High-speed permanent magnet motor rotor structure

A permanent magnet motor and rotor structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of repulsive force generated by permanent magnets, difficult to fit tooling, etc., to avoid broken, convenient tooling difficulty , The effect of convenient finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

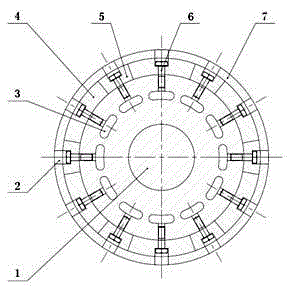

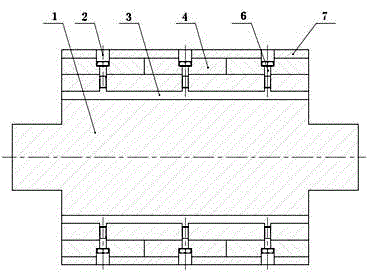

[0019] Such as figure 1 , 2, the rotor structure of the high-speed permanent magnet motor of the present invention includes a rotor 1, a permanent magnet block 4, a magnetic pole interval 5, a bolt 6, a sheath 7, and the like.

[0020] There are radial bolt holes 2 and axial ventilation holes 3 on the rotor 1, and the two are connected. The permanent magnet block 4 and the magnetic pole spacer 5 also have bolt holes, and the permanent magnet block 4 and the magnetic pole spacer 5 are fixed on the rotor 1 by bolts 6 . At this time, the entire rotor 1 can be finished with the outer circle of the rotor to reduce the fit tolerance, improve its concentricity, and ensure the dynamic balance of the rotor at high speed.

[0021] The sheath 7 is made of high-strength metal such as titanium alloy or steel, and has holes corresponding to rotor bolts on it, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com