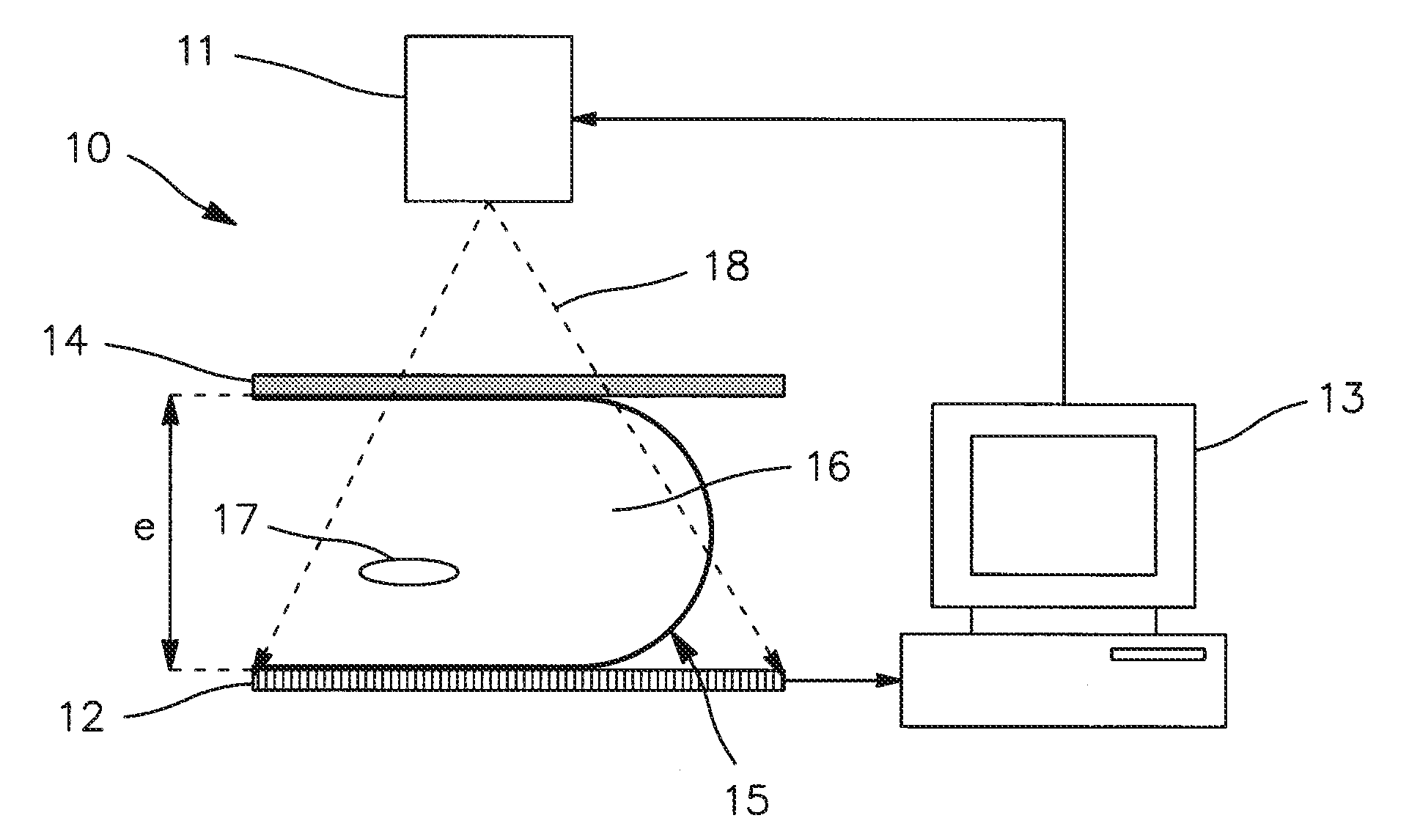

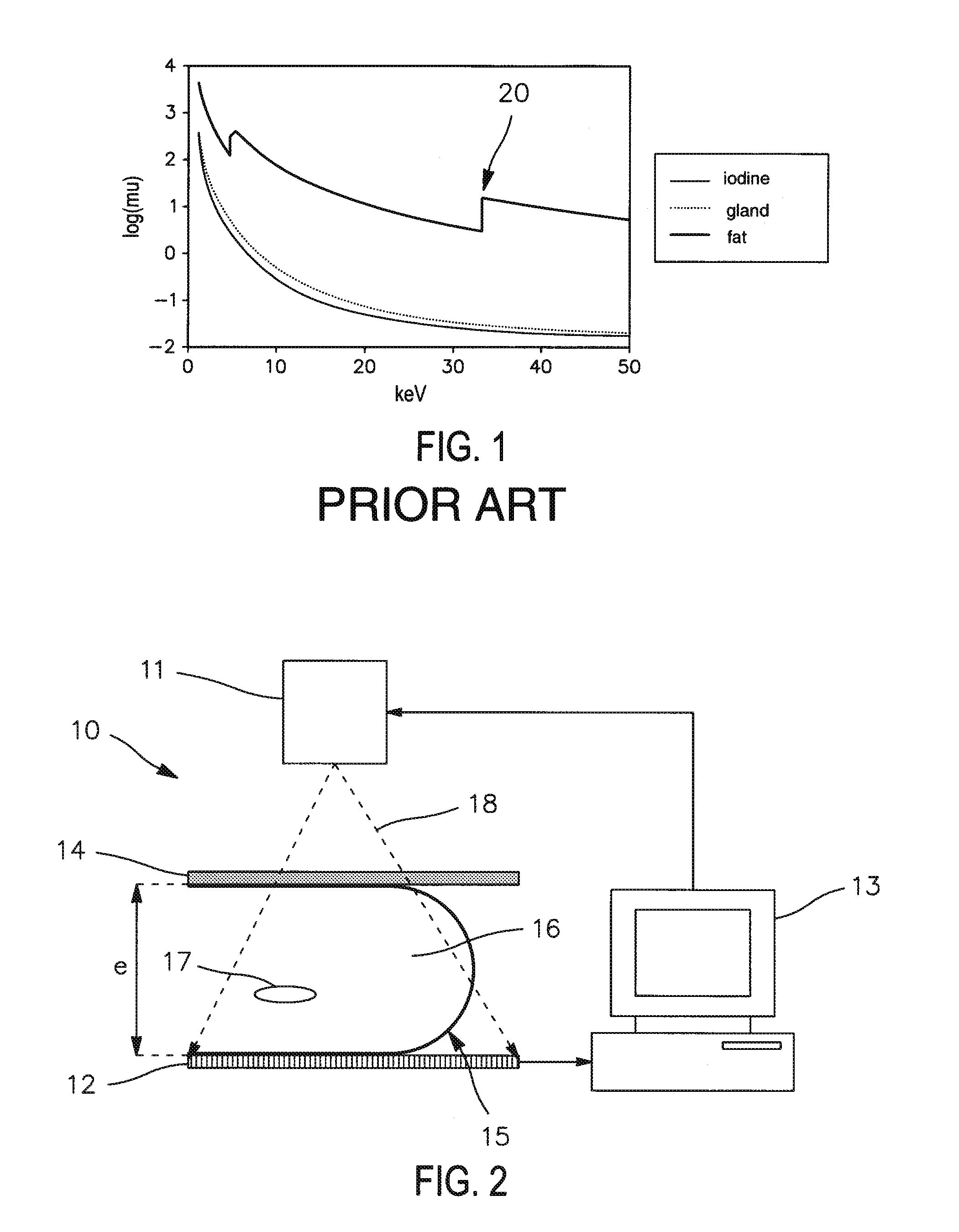

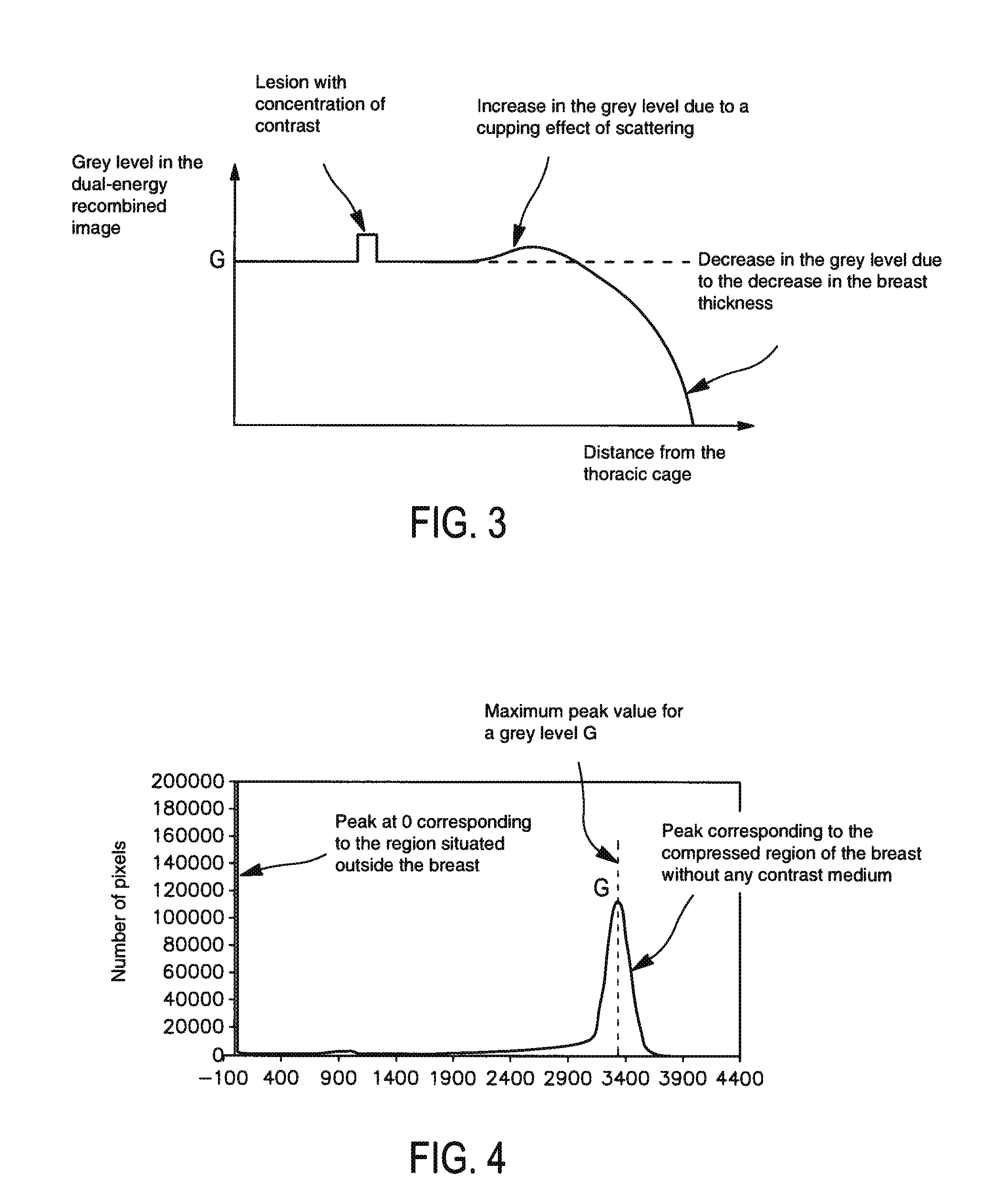

Method of processing radiological images, and, in particular, mammographic images

ActiveUS20090304253A1Quality improvementNon-uniform areaImage enhancementPatient positioning for diagnosticsHigh energyGrey level

A method of processing a radiological image of an organ. The method may comprise generating a recombined image (R) from at least one previously acquired low energy image (L) and one high energy image (H) of a portion of the organ. The recombined image comprises a background and one or more areas corresponding to the presence of a contrast medium in the organ. The method may further comprise correcting the recombined image (R) by compensating (C) for the nonuniformities present in the background to obtain a compensated recombined image in which the background has a substantially uniform grey level.

Owner:GENERAL ELECTRIC CO

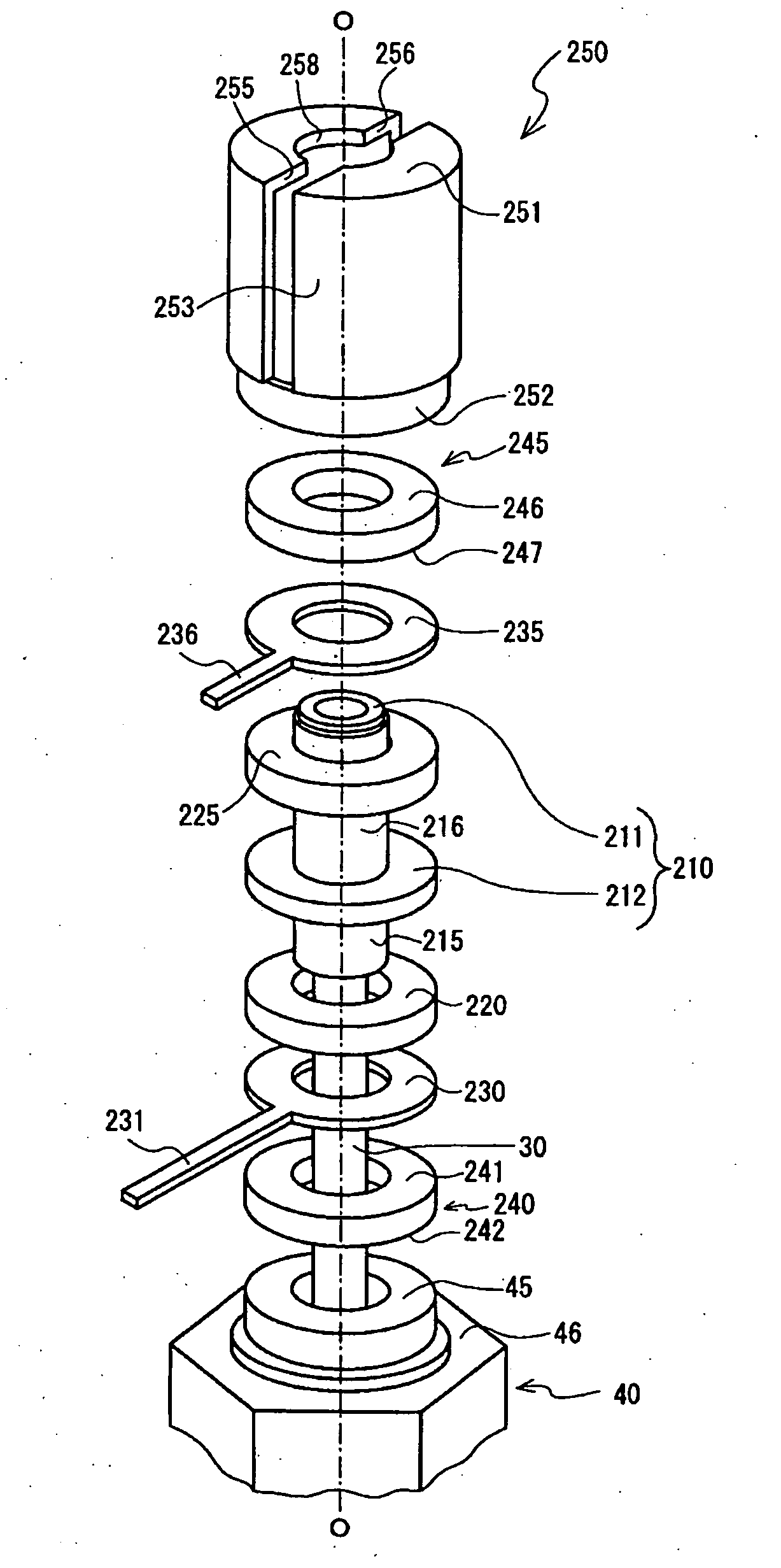

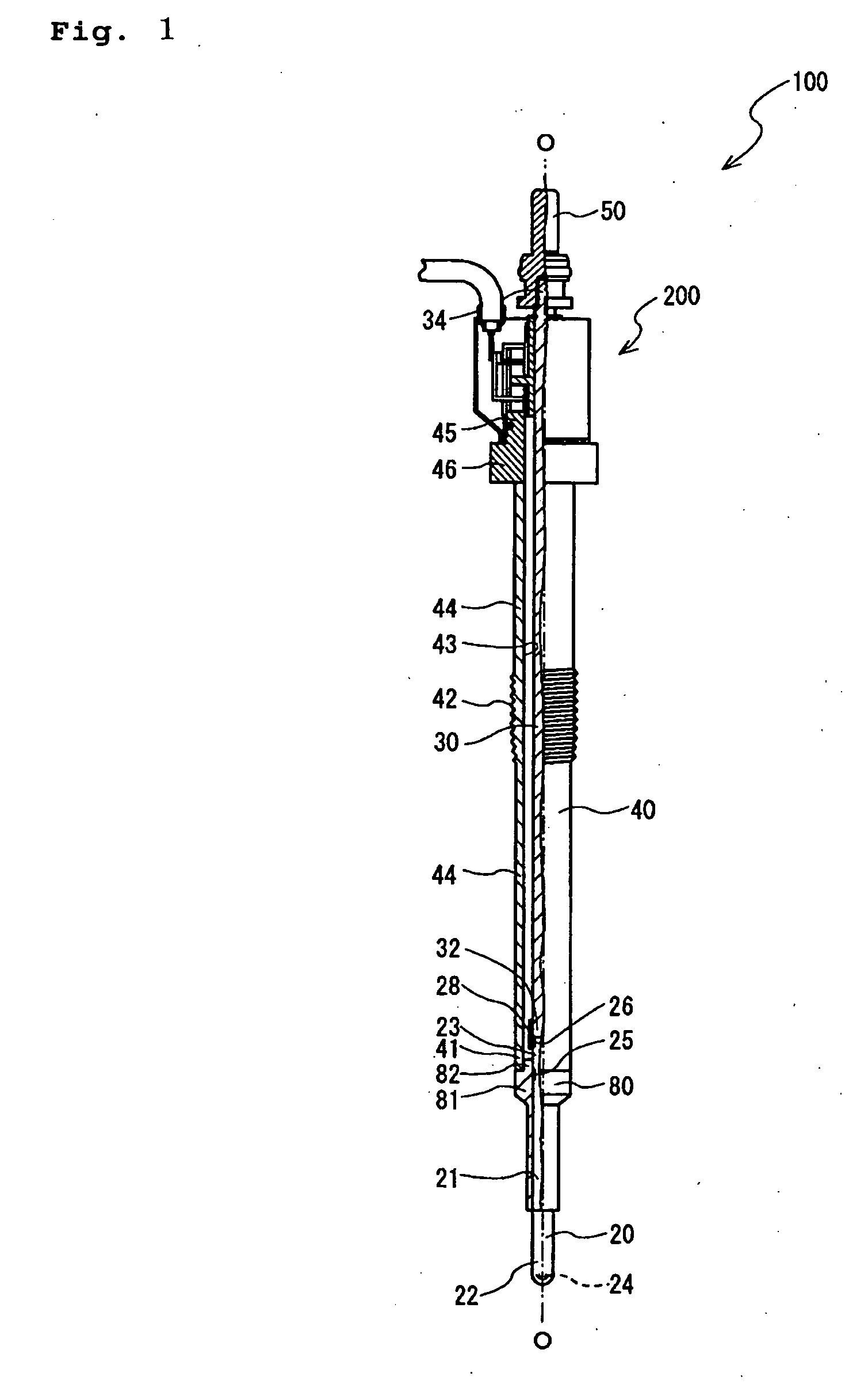

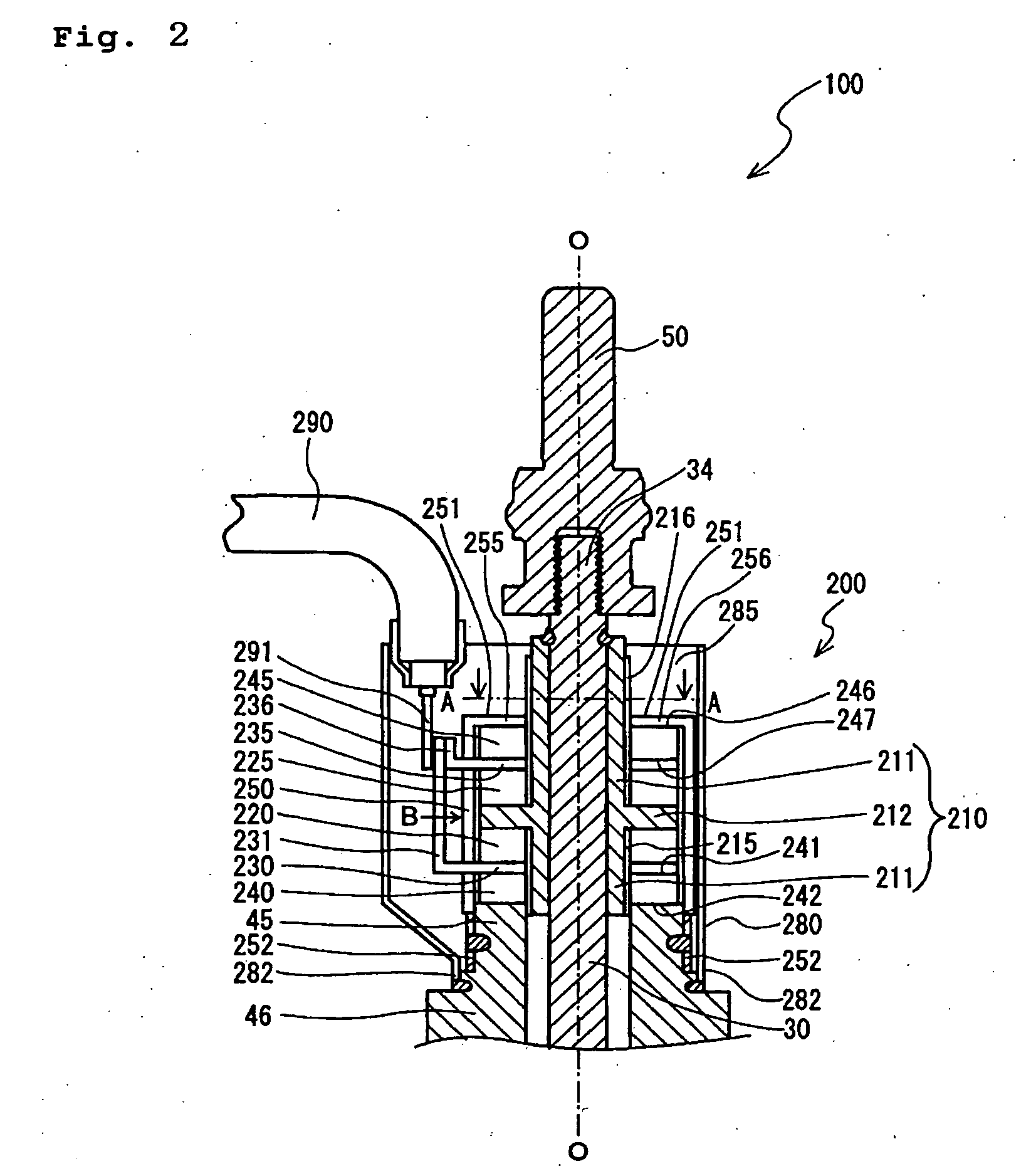

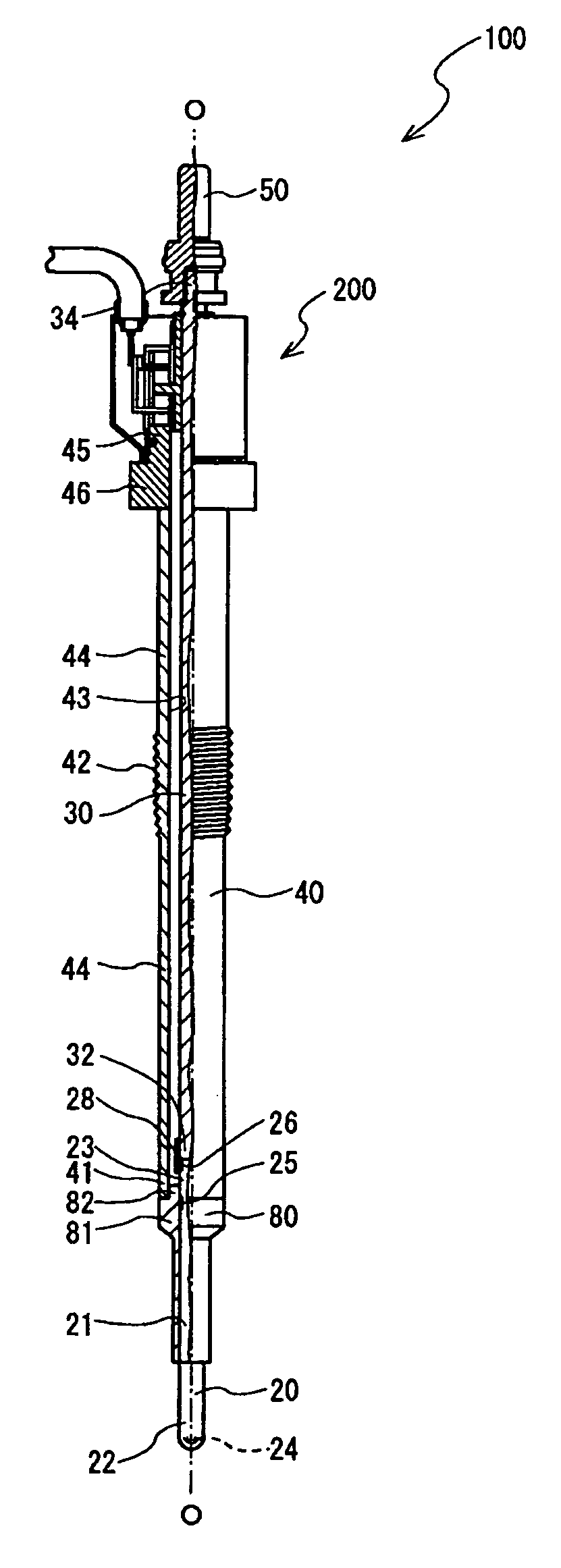

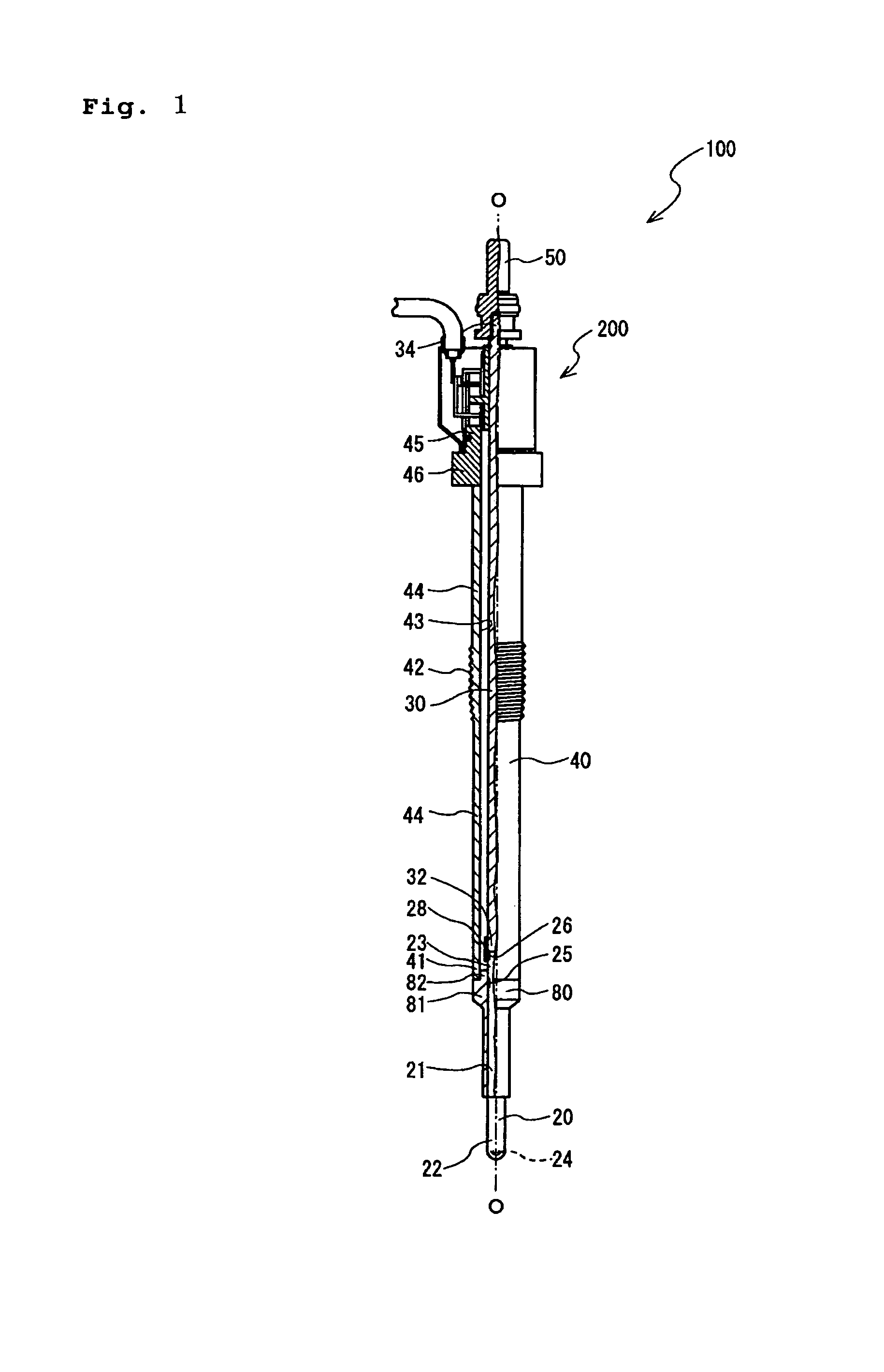

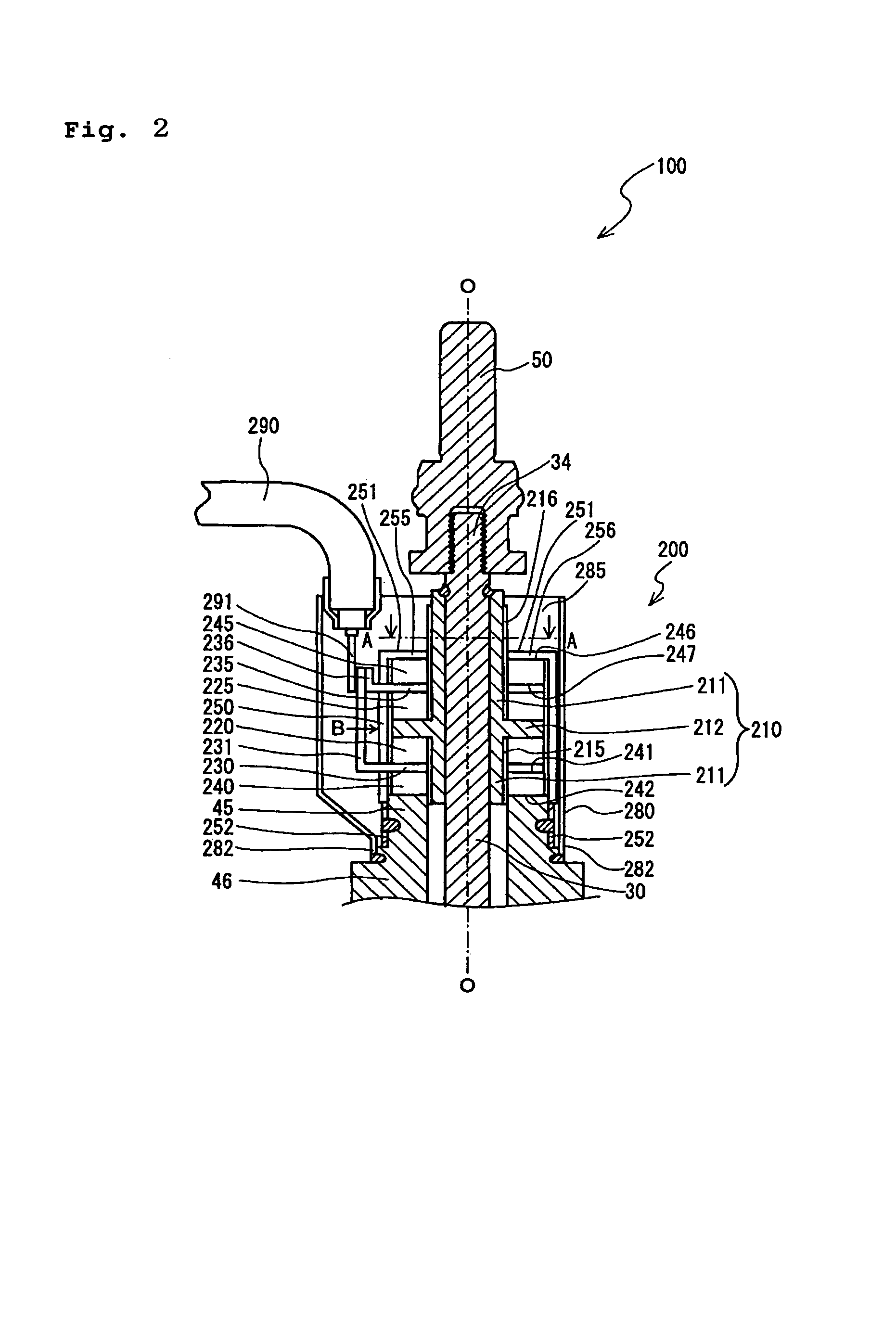

Combustion pressure sensor and glow plug including the same

InactiveUS20060218997A1High sensitivityReduce noiseIncandescent ignitionEngine testingElectric heatingElectricity

To provide a combustion pressure sensor capable of reducing noises generated by the force in a rocking direction by making uniform the stress exerted onto the piezoelectric element; and a glow plug having the same.

Owner:NGK SPARK PLUG CO LTD

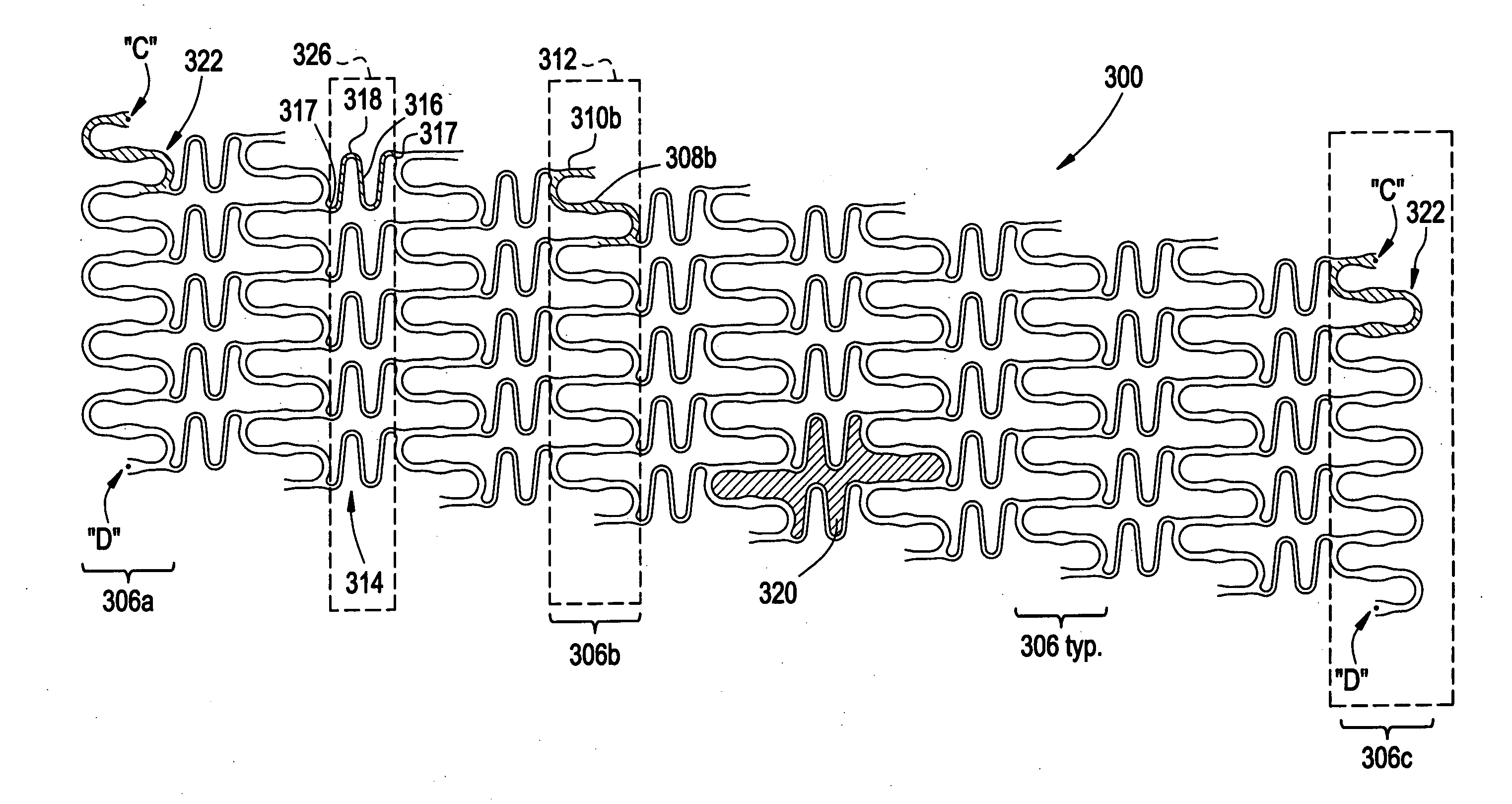

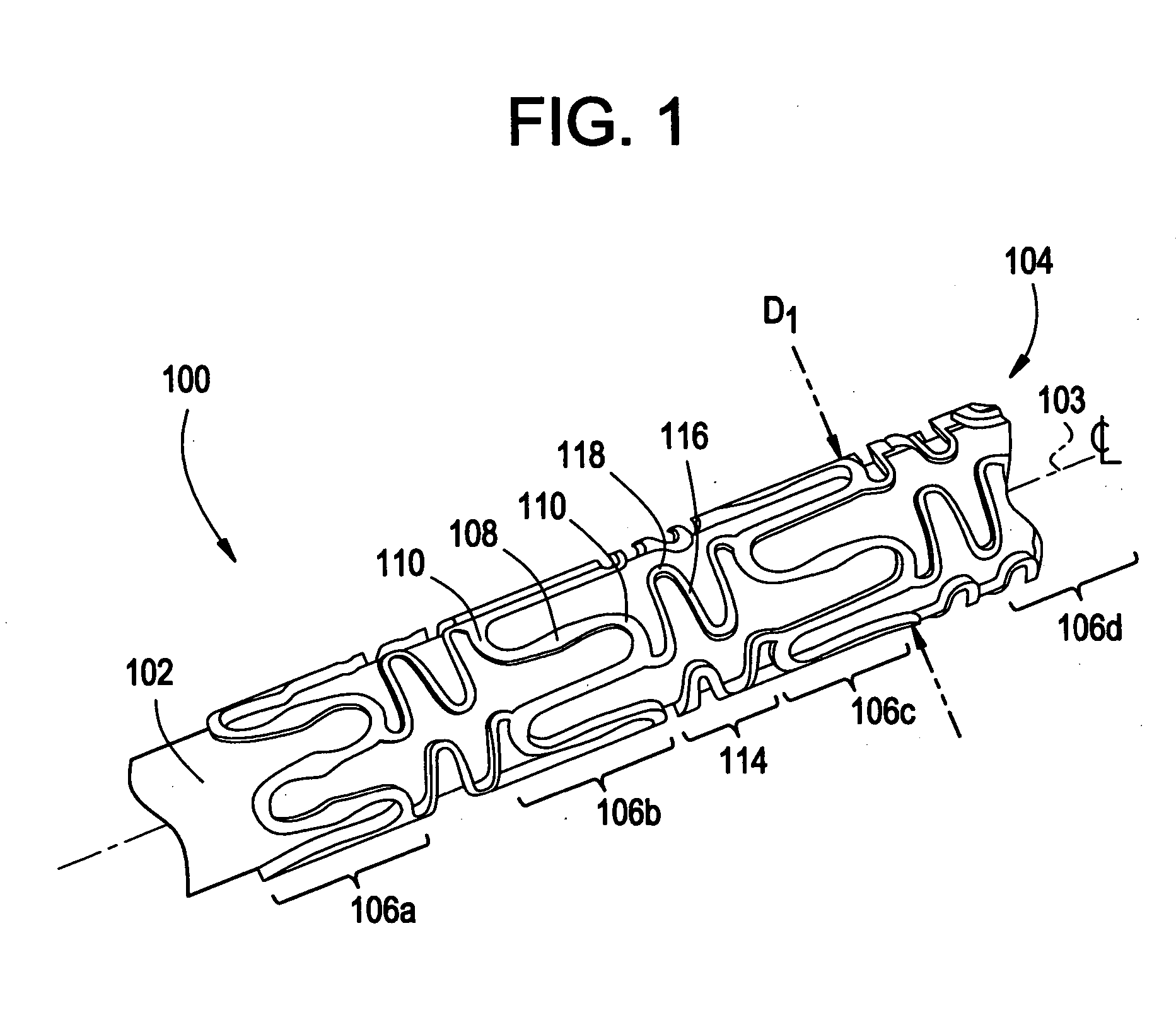

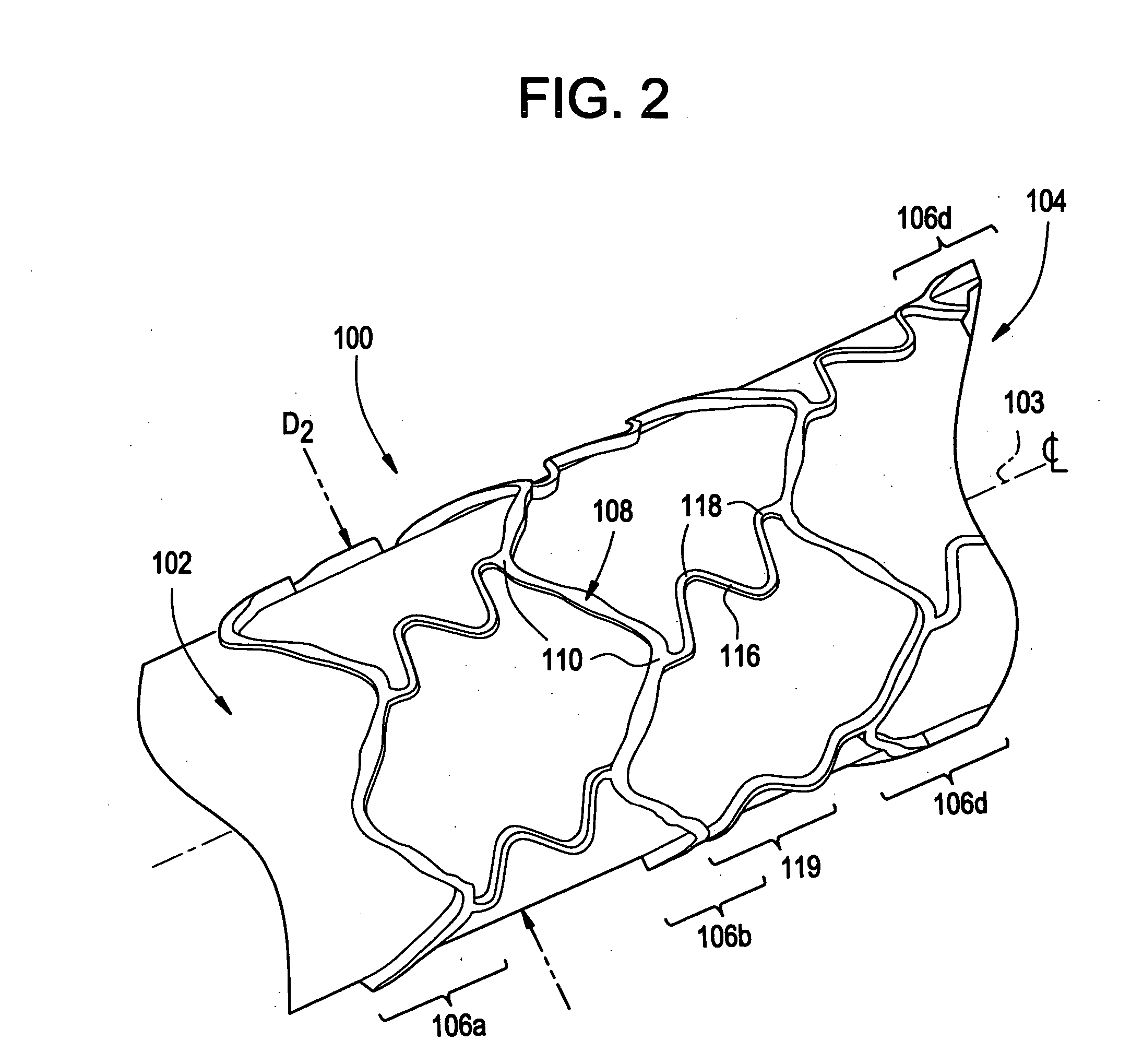

Intraluminal medical device having asymetrical members

InactiveUS20060009836A1Non uniformNon-uniform profileStentsBlood vesselsStress distributionInsertion stent

This invention relates generally to expandable intraluminal medical devices for use within a body passageway or duct, and more particularly to an optimized stent having asymmetrical strut and loop members. In one embodiment of the invention the stent includes one or more members each having at least one component. The component has non-uniform cross-sections to achieve near-uniform stress distribution along the component when the component undergoes deformation.

Owner:BURGERMEISTER ROBERT +5

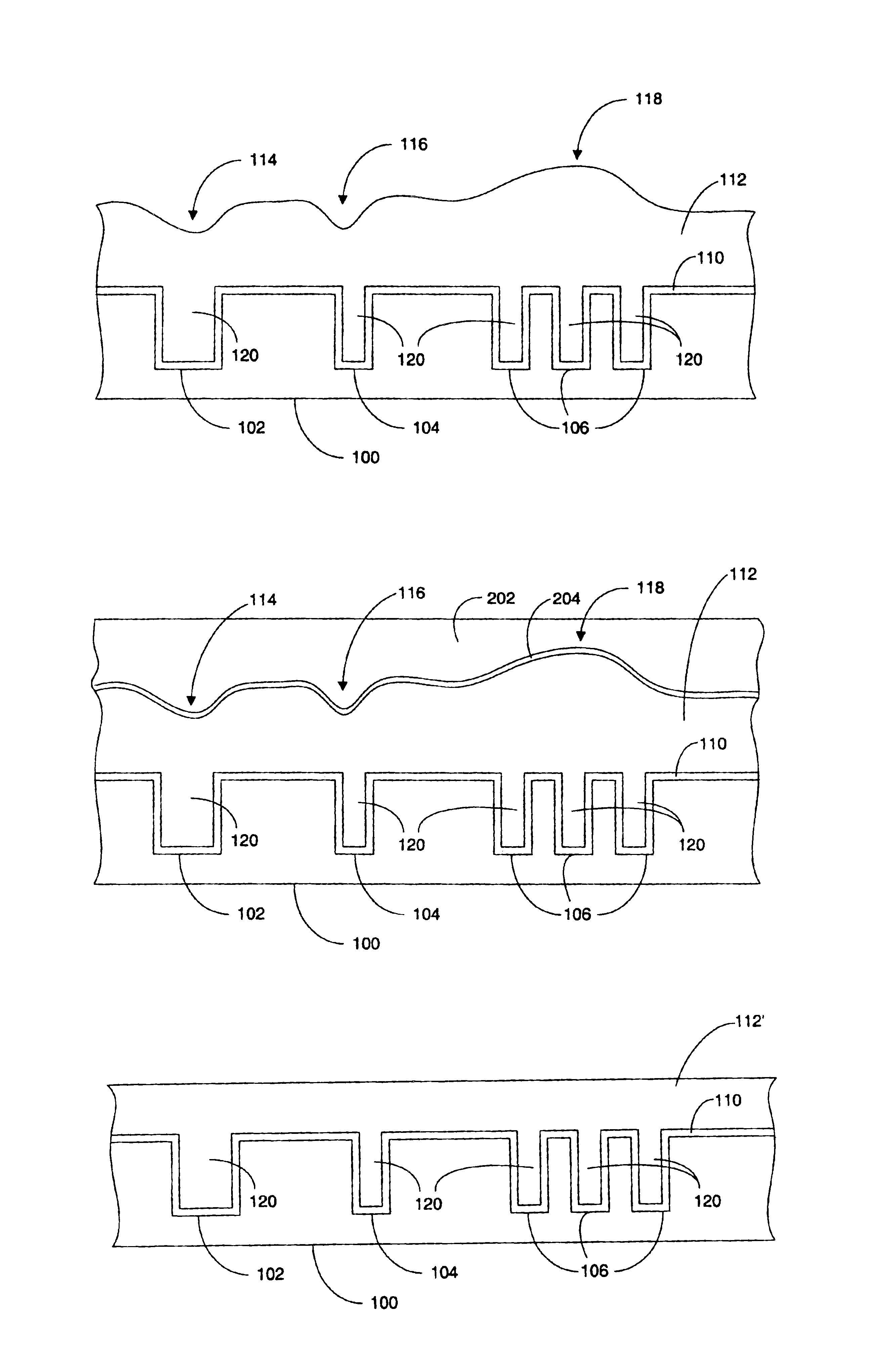

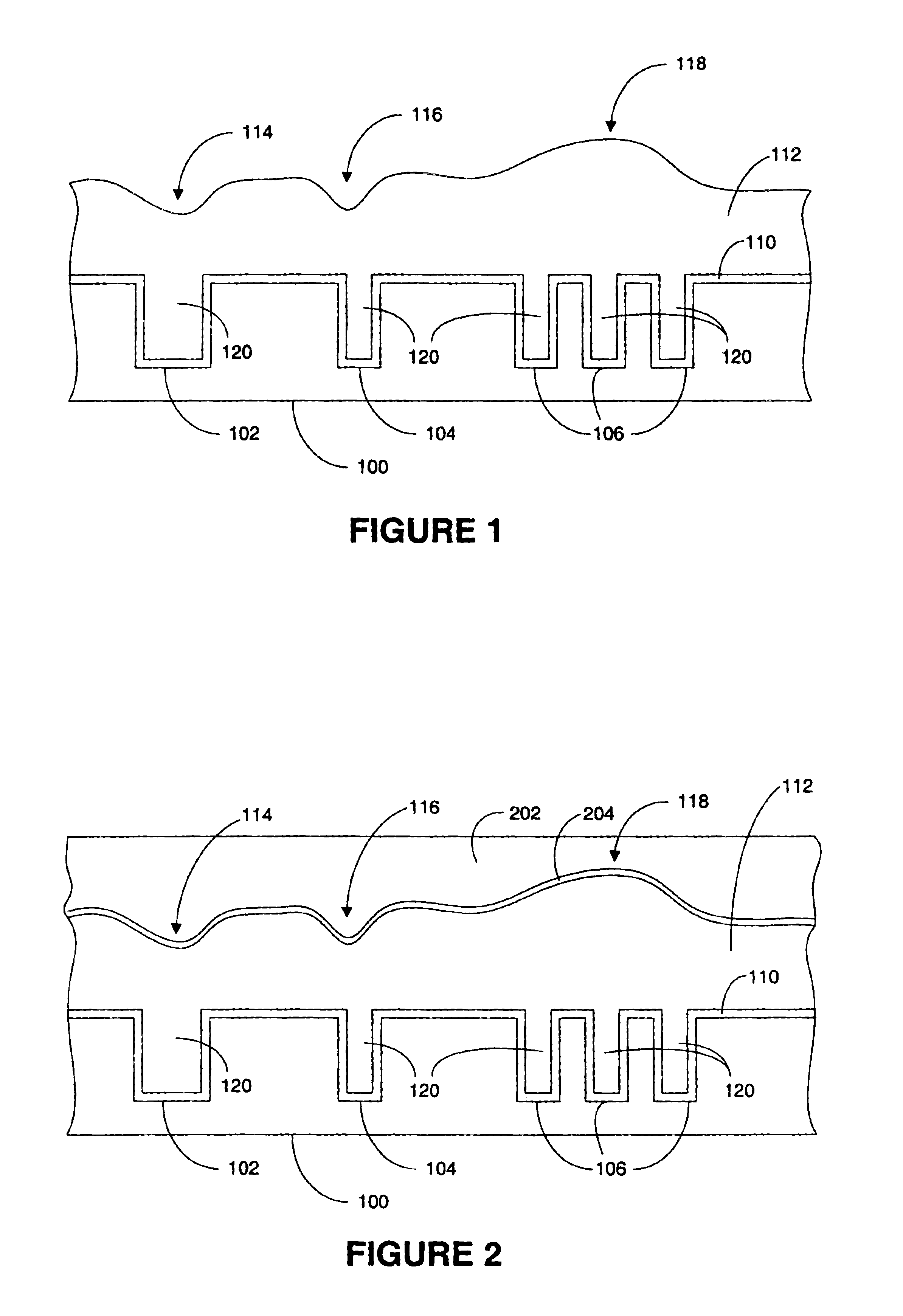

System, method and apparatus for improved global dual-damascene planarization

InactiveUS6939796B2Non uniformMinimizing any recessDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A system and method for planarizing a patterned semiconductor substrate includes receiving a patterned semiconductor substrate. The patterned semiconductor substrate having a conductive interconnect material filling multiple of features in the pattern. The conductive interconnect material having an overburden portion. The overburden portion having a localized non-uniformity. A bulk portion of the overburden portion is removed to planarize the overburden portion. The substantially locally planarized overburden portion is mapped to determine a global non-uniformity. The substantially locally planarized overburden portion is etched to substantially remove the global non-uniformity.

Owner:LAM RES CORP

Combustion pressure sensor and glow plug including the same

InactiveUS7201043B2Reduce stiffnessReduce noiseIncandescent ignitionEngine testingElectricityCombustion

To provide a combustion pressure sensor capable of reducing noises generated by the force in a rocking direction by making uniform the stress exerted onto the piezoelectric element; and a glow plug having the same.

Owner:NGK SPARK PLUG CO LTD

Electrolytic passivated tin plated steel

InactiveUS20100181201A1Less expensiveIncrease surface areaAnodisationDuplicating/marking methodsOrganic acidPhenols

An electrolyte composition for passifying tin plated steel wherein the essential ingredient consists of a mixture of organic hydroxyl acids and phenol organic acids; a method of passifying tin plate steel articles with the composition by electrolysis with a pH of about 7.0-10.0 and preferably a pH of 8.0-9.5; and providing the passified tin plated steel article produces by the method along with the passified articles having an appropriate paint thereon.

Owner:BIBBER JOHN W

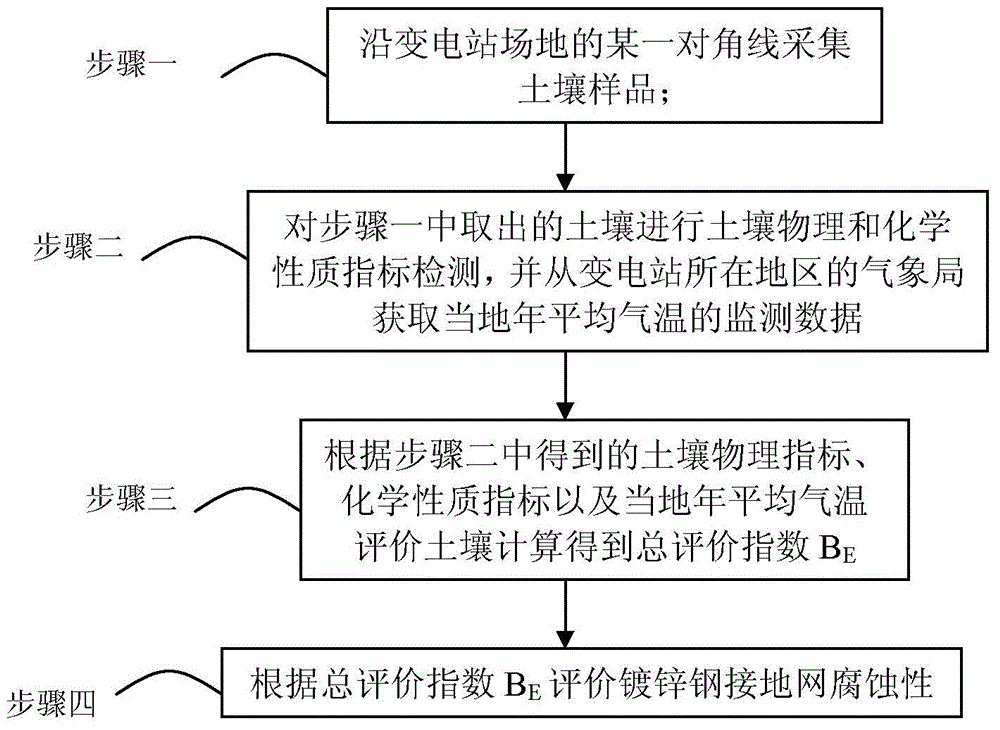

Method for evaluating corrosivity of transformer station soil to galvanized steel grounding grid

The invention provides a method for evaluating the corrosivity of transformer station soil to a galvanized steel grounding grid, relates to the field of evaluation of the corrosivity to the galvanized steel grounding grid, and aims to solve the problem that as soil has various characteristics of diversity, immobility, heterogeneity, timeliness, seasonality, territoriality and the like in corrosivity to metal, evaluation to the corrosion property of soil fails. The method comprises the following steps: step I, collecting a soil sample along a certain diagonal line of a transformer station; step II, conducting soil physical and chemical property index detection on the soil sample obtained in the step I, and acquiring monitoring data of local annual mean temperature from the weather bureau of the region of the transformer station; step III, evaluating the soil sample to obtain a total evaluation index BE through calculation; step IV, evaluating the corrosivity to the galvanized steel grounding grid according to the total evaluation index BE. The method is applied to the field of evaluation of the corrosivity to the galvanized steel grounding grid.

Owner:STATE GRID CORP OF CHINA +1

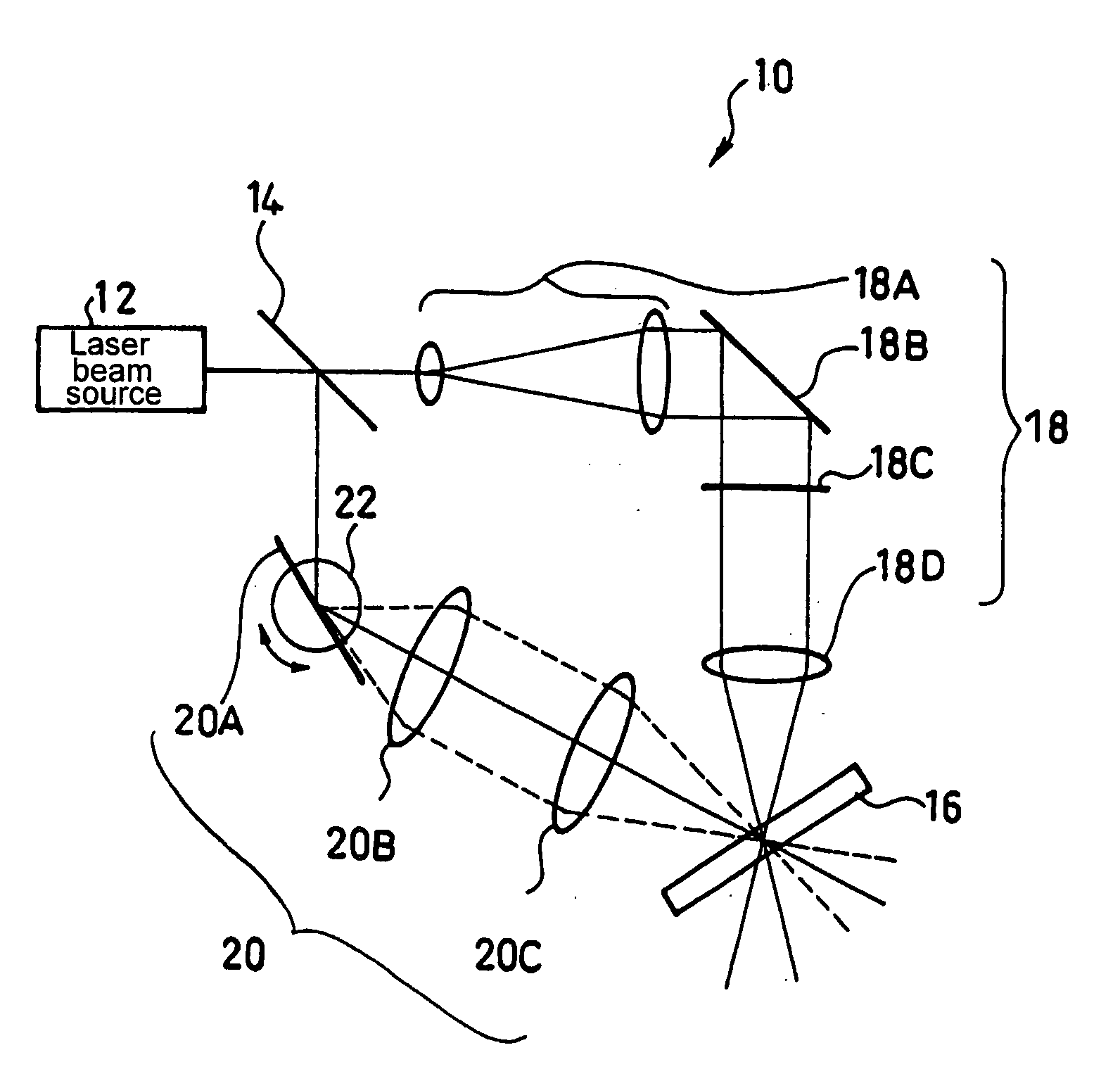

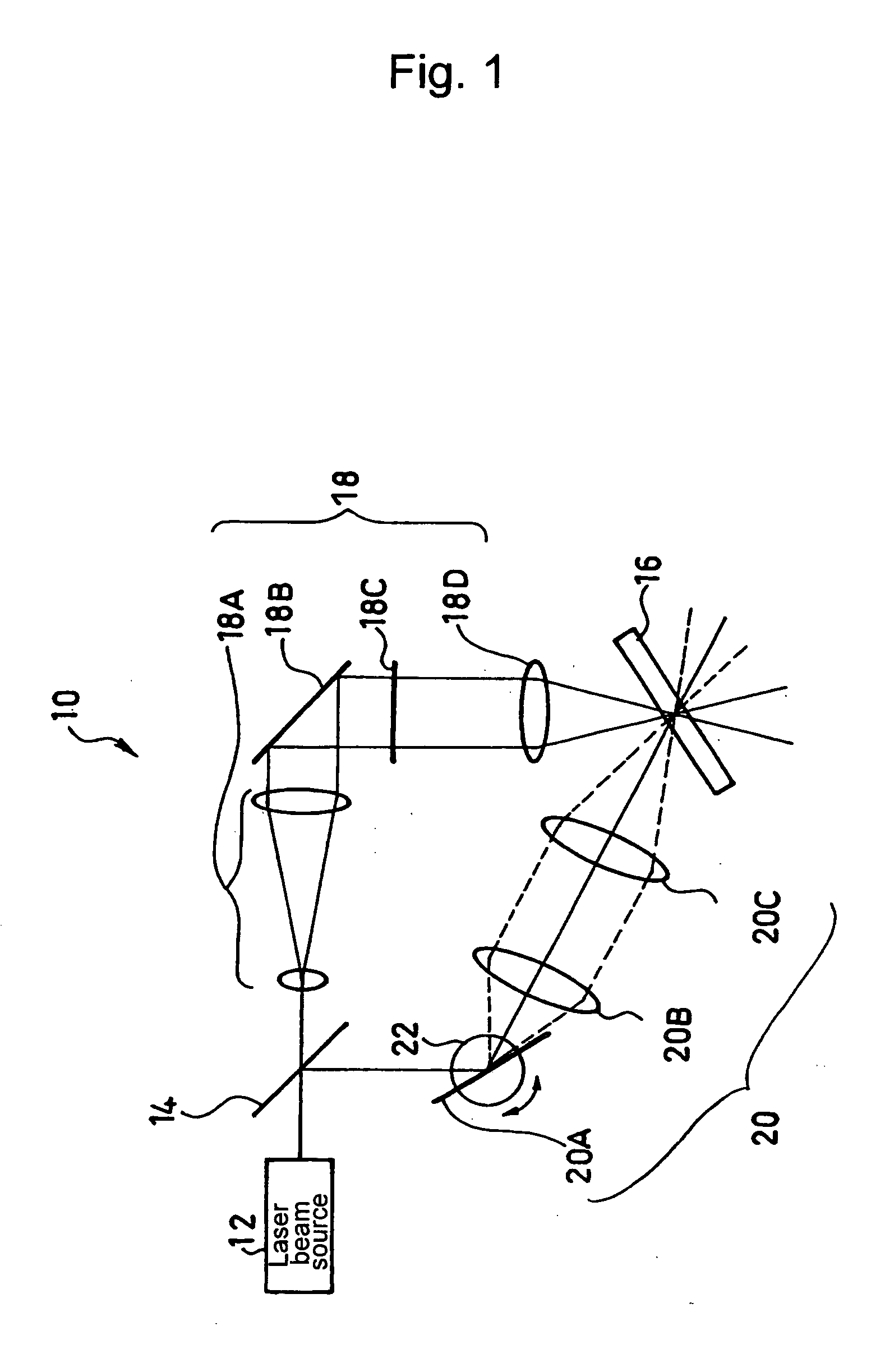

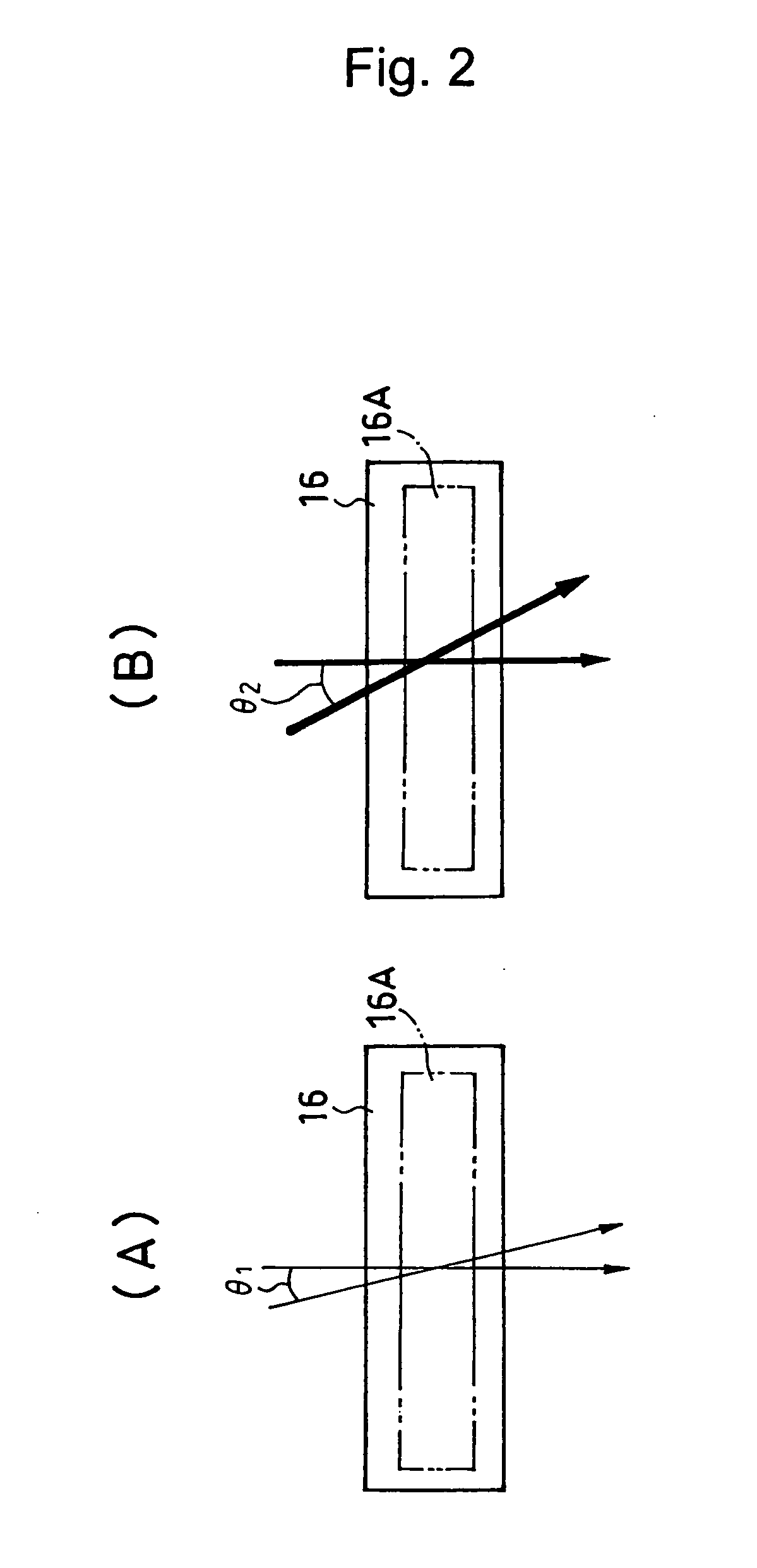

Holographic multiplex recording method, and holographic recording apparatus and holographic recording medium employing the method

InactiveUS20070183009A1Constant recording data rateEqualize nonuniformityOptical beam sourcesRecord information storageMultiplexingLight beam

A holographic multiplex recording method which can keep a recording data rate constant and equalize nonuniformity in recording due to vibrations or the like, and a holographic recording apparatus and a holographic recording medium, which employ the method are provided. In a process of multiplex-recording information, the time of exposure to a laser beam per data page is kept constant, and the laser output power of the laser beam is increased in accordance with a decrease in recording sensitivity of the holographic recording medium.

Owner:TDK CORPARATION

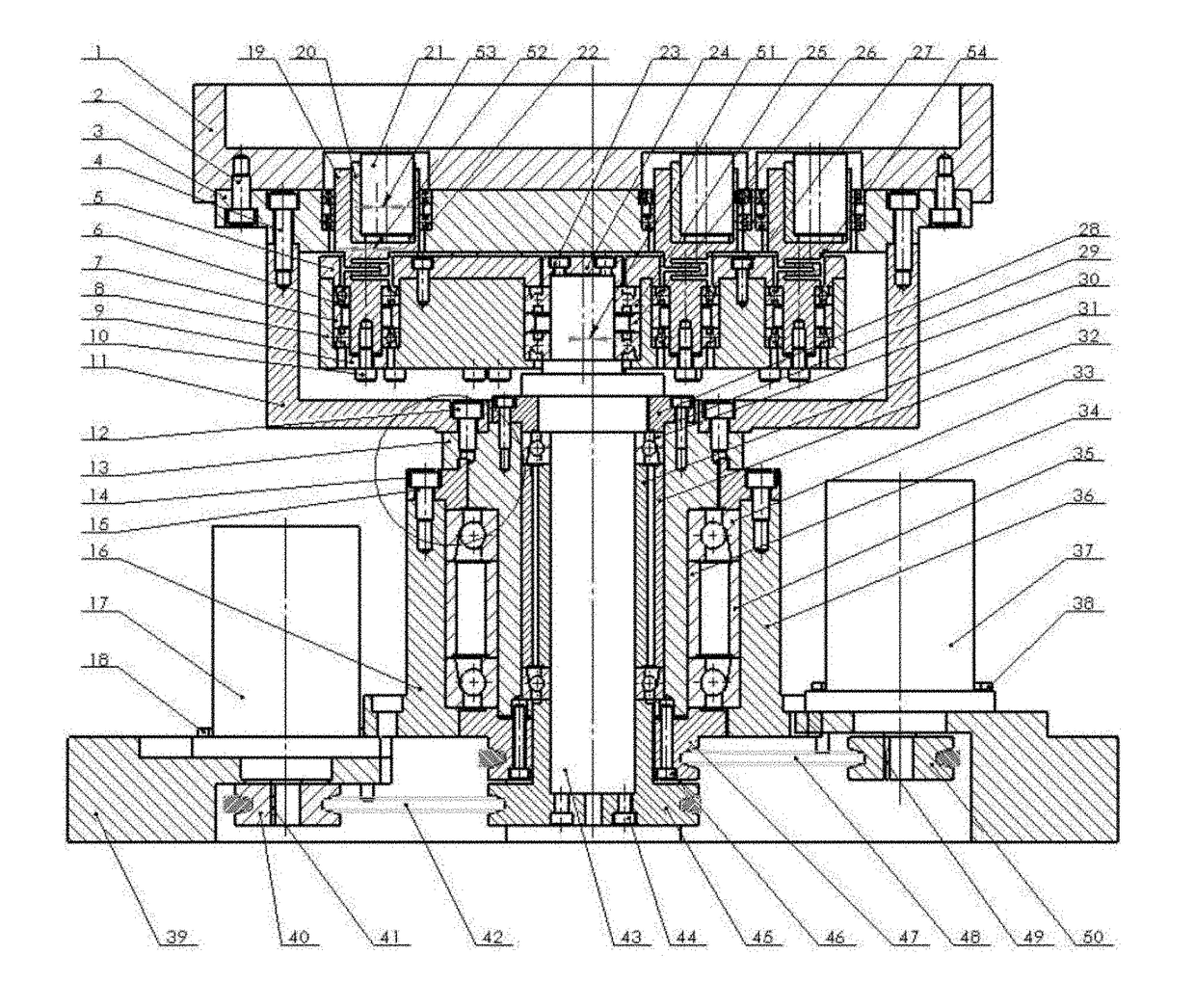

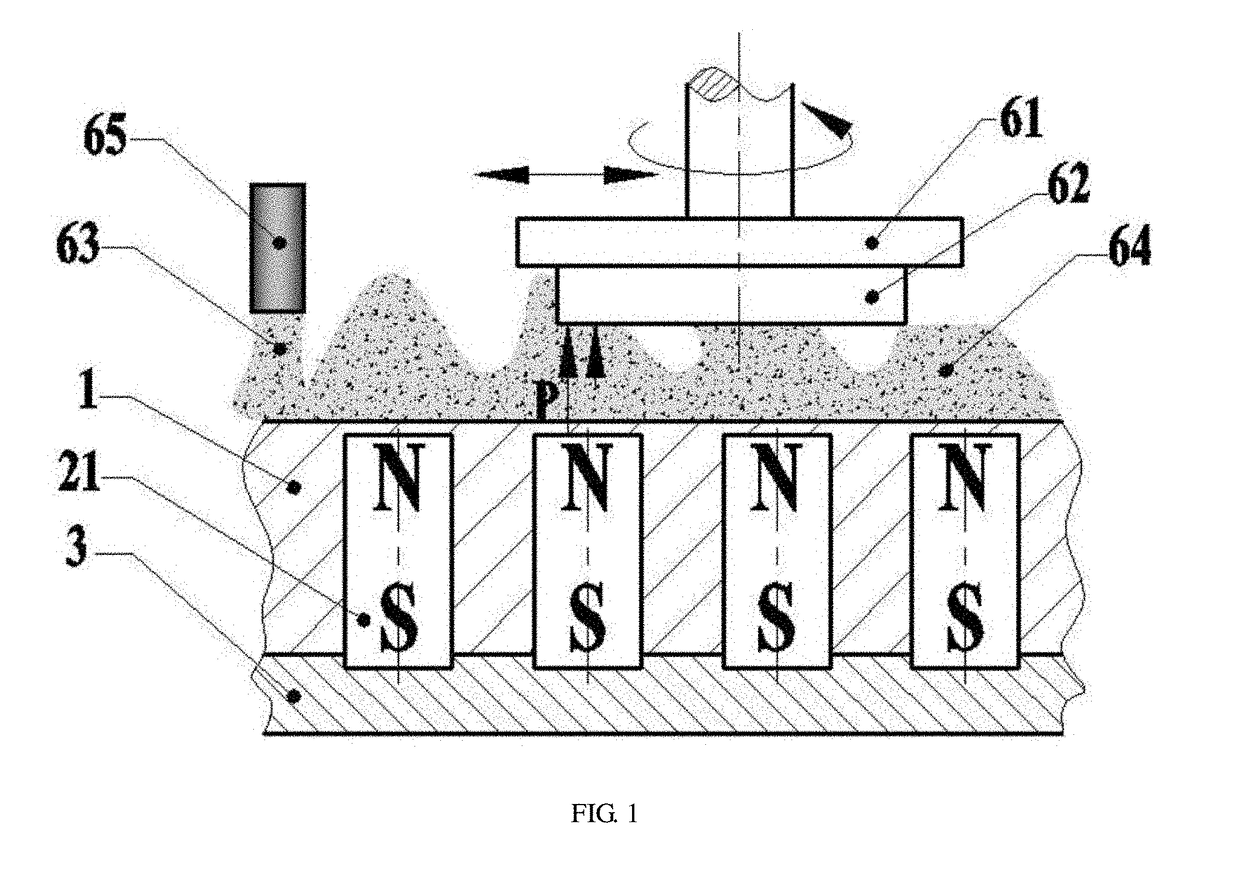

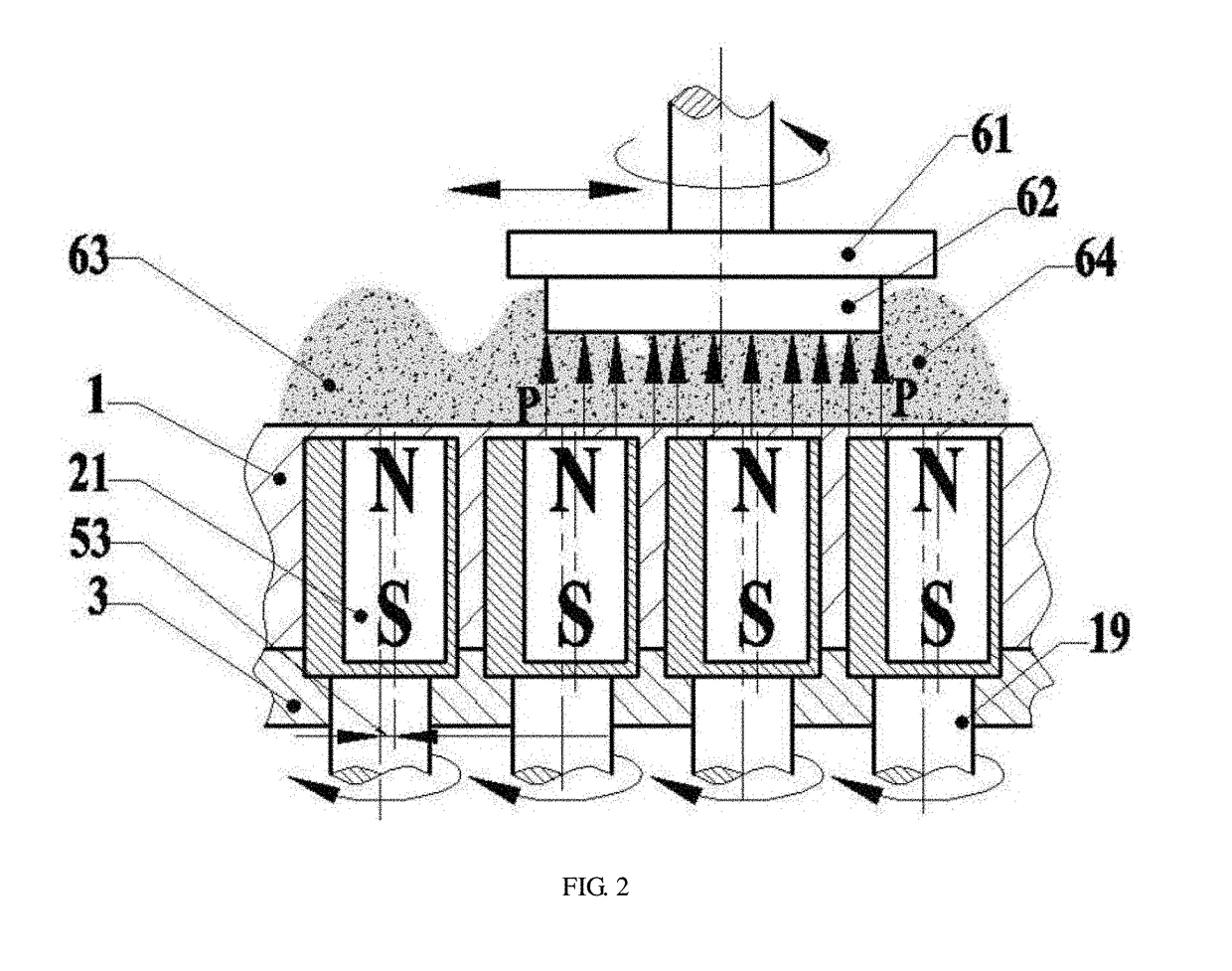

A self-sharpening polishing device with magnetorheological flexible polishing pad formed by dynamic magnetic field and polishing method thereof

InactiveUS20180021910A1Space saveLow costGrinding drivesAbrasive surface conditioning devicesEngineeringMagnetic current

Provided is a self-sharpening polishing device with magnetorheological flexible polishing pad formed by dynamic magnetic field and polishing method thereof. The device includes a polishing disc revolution mechanism and a multi-magnetic-pole synchronous rotary drive mechanism, the polishing disc revolution mechanism including a transmission shaft motor, a transmission shaft, a transfer disc, an eccentric shaft fixing disc, a cup-shaped polishing disc and a transmission shaft transmission mechanism, the multi-magnetic-pole synchronous rotary drive mechanism including an eccentric spindle, a synchronous rotary drive disc, flexible eccentric rotating shafts, eccentric sleeves, magnetic poles, the eccentric shaft fixing disc, and a spindle motor, etc. The device does not need a circulating device to renew magnetorheological fluid and does not need to renew the magnetorheological fluid during the finishing process; in fact the entire process from rough polishing to precise polishing can be done at one time. The device maintains a consistent workpiece surface and delivers a low cost and very efficient polishing process that is eminently suitable for the planes of optical elements with large diameter; it is also suitable for studying the material removal mechanism of planar optical materials and detecting sub-surface damage, as well as other experimental studies.

Owner:GUANGDONG UNIV OF TECH

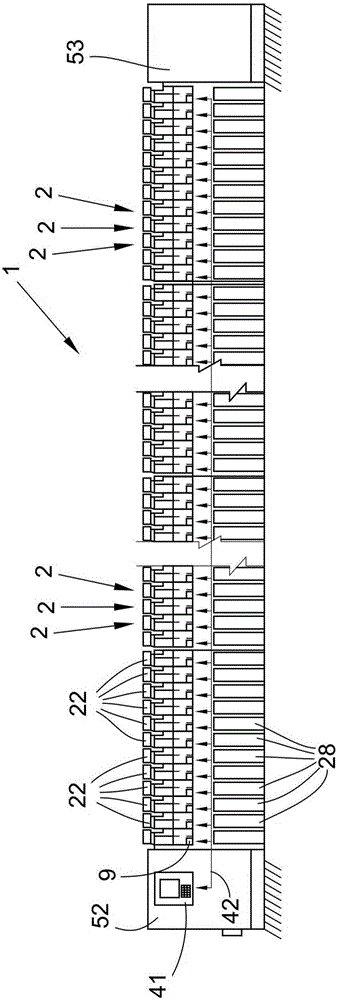

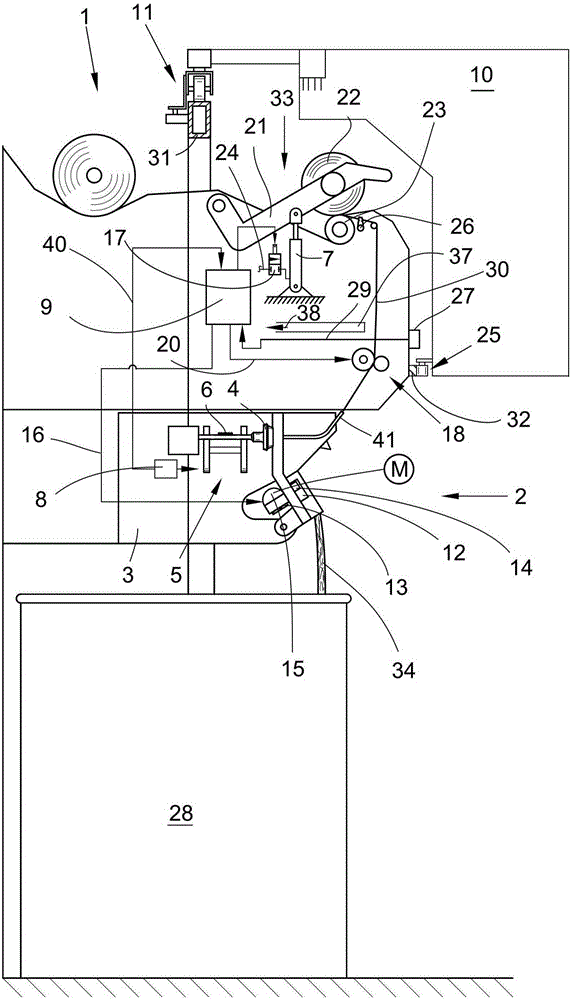

Semi-automatic opening rotor spinning machine

ActiveCN105177774ANon-uniformImprove productivityContinuous wound-up machinesOpen-end spinning machinesYarnProduction line

The invention relates to a semi-automatic free end rotor spinning machine, it has a location, each station has used in the production line of spinning device, used to check the quality of the line of production of slub yarn, and extraction device, used in the production of rotating to remain in the cross winding bobbin creel collecting device and location control device, collecting device has in its spinning casing high-speed rotating rotor spinning and fiber sliver feeding device and the opening roller, spinning rotor winding device, opening roller and bobbin driven roller and guide apparatus has along the length of the machine drive, and the fiber sliver feeding device of sliver feeding tube by a single motor drive. Size can be free to choose the location of group control device were so design, that is, they are in control of at least one of the following functions are different from other groups: qing yarn machine adjustment and yarn machine adjustment, fiber sliver feeding, bobbin diameter, the fineness of yarn and fancy adjustment.

Owner:SAURER GERMANY GMBH & CO KG

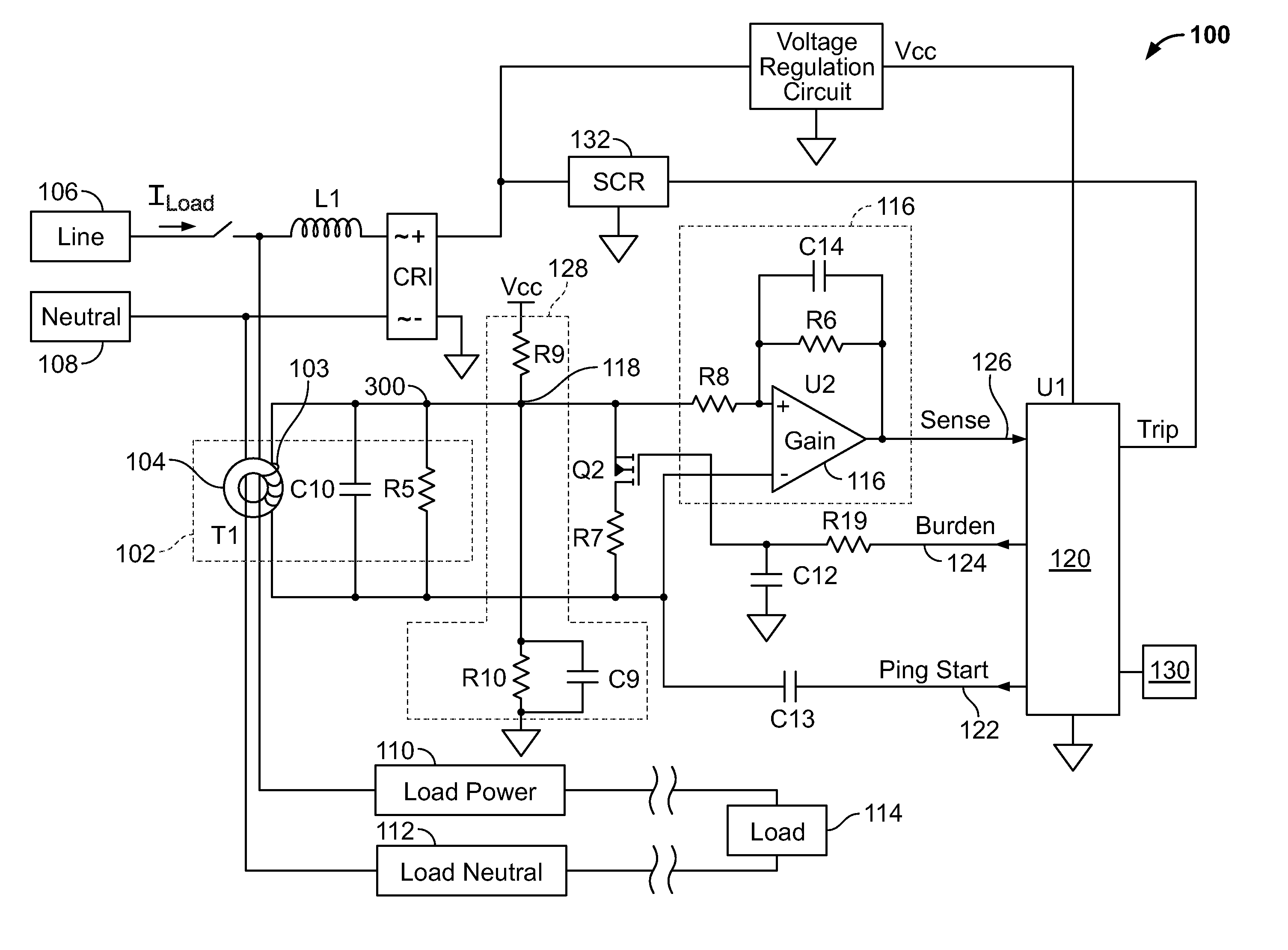

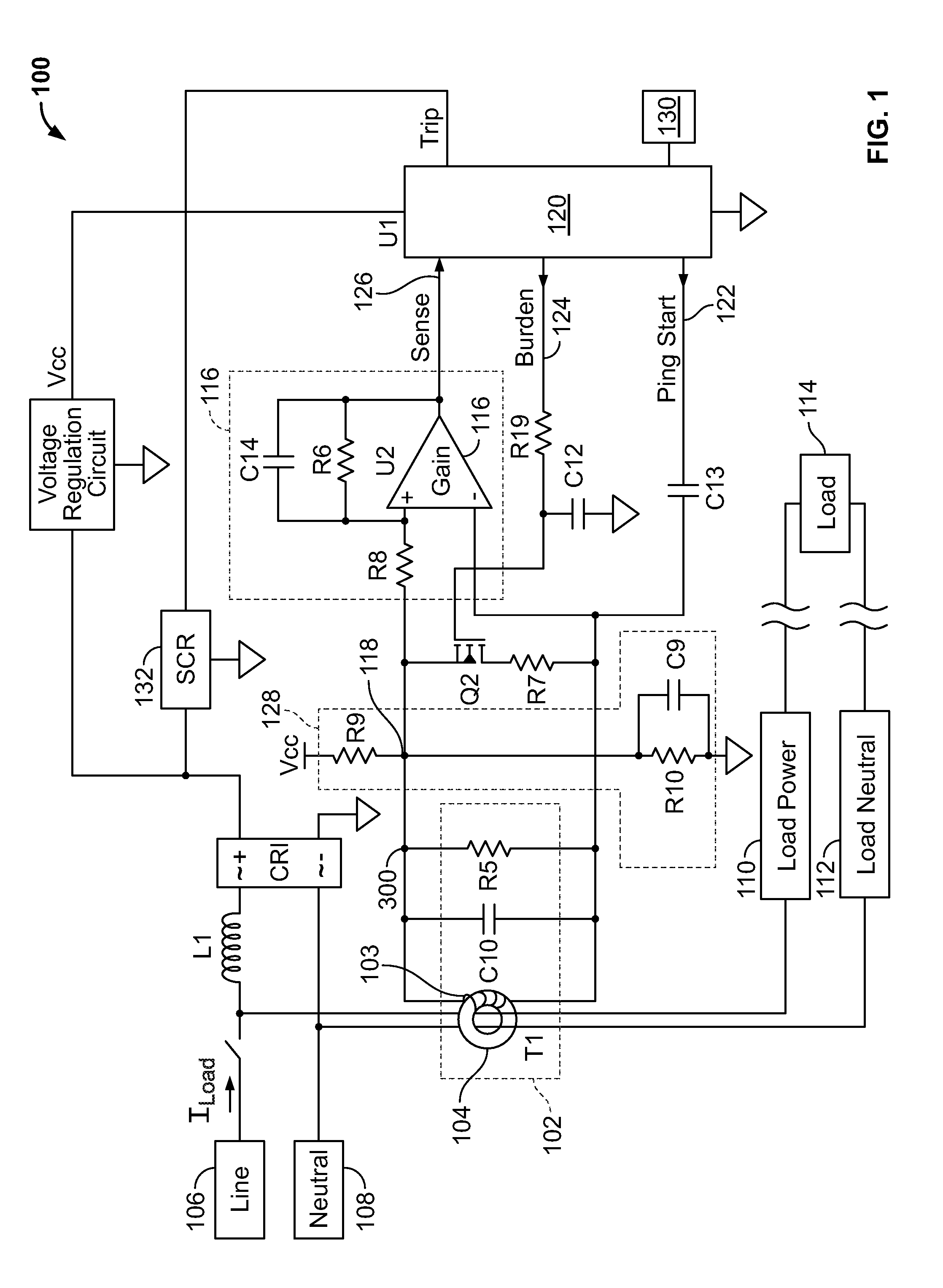

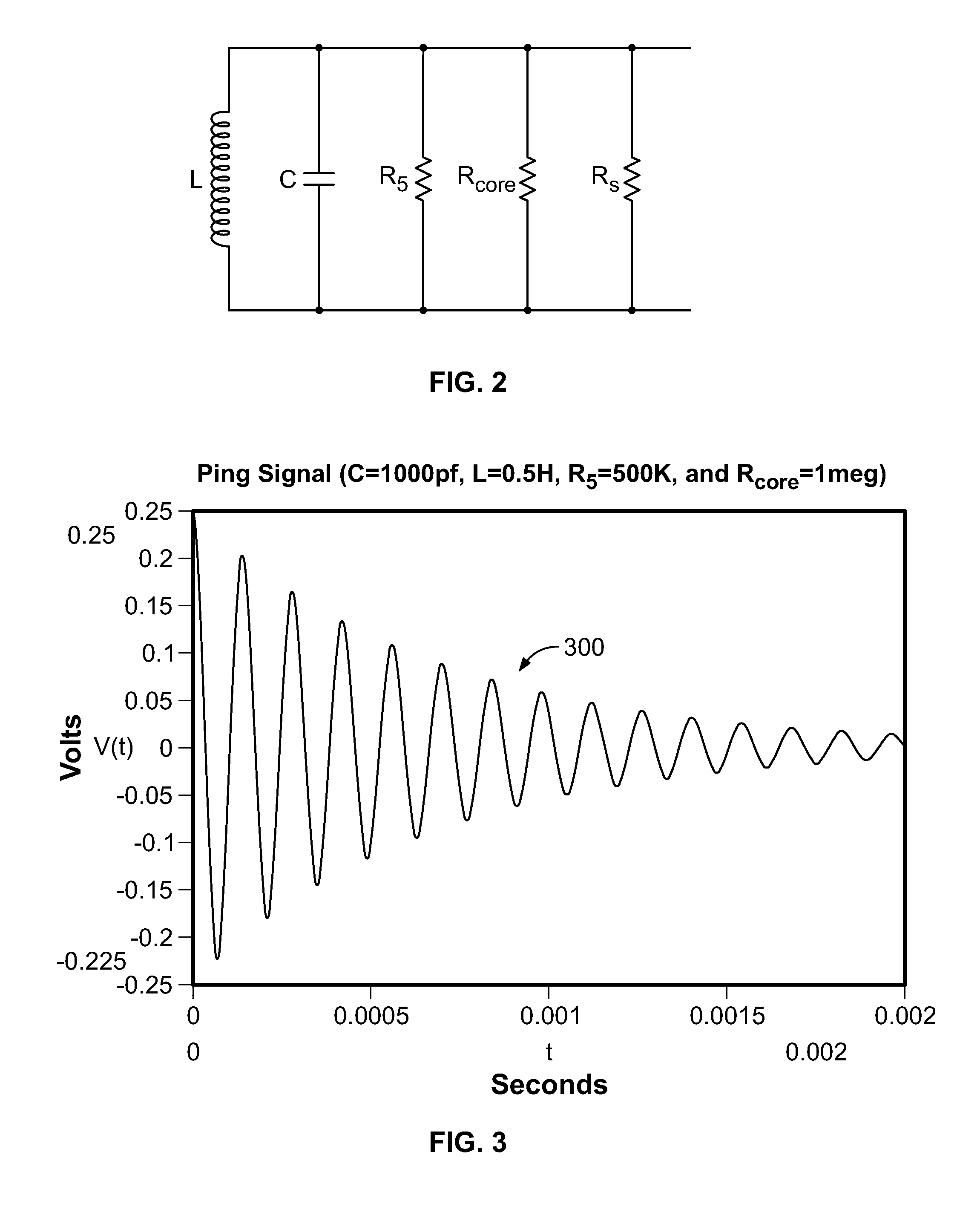

Apparatus and Method for Measuring Load Current Using a Ground Fault Sensing Transformer

ActiveUS20100169034A1Non uniformCurrent measurements onlyShort-circuit testingCapacitanceElectrical resistance and conductance

A circuit that includes a single grounded fault sensing transformer coupled to a resonant circuit that produces an output signal used by a microcontroller to determine a load current flowing through at least two conductors passing through the center of the sensing transformer. The microcontroller pings the resonant circuit, causing an impulse disturbance at the output signal, and the microcontroller calculates the inductance component of the resonant circuit based on the frequency of the decaying output signal. The microcontroller calculates the resistive core loss as a function of a known resistance of the resonant circuit, a known capacitance of the resonant circuit, the calculated inductance, and the determined rate of decay of the output signal. The calculated resistive core loss is compared to a table or to a polynomial function that characterizes known resistive core losses with known load currents to determine the load current corresponding to the calculated resistive core loss.

Owner:SCHNEIDER ELECTRIC USA INC

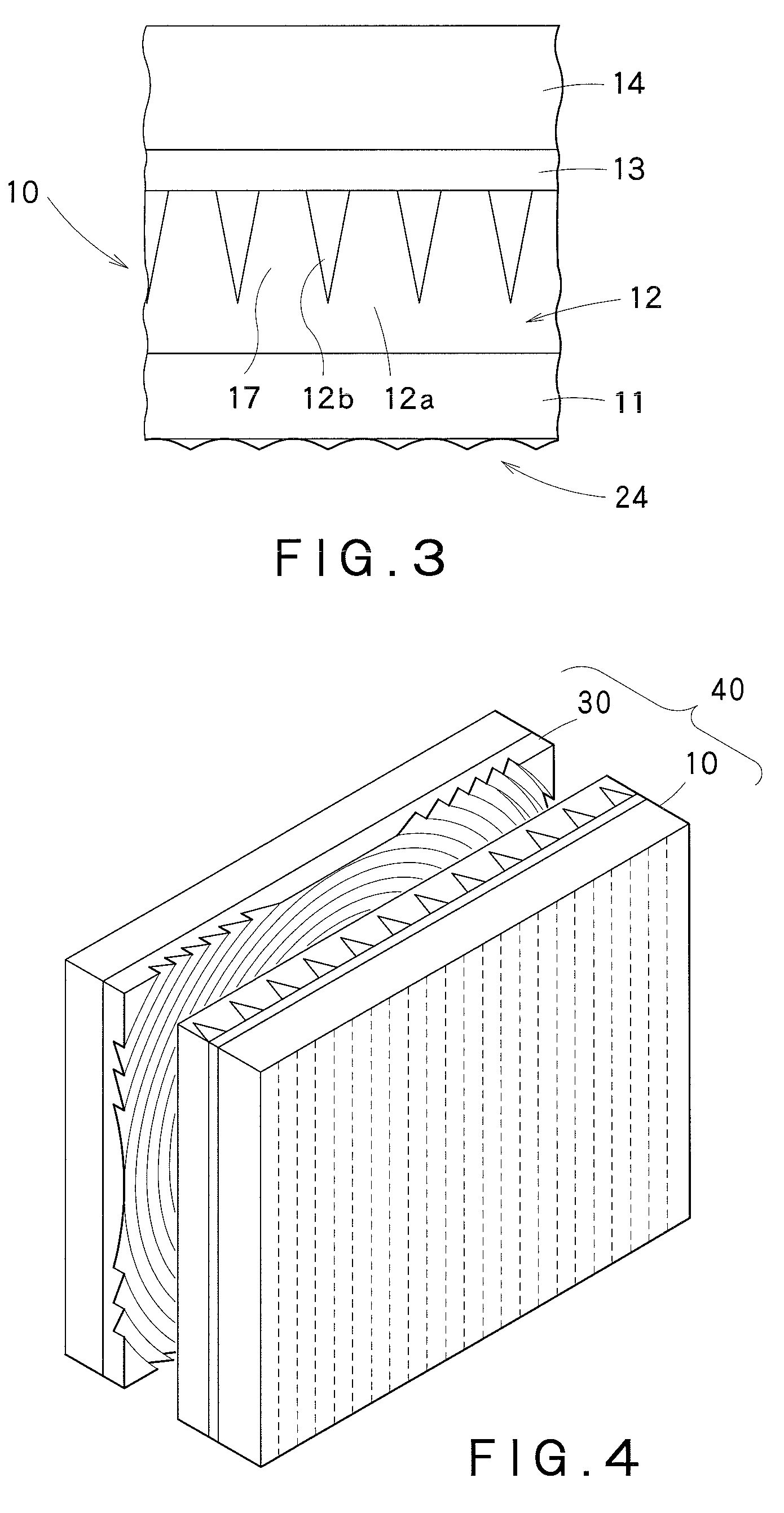

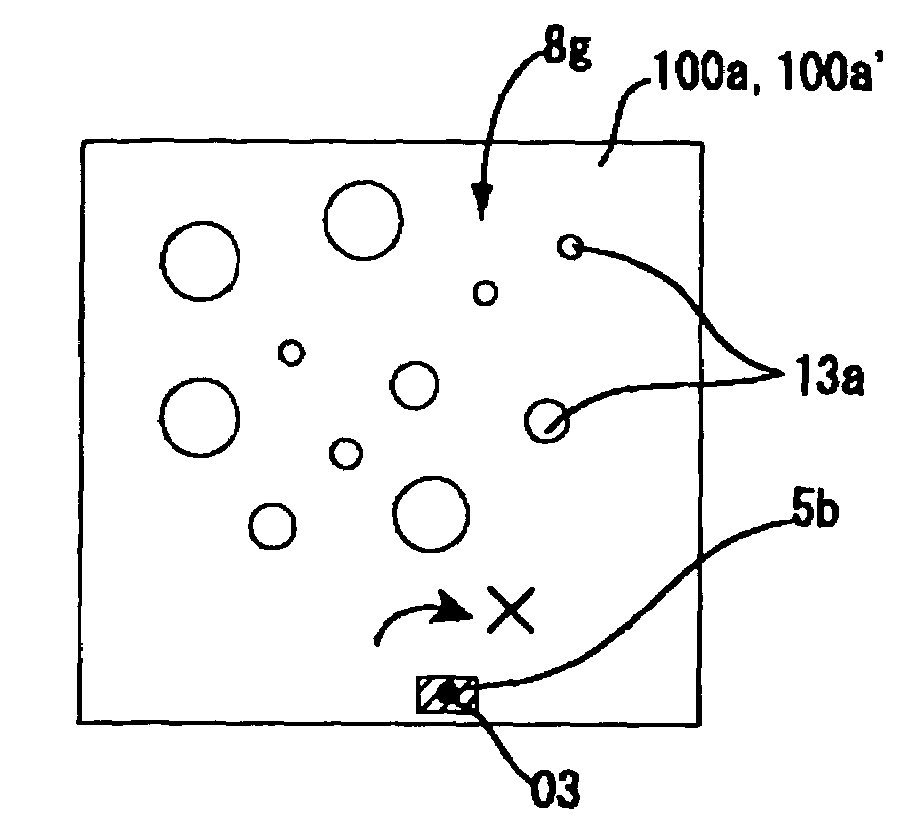

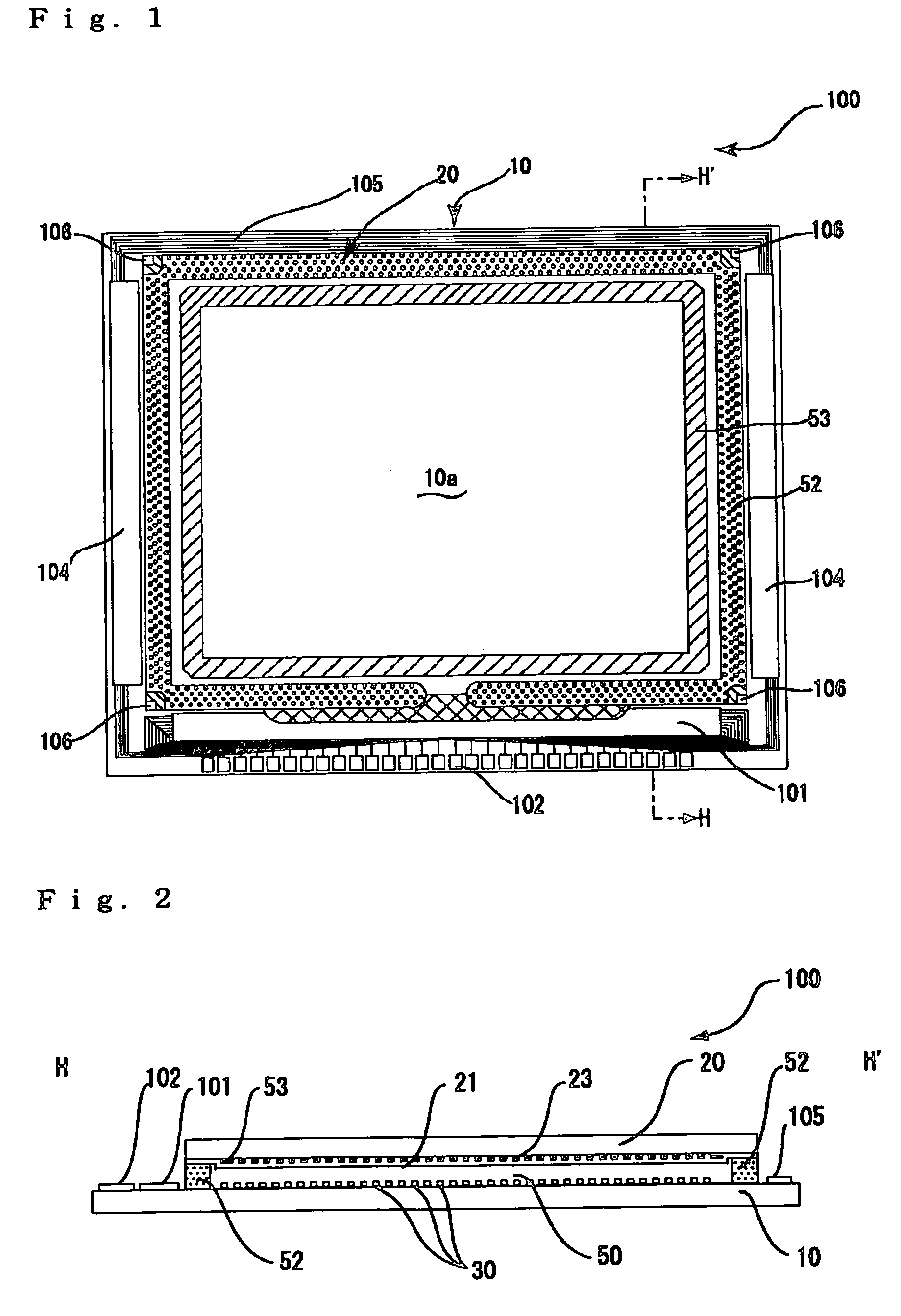

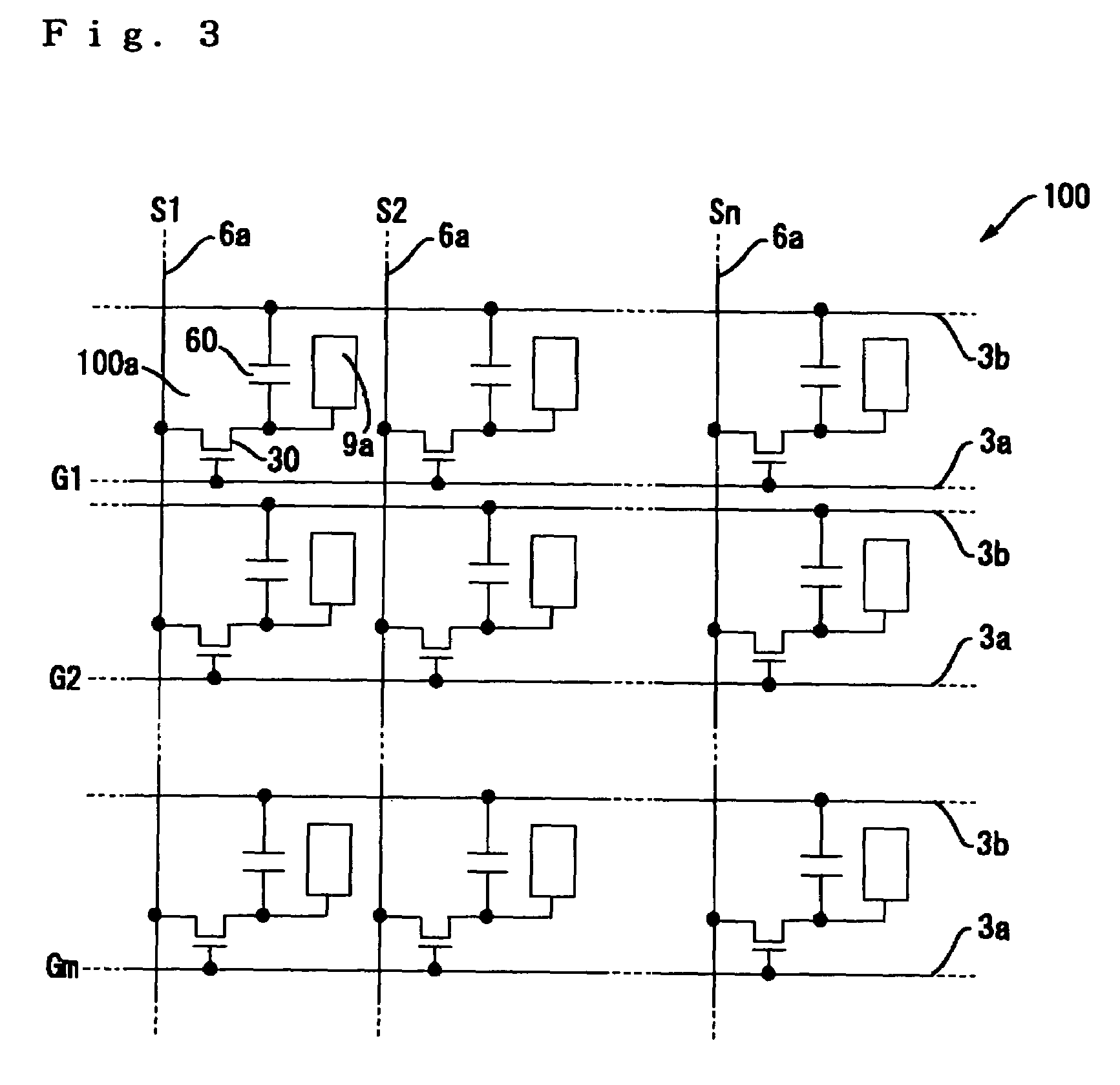

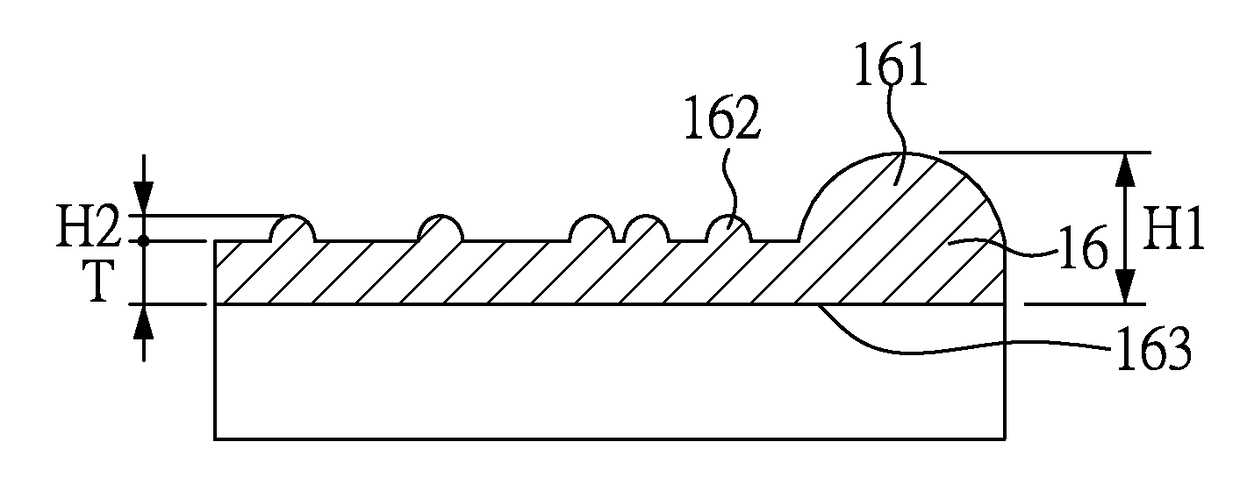

Electro-optic device comprising a recess/projection pattern obtained by rotating a reference pattern about a predetermined position

ActiveUS7084940B2Reduce and prevent interferenceReducing and avoiding occurrenceSolid-state devicesSemiconductor/solid-state device manufacturingScattered lightReference patterns

An electro-optic device is provided that is capable of preventing an interference of reflected lights from a light reflecting film and avoiding the occurrence of glare and chrominance non-uniformity among pixels, and an electronic apparatus using the electro-optic device. In a TFT array substrate of a reflective or transflective electro-optic device, a lower-side recess / projection forming film 13a, is formed in each of pixels 100a in the form of a matrix pattern so that a recess / projection pattern to scatter light is formed on the surface of a light reflecting film. The pixels are grouped into a plurality of units, each including a plurality of pixels, and the recess / projection pattern is formed to provide a different pattern for each pixel at least in each of the units. Different recess / projection patterns are obtained, for example, by rotating the recess / projection pattern for a pixel as a reference.

Owner:BOE TECH GRP CO LTD

Insert device for culturing cells

InactiveUS20060223174A1Non uniformAvoid chanceBioreactor/fermenter combinationsBiological substance pretreatmentsCulture vesselBiology

The present invention involves a device for culturing cells on removable membranes / sponges for the purpose of transplantation. The device includes a base plate with snaps and a ring, which fits into the base plate. The membrane / sponge of choice for culturing cells is placed on the base plate and fixed by the ring, which fits tightly to the base. The device is placed inside a suitable culture vessel or receptacle and the cell suspension is added within the insert device. The cells are retained on the membrane, which enables cell attachment and proliferation. Alternatively, small tissue explants can be placed on the membrane enabling cell migration and proliferation. Cells are cultured under standard conditions with regular media changes. Following shipping to the hospitals under appropriate conditions, the insert device would be dismantled and the membrane lifted and placed at the site of transplantation.

Owner:RELIANCE LIFE SCI PVT

Method of processing radiological images, and, in particular, mammographic images

ActiveUS8165379B2Quality improvementNon-uniform areaImage enhancementPatient positioning for diagnosticsHigh energyComputer vision

A method of processing a radiological image of an organ. The method may comprise generating a recombined image (R) from at least one previously acquired low energy image (L) and one high energy image (H) of a portion of the organ. The recombined image comprises a background and one or more areas corresponding to the presence of a contrast medium in the organ. The method may further comprise correcting the recombined image (R) by compensating (C) for the nonuniformities present in the background to obtain a compensated recombined image in which the background has a substantially uniform grey level.

Owner:GENERAL ELECTRIC CO

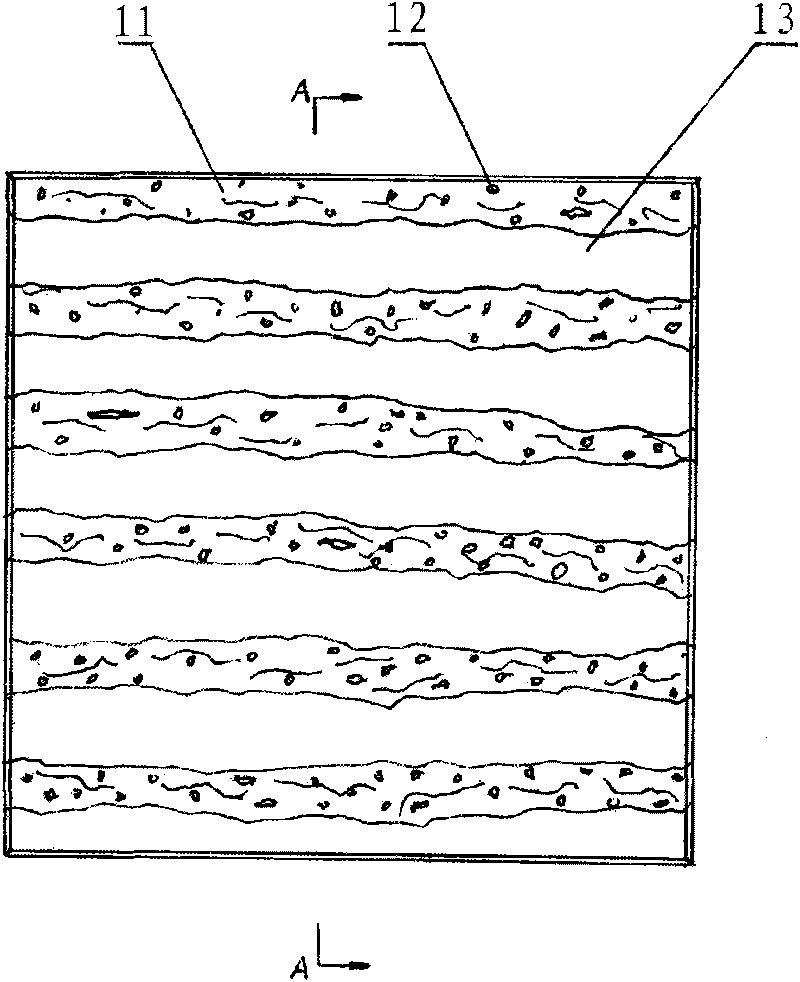

Process for producing natural travertine-imitated vitrified brick

ActiveCN101747019AStrong ornamentalNon-uniformPolishing machinesFeeding arrangmentsBrickMixed materials

The invention relates to a process for producing a natural travertine-imitated vitrified brick. The process comprises the following steps: feeding a base material and travertine in a material blanking roller through a roller hopper respectively, wherein the travertine is positioned on the middle material blanking roller; controlling the blanking proportion of the base material and the travertine by adjusting the rotating speed of the material blanking roller; rotating the base material and the travertine to a feeding belt through the rotation of the material blanking roller; conveying a laminated material consisting of the base material and the travertine to a movable storage hopper through the rotation of the feeding belt; moving a gate of the storage hopper; conveying the mixed materialto a straight grain shaping grille for shaping along with the movement of the movable storage hopper; conveying the mixed material to a press die cavity for pressing and shaping through the straight grain shaping grille; conveying the shaped product to a kiln and burning a burnt brick by controlling the temperature of the kiln; and polishing the burnt brick to obtain the natural travertine-imitated vitrified brick. Compared with the prior art, the natural travertine-imitated vitrified brick has the advantages of controllable distribution of textures and holes, strong appreciation, wide application range and the like.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

Rare earth-copper alloy glass mold and preparation method thereof

The invention relates to a rare earth-copper alloy glass mold and a preparation method thereof and belongs to the field of glass mold materials. The rare earth-copper alloy glass mold is composed of, by mass, 9-12% of nickel, 7-10% of aluminum, 8-12% of zinc, less than 0.5% of iron, 0.01-0.5% of rare earth and the balance copper. The preparation method includes the steps that brass alloy is prepared from zinc and electrolytic copper; the aluminum, nickel, iron and copper which are weighed are put into a smelting furnace, the brass alloy is added, standing is carried out, impurities float upward, slagging-off is carried out, copper-rare earth intermediate alloy is added, and slagging-off is carried out again; the temperature of rare earth-copper alloy glass mold melt to be poured is increased, and the rare earth-copper alloy glass mold melt to be poured is discharged out of the furnace and poured into a resin sand casting mold; the obtained rare earth-copper alloy glass mold to be annealed is subjected to stress relief annealing and heat preservation and cooled to the room temperature, and the finished rare earth-copper alloy glass mold is obtained. The flowability and toughness of the alloy are improved. The strength and hardness of the alloy are improved, and the abrasion resistance is enhanced. The mechanical properties and impingement corrosion resistance of materials are improved. The toughness and thermal conductivity of the materials are improved.

Owner:ORI MOLD TECH SUZHOU

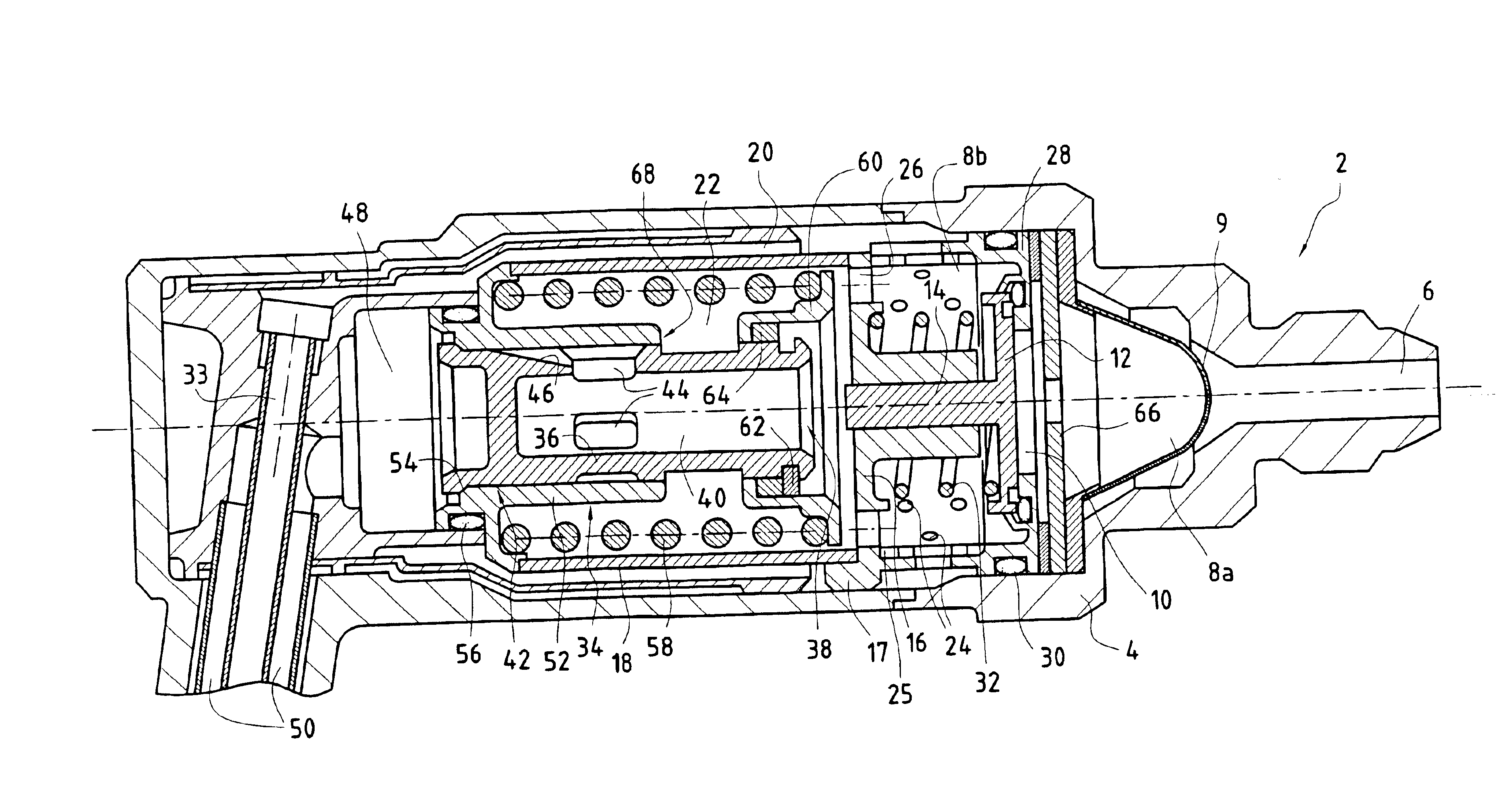

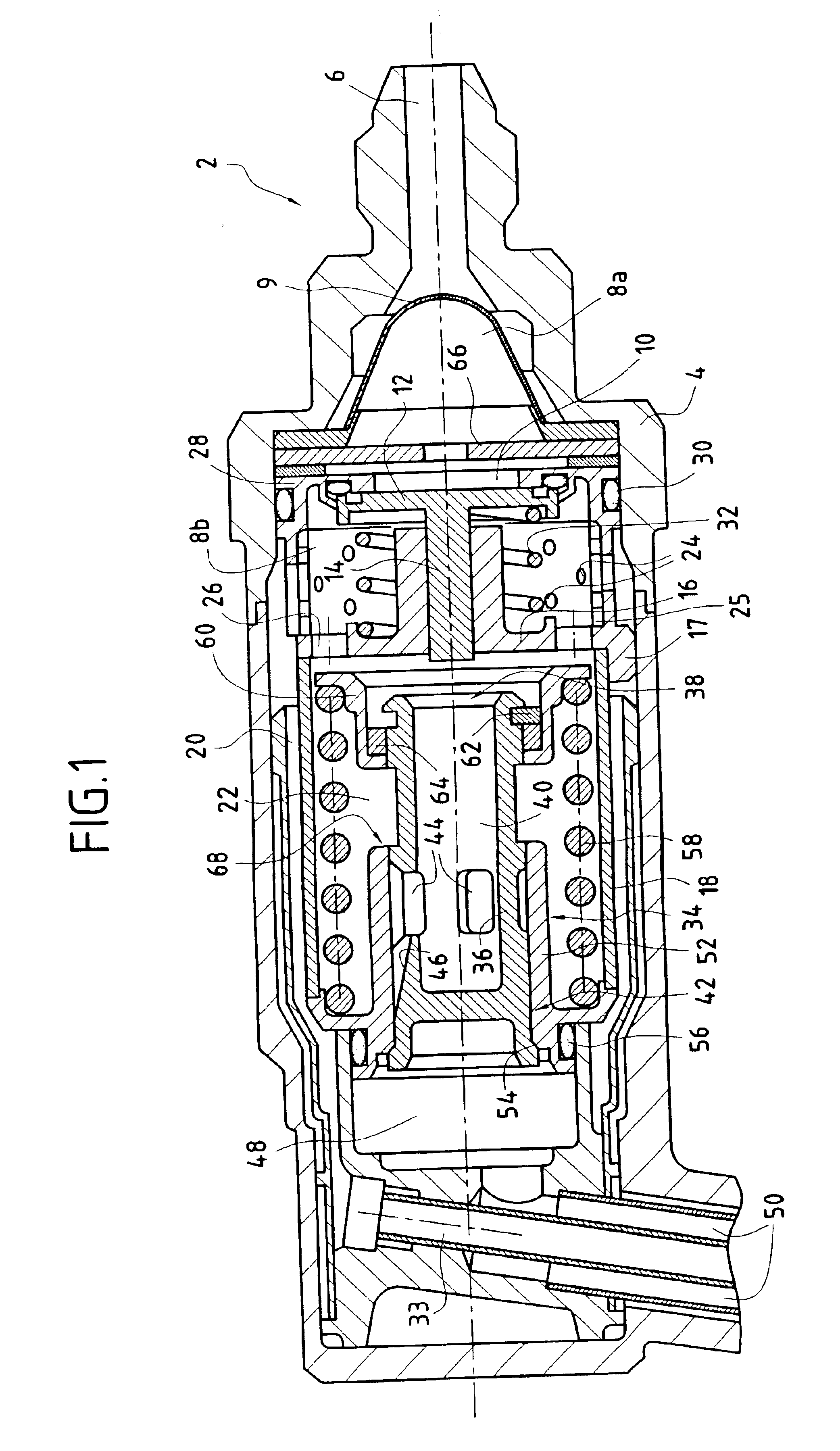

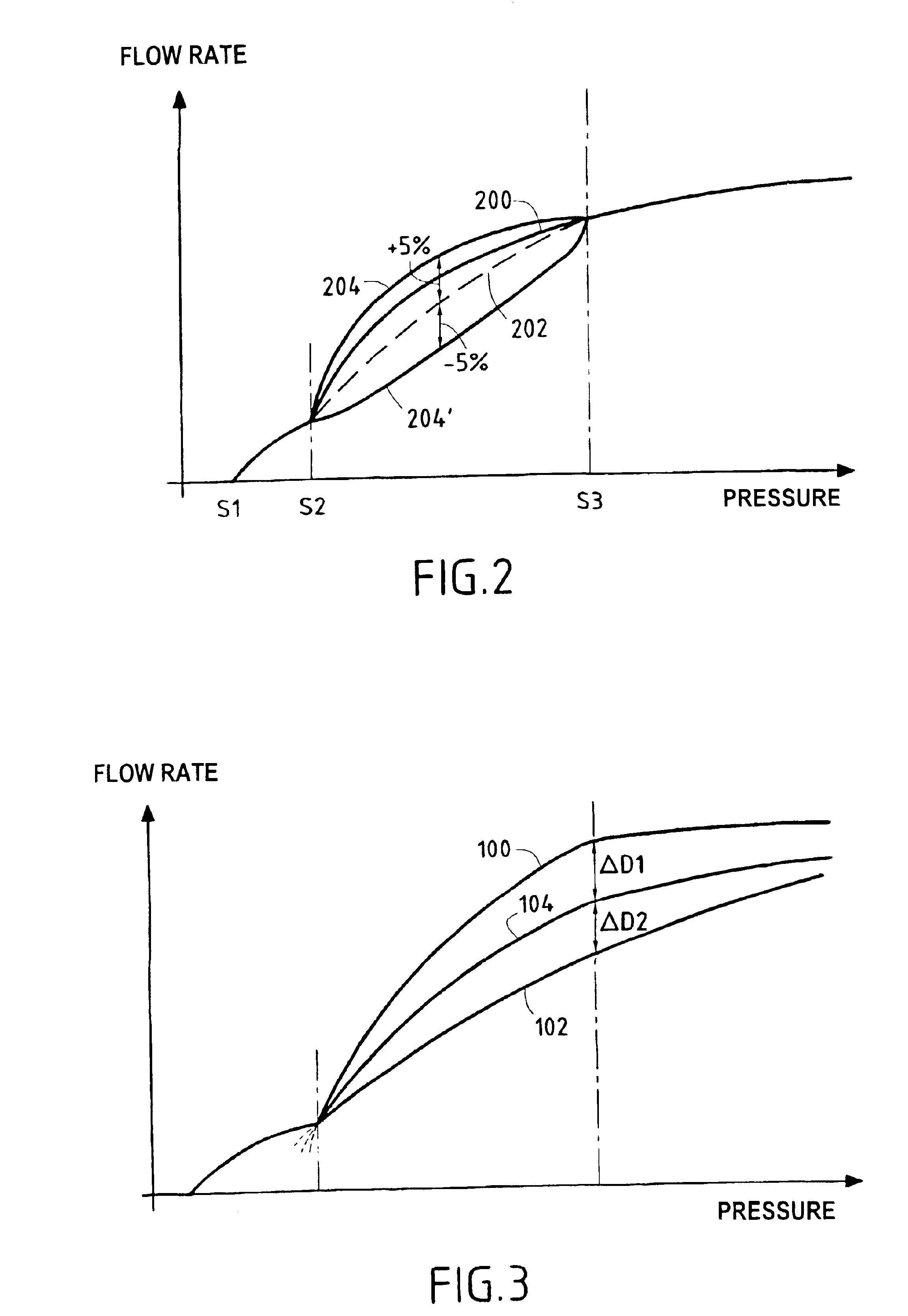

Turbomachine injectors

InactiveUS6758043B2Simple processMitigate such drawbackLiquid fuel feeder/distributionGas turbine plantsEngineeringInjector

A fuel injector for a turbomachine engine, the injector comprising an injector body having pressurized fuel admission means, a first valve mounted downstream from the pressurized fuel admission means and arranged to admit fuel into the injector body, a second valve mounted downstream from the first valve and capable of opening in order to meter at least a fraction of the fuel admitted into the injector body for utilization means for using the fuel, the metered fuel flow rate to the utilization means being a function of flow sections formed through the second valve, the injector further comprising a diaphragm placed between the pressurized fuel admission means and the first valve so as to set the rate at which fuel is admitted into the injector body at a determined value.

Owner:HISPANO SUIZA SA

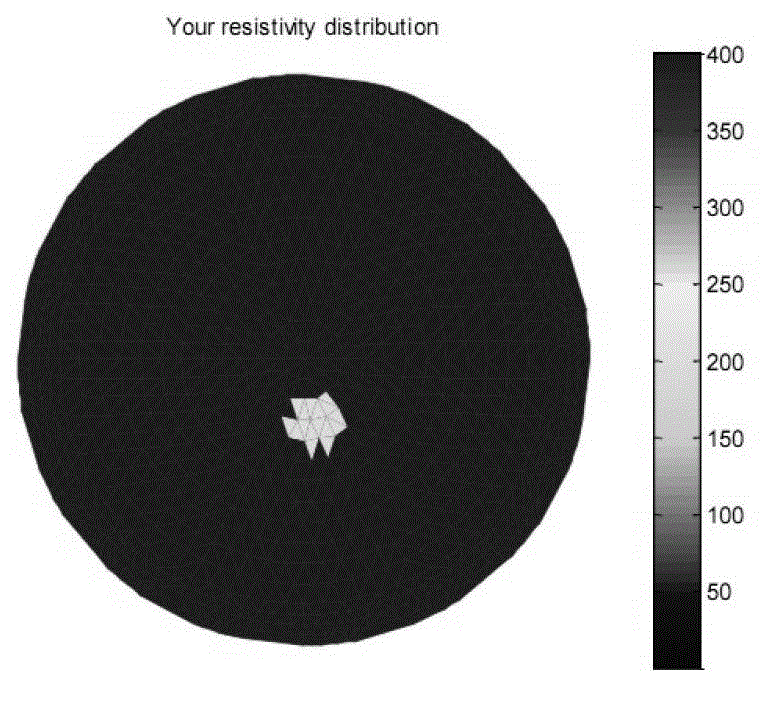

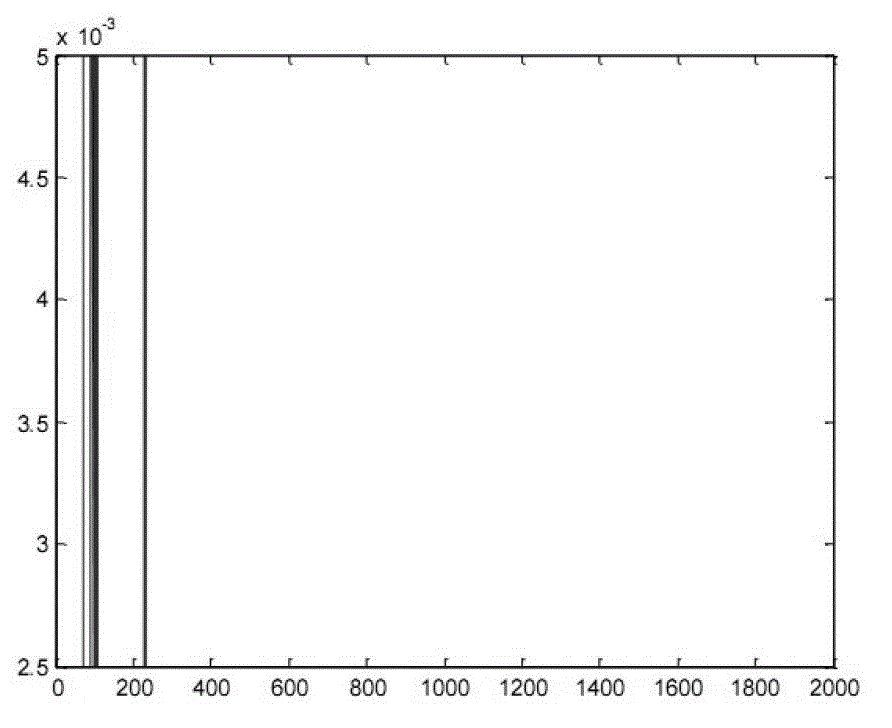

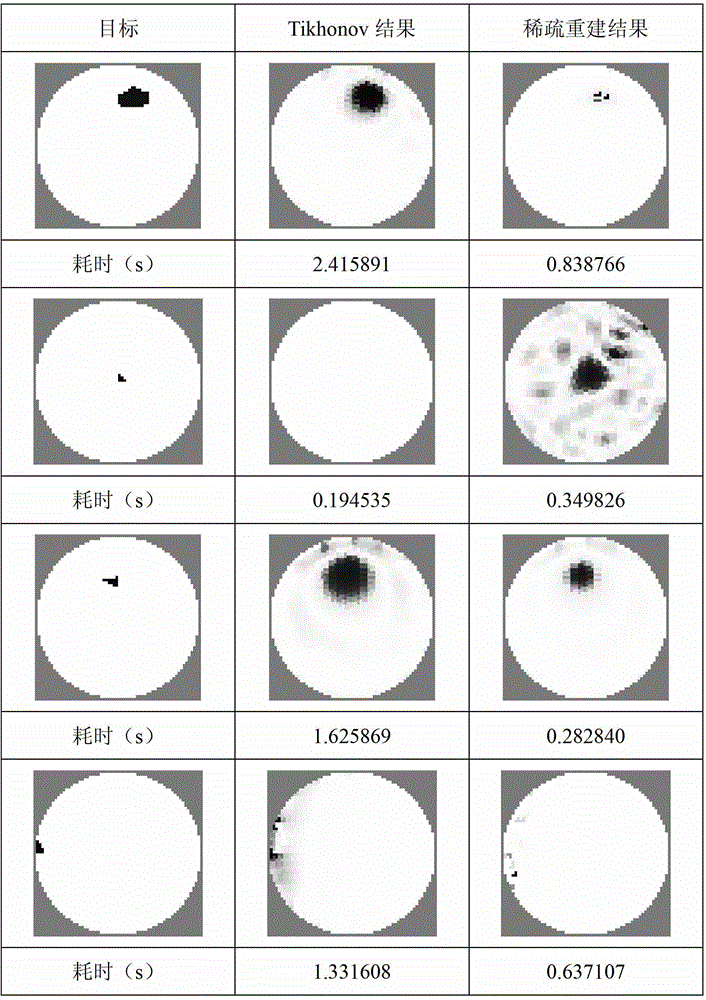

Sparse reconstruction method for electrical impedance tomography

InactiveCN103054577AQuality improvementImprove noise immunityDiagnostic recording/measuringSensorsElectrical resistance and conductanceElectrical impedance tomography

The invention discloses a sparse reconstruction method for electrical impedance tomography. The conductivity distribution of the dynamic electrical impedance tomography has the sparse property, when the electrical impedance tomography is restructured, regular terms of the restructured objective function use the L1 normal number, the sparse property of non-uniform conductivity is introduced to regular terms, the objective function is calculated through a convex optimization problem solving method, and the restructured electrical impedance tomography is obtained. L1 normal regular terms are used for resisting noise effectively, the non-uniform conductivity is introduced to regular terms, the quality and the noise-resisting capability of the electrical impedance tomography can be improved, and the calculation speed is fast.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

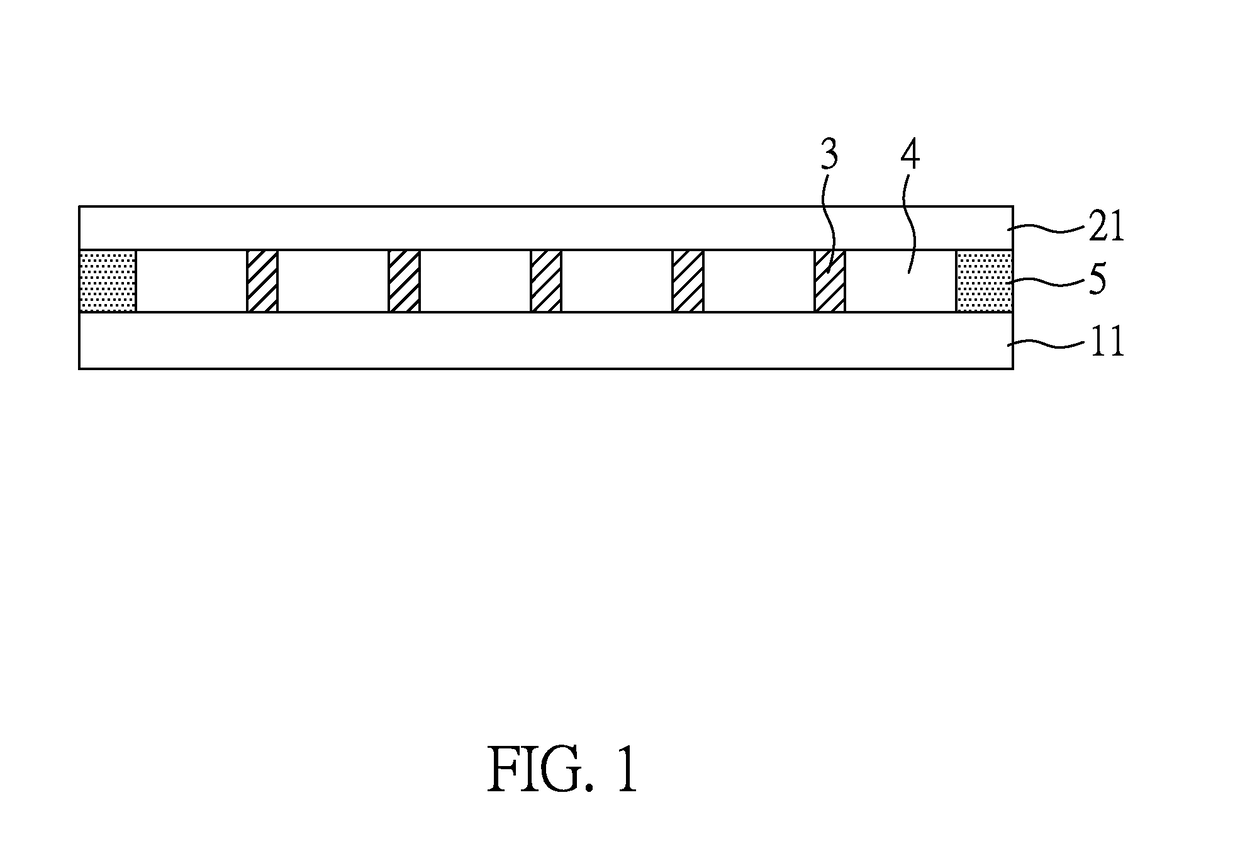

Liquid crystal display panel and liquid crystal display device containing the same

ActiveUS9632362B2Improve display qualityDifference of distanceNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display panel and a liquid crystal display device containing the same are disclosed. The liquid crystal display panel of the present invention comprises: a first substrate with a pixel electrode region and a non-pixel electrode region; a second substrate opposite to the first substrate; a first alignment layer disposed on the pixel electrode region and the non-pixel electrode region; and a liquid crystal layer disposed between the first substrate and the second substrate. Herein, the first alignment layer on the pixel electrode region has a first thickness, that on the non-pixel electrode region has a second thickness, and the first thickness is larger than the second thickness.

Owner:INNOLUX CORP

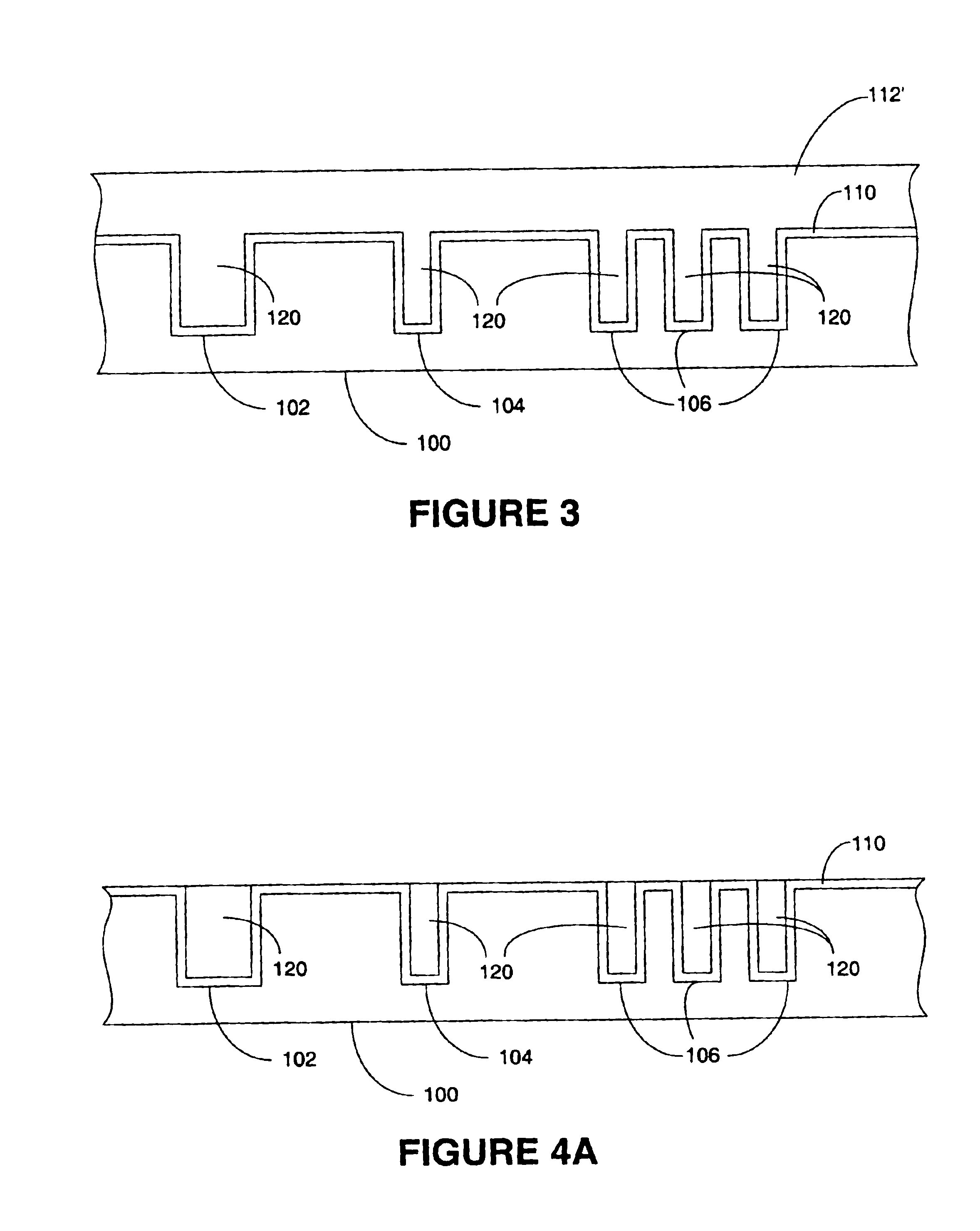

Lateral flow assay test strip and method of making the same

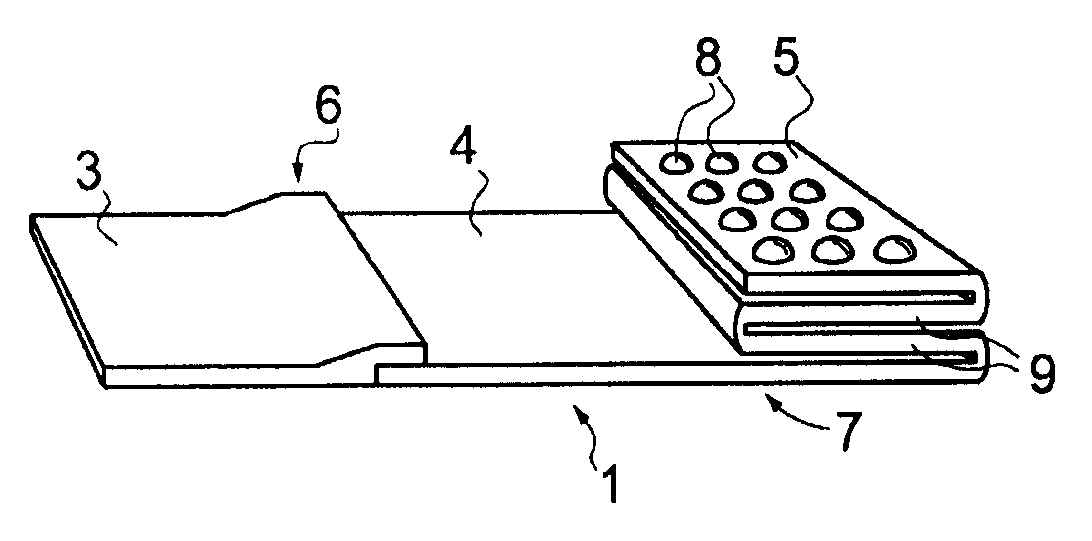

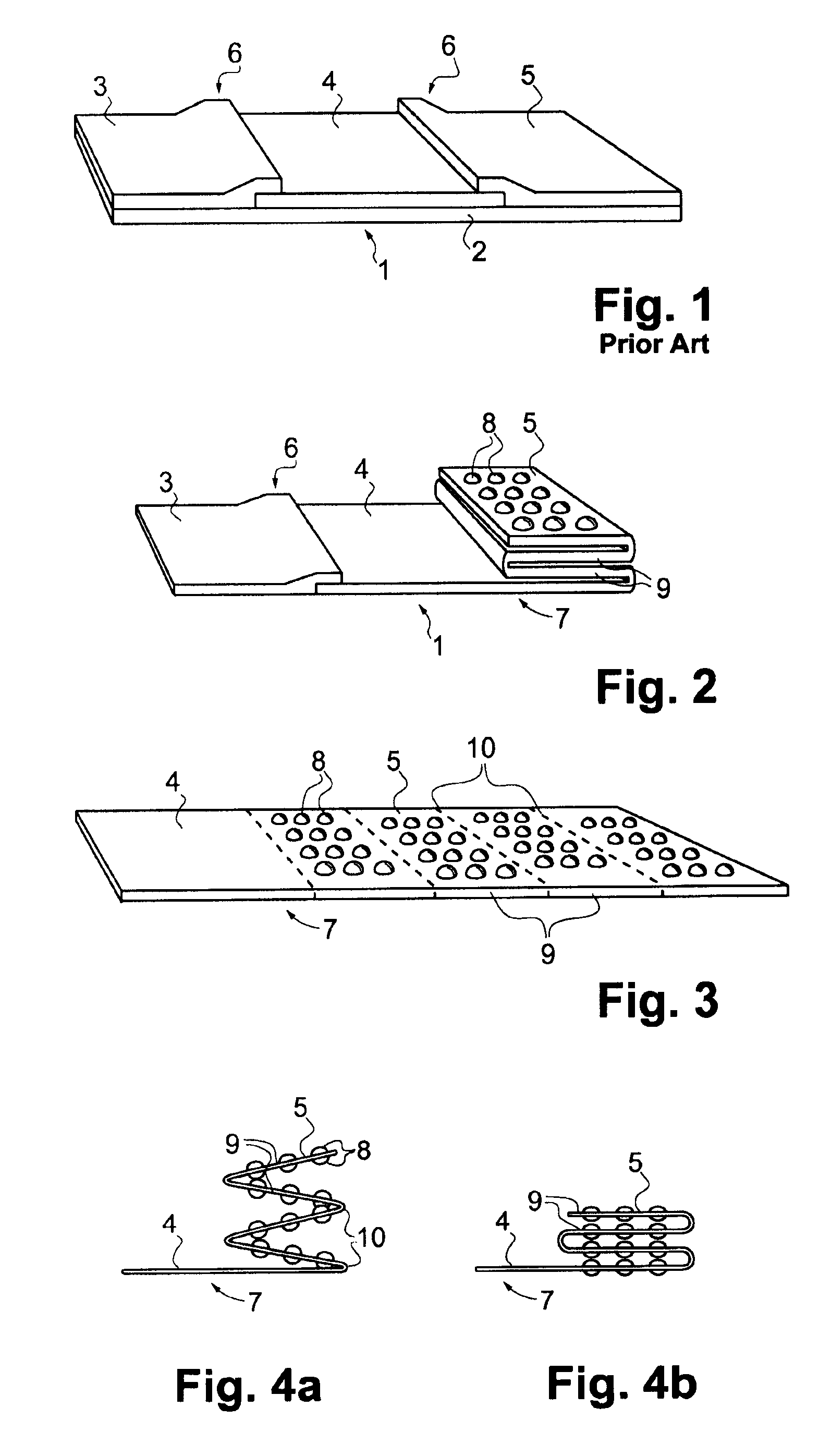

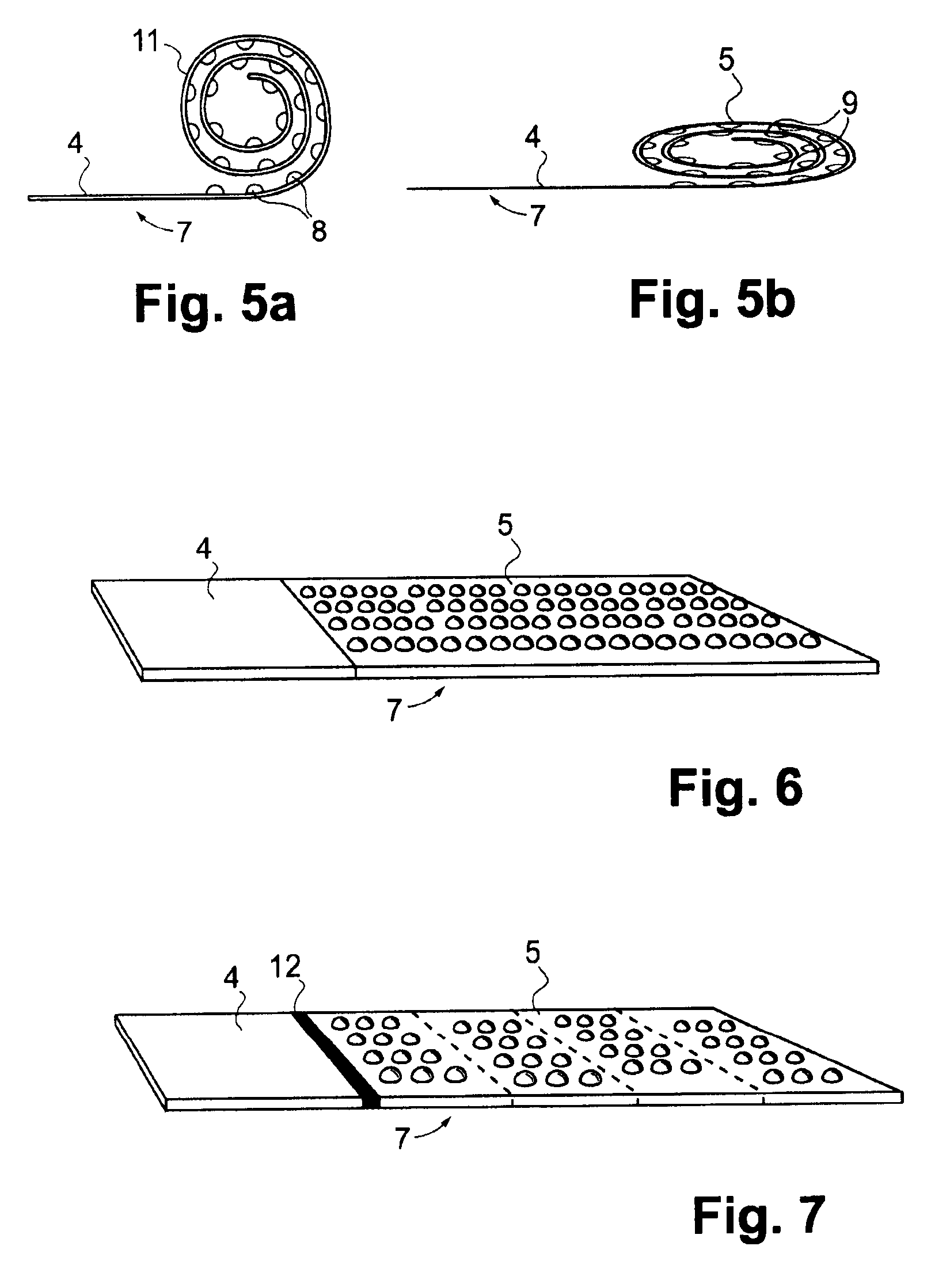

ActiveUS8580572B2Low priceHigh mechanical strengthAnalysis using chemical indicatorsLaboratory glasswaresAbsorption capacityPaper tape

The invention relates to a lateral flow assay test strip and a method for making the same. The strip comprises, in the flow direction, a selectively activated membrane for a test reaction and an absorption pad, which are both made of paper and may comprise an integral paper strip. The absorption pad has the paper strip embossed and / or folded to increase the strip's absorption capacity. The folded pad may have an accordion-like configuration, the strip running to-and-from, or it may have the strip rolled and then flattened to a stack of layers.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

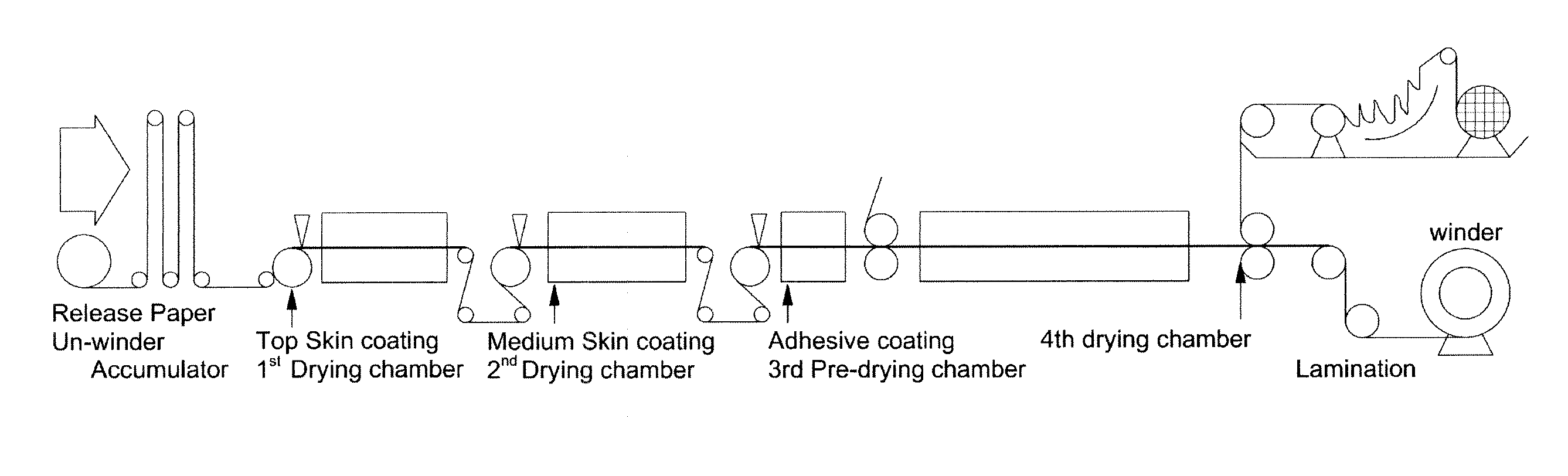

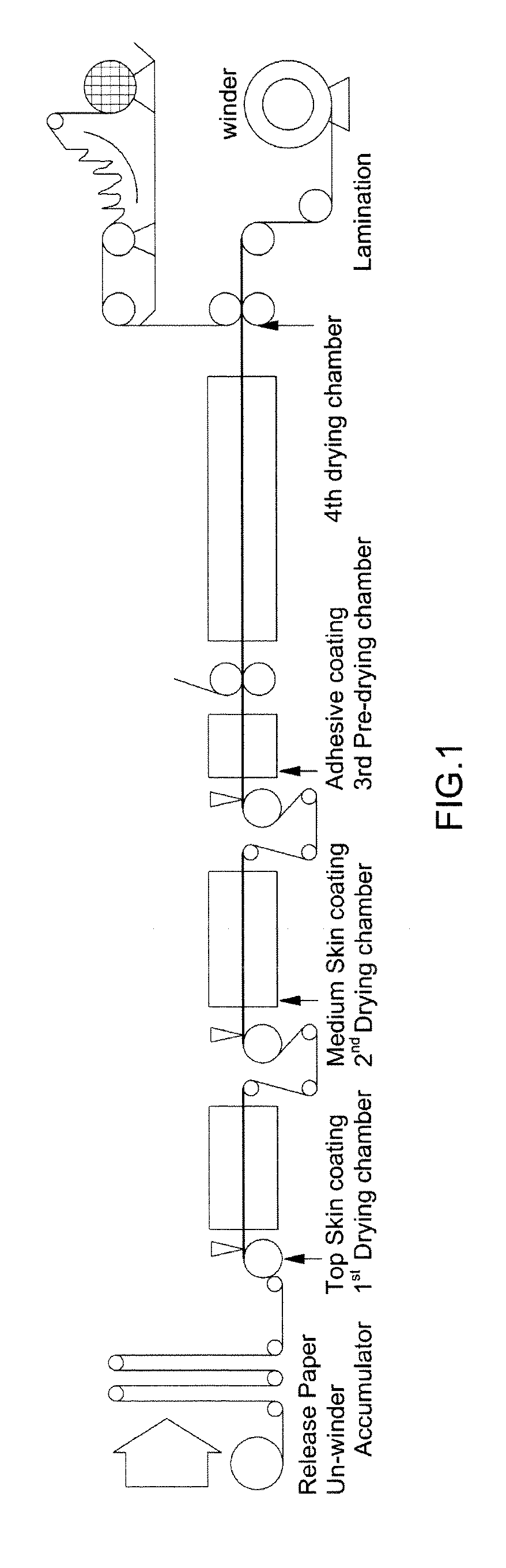

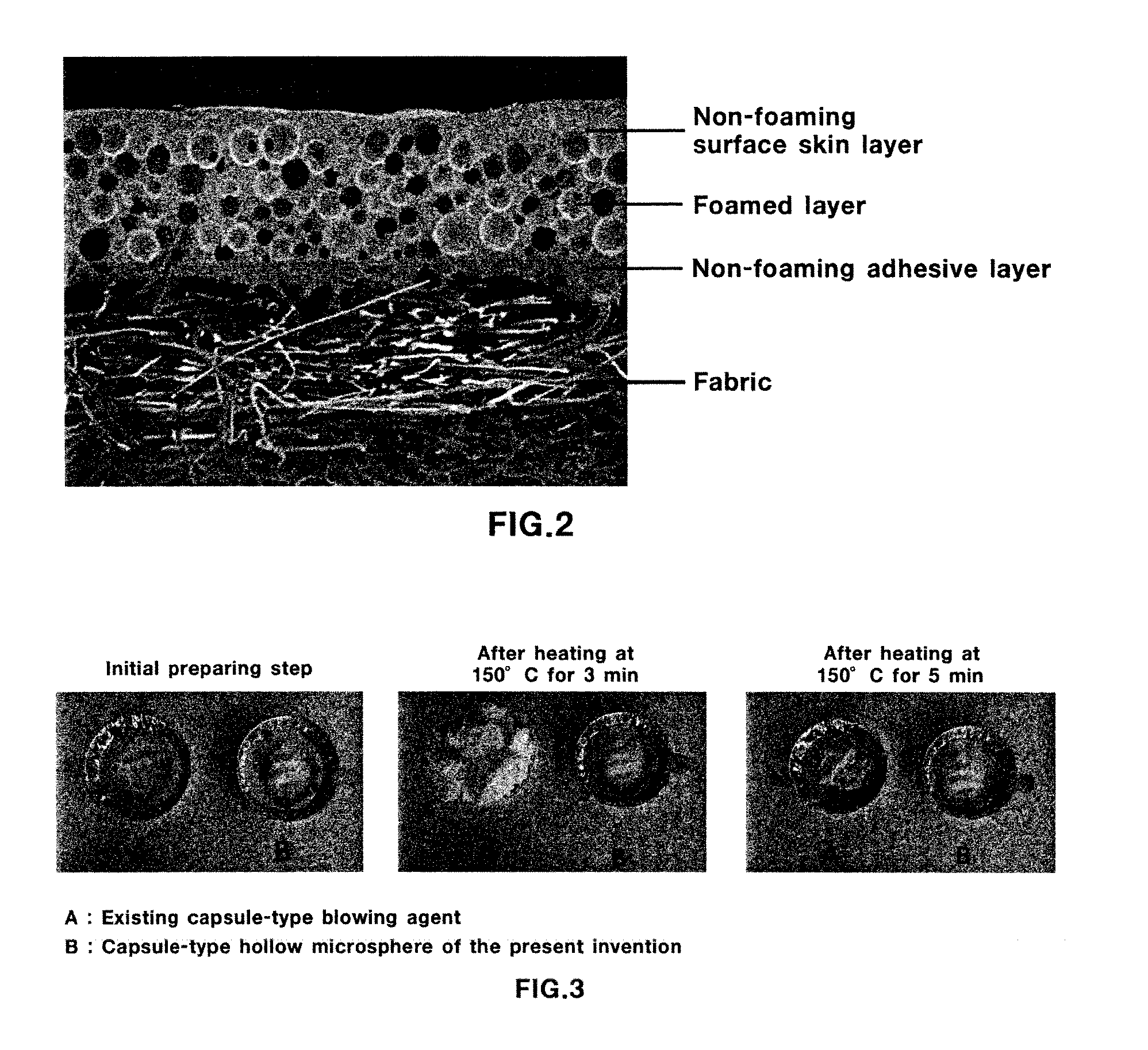

Ultra-light polyurethane artificial leather composition

ActiveUS20160002444A1Non uniformExcellent various physical propertyDomestic articlesCoatingsChemistryMicrosphere

An ultra-light polyurethane artificial leather composition comprises a one-component type blocked polyurethane high solid resin of 100 parts per weight, a capsule-type hollow microsphere of 1 to 10 parts per weight, a curing agent of 1 to 10 parts per weight, and a high solid type toner of 1 to 20 parts per weight.

Owner:HYUNDAI MOTOR CO LTD +3

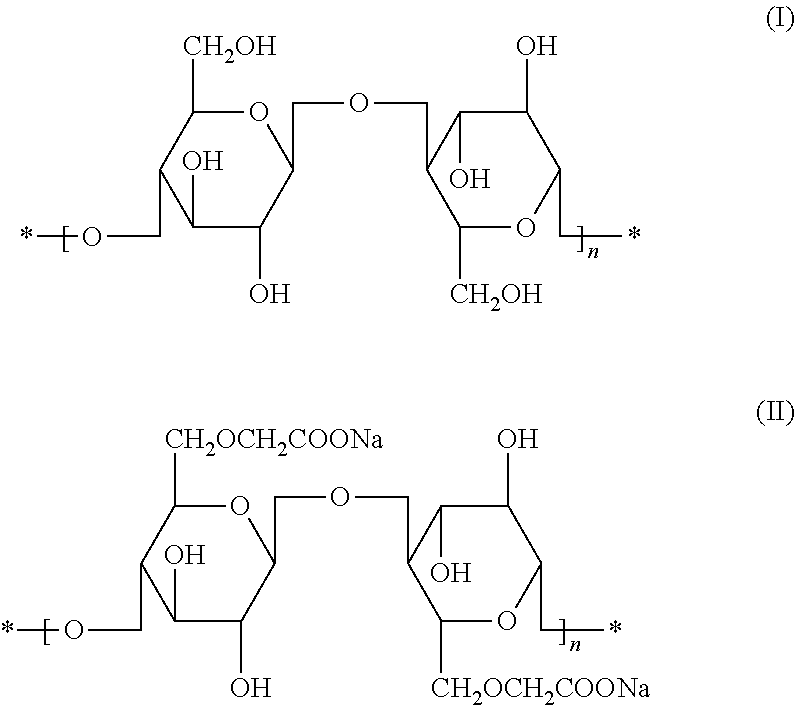

Dental etching gel composition and method of use thereof

InactiveUS20120161067A1Increase surface roughnessNon uniformCosmetic preparationsToilet preparationsDegree of substitutionSodium carboxymethylcellulose

The present invention provides a dental etching gel composition including phosphoric acid in aqueous solution form, a viscosity-enhancing agent and optionally additives, in which the viscosity-enhancing agent is carboxymethyl cellulose (CMC) with the following properties:(a) having a viscosity of about 100 to about 2000 cps when formulated as an aqueous solution containing 1 wt % of CMC; and(b) having an average degree of substitution of sodium salts in molecular formula of about 21% to about 33%.The dental etching gel composition of the present invention can be used to pre-treat the surface of teeth prior to repair or filling. The etching gel formed by combining phosphoric acid in aqueous solution form with CMC viscosity-enhancing agent having the specific properties stated above is less fluid and thus can be used to etch the specific surface of the tooth so as to obtain a rough surface which improves the close adhesion between teeth and filling resins in the subsequent repairing or filling process.

Owner:FAR EASTERN NEW CENTURY COPRRATION

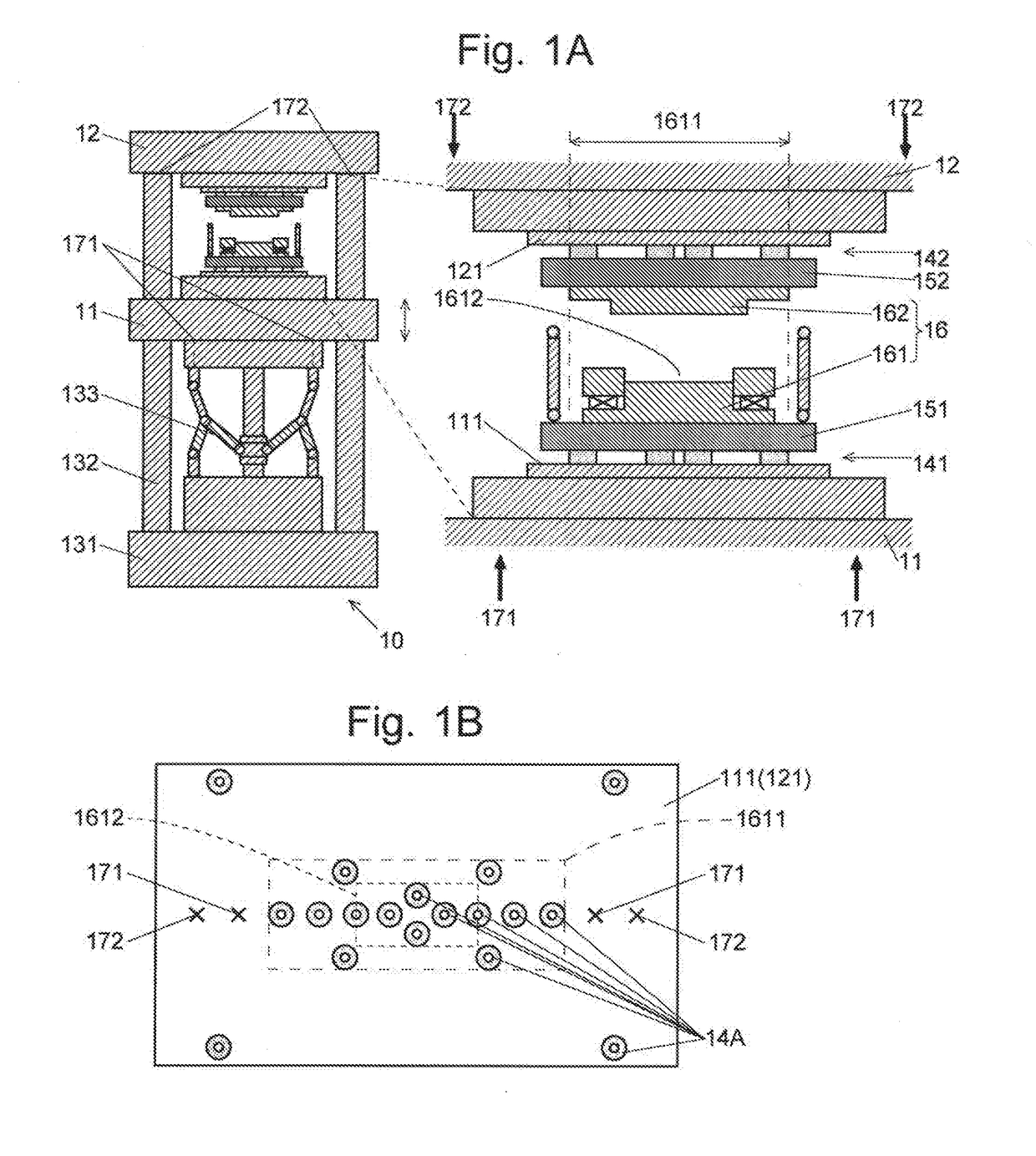

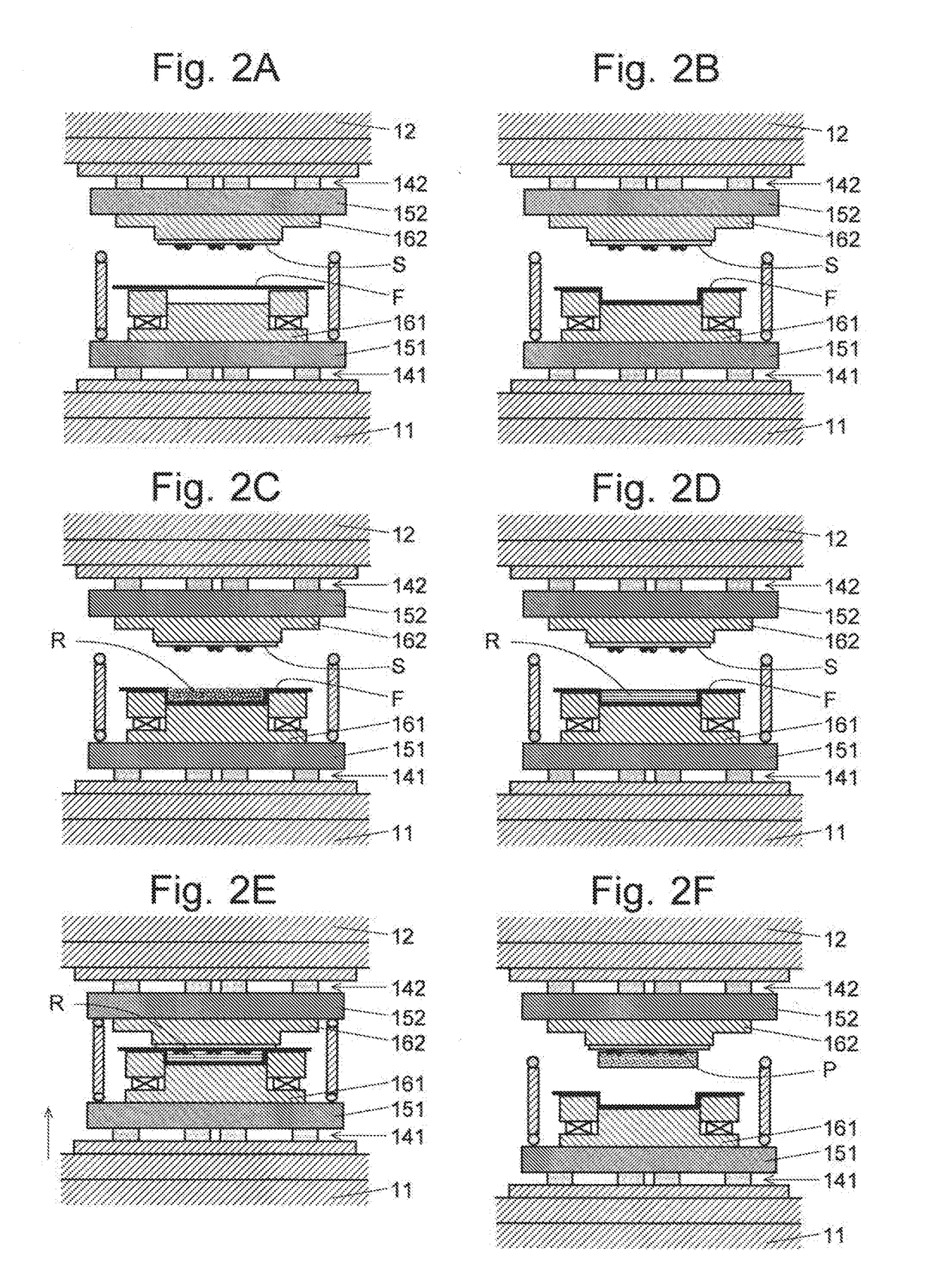

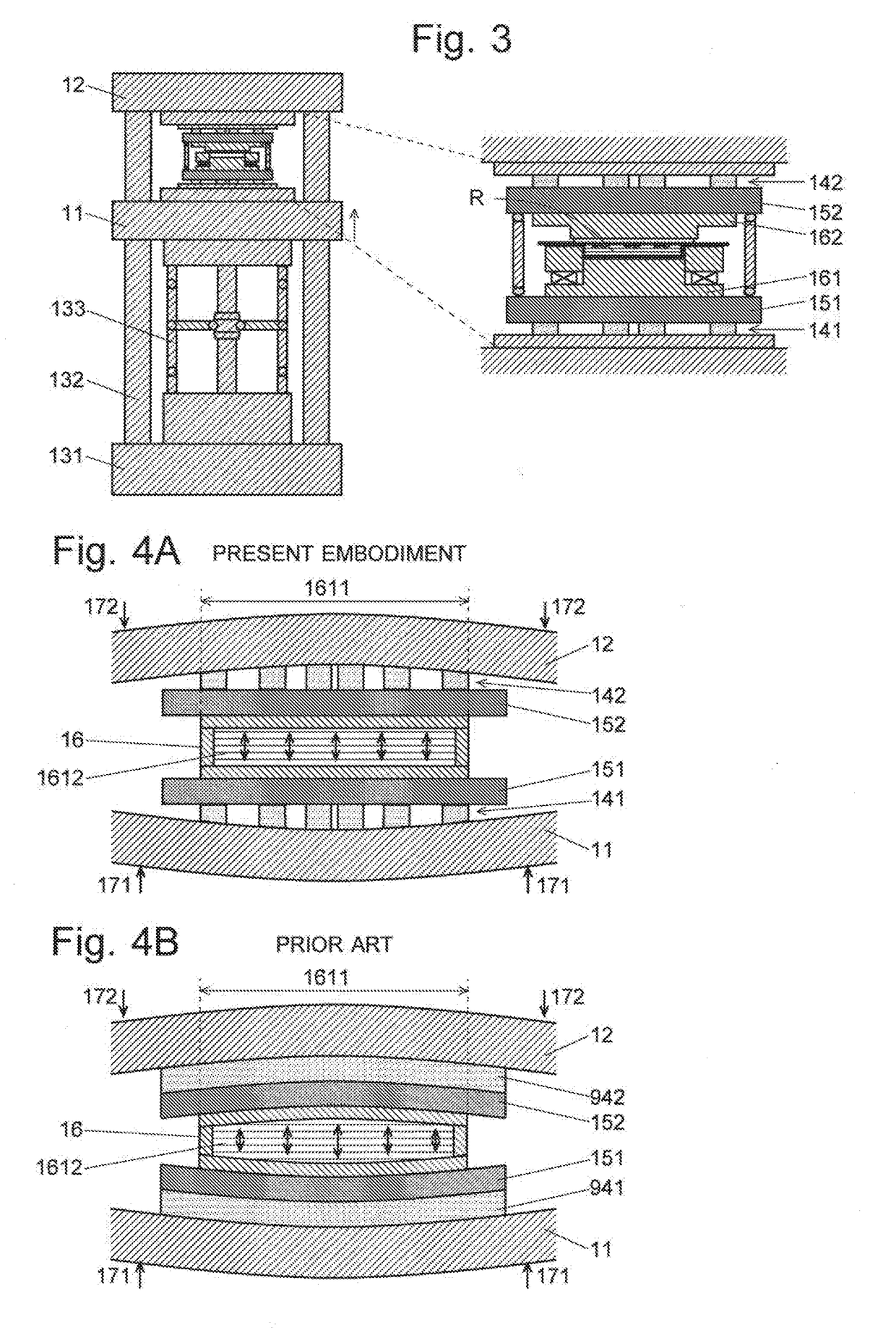

Resin-molding device and method for producing resin-molded product

ActiveUS20190001536A1Non uniformSolid-state devicesSemiconductor/solid-state device manufacturingShell moldingEngineering

A resin-molding device capable of preventing a resin-molded product from being non-uniform in thickness. A resin-molding device includes: a first and second platen (outside-loaded platen) which are two plate-shaped members arranged parallel to each other to allow a molding die to be arranged in a die arrangement section which is a central region between the platens; a force applier (toggle link and tie bars) for applying a force to the platens from loading points located outside the die arrangement section; a heating mechanism (lower and upper heater plates) provided between the outside-loaded platen and the molding die; and a heat-insulating member (lower and upper heat-insulating members) formed by a plurality of elastic pillar members arranged between the outside-loaded platen and the heating mechanism, the pillar members configured so that the amount of deformation of each pillar member increases from the center of the die arrangement section toward the loading point.

Owner:TOWA

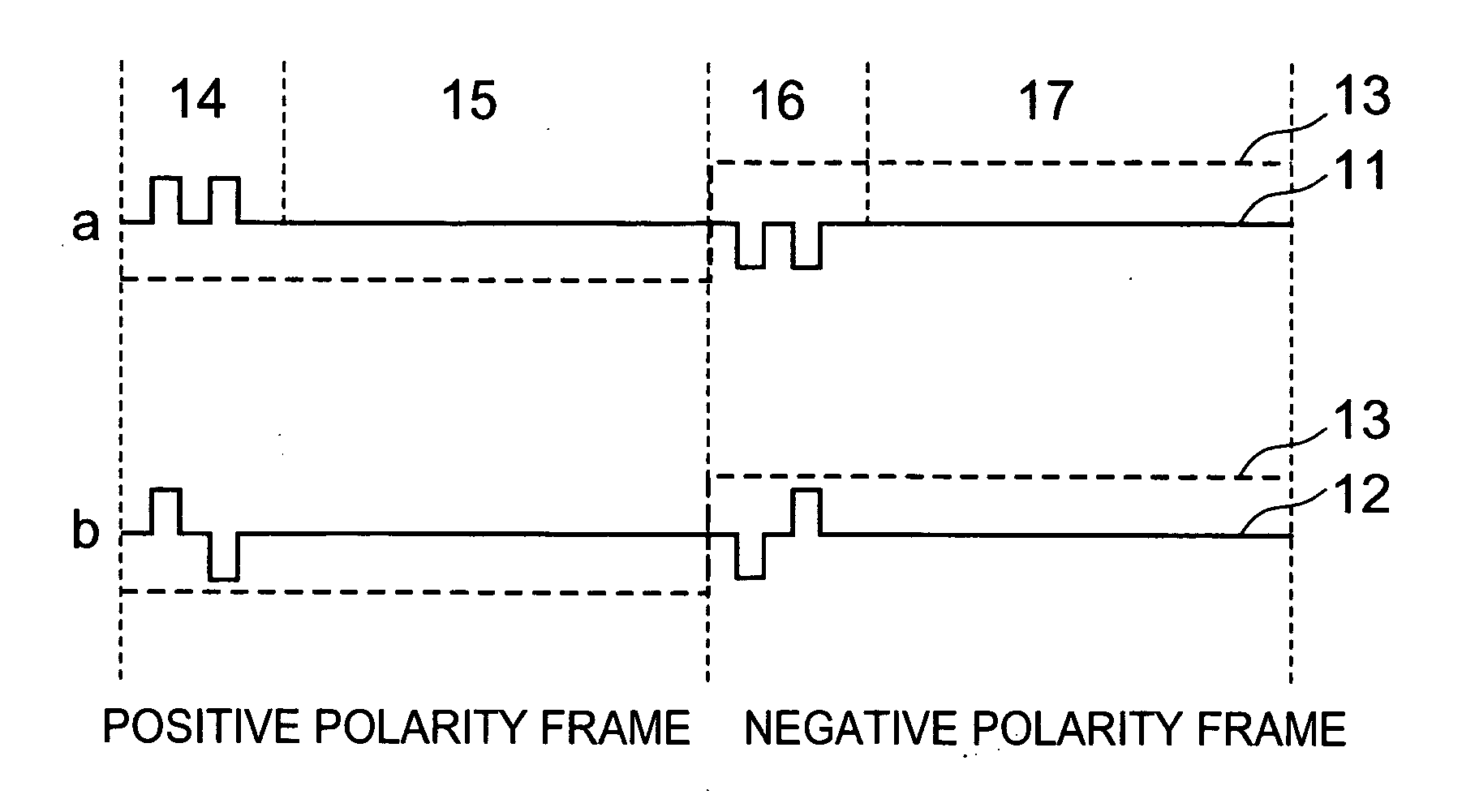

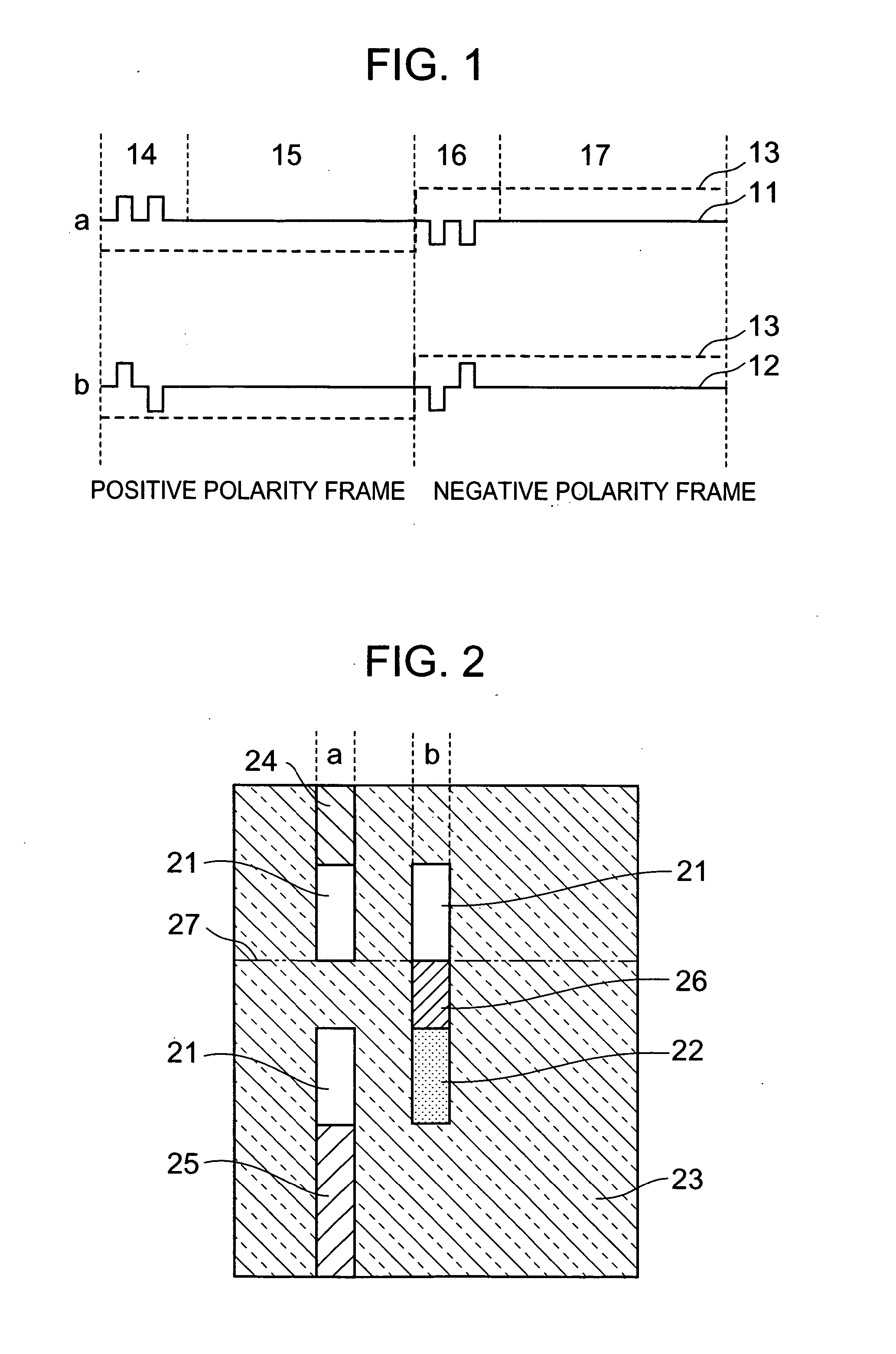

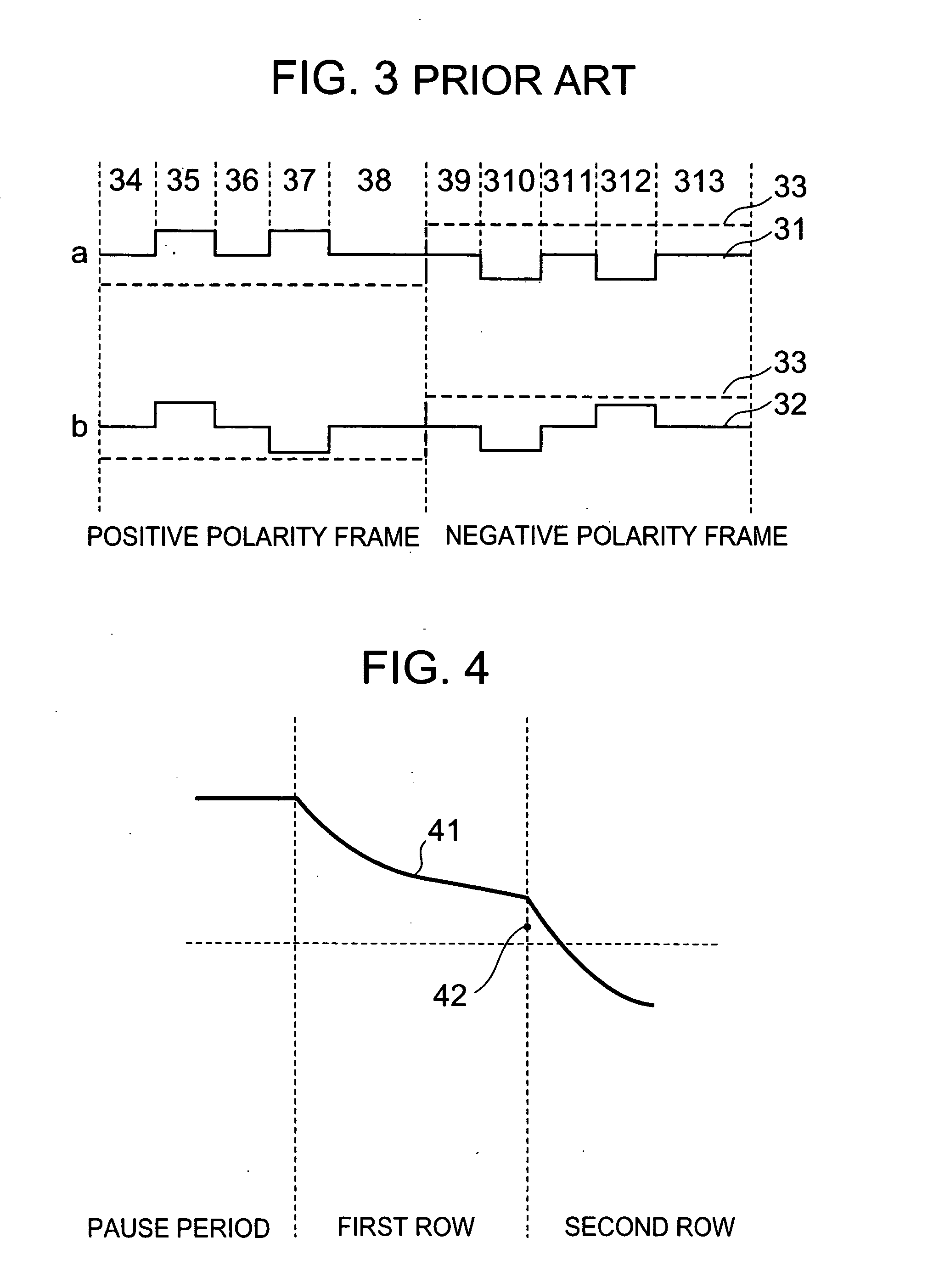

TFT liquid crystal display driving method and TFT liquid crystal display driving module

InactiveUS20050104831A1Reduce power consumptionNon uniformStatic indicating devicesLiquid-crystal displayPerpendicular direction

To provide a TFT liquid crystal display driving method for realizing low electric power consumption compared to line inversion driving and dot inversion driving by means of improving cross talk, brightness non-uniformity in a perpendicular direction, and flicker in frame inversion driving. Write scanning to the TFT liquid crystal display is performed at a speed equal to several times a normal speed, and a pause period is formed thereafter having a length equal to several times the length of the write period. Further, by maintaining a signal electrode waveform during the pause period at a constant gray scale level, the difference between a display pattern integrated over one frame period and the value of the waveform integrated over one frame period becomes relatively small. In addition, by setting memory in a standby mode during the pause period, and by slowing an electric power source booster circuit clock, the energy consumption of a TFT liquid crystal display driving module decreases.

Owner:SEIKO INSTR INC

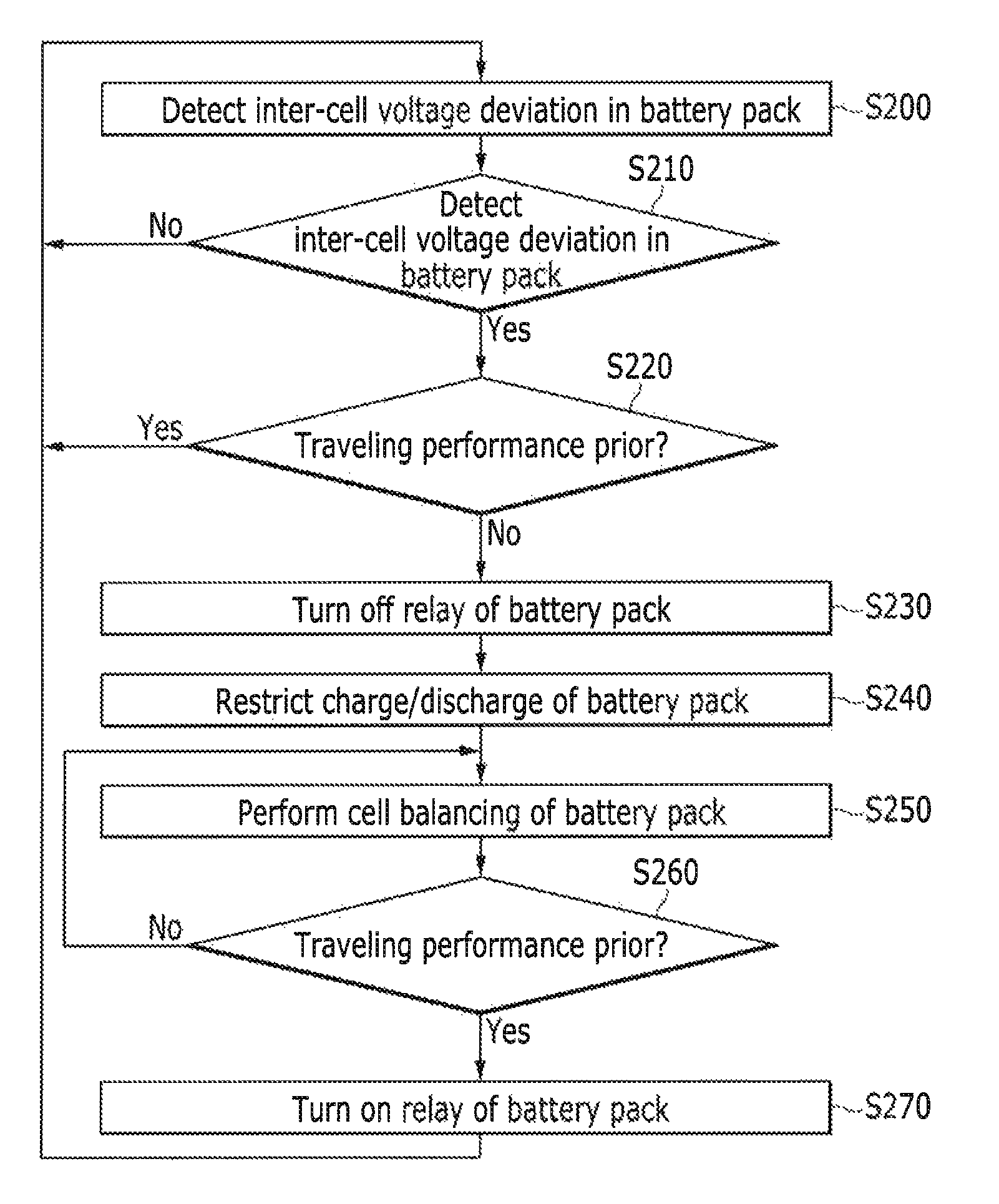

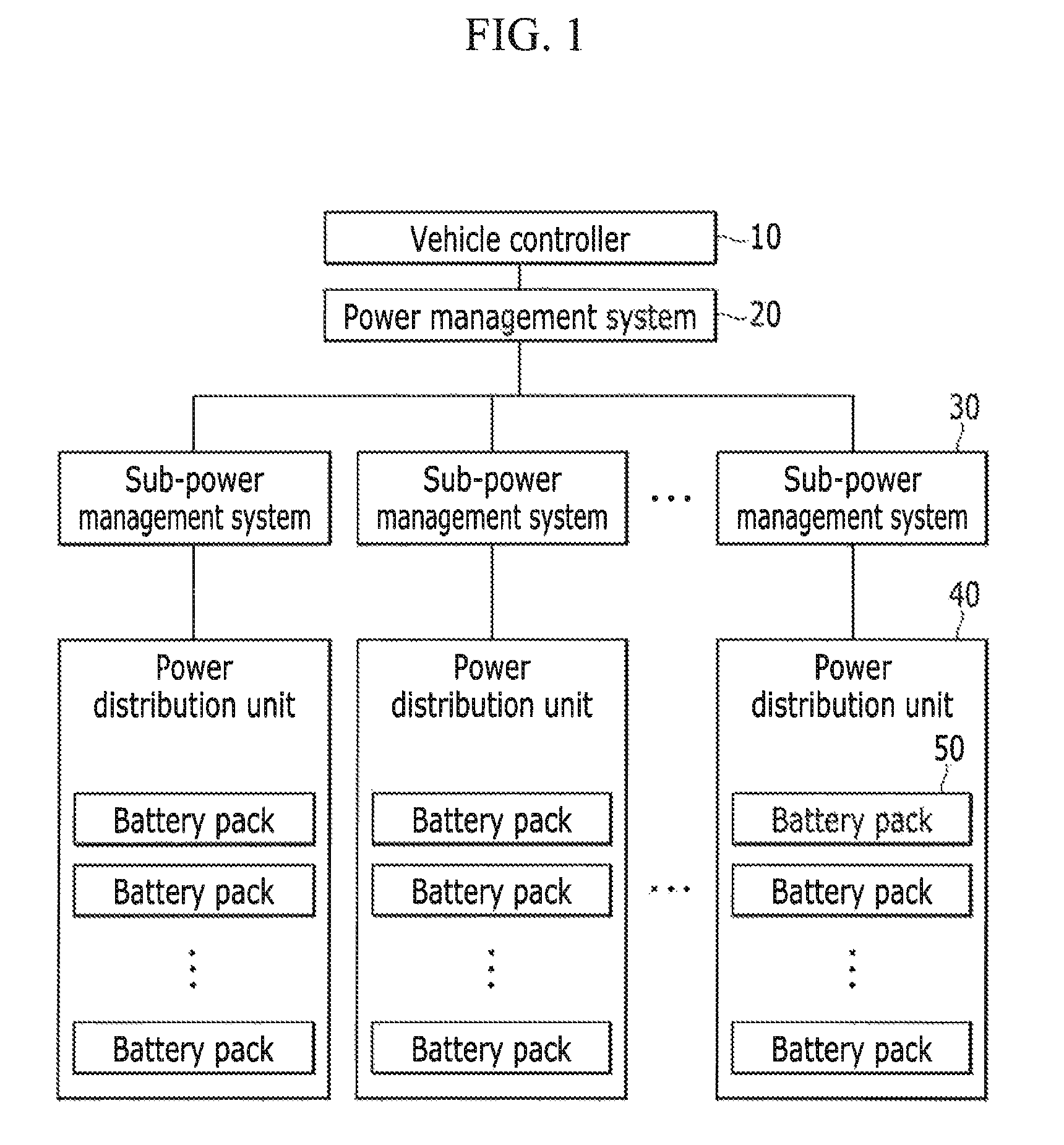

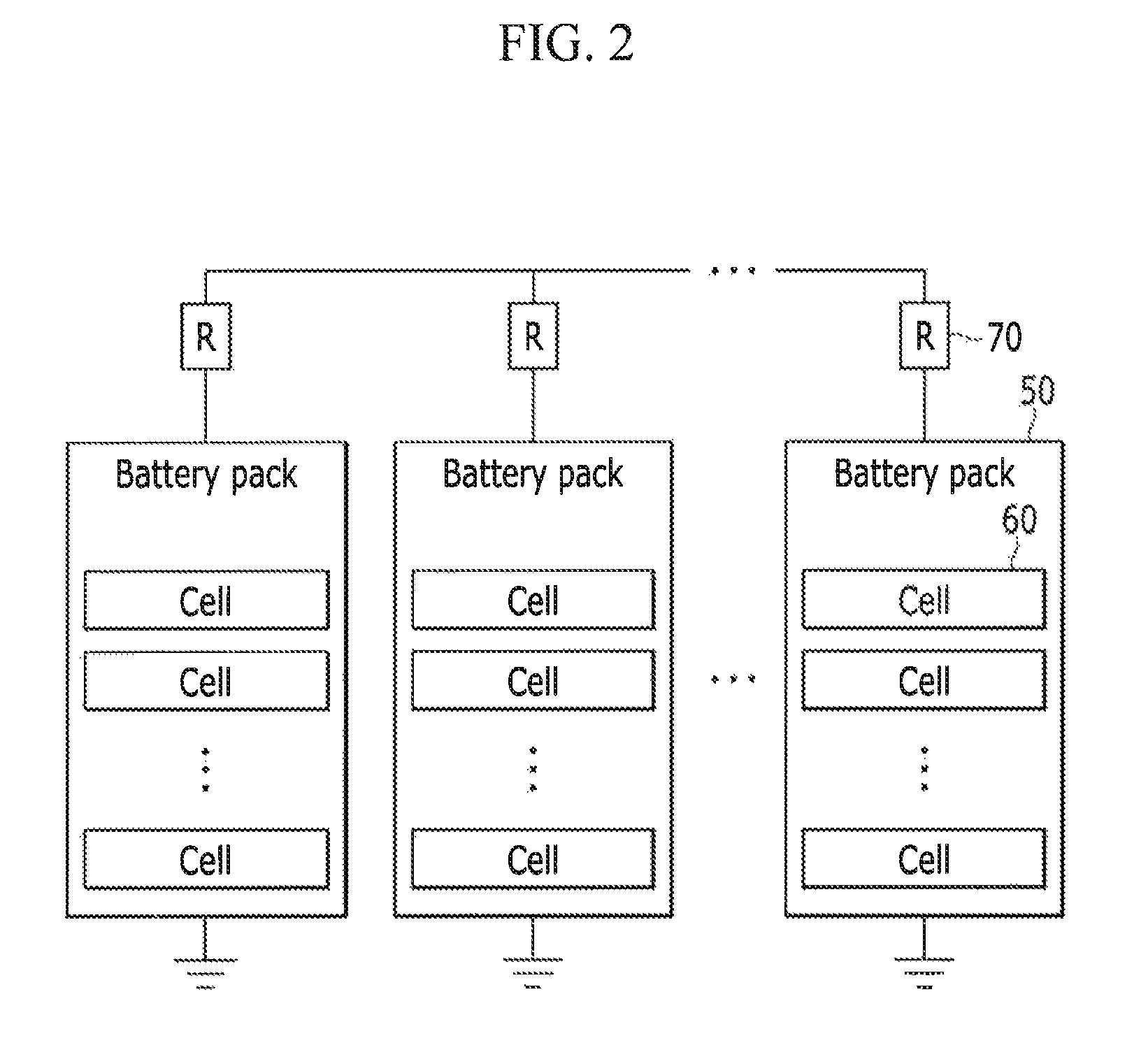

System and method for cell balancing of battery pack

ActiveUS9067505B2Non uniformIncreased non-uniformityCharge equalisation circuitSecondary cells charging/dischargingSimulationCell voltage

A system and method of cell balancing of a battery pack using a cell balancing device of a battery pack is provided and includes a controller that detects an inter-cell voltage deviation in the battery pack. In addition, the controller is configured to determine whether to perform cell balancing on the battery pack and inactivate a relay connected with the battery pack. The controller is further configured to perform cell balancing in the battery pack.

Owner:HYUNDAI MOTOR CO LTD +1

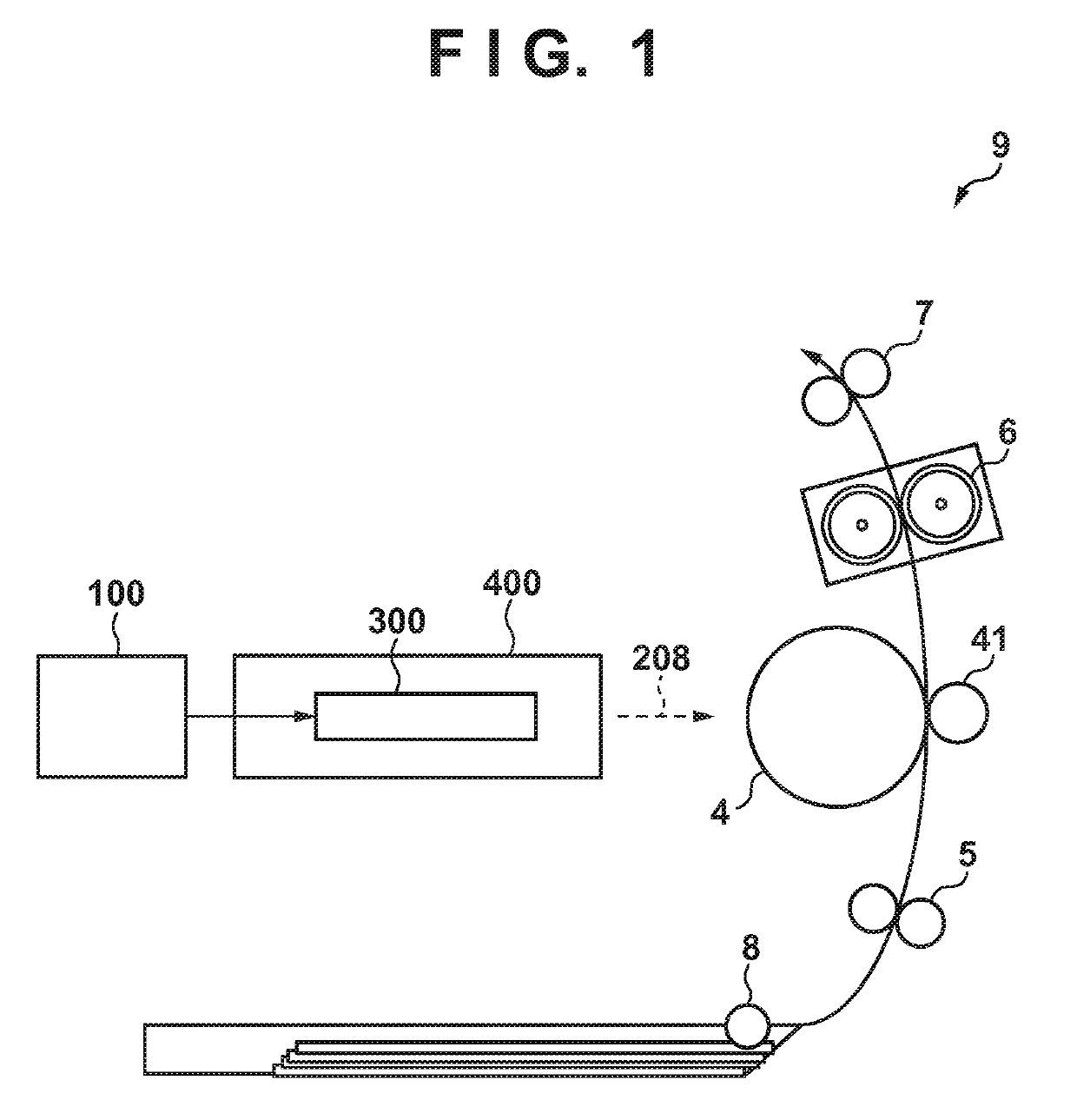

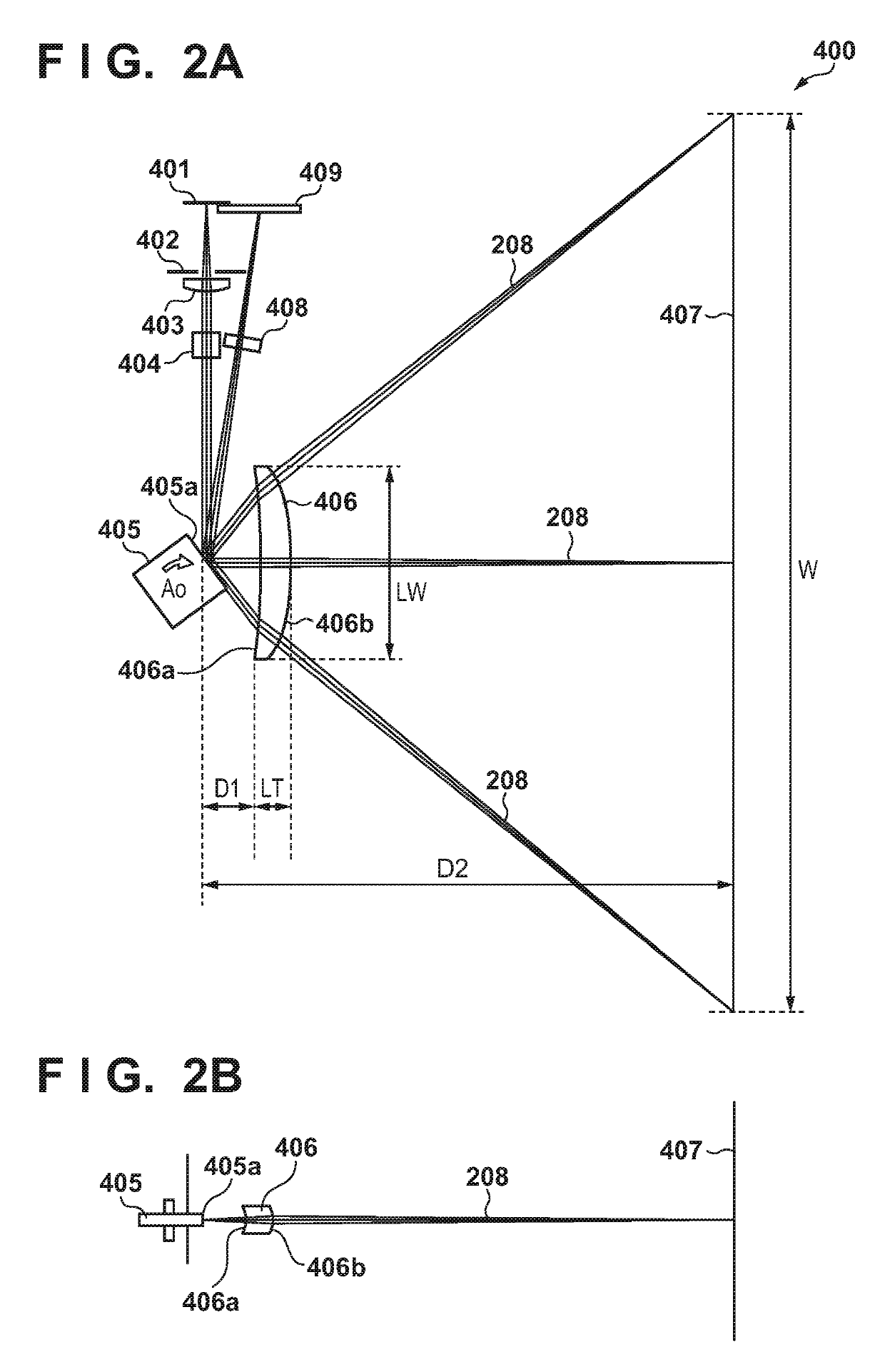

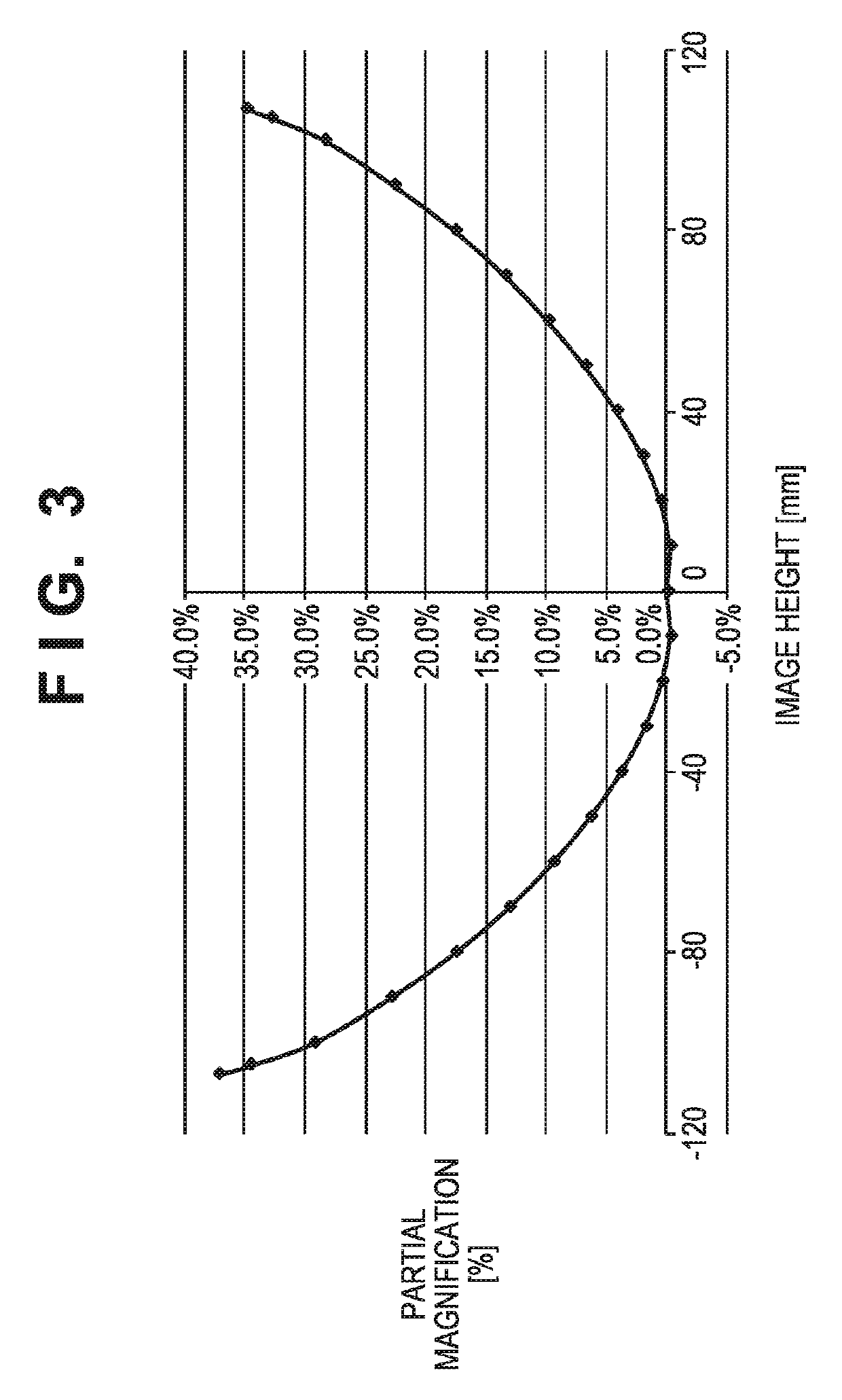

Image forming apparatus and control method thereof

An image forming apparatus comprises: a photosensitive member; a charger unit configured to charge the photosensitive member; an exposing unit configured to form a latent image by scanning the photosensitive member by laser light which has a different spot diameter in accordance with a scanning position of the photosensitive member in a main scanning direction; a developing unit configured to develop an image by adhering a toner to the photosensitive member on which the latent image is formed; and a control unit configured to control a luminance of the laser light and a resolution of the photosensitive member in a sub-scanning direction in accordance with the scanning position of the photosensitive member in the main scanning direction.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com