A kind of magnetic grinding device and method of ultrasonic composite high-pressure air flow

A high-pressure airflow and magnetic grinding technology, applied in the field of ultrasonic-assisted magnetic grinding, can solve the problems of single structure and low relative movement speed of the magnetic abrasive polishing device, and achieve complex grinding trajectory, easy adjustment and assembly, and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

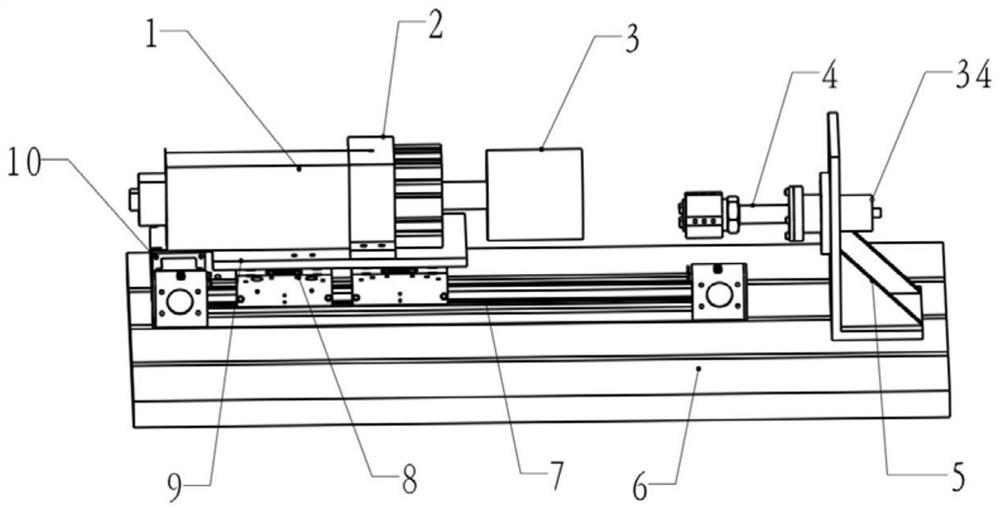

[0032] 1) Put the magnetic abrasive into the cylindrical workpiece 3, and install the cylindrical workpiece 3 on the ultrasonic vibrator 1;

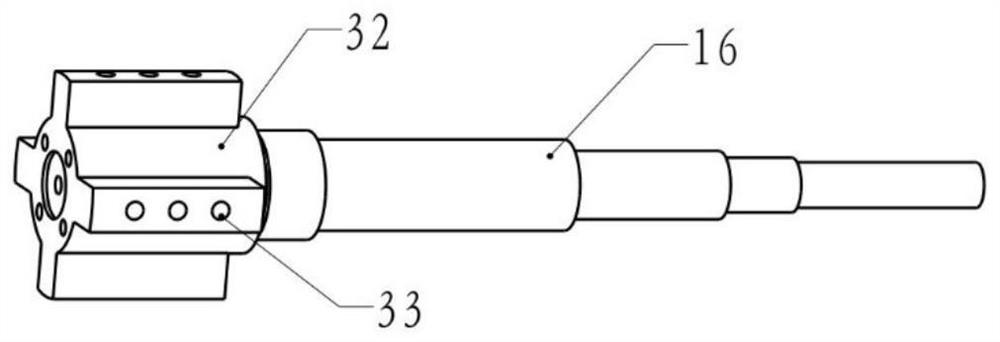

[0033] 2) Connect the polishing spindle assembly 4 with the hollow motor 34, and pass the high-pressure gas of the compressor into the hollow shaft through the rotary joint;

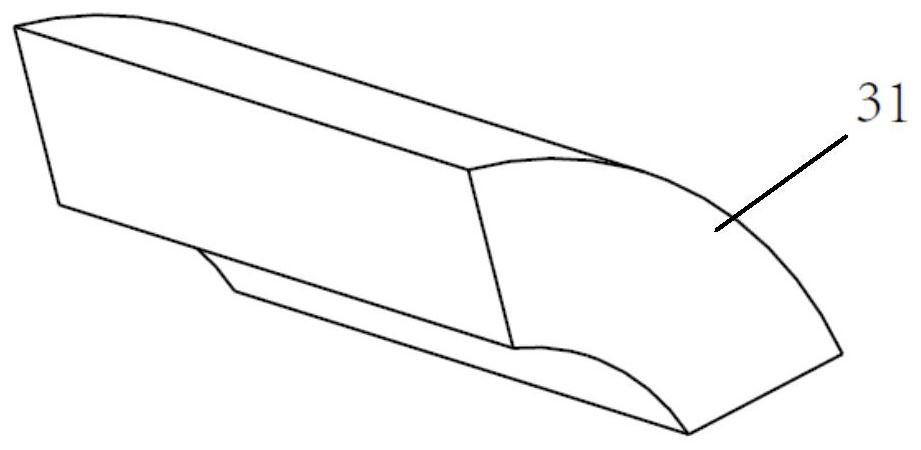

[0034] 3) Adjust the position of the slide block 8 on the guide rail 7 so that one end of the polishing spindle assembly 4 equipped with the curved surface permanent magnet 31 is placed inside the cylindrical workpiece 3, and the distance between the curved surface permanent magnet 31 and the inner wall of the cylindrical workpiece 3 is controlled at 1- Between 2 mm;

[0035] 4) The abrasive in the cylindrical workpiece 3 is displaced relative to the inner wall of the cylindrical workpiece 3 under the compound action of high-pressure airflow, magnetic field and ultrasonic vibration; the abrasive forms a magnetic brush under the action of the magnetic force, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com