Graphene-based coating agent

A graphene-based, graphene dispersant technology, applied in the direction of metal material coating process, etc., can solve the problems of weak metal surface bonding force, insufficient surface film-forming performance, etc., and achieves short film-forming time, good film-forming property, The effect of high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare material A and material B respectively in parts by mass.

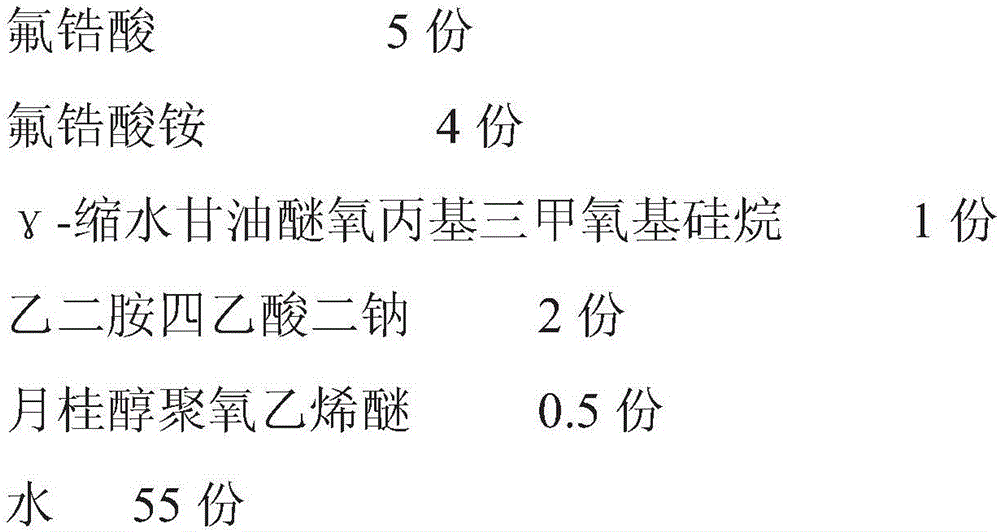

[0039] 1) Material A:

[0040]

[0041] 2) Material B

[0042] Monolayer graphene oxide 0.1 parts

[0043] 1 part polyvinyl alcohol

[0044] 30 parts of water

[0045] 3) Mix material A and material B evenly to make the graphene-based coating agent of the present invention.

[0046] Dilute the graphene-based coating agent 20 times with water for use.

[0047] Clean the surface of the aluminum alloy with an acidic or neutral cleaning solution to remove oil and dust on the surface of the aluminum alloy; then clean other impurities remaining on the surface of the aluminum alloy with water; directly soak the aluminum alloy in the diluent of the graphene-based coating agent, The temperature is room temperature, the drying time is about 2 minutes, and it is dried at 80-120°C, or it can be dried at room temperature.

Embodiment 2

[0049] Prepare material A and material B respectively in parts by mass.

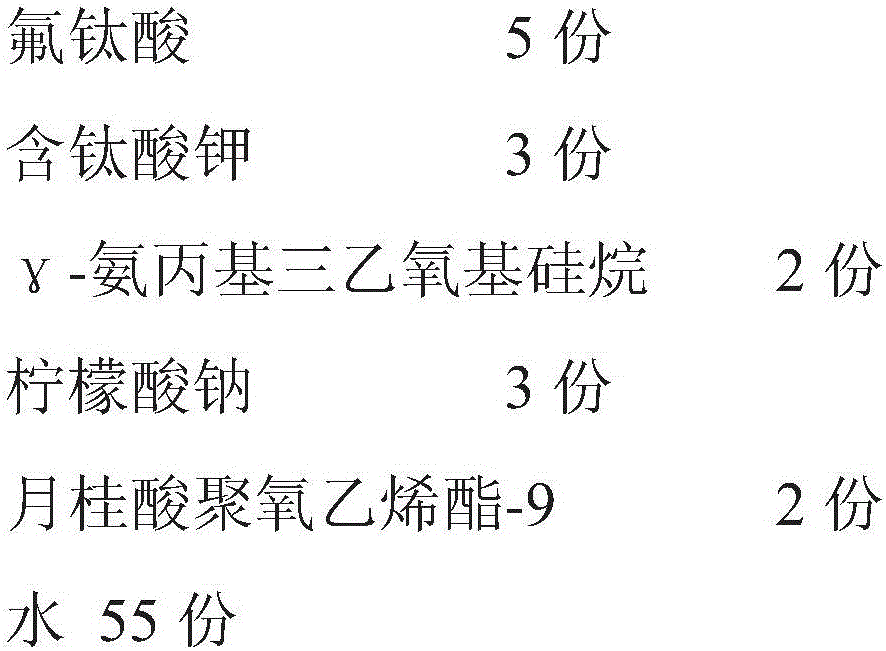

[0050] 1) Material A:

[0051]

[0052] 2) Material B

[0053] Few-layer graphene oxide 0.3 parts

[0054] Sodium polyacrylate 2 parts

[0055] 30 parts of water

[0056] 3) Mix material A and material B evenly to make the graphene-based coating agent of the present invention.

[0057] Dilute the graphene-based coating agent 15 times with water for use.

[0058] First clean the surface of the steel parts with an acidic or neutral cleaning solution to remove oil and dust on the surface of the steel parts; then clean other impurities remaining on the surface of the steel parts with water; soak the steel parts directly in the graphene-based coating agent dilution, The temperature is room temperature, the drying time is about 2 minutes, and it is dried at 80-120°C, or it can be dried at room temperature.

Embodiment 3

[0060] Prepare material A and material B respectively in parts by mass.

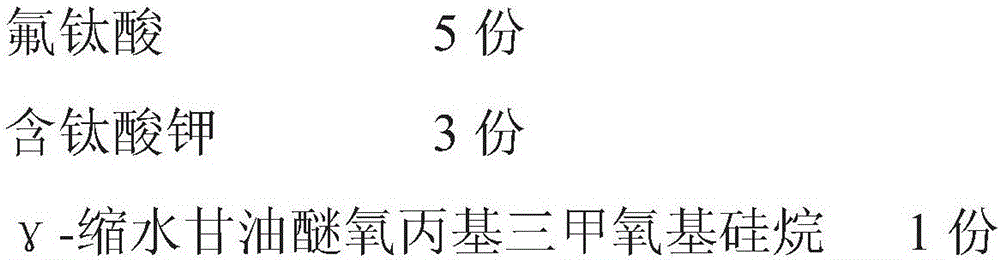

[0061] 1) Material A:

[0062]

[0063]

[0064] 2) Material B

[0065] Few-layer graphene oxide 0.3 parts

[0066] 2 parts polyacrylamide

[0067] 20 parts of water

[0068] 3) Mix material A and material B evenly with the graphene-based coating agent of the present invention.

[0069] Dilute the graphene-based coating agent 20 times with water for use.

[0070] Clean the surface of the aluminum alloy with an acidic or neutral cleaning solution to remove oil and dust on the surface of the aluminum alloy; then clean other impurities remaining on the surface of the aluminum alloy with water; directly soak the aluminum alloy in the diluent of the graphene-based coating agent, The temperature is room temperature, the drying time is about 2 minutes, and it is dried at 80-120°C, or it can be dried at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com