Semi-automatic opening rotor spinning machine

A rotor spinning machine, free end technology, applied in the directions of free end spinning machine, spinning machine, continuous winding spinning machine, etc., can solve problems such as inflexibility, and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

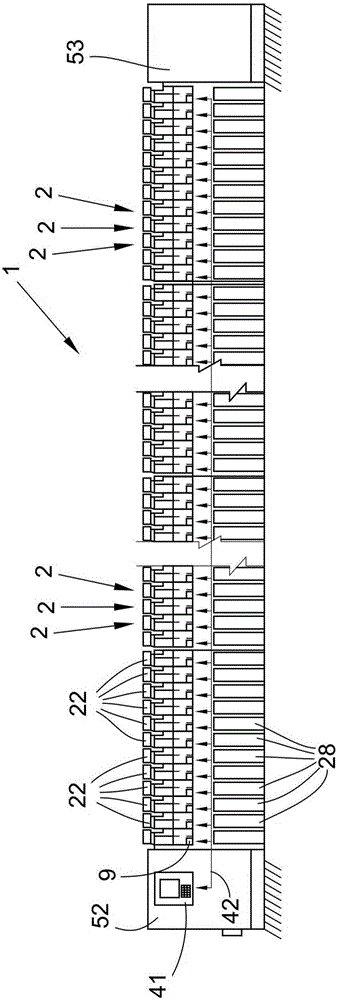

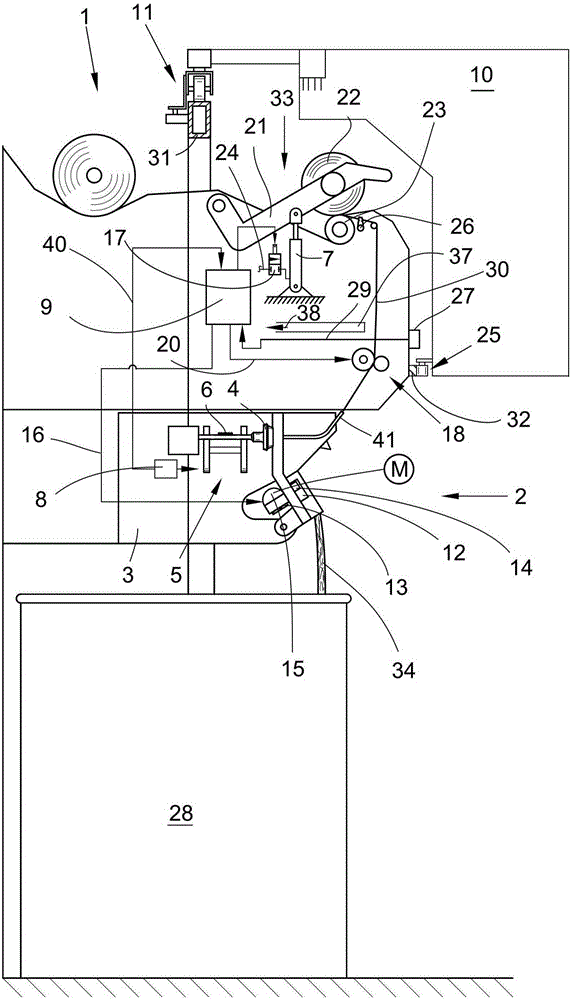

[0039] figure 1A schematic front view shows an open-end rotor spinning machine 1 with so-called end frames 52 , 53 , as known and therefore not shown in detail, The end frames are connected by continuous supply and processing channels, such as a vacuum channel for supplying the spinning vacuum to the winding device, an electronic channel for the bus system and / or the yarn monitoring device and supply for station 2 Cable channels for electrical energy.

[0040] On said supply and handling channel, which is almost the "backbone" of the textile machine, the yarn forming device of the open-end rotor spinning machine 1 or the cross-winding bobbin winding device can be placed, which constitute a plurality of normal work stations 2 .

[0041] At station 2, a sliver of feed fiber stored in a spinning pot 28 is spun into yarn, which is wound onto a cross-winding bobbin 22 .

[0042] In the end frames 52 , 53 , for example, the vacuum supply of the textile machine itself (not shown),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com