Patents

Literature

94results about How to "Does not affect subsequent use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-based coating agent

ActiveCN106011816AImprove corrosion resistanceImprove performanceMetallic material coating processesGraphiteGraphene

The invention discloses a graphene-based coating agent. The graphene-based coating agent comprises, 0.1-1 part of nano-graphite, 1-3 parts of a graphene dispersing agent, 2-10 parts of fluorine-bearing acid, 2-10 parts of fluorine-bearing acid salt, 1-2 parts of a silane coupling agent, 2-5 parts of a complexing agent, 0-2 parts of a surface wetting agent and 70-95 parts of water. The graphene-based coating agent has the advantages of short film forming time, good film forming property and environment friendliness. An inorganic film formed on the surface of metal through the graphene-based coating agent has excellent lubricity and corrosion resistance and is thin. The formed inorganic nanofilm has excellent conductivity, lubricating property and corrosion resistance and has higher corrosion resistance and longer salt mist time, and therefore corrosion resistance of a metal substrate is better improved, surface impedance of the metal is not influenced after the film is formed, and finish machining of the metal is better facilitated.

Owner:苏州禾川化学技术服务有限公司

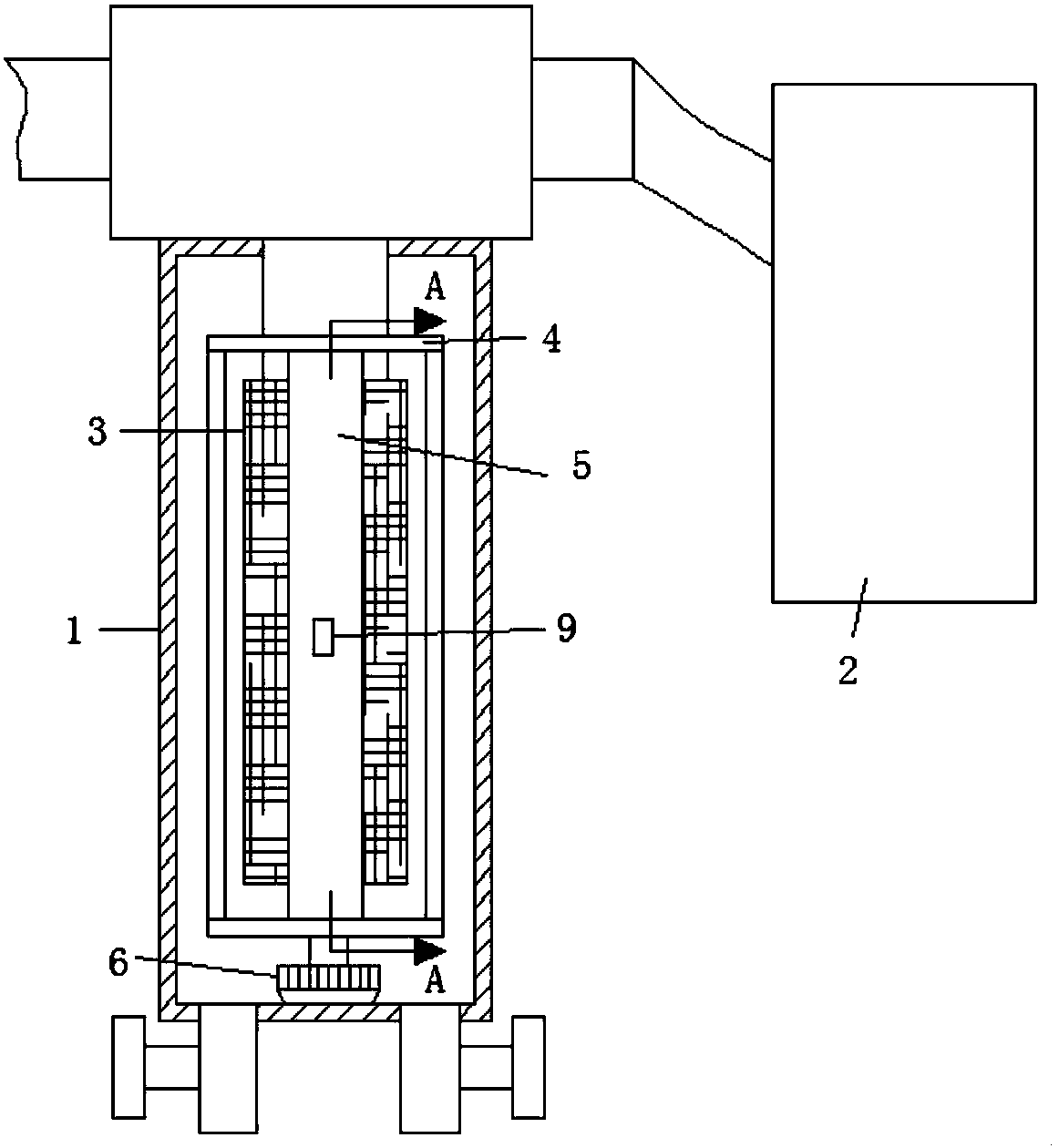

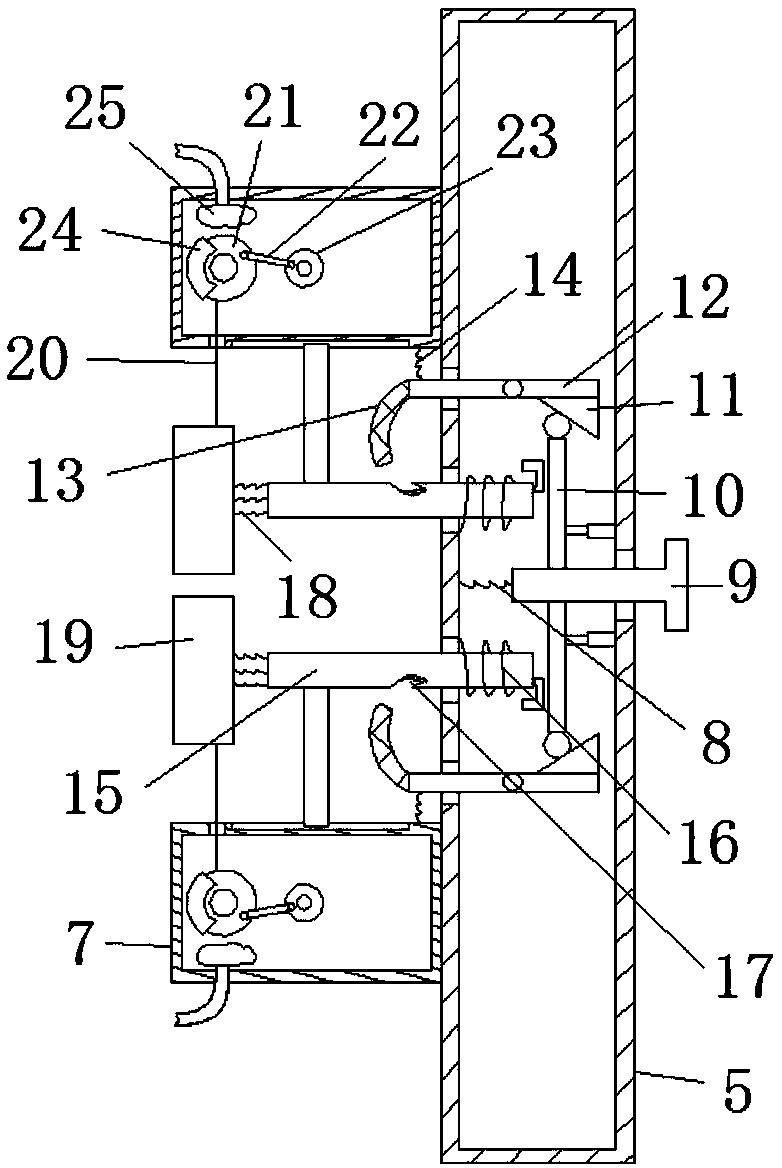

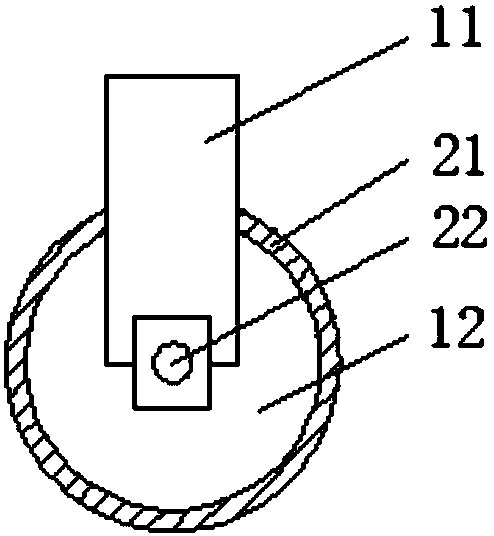

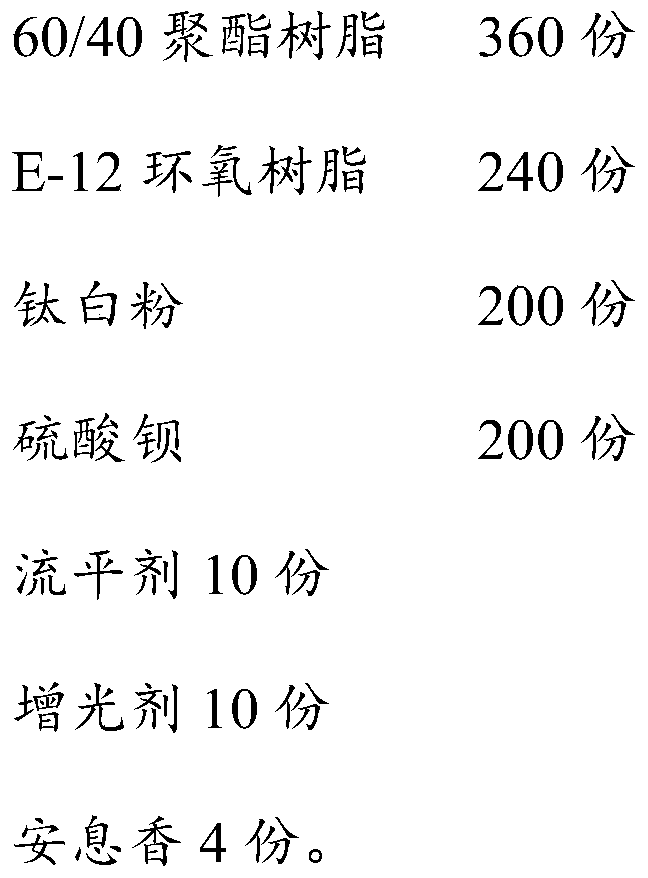

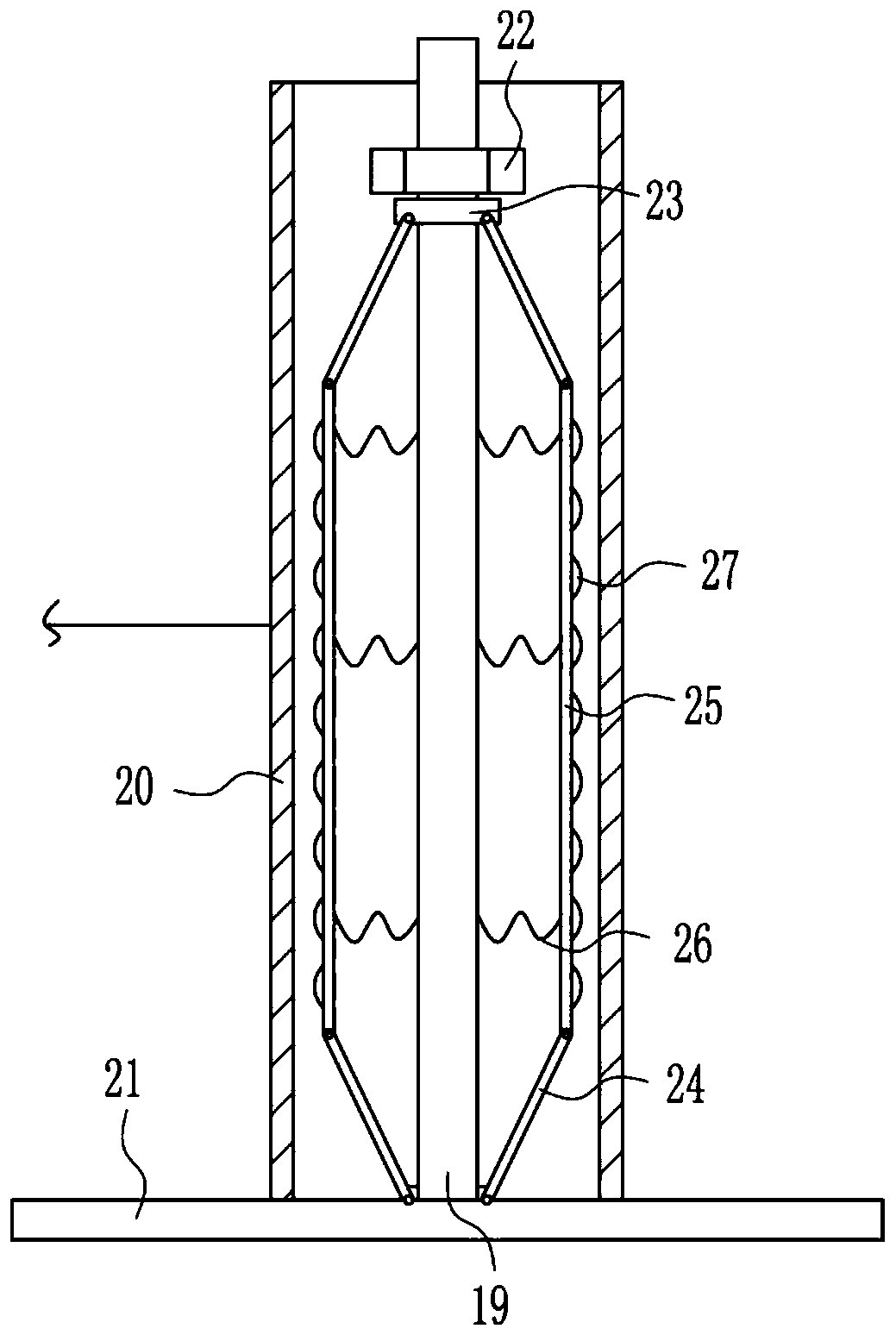

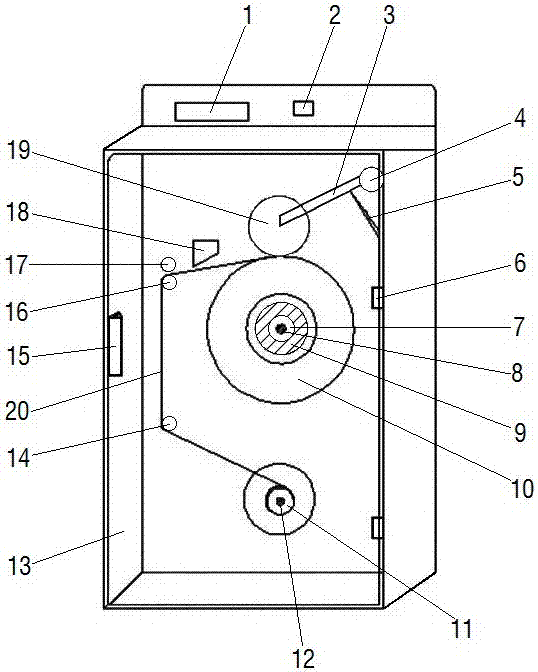

Water diversion device with automatic cleaning function for water turbine

InactiveCN108105015AWith automatic cleaning functionSimple structureHydro energy generationMachines/enginesMotor driveWater turbine

The invention discloses a water diversion device with an automatic cleaning function for a water turbine. The water diversion device comprises a water diversion device body. The water diversion devicewith the automatic cleaning function for the water turbine is simple in structure; dirt on a filter screen is scraped away through large wiping blocks on strip-shaped scraping plates; when the strip-shaped scraping plates rotate, attraction force between strip-shaped magnets and iron sliding rods is weakened, under the action of third springs, the iron sliding rods move leftwards, the dirt on thefilter screen is wiped away by small wiping blocks, and thus the cleaning efficiency is improved; when the strip-shaped magnets move rightwards, two triangular blocks move oppositely, rotating rods rotate, and arc-shaped rods are clamped by limiting grooves so that the small wiping blocks can wipe the filter screen more stably; meanwhile, first electric conduction pieces make contact with secondelectric conduction pieces, second motors drive rotating discs to rotate, winding discs rotate forwards and backwards through connecting rods, the small wiping blocks move up and down for wiping underthe action of pull ropes and fourth springs, and thus the cleaning efficiency is further improved.

Owner:朱利良

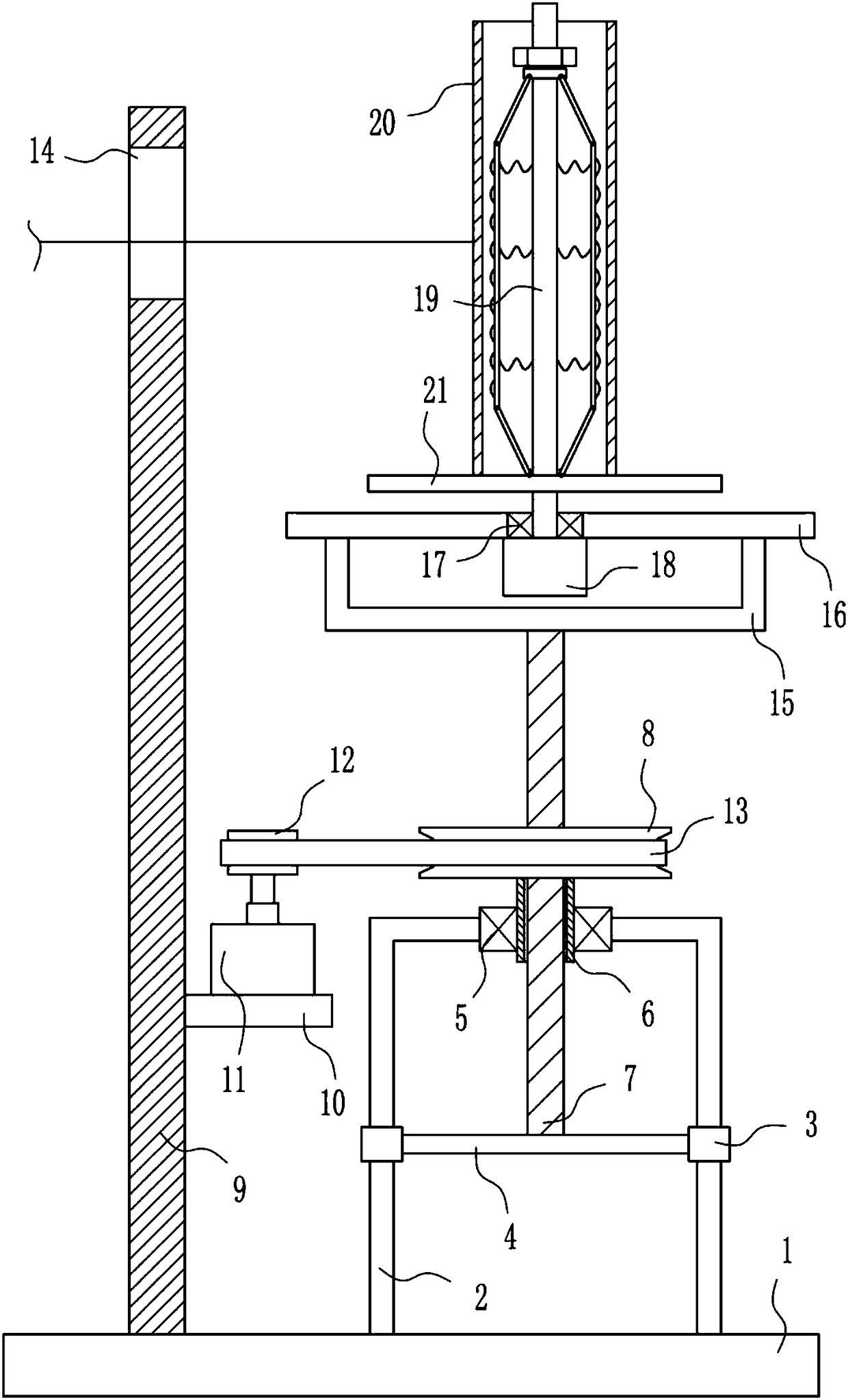

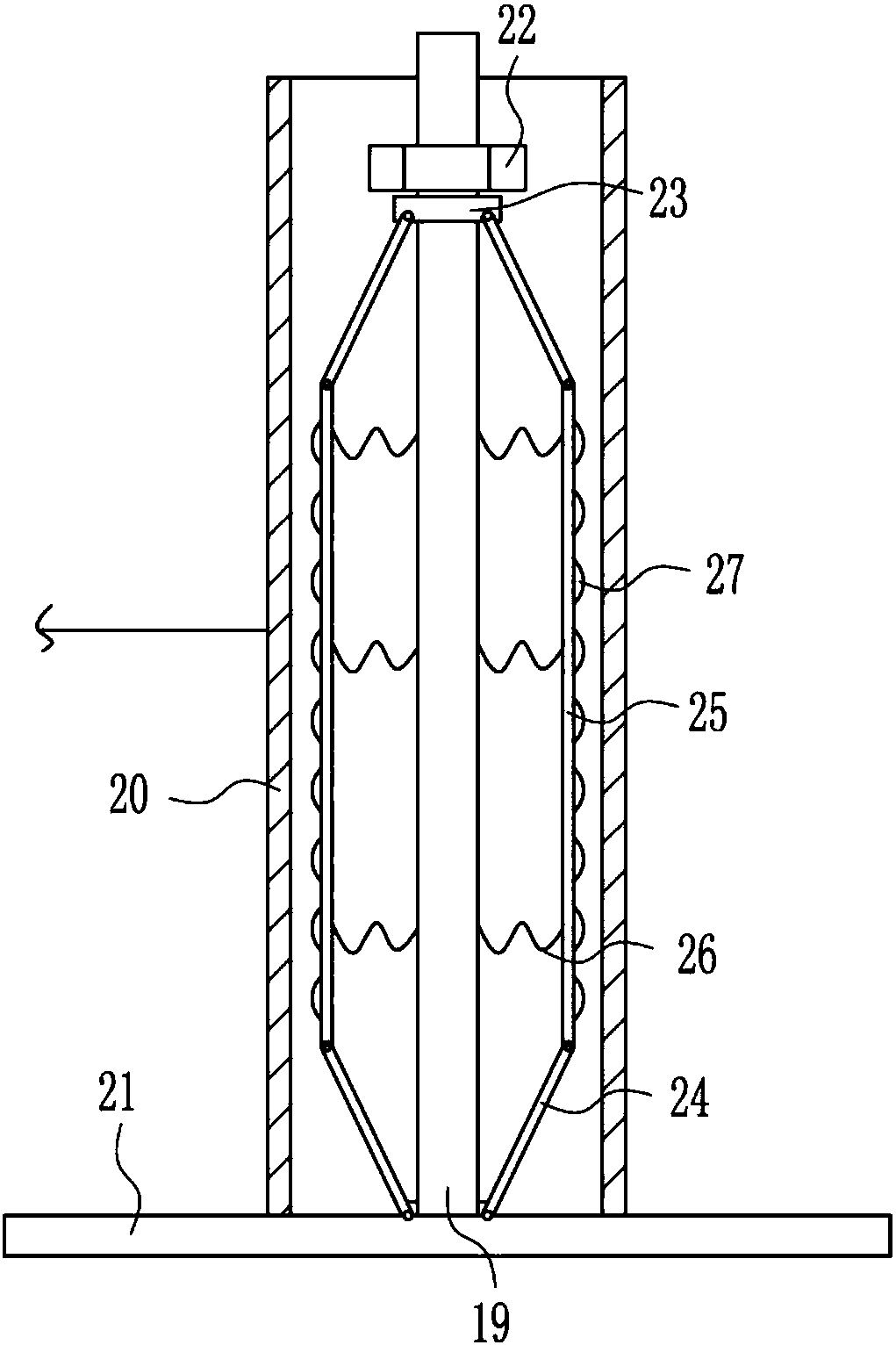

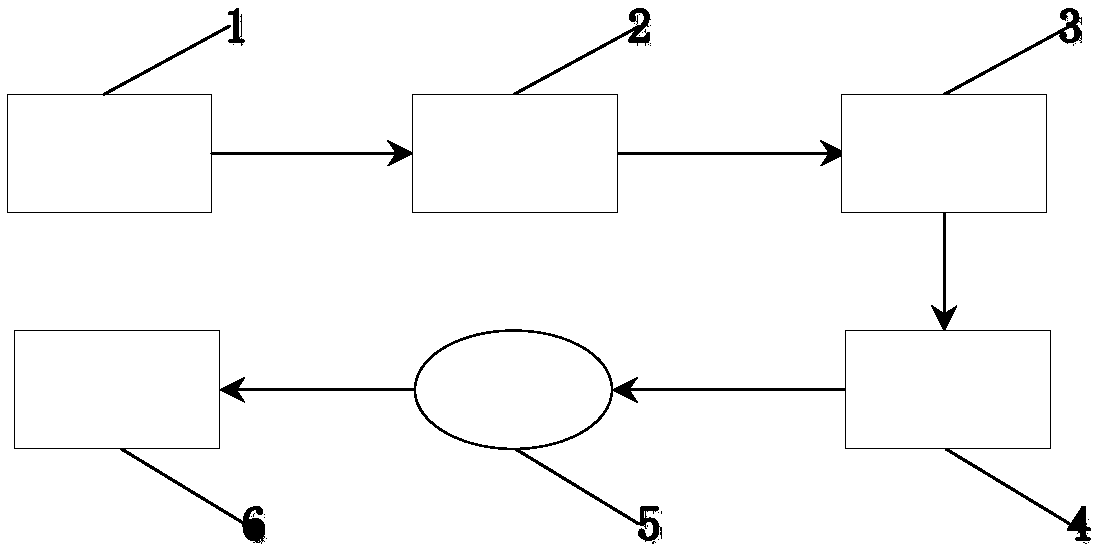

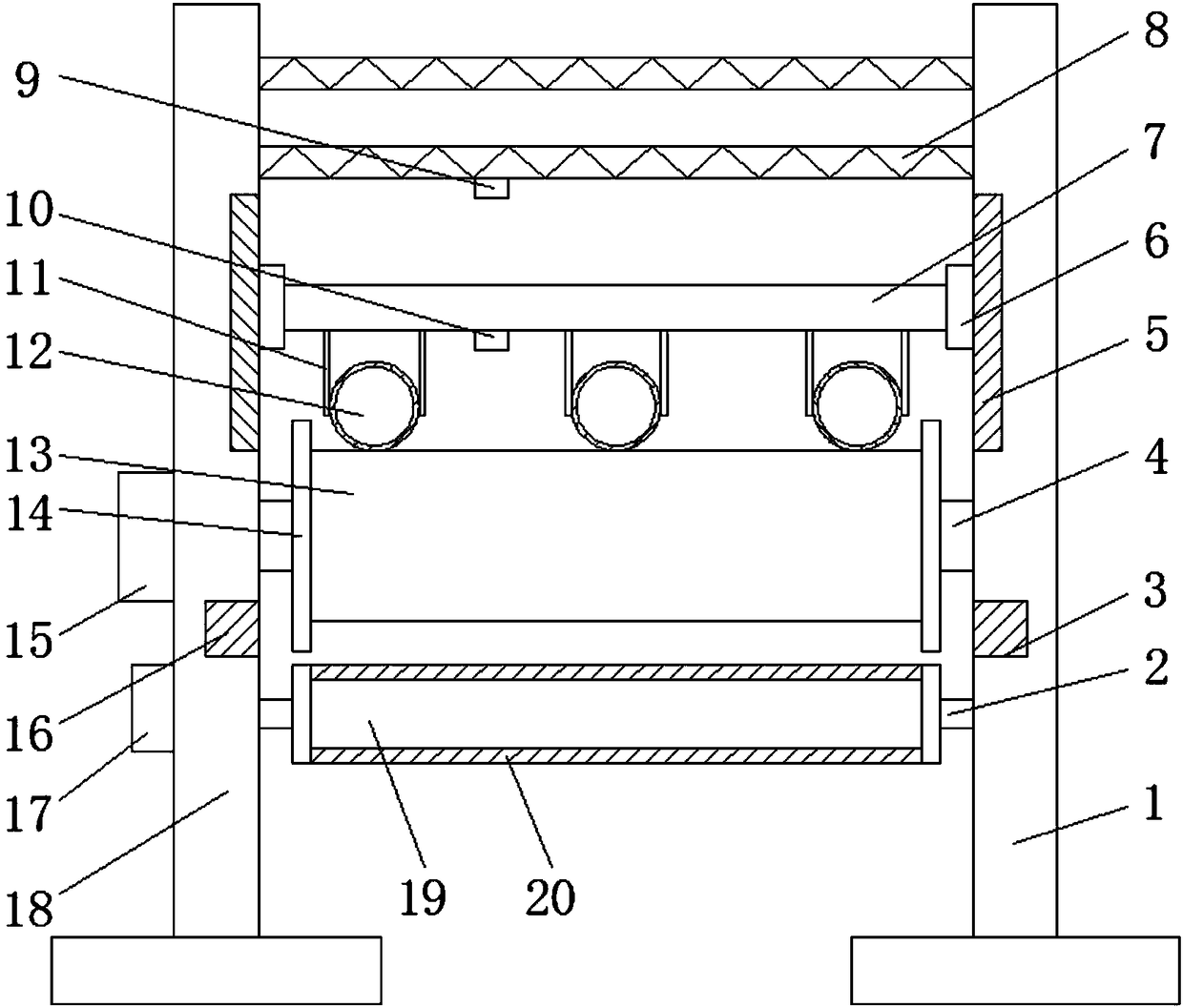

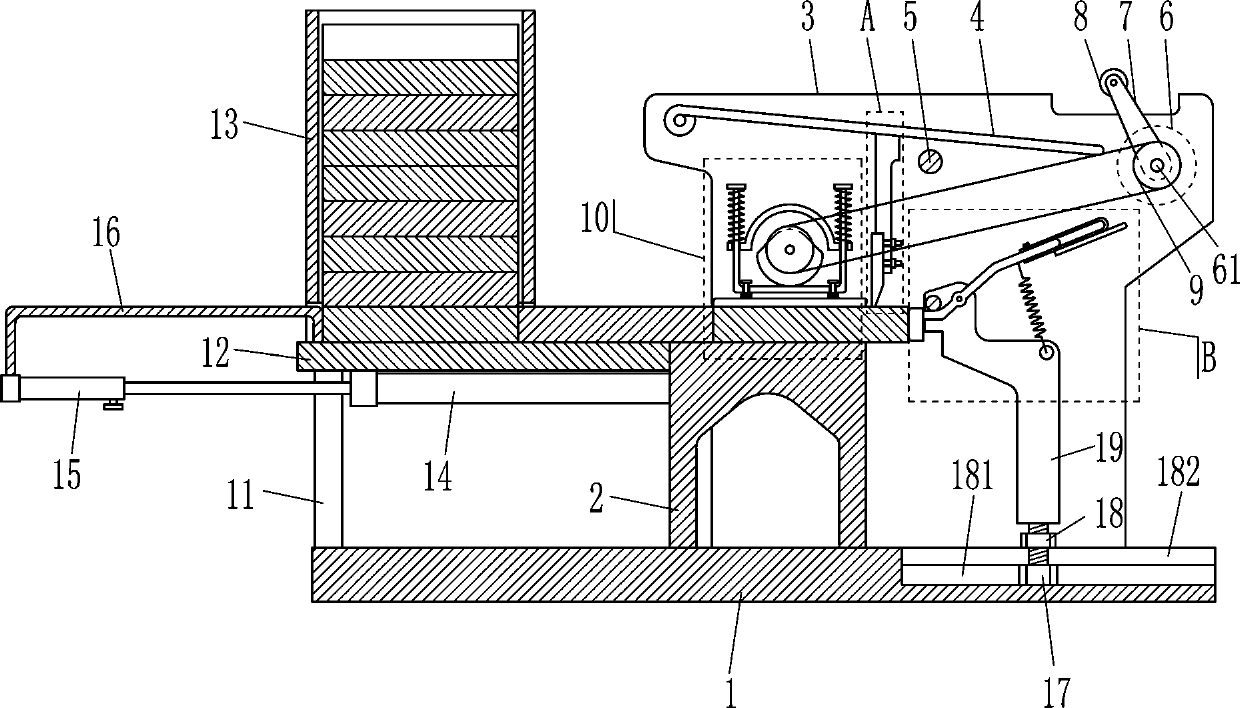

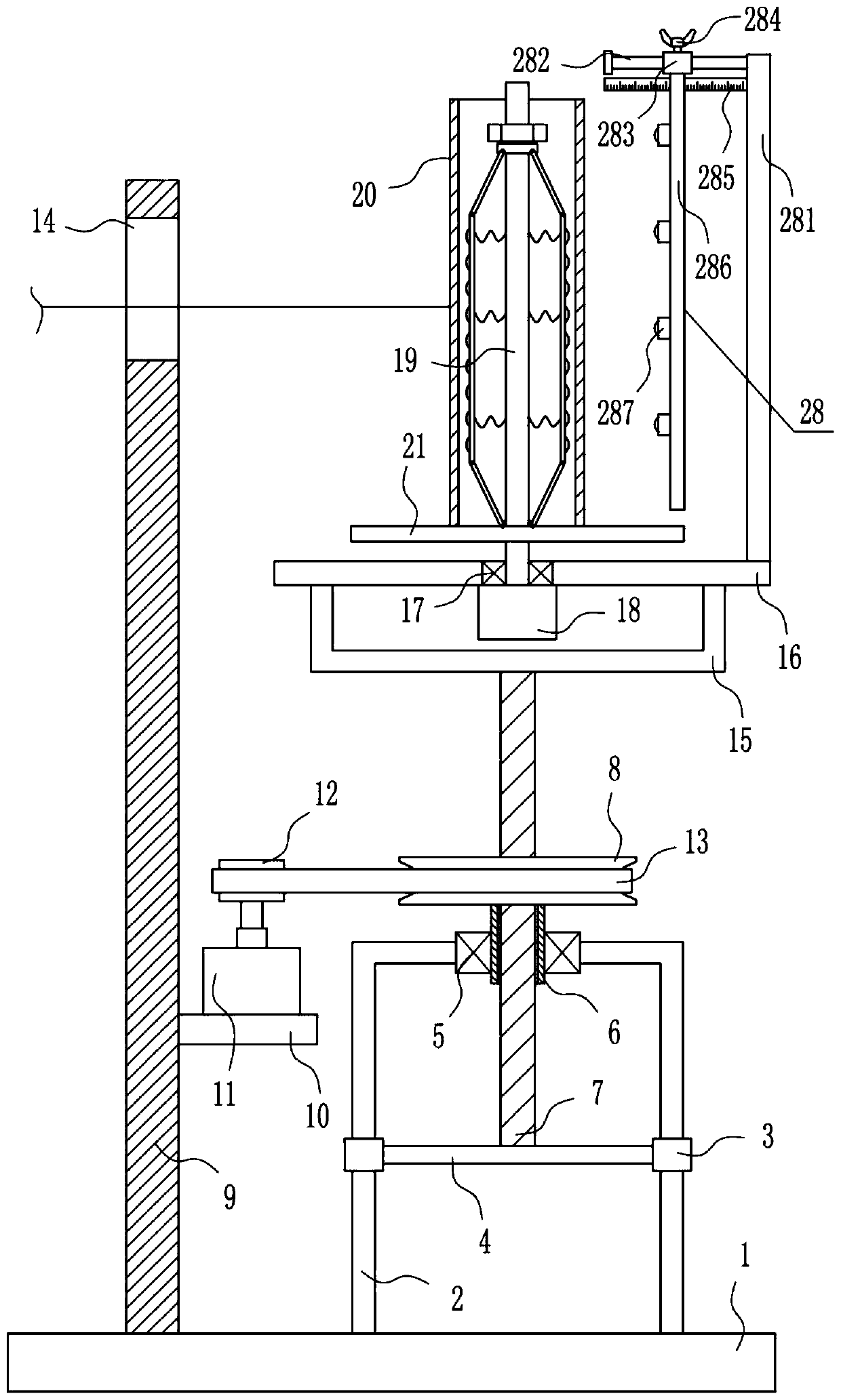

Spinning cotton thread winding device

The invention relates to a winding device, in particular to a spinning cotton thread winding device, and aims at achieving the technical purpose of providing the spinning cotton thread winding devicewhich is capable of saving time and labor and uniform in winding and does not influence later usage of a cotton thread. The spinning cotton thread winding device is provided and comprises a bottom plate, an n-shaped frame, guide sleeves, a connecting plate, a first bearing block, an inner thread sleeve, a screw, a first belt wheel, a vertical plate, a fixing plate, a first motor and the like. Then-shaped frame is arranged on the right side of the top of the bottom plate, the guide sleeves are arranged on the left side and the right side of the n-shaped frame, the connecting plate is arrangedbetween the inner side faces of the guide sleeves on the left side and the right side, and the first bearing block is embedded in the middle of the top of the n-shaped frame. Through a triggering device, the cotton thread amount of a coiling block reel can be controlled, and the needed amount is achieved; through a guiding device, the cotton thread is not loose and is better wound around a coilingblock, and the effects that the time and labor are saved, winding is uniform, and the later usage of the cotton thread is not influenced are achieved.

Owner:JIANGSU XIANGHE TEXTILE

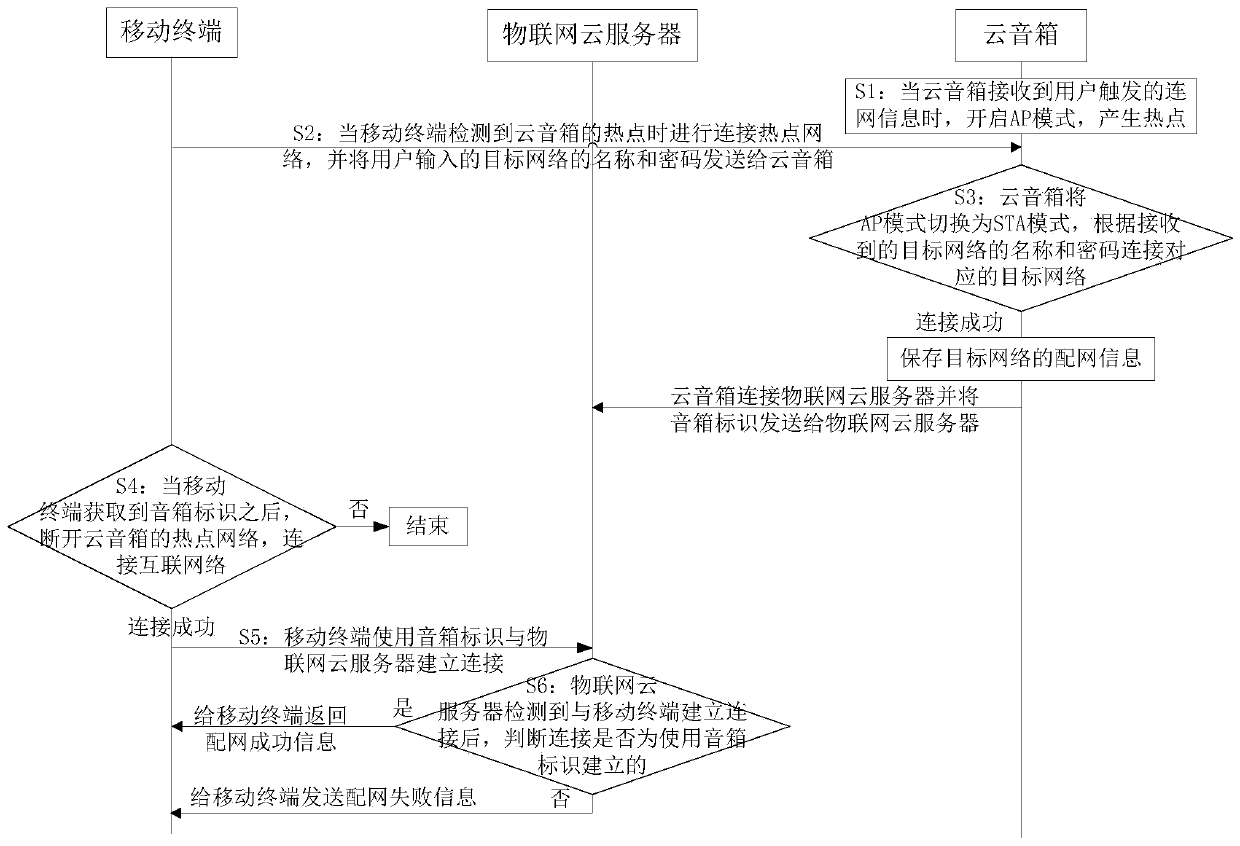

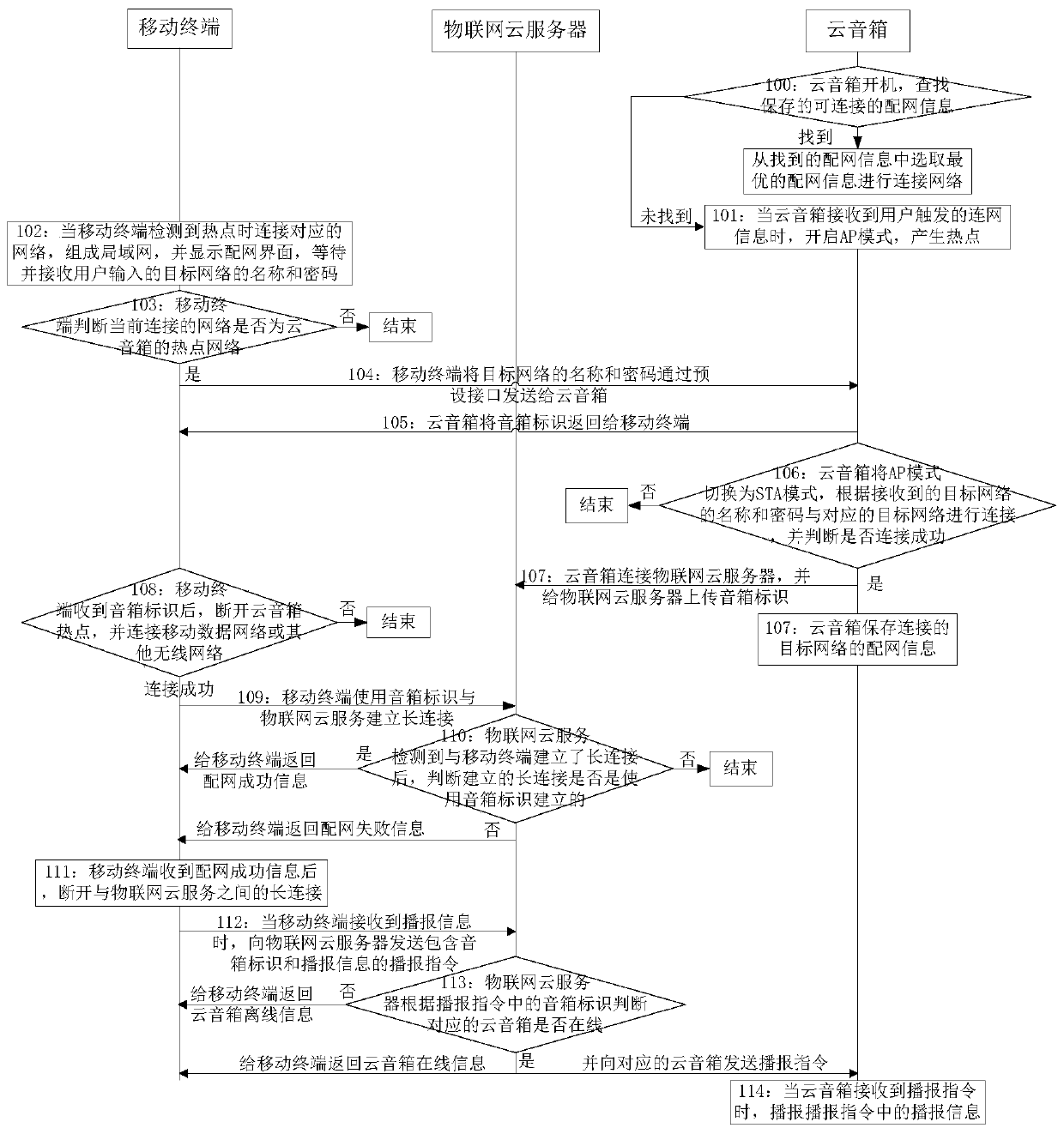

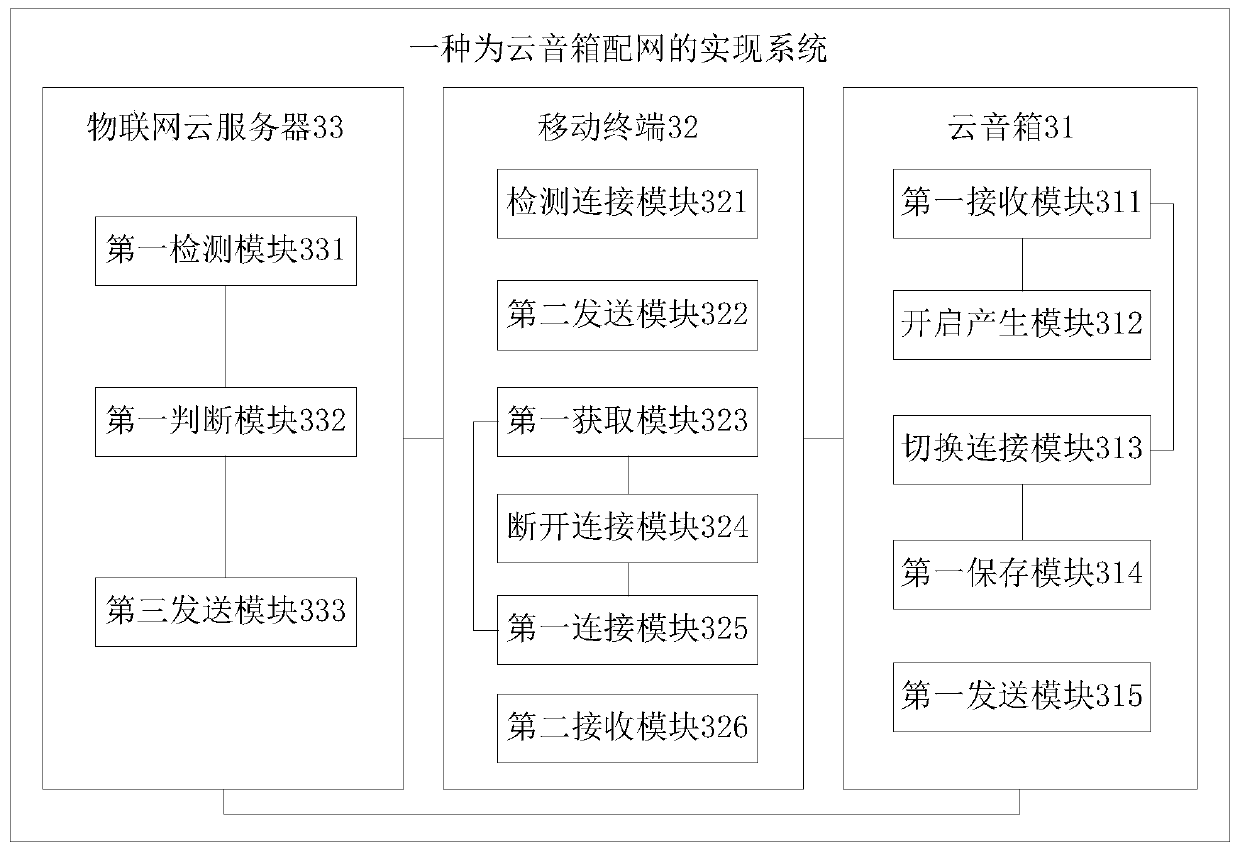

Method and device for realizing network distribution for cloud sound box

InactiveCN110225492ADoes not affect subsequent useConvenient, fast and safe network distribution modeAssess restrictionConnection managementPasswordUser input

The invention discloses a method and system for realizing network distribution for a cloud sound box, and the method comprises the steps: enabling an AP mode to generate a hot spot when the cloud sound box receives networking information triggered by a user; when the mobile terminal is connected with the hotspot network, sending a name and a password of a target network input by a user to the cloud sound box; enabling the cloud sound box to switch the AP mode into an STA mode, connect the target network according to the name and password of the target network, store the distribution network information of the target network, connect the Internet of Things cloud server, and send a sound box identifier to an Internet of Things cloud server; after the mobile terminal obtains the sound box identifier, disconnecting the hotspot network of the cloud sound box, connecting the Internet, and if the connection is successful, establishing the connection with the Internet of Things cloud server byusing the sound box identifier; and enabling the Internet of Things cloud server to judge whether the connection is established by using the sound box identifier, if yes, network distribution successinformation is returned to the mobile terminal, and if not, network distribution failure information is sent to the mobile terminal. According to the invention, a convenient, fast and safe network distribution mode is realized.

Owner:FEITIAN TECHNOLOGIES

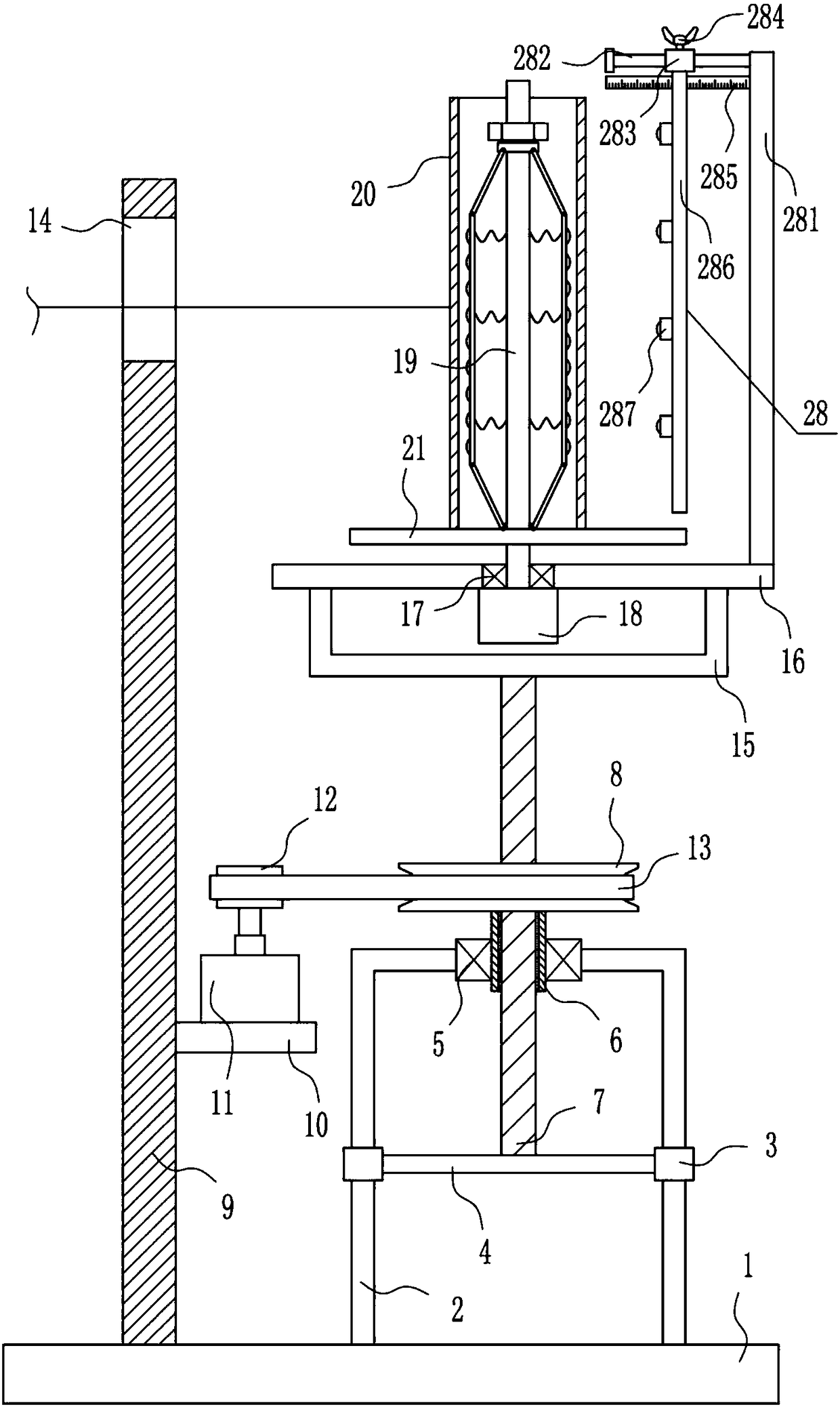

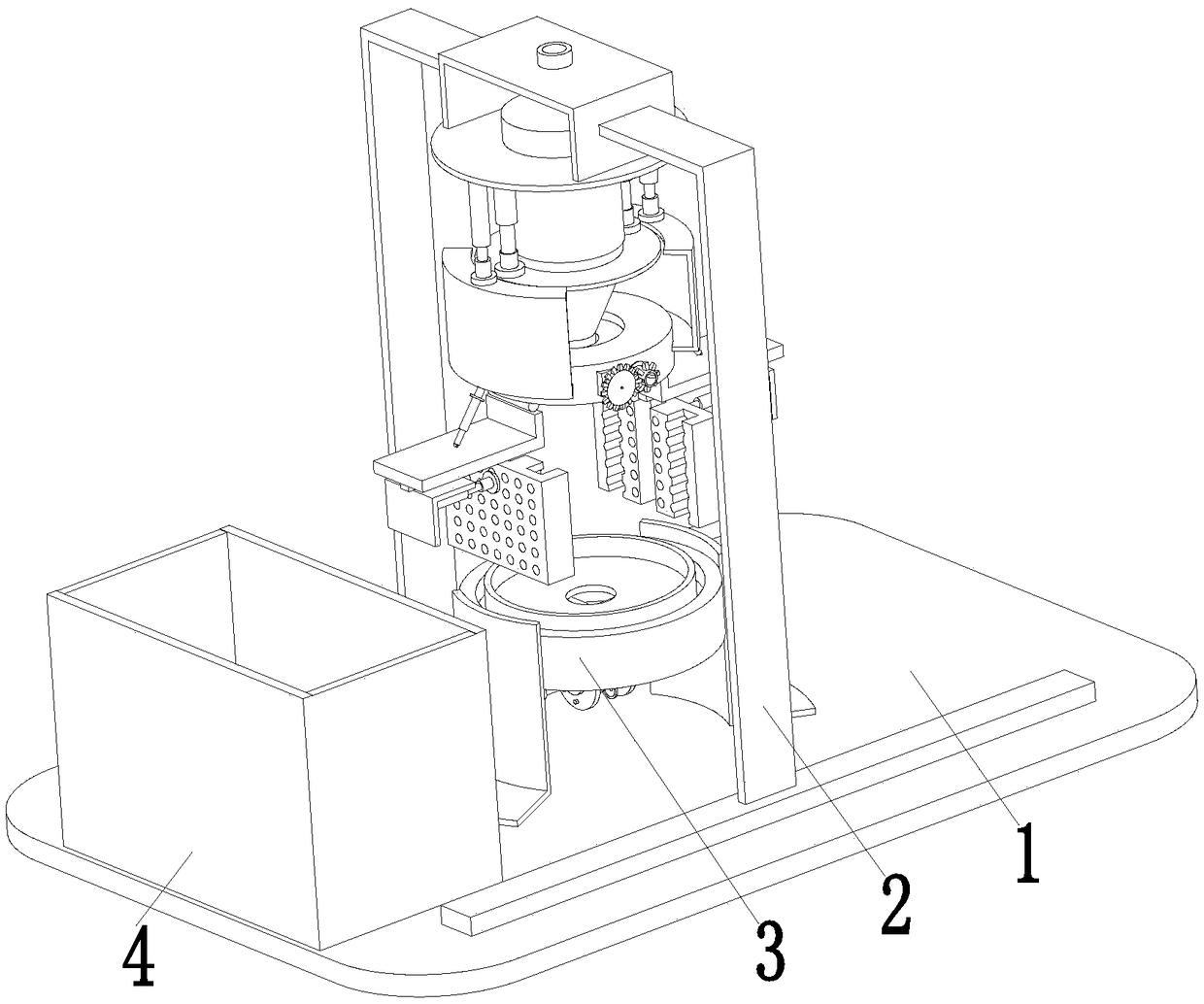

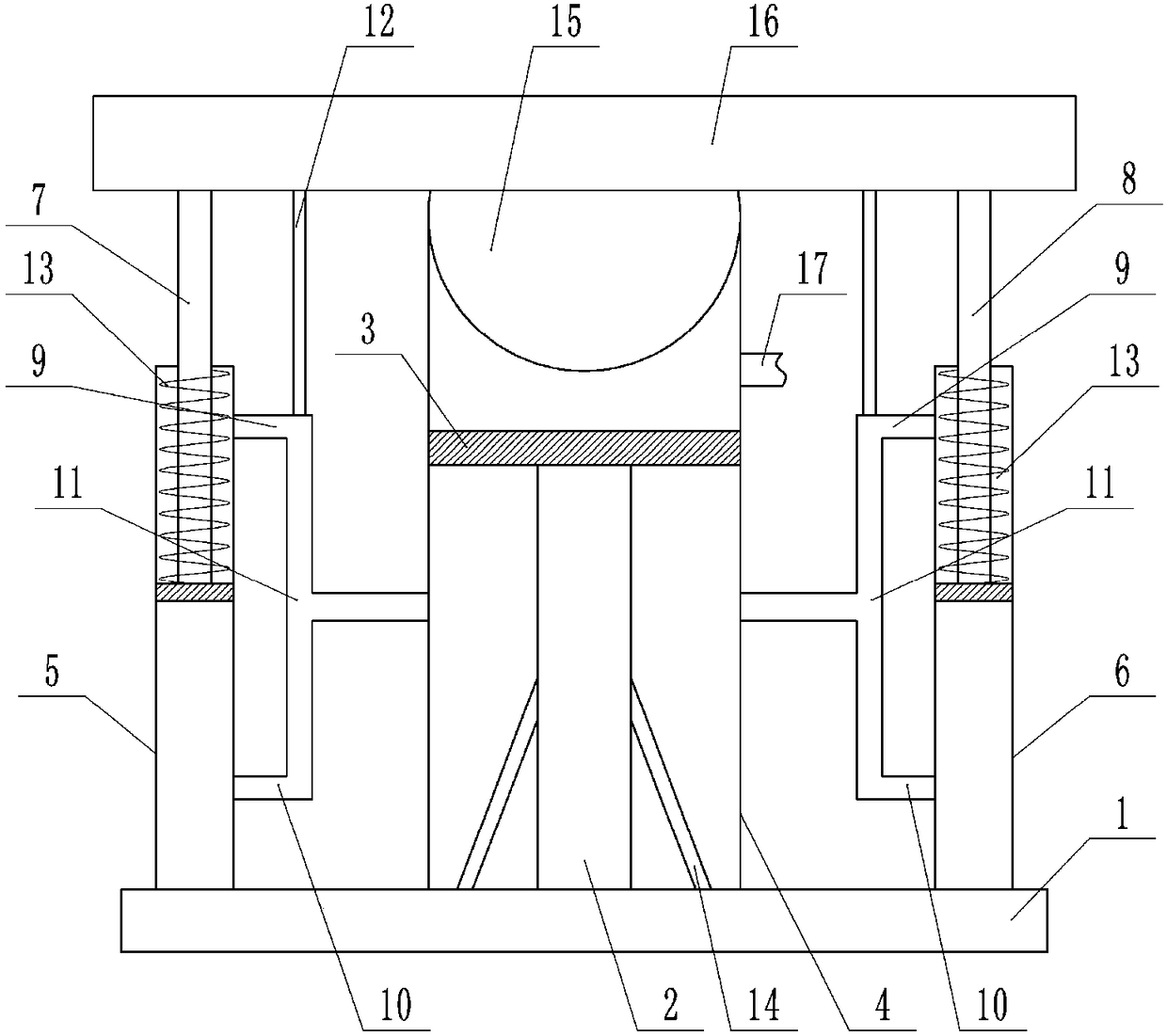

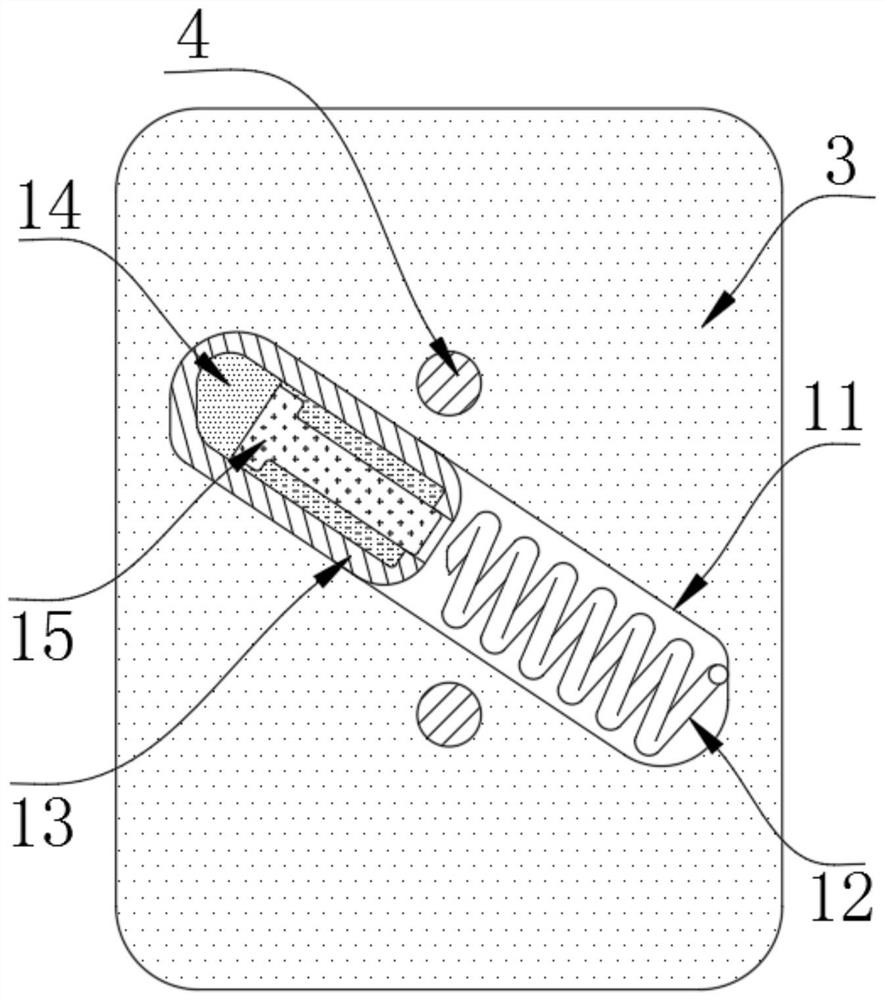

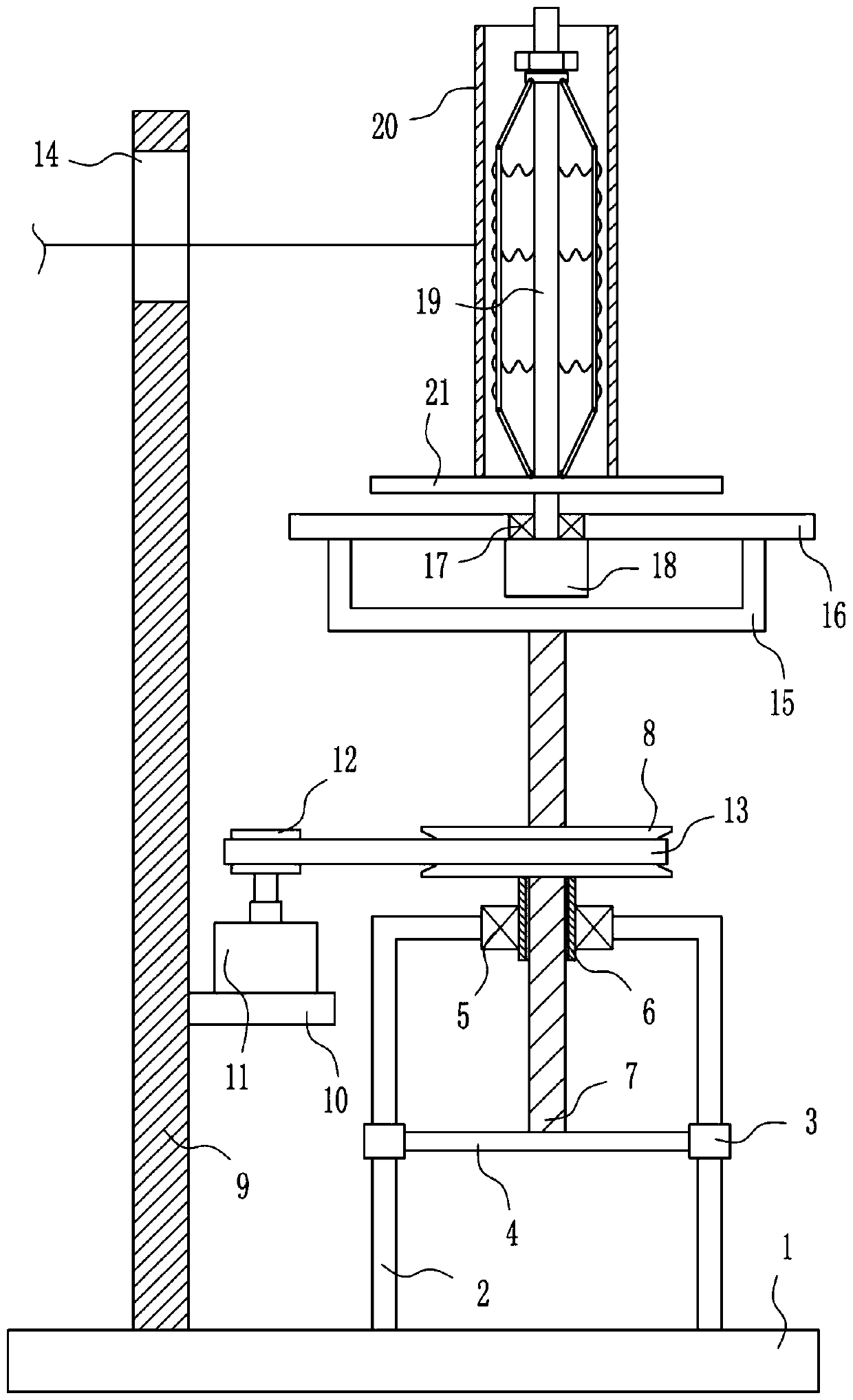

Device for detecting medical sterile glove for surgery

ActiveCN108956033AReduce labor intensityImprove efficiencyDetection of fluid at leakage pointDisinfectantEngineering

The invention relates to a device for detecting a medical sterile glove for a surgery. The device comprises a bottom plate, and a fixed sealing device, a tensioning control device and a test water tank are mounted on the bottom plate, wherein the tensioning control device is located directly under the fixed sealing device, and the test water tank is located at the front side of the bottom plate. The manual detection of the airtightness of a sterile glove is needed during the existing production inspection process of the medical sterile glove, the glove needs to be manually inflated, an openingof the glove needs to be manually expanded, an air pump is manually inserted into the glove, the glove during an inflation process is manually sealed, the inflated glove is manually immersed into a disinfectant for observation, the manual detection of the sterile glove has a bacterial infection problem, the procedure of manually wearing sterile clothes is tedious, the manually tested sterile glove can only be treated as garbage, resources are wasted, the labor intensity is large, and the working efficiency is low, the problems can be solved by the device, and the function of the automatic airtightness detection of the medical sterile glove can be achieved.

Owner:山东英科医疗制品有限公司

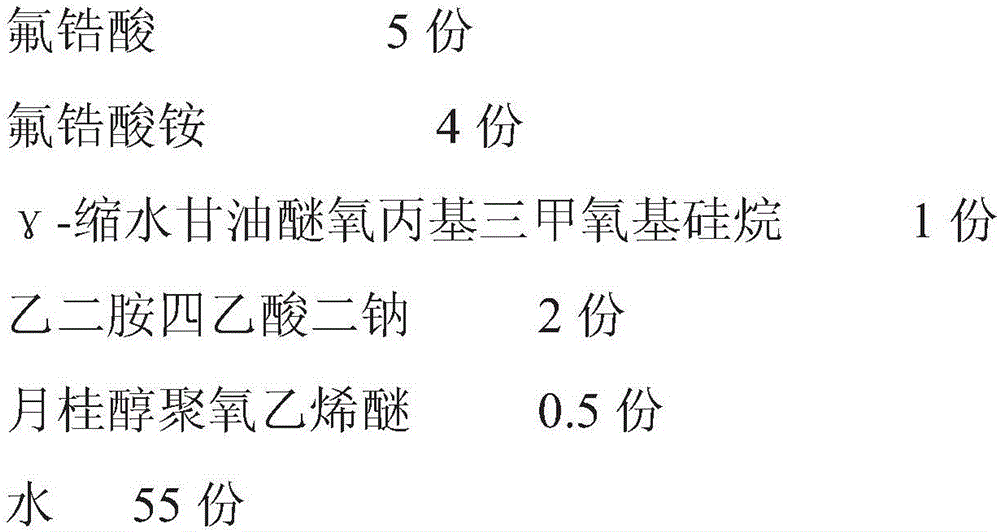

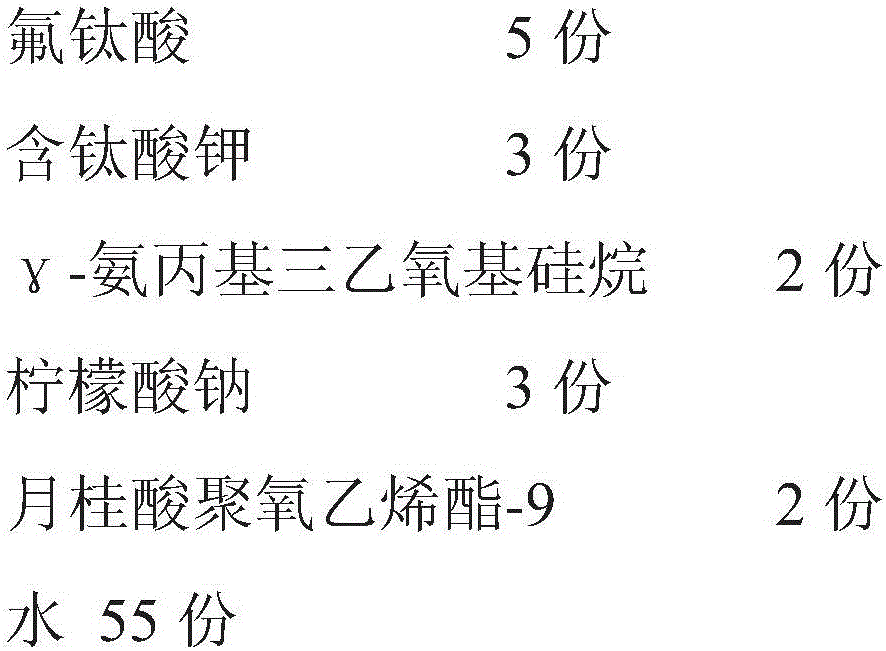

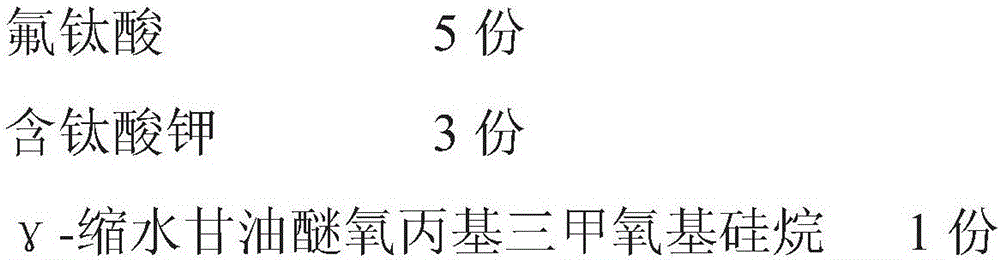

Method for regenerating vanadium-titanium SCR denitration catalyst by utilizing regeneration activity complementing solution

PendingCN108355722AAvoid reunionIncrease profitCatalyst regeneration/reactivationIonAqueous solution

The invention discloses a method for regenerating a vanadium-titanium SCR denitration catalyst by utilizing a regeneration activity complementing solution. The method comprises the steps of deactivated catalyst preliminary treatment, ultrasonic water washing, acid pickling, novel regeneration activity complementing solution preparation, novel regeneration activity complementing solution dipping, microwave calcining treatment and the like. A complexation product of a valonea extract aqueous solution and vanadium serves as a novel regeneration activity complementing solution; through uniform adsorption of organic matters to the surface of the catalyst and stabilization of complexing ions, vanadium can form a uniform load layer on the surface of the catalyst, the production efficiency of regeneration of the deactivated catalyst is increased, and the load amount of active ingredients on the surface of the catalyst is increased; complexed organic matters can be simply removed through a microwave calcining method, the implementation is easy, and the subsequent use of the regenerated catalyst is unaffected; the agglomeration of vanadium in the solution and on the surface of the catalyst is effectively avoided, the utilization ratio of vanadium is increased, the consumption of vanadium required for regeneration is lowered, and thus, the overall regeneration cost is reduced.

Owner:HUANENG CLEAN ENERGY RES INST

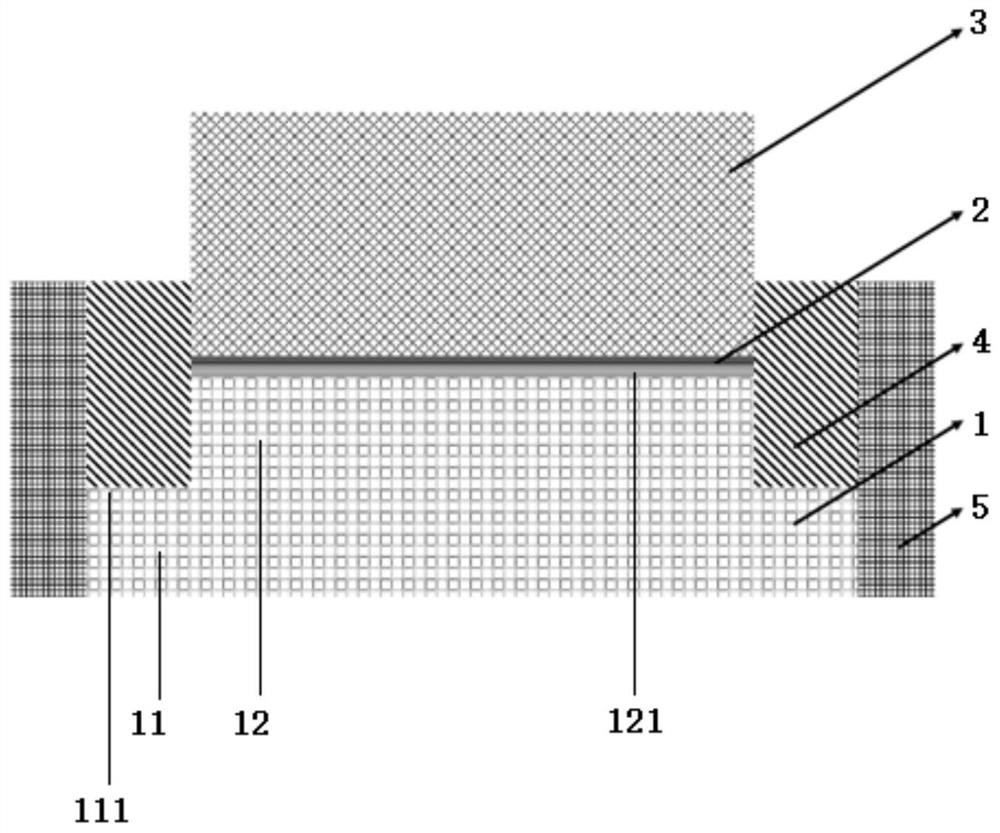

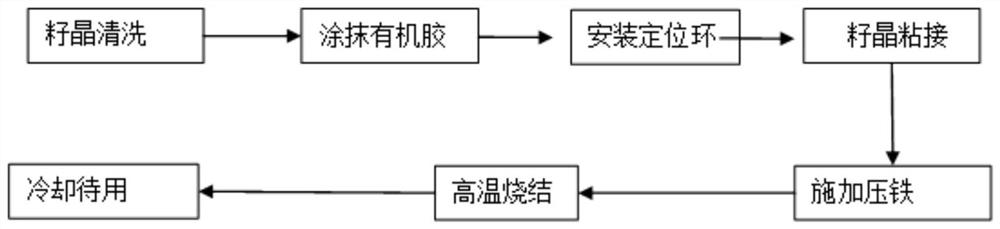

Method for improving bonding quality of silicon carbide seed crystals

InactiveCN112725892AClever settingGuaranteed flatnessPolycrystalline material growthAfter-treatment detailsCarbide siliconPhysical chemistry

The invention provides a method for improving the bonding quality of silicon carbide seed crystals. The bonding quality of the SiC seed crystals is one of the most basic and most important influence factors influencing crystal growth, the bonding quality directly determines the quality of the crystals, and the crystals are difficult to remedy or improve through control of other technological parameters. A weight is added on the upper surface of the seed crystals, and the weight applies a vertically downward acting force so that gas escape is facilitated. A fixed ring is designed to ensure that the seed crystals do not deviate. The fixed ring is made of high-purity graphite so that pollution of other materials is reduced. The height of the fixed ring is 20-50 mm, and the thickness of the fixed ring is 5-10 mm. In order to reduce the temperature gradient and improve the uniformity of seed crystal bonding, a circle of high-purity graphite felt wraps the periphery of the fixed ring, and the height of the high-purity graphite felt is the same as that of the fixed ring. The graphite felt reduces the pollution to the graphite cover and the seed crystals, enhances the heat preservation property, and reduces the temperature gradient inside and outside the graphite cover.

Owner:北京汇琨新材料有限公司

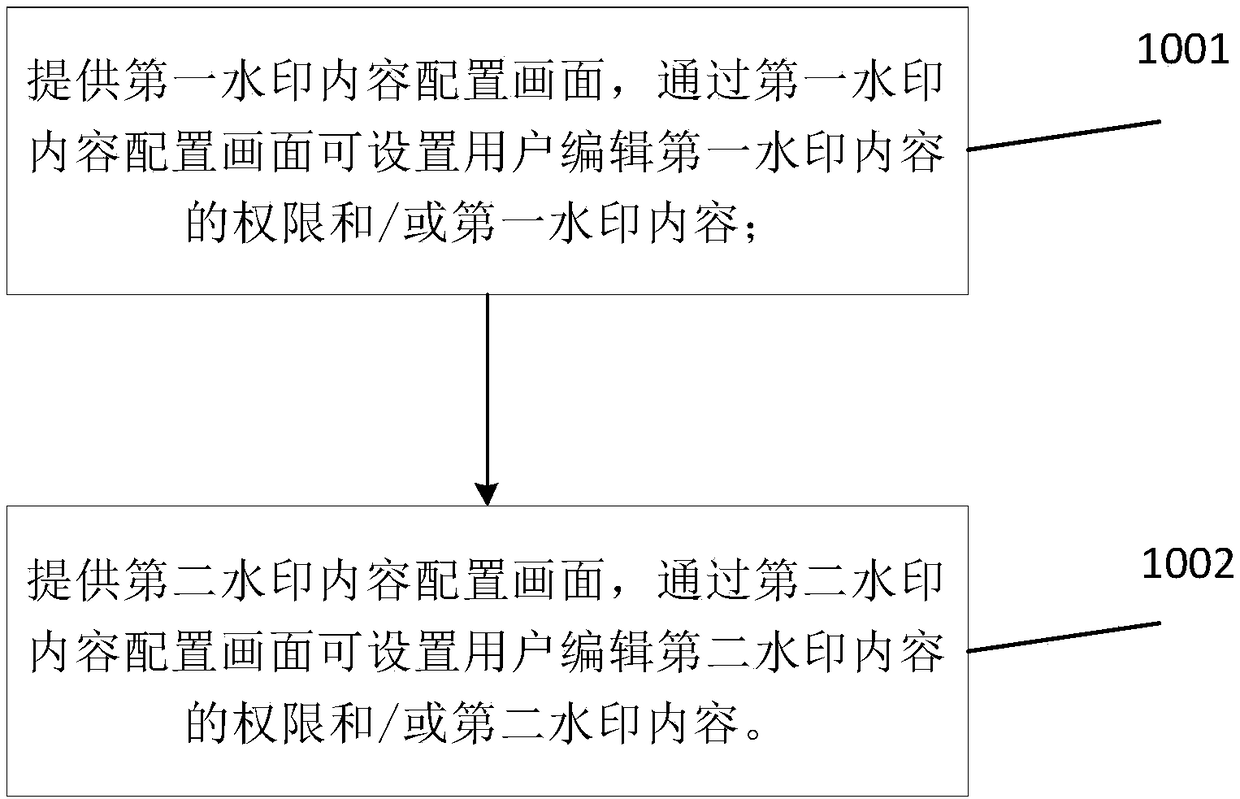

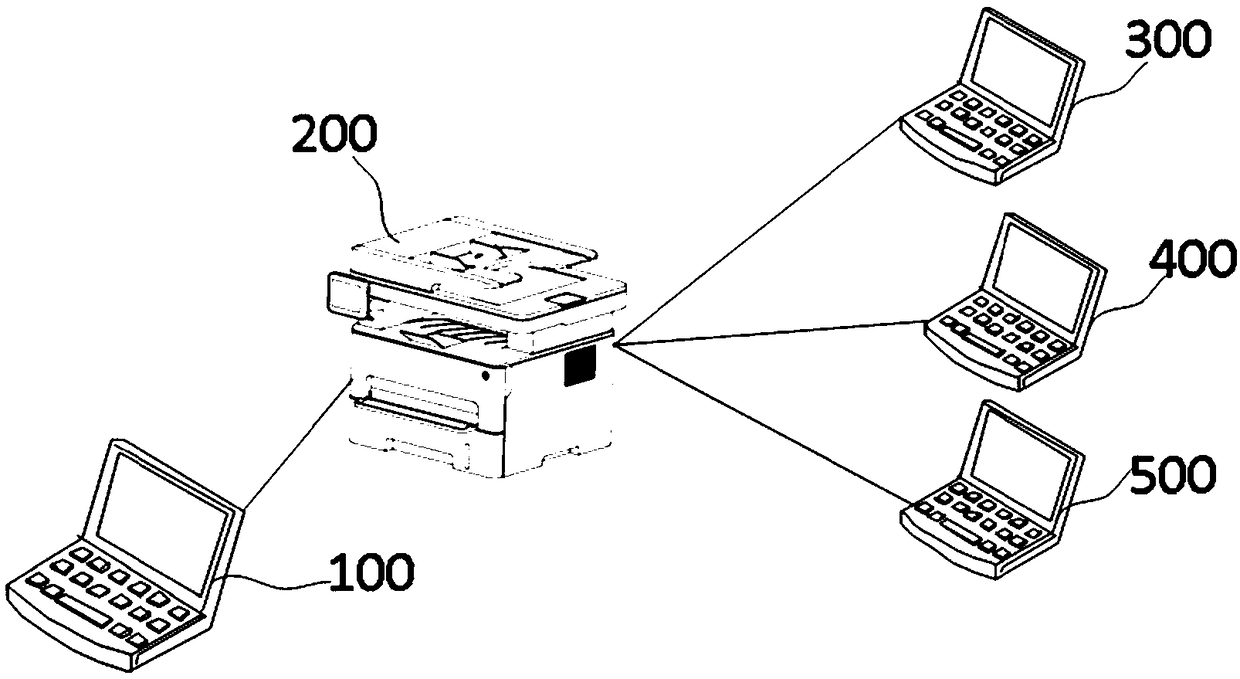

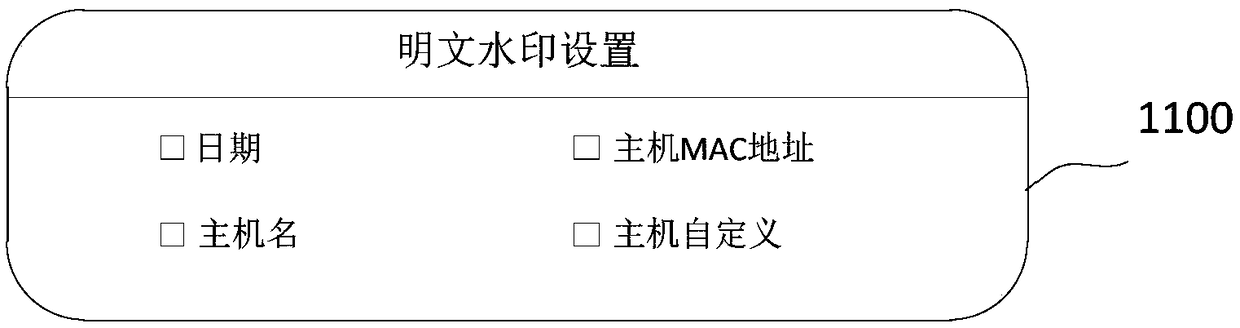

Watermark configuration method, watermark configuration apparatus, and image formation apparatus

PendingCN108765252AMeet the needs of traceabilityEasy to make trackingImage data processing detailsPersonalizationComputer graphics (images)

The invention provides a watermark configuration method, a watermark configuration apparatus, and an image formation apparatus. The method includes steps: providing a first watermark content configuration picture, and setting a permission for editing first watermark content by a user and / or first watermark content through the first watermark content configuration picture; and providing a second watermark content configuration picture, and setting a permission for editing second watermark content by the user and / or second watermark content through the second watermark content configuration picture, wherein after a first watermark is inserted into a document, the corresponding first watermark content is visible, and after a second watermark is inserted into the document, the corresponding second watermark content is invisible, or the corresponding second water market cannot be directly seen. According to the technical scheme, the user and / or an administrator can edit different watermarkcontents so that the requirement of watermark management for the administrator can be met, and the personalized requirements of watermark setting for different users can be met.

Owner:ZHUHAI PANTUM ELECTRONICS

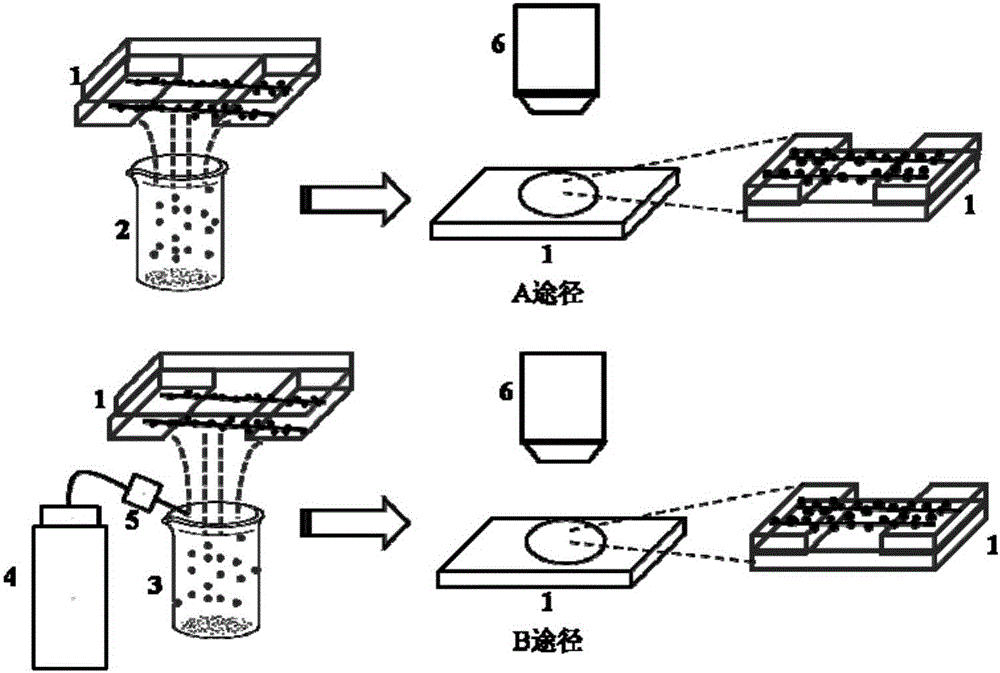

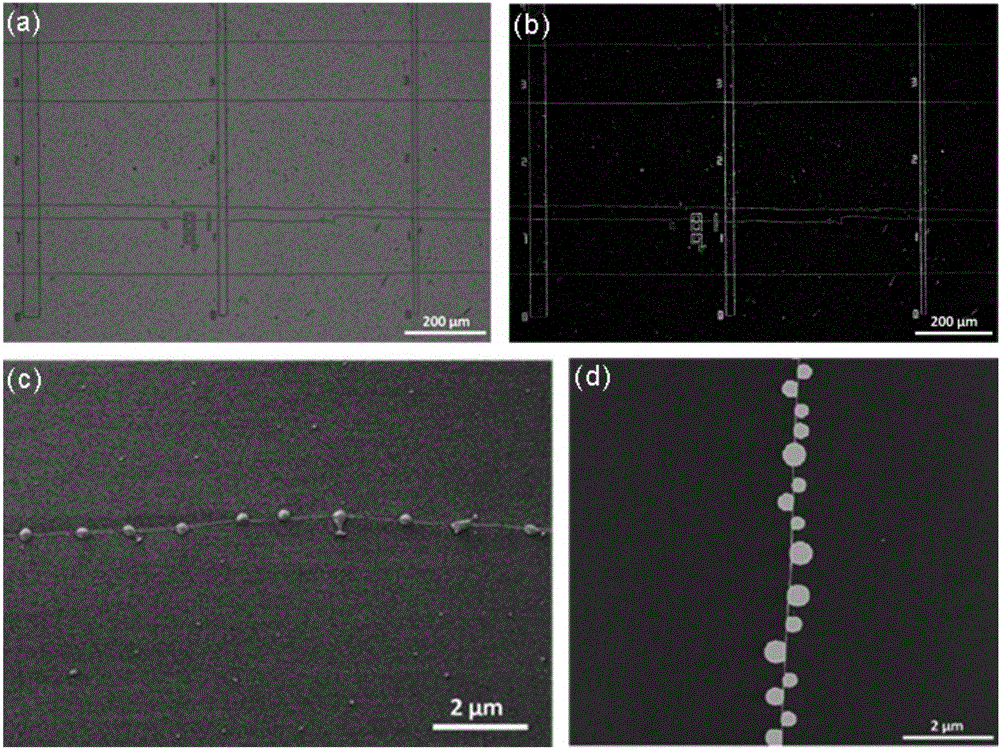

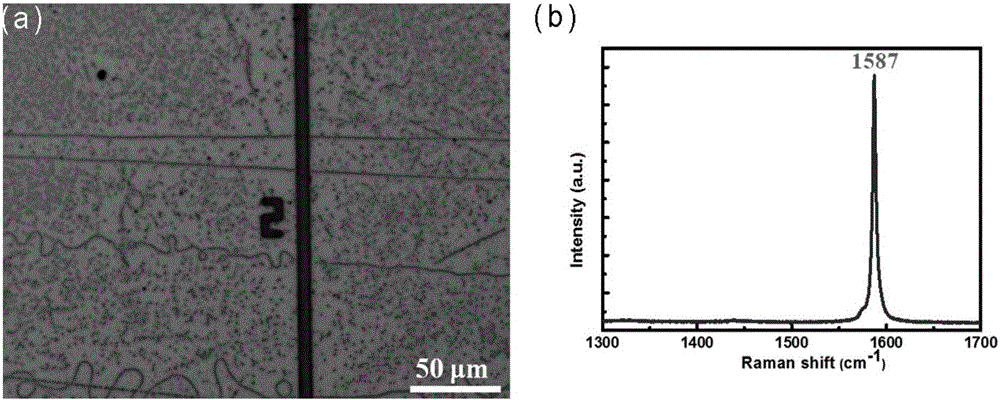

Method for achieving optical visualization of low-dimensional nanomaterials

ActiveCN105158158ALow toxicityDoes not affect subsequent useMaterial analysis by optical meansAmmonium sulfateLaboratory research

The invention discloses a method for achieving optical visualization of low-dimensional nanomaterials, and one or more sublimable / volatile markers are deposited on the nanomaterials. The method comprises the following steps: the marker is placed in a vessel, and is heated in the atmospheric environment; a substrate containing the low-dimensional nanomaterials is placed above the marker, and the marker is deposited on the nanomaterials, and the substrate is taken down and observed by utilizing an optical microscope. The marker is selected from one or more of sublimed sulfur, metallo-organic compound, inorganic ammonium salt, carbamide, ammonium persulfate, paraffin or fatty acid. Compared with the prior art, the method is simple and high in applicability and controllability, the low-dimensional nanomaterials do not need to be pretreated, and the location of the nanomaterials under a common optical microscope is realized; the laboratory investigation and industrial manufacture as well as application of the nanomaterials are greatly convenient; the adopted marker can be controllably removed, pollution and destruction of nanomaterials do not exist, and the later use of the nanomaterials is not influenced.

Owner:TSINGHUA UNIV

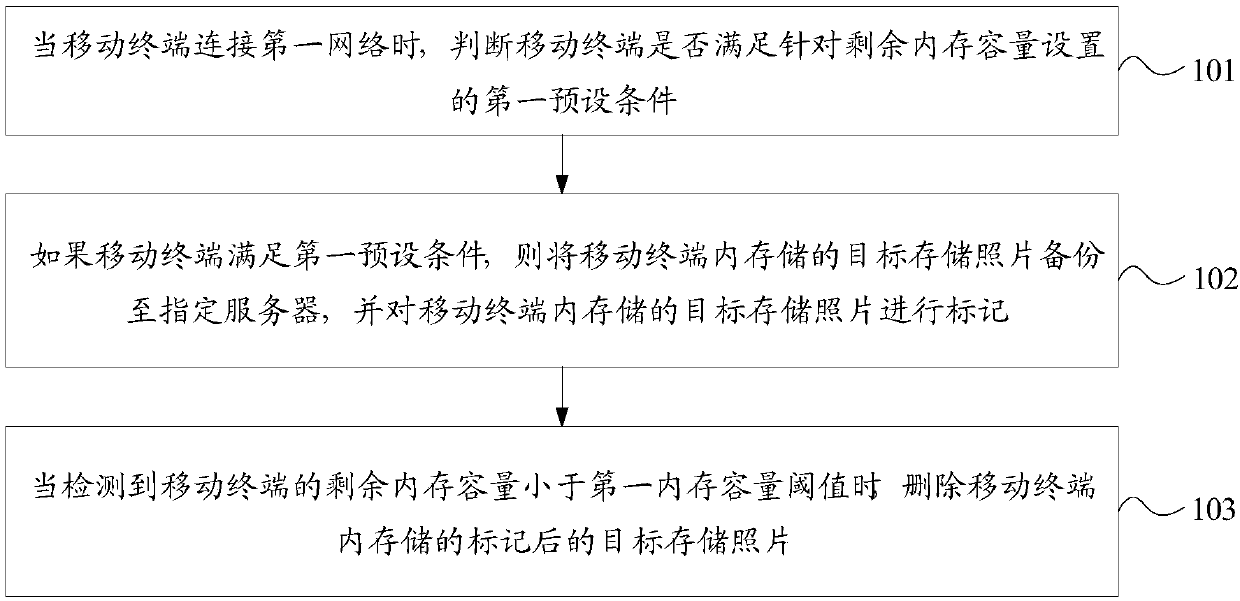

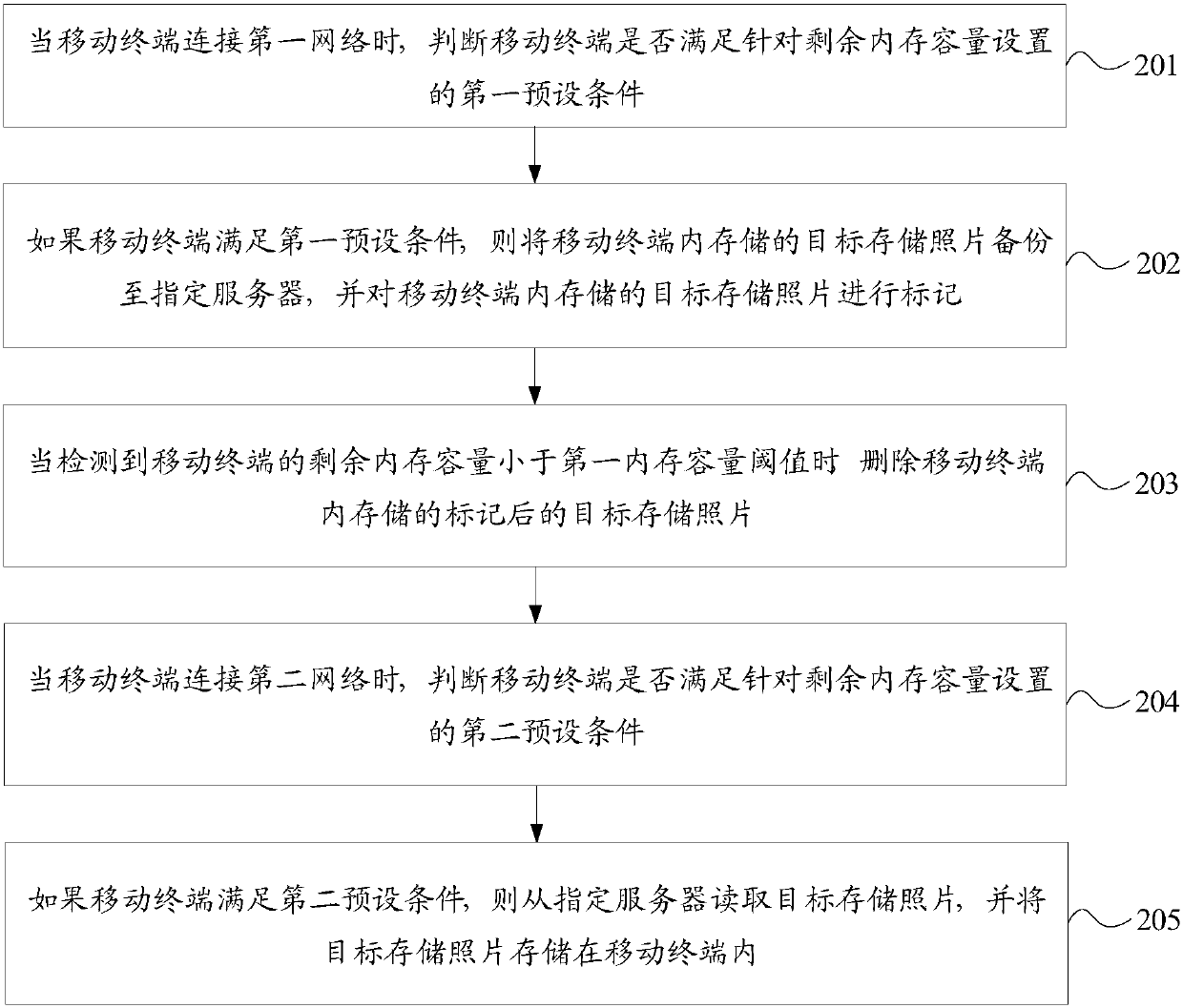

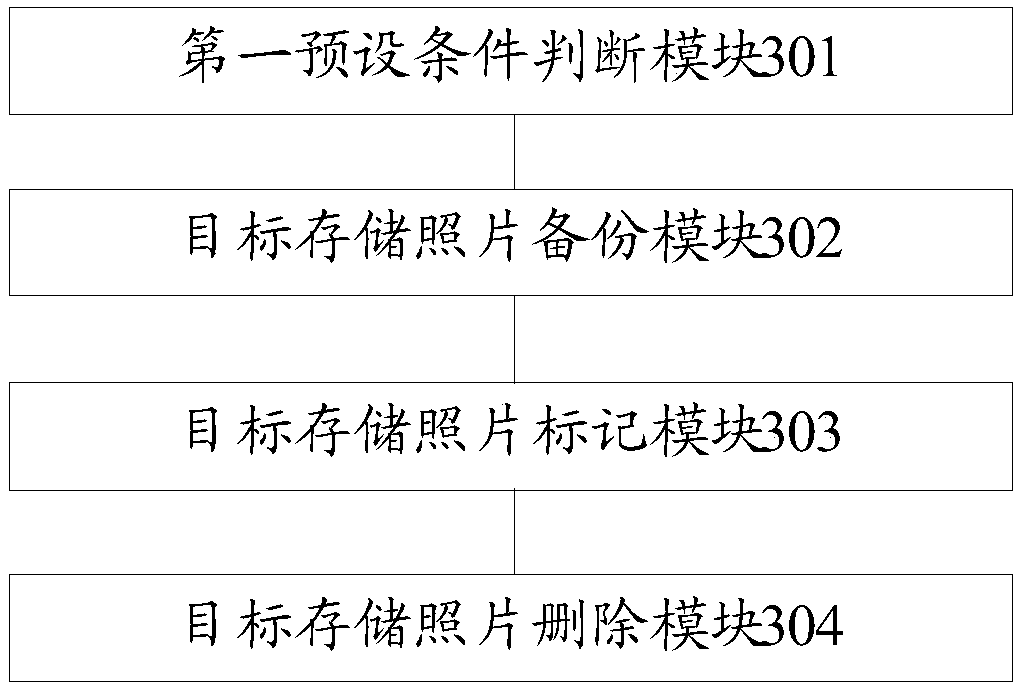

Photograph processing method and mobile terminals

InactiveCN107608823AEnable smart recoveryEasy to viewResource allocationTransmissionComputer science

The embodiment of the invention discloses a photograph processing method and mobile terminals. The method is applied to the mobile terminals, and includes: when the mobile terminal is connected to a first network, determining whether the mobile terminal meets a first preset condition set for remaining memory capacity; if the mobile terminal meets the first preset condition, backing up target storage photographs, which are stored in the mobile terminal, to a designated server, and labeling the target storage photographs stored in the mobile terminal; and deleting the labeled target storage photographs, which are stored in the mobile terminal, to release memory capacity of the mobile terminal when it is detected that the remaining memory capacity of the mobile terminal is less than a first memory capacity threshold value. Through a method of deleting the labeled target storage photographs, the problem of insufficient remaining memory capacity of the mobile terminal is solved while intelligent backing-up of the target storage photographs is realized, and the deleted photographs can be acquired again through a manner of downloading from the designated server.

Owner:VIVO MOBILE COMM CO LTD

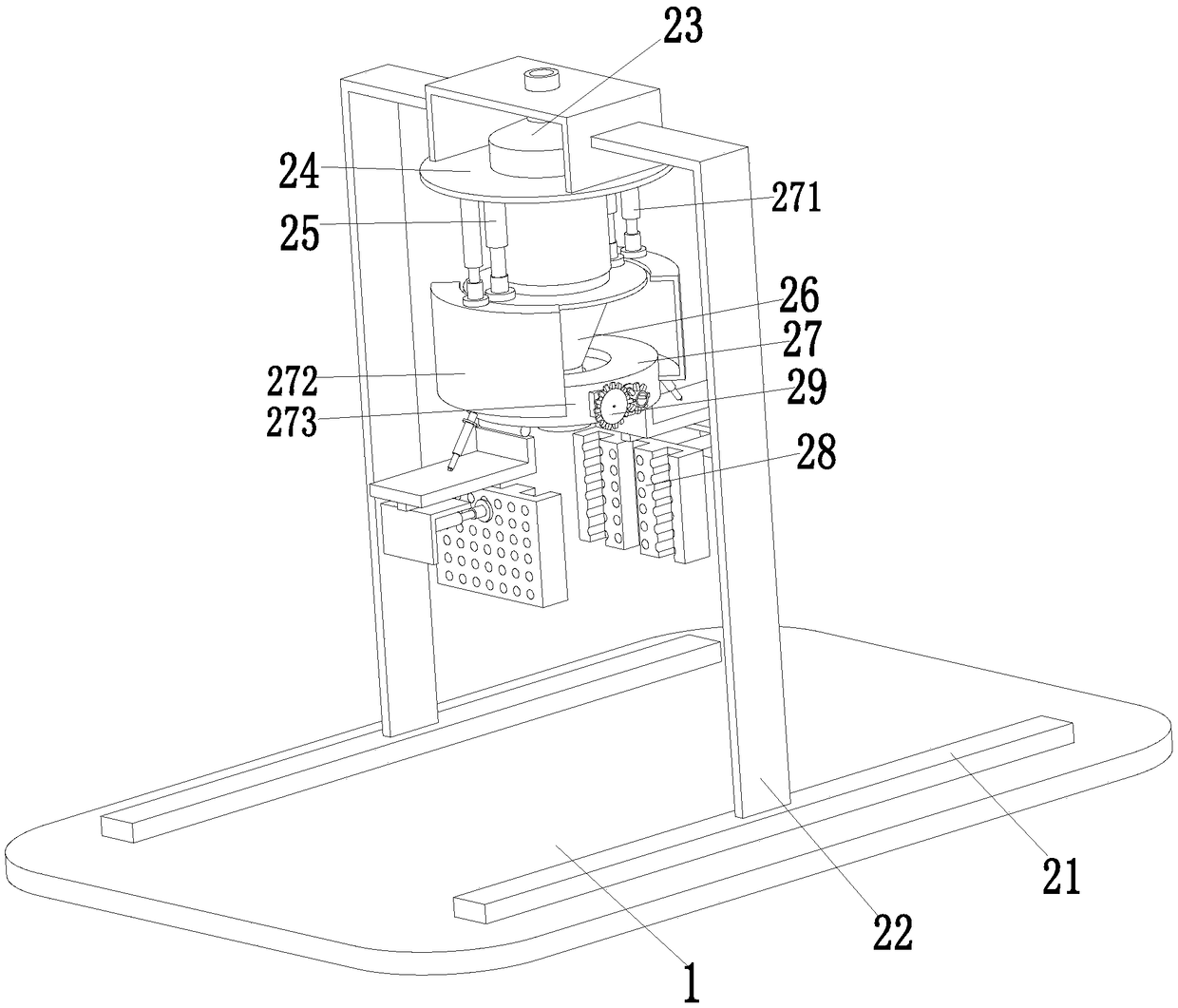

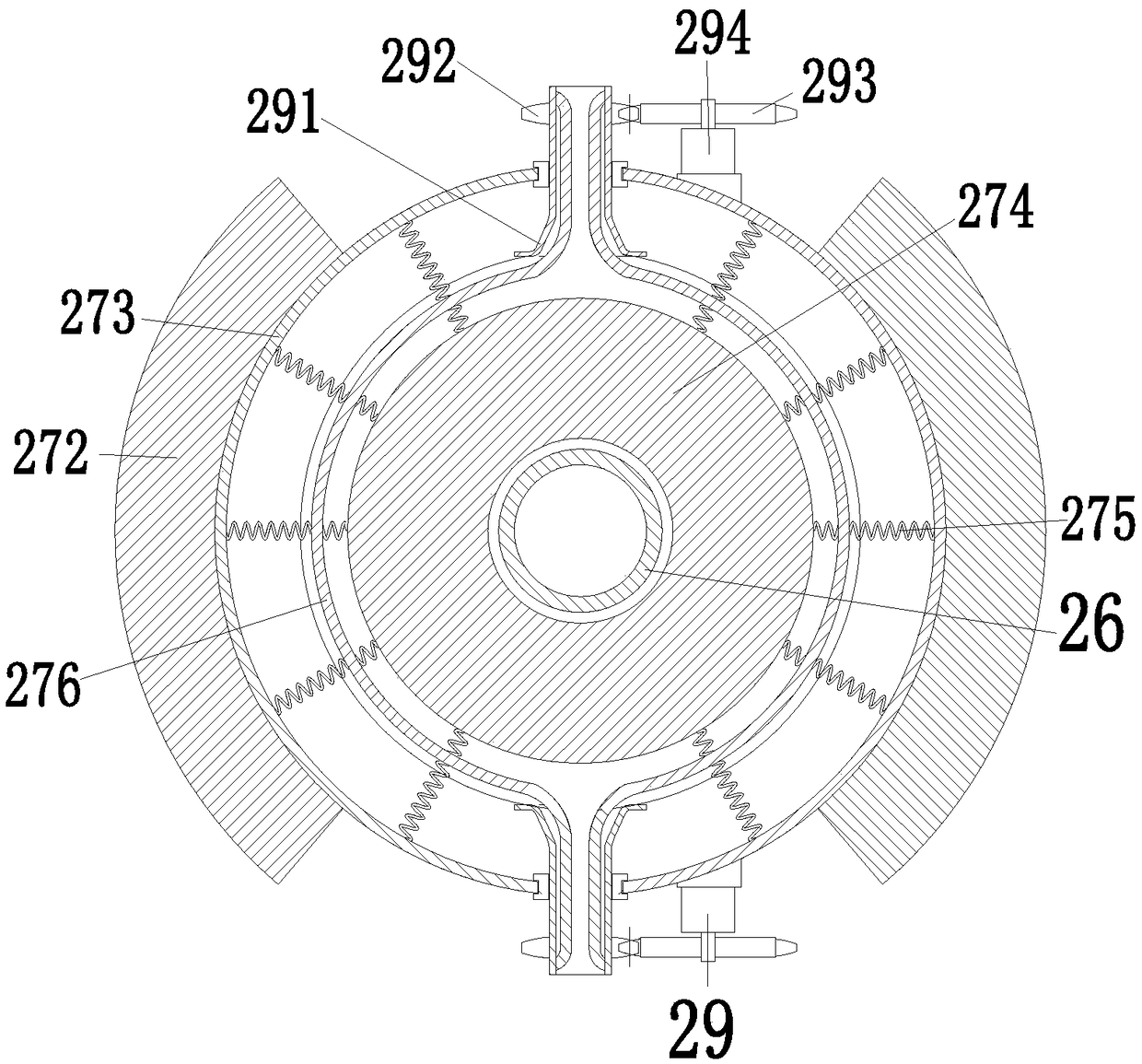

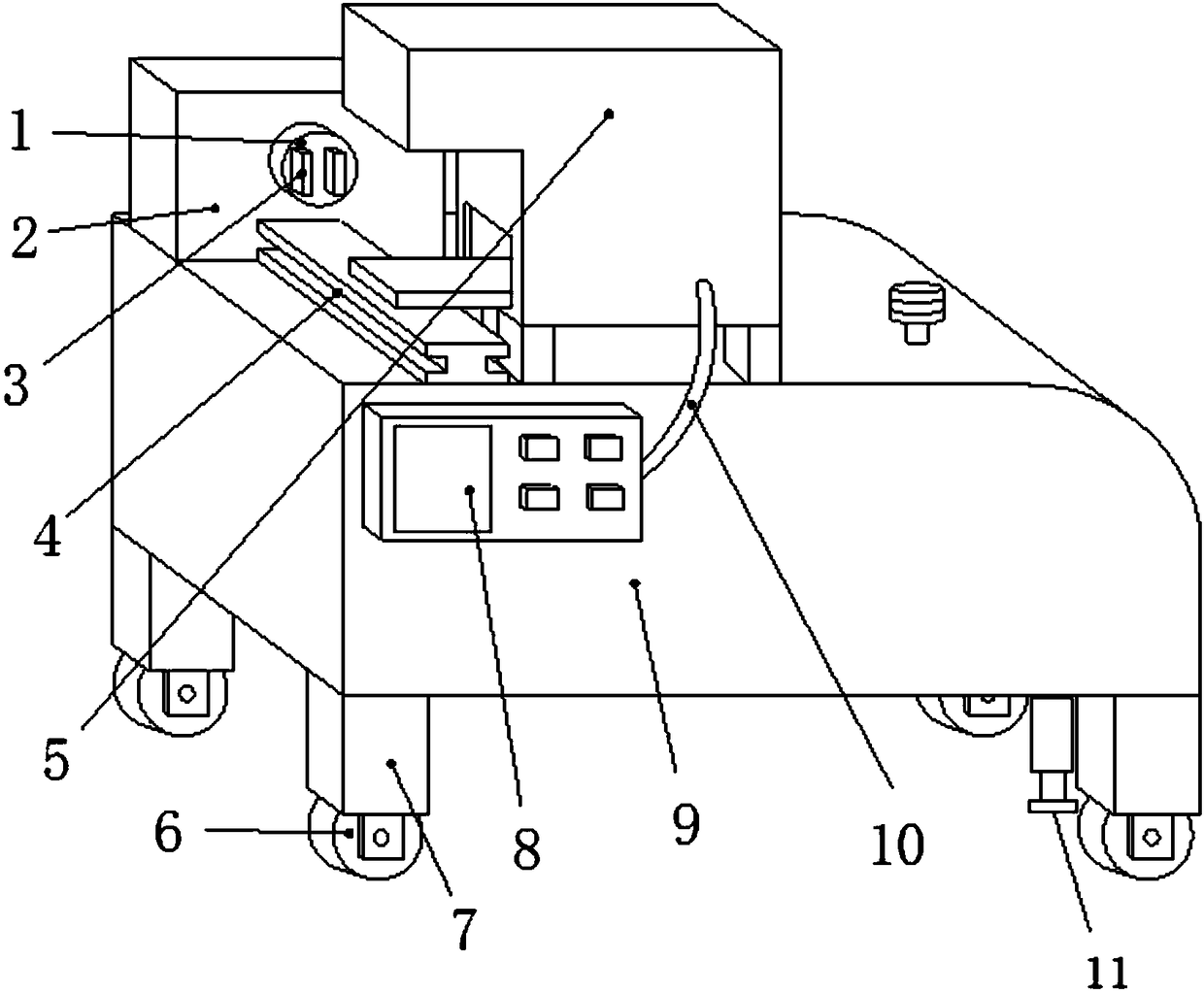

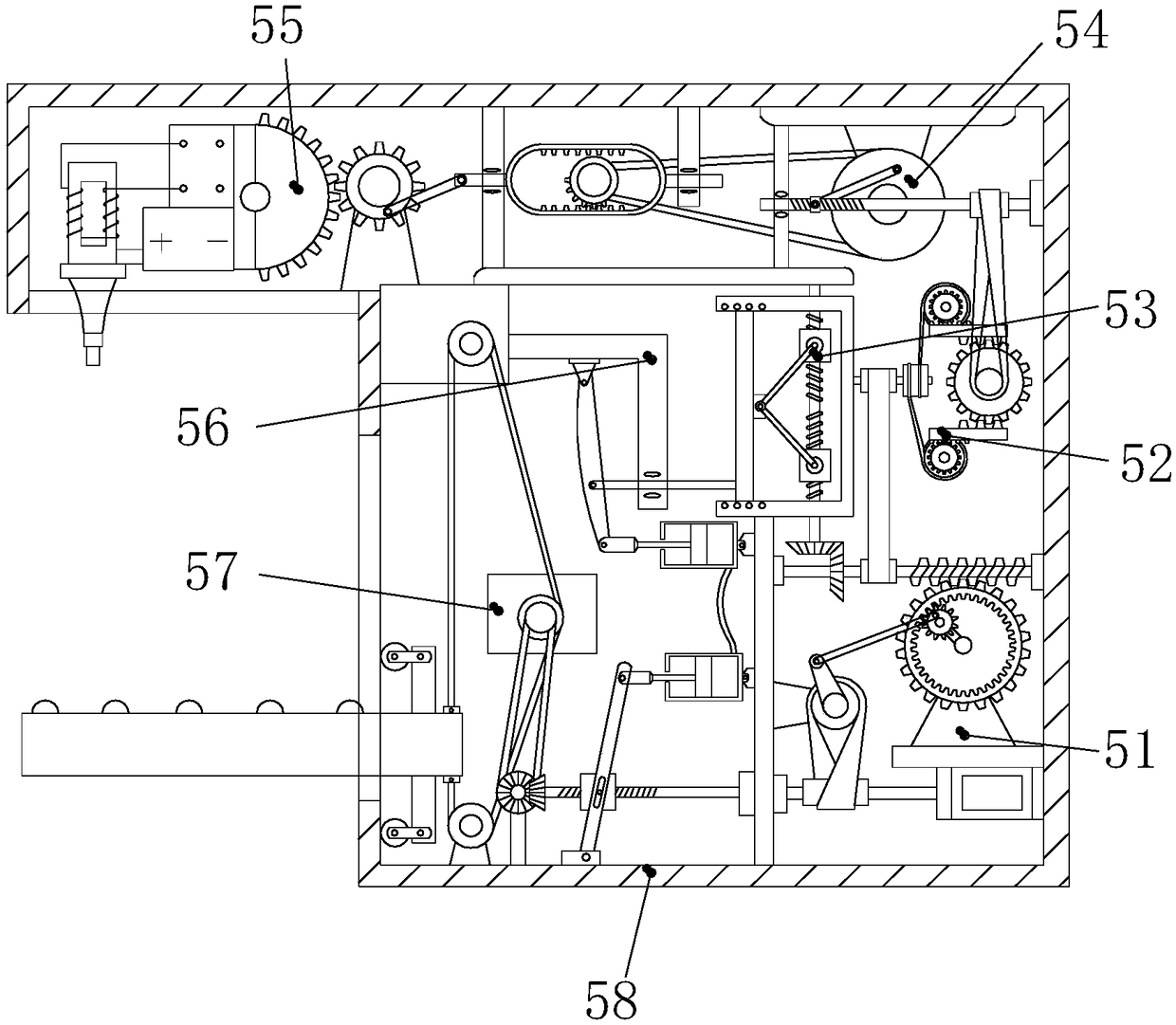

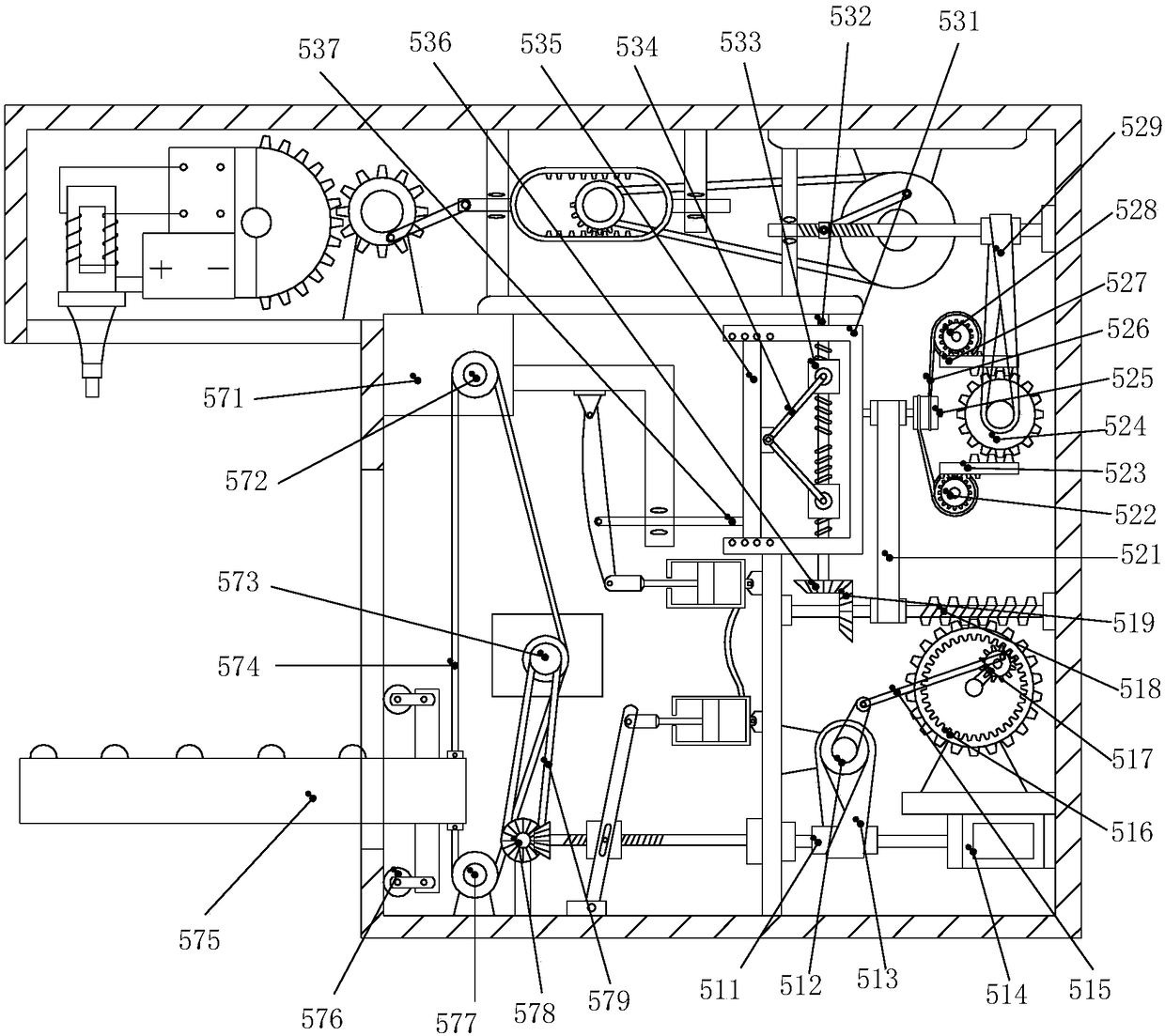

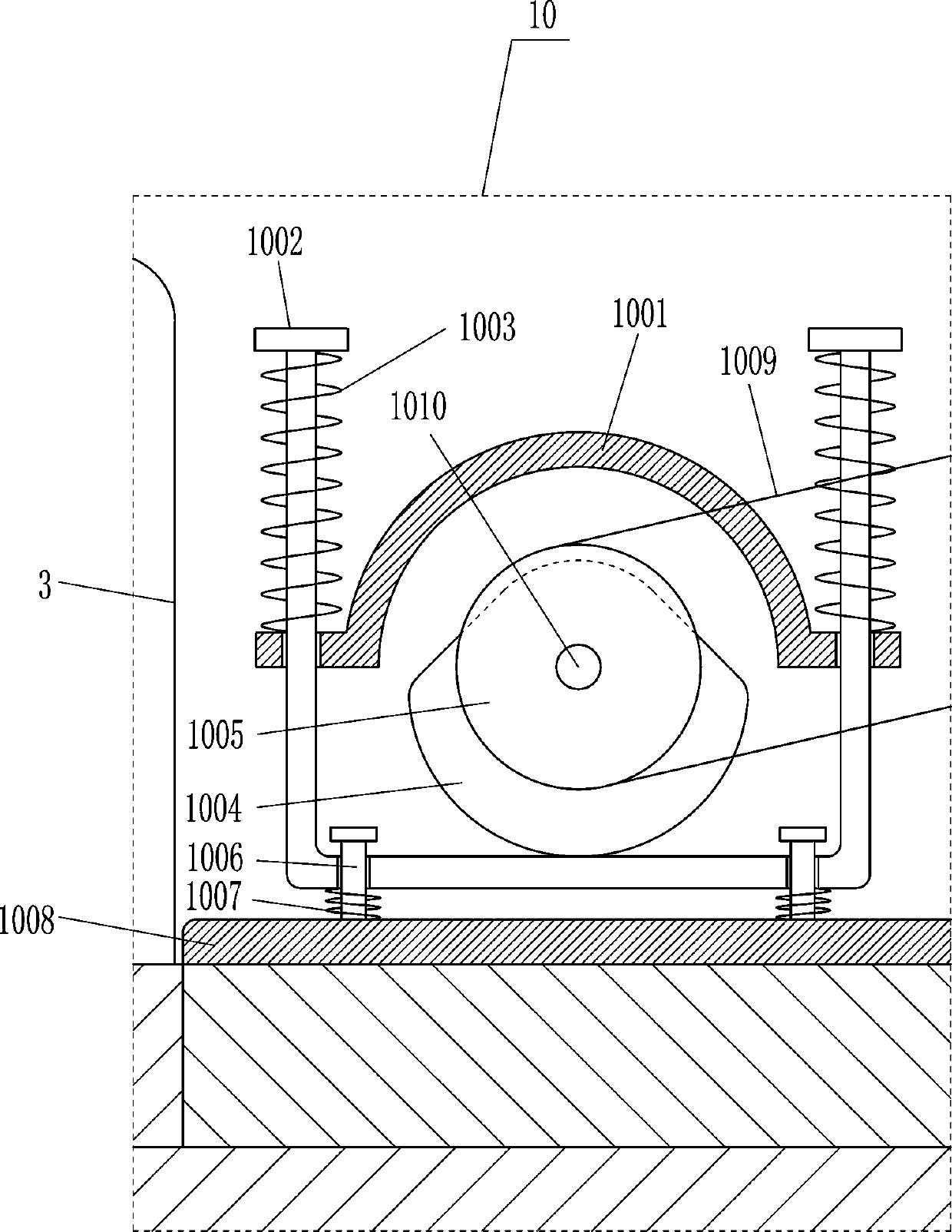

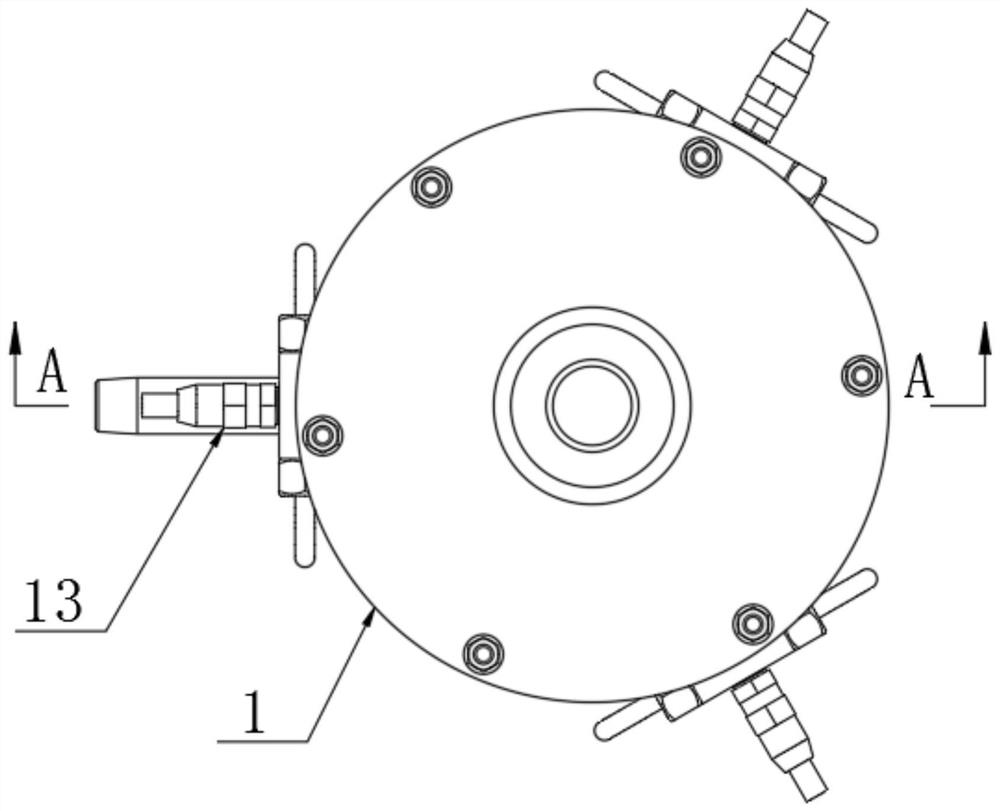

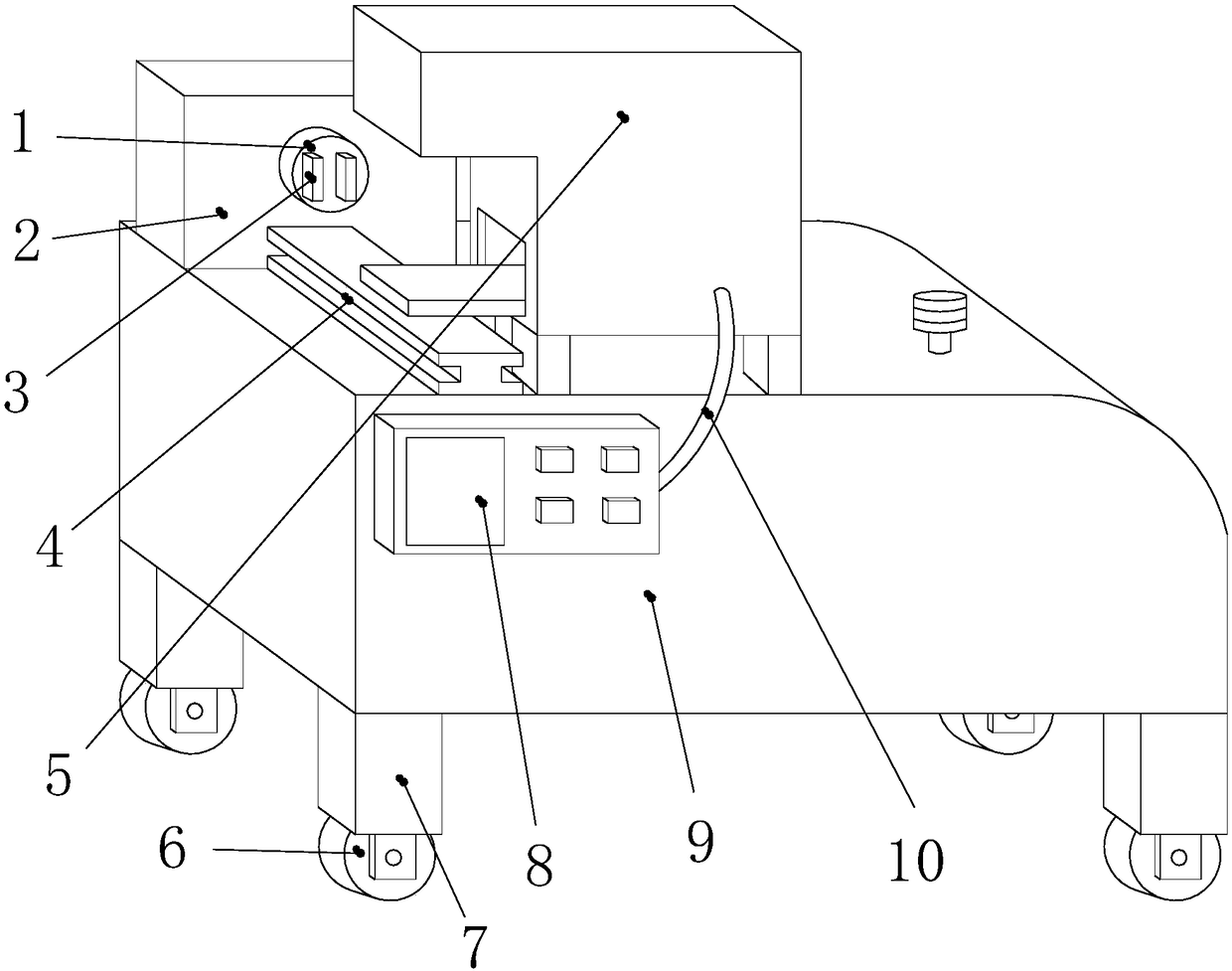

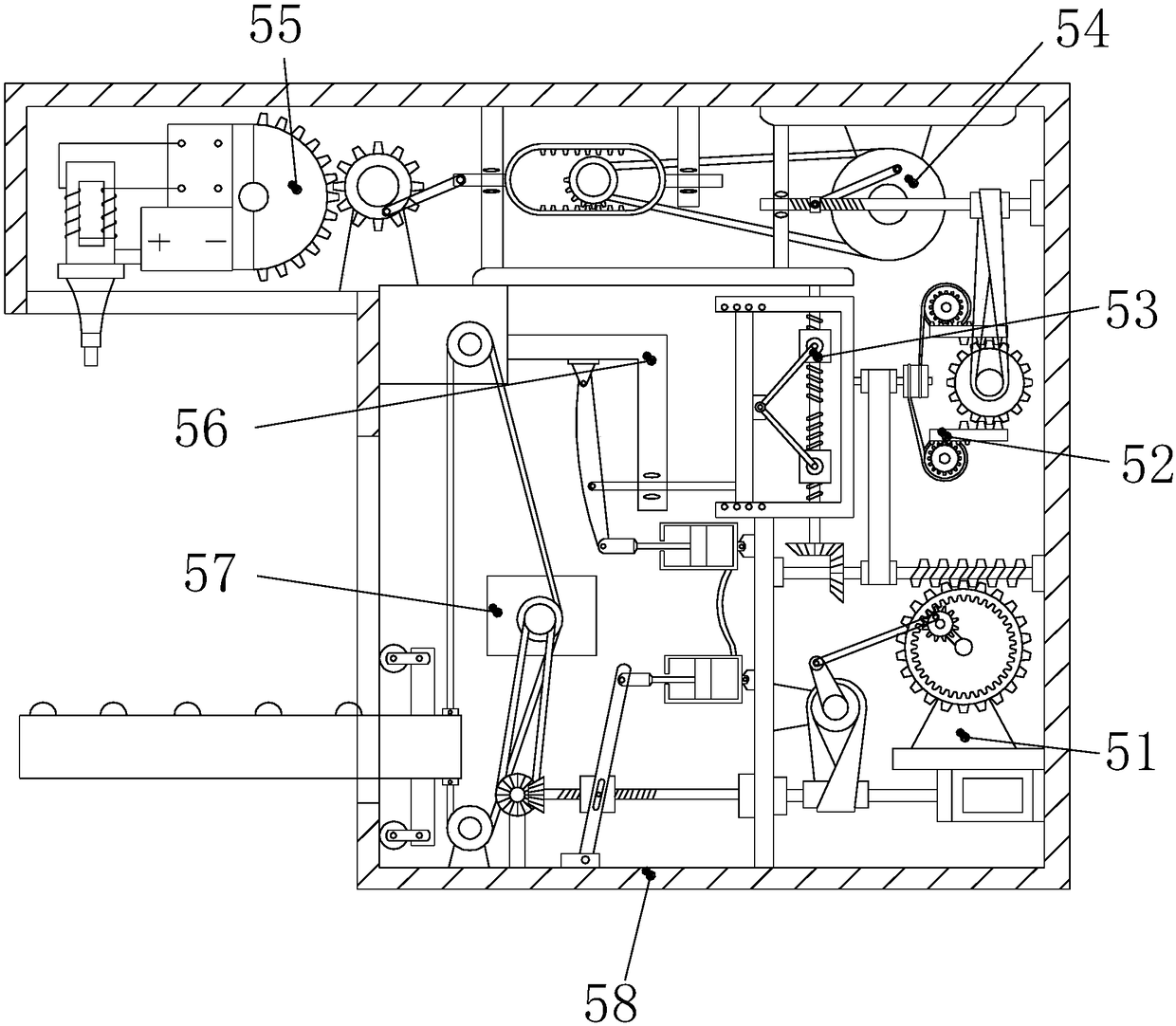

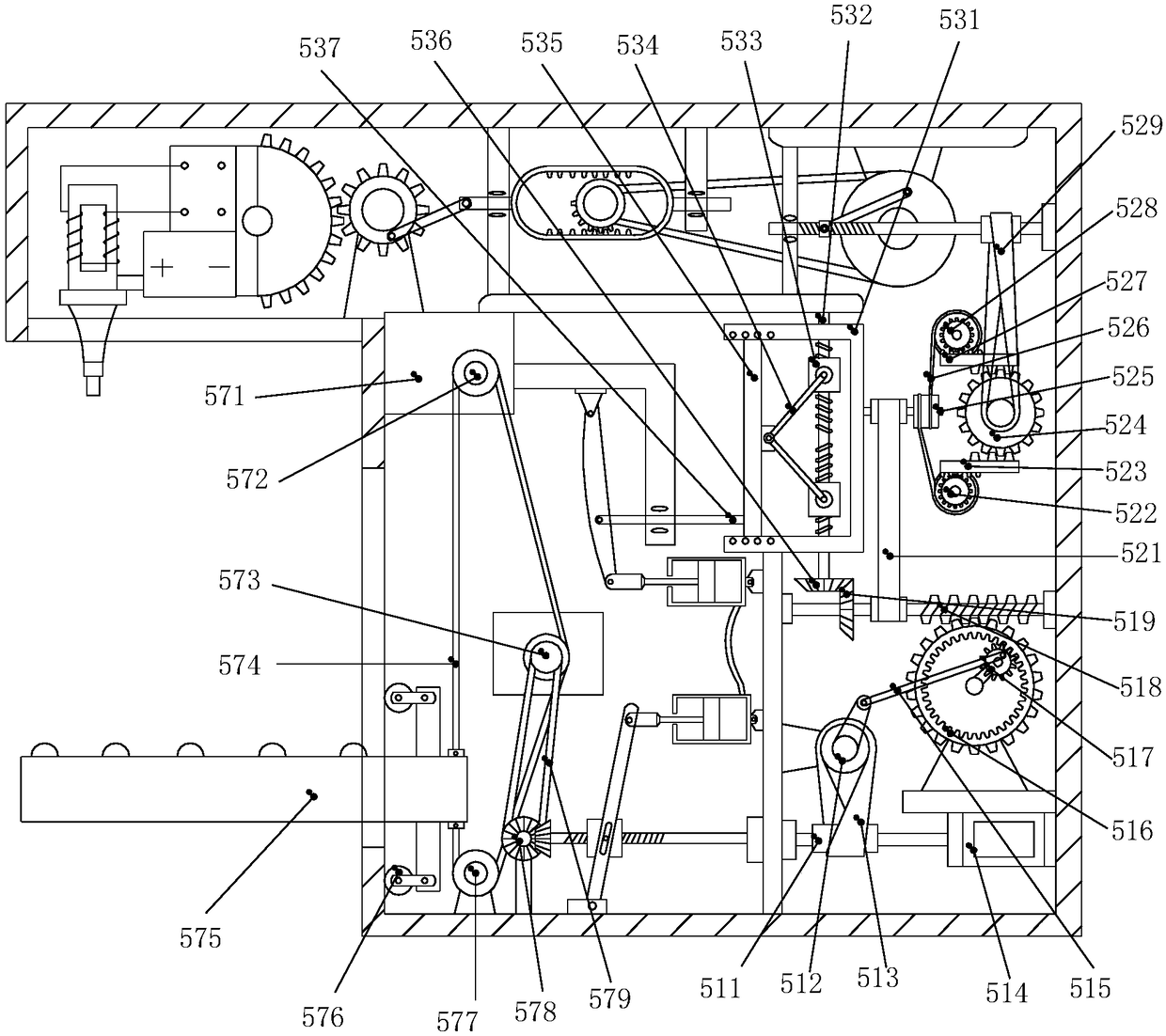

Automatic clamping device for welding blades

InactiveCN108555431AReduce welding stressImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesGear transmissionMotor drive

The invention discloses an automatic clamping device for welding blades. The automatic clamping device comprises a rotary clamping seat, a sliding seat, a blade clamping plate, a slide rail, an ultrasonic wave welding protecting device, castors, cushion blocks, a control panel, a device main body, a transmission lead and a stabilizing device, wherein the ultrasonic wave welding protecting device comprises a motor driving structure, a gear transmission structure, a bidirectional worm structure, a rotating disc transmission structure, an ultrasonic wave welding structure, a hydraulic transmission structure, a support plate matching structure and a device shell; and the stabilizing device comprises a single chip microcomputer and support seats, the number and positions of the support seats are matched with those of the castors, pressure sensors connected to the single chip microcomputer are arranged at the bottoms of the support seats, the support seats are mounted at the bottom of the device main body, and buffer telescopic rods are arranged at the joints between the support seats and the device main body. According to the automatic clamping device, the welding stress borne by the blades can be reduced, so that the deformation of the blades is controlled within a tolerance range, the welding strength of the welded blades can approximate to the strength of a raw material, the welding precision is high, and the subsequent use of the blades is not influenced.

Owner:余燕

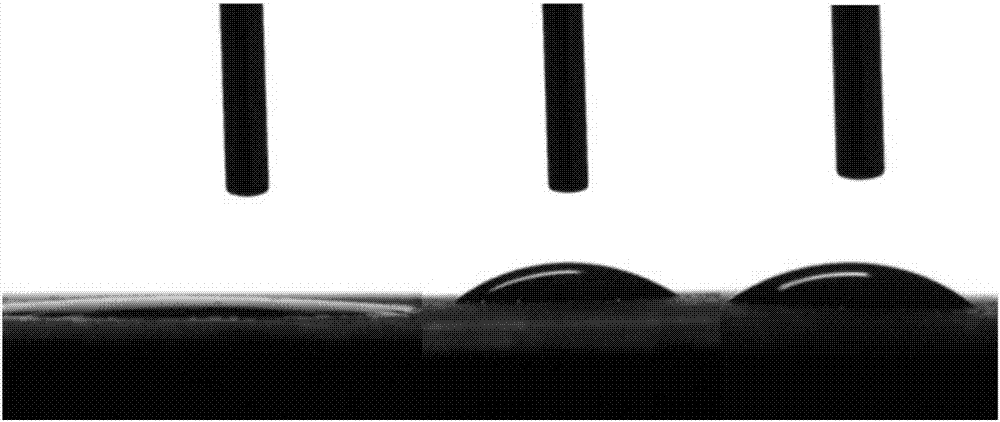

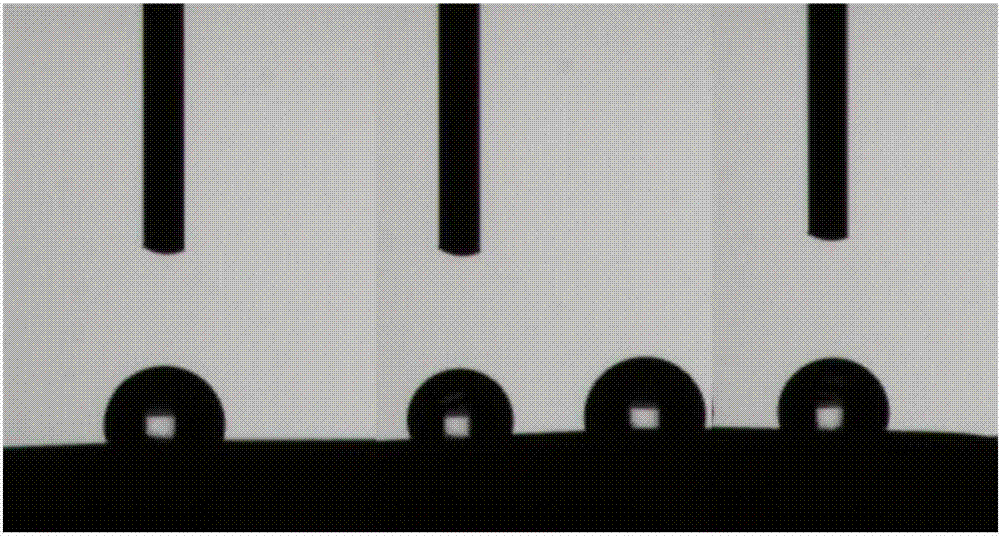

Method for changing wettability of surface of metallic nickel through hydrofluoric acid etching

The invention discloses a method for changing wettability of the surface of metallic nickel through hydrofluoric acid etching. The method comprises the steps that (1) an ultrasonic cleaning mode is adopted to wash the surface of the metallic nickel, and oil stains and impurities on the surface of metallic nickel sheets are removed; (2) the metallic nickel sheets are put into a hydrofluoric acid solution with the concentration being 40% or above, and then are put into a water bath with the temperature being over 30 DEG C to be subjected to chemical etching for 7-28 hours, and in the etching process, the surfaces of the metallic nickel sheets are turned once every one hour; and (3) the etched metallic nickel sheets are taken out, flushed and dried, and the metallic nickel sheets with the wettability being changed are obtained. The surface of the metallic nickel is subjected to etching treatment through the hydrofluoric acid solution, rough microcosmic structures are formed on the surface of the metallic nickel, and accordingly the wettability of the metallic nickel is changed only in the mode of improving the surface roughness, hydrophobicity of the surface of the metallic nickel is improved, then the service life of the metallic nickel under the wet or vapor condition is effectively prolonged, and the application range of the nickel is widened.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Wrap-up device for textile

The invention discloses a wrap-up device for textile. The wrap-up device comprises a first bracket, wherein the vertical inner side wall of one side of the first bracket is fixedly connected with an ultraviolet lamp tube; the lower surface of the ultraviolet lamp tube is fixedly connected with a first distance sensor; the outer wall of one side, away from the first bracket, of the ultraviolet lamptube is fixedly connected with a second bracket; the vertical inner side wall of the first bracket and the vertical inner side wall of the second bracket are movably connected with the same first rotary rod and the same second rotary rod; the second rotary rod is arranged above the first rotary rod; the outer surface of the first rotary rod is fixedly connected with a rolling barrel; and the outer surface of the rolling barrel is movably connected with a first adhesive pad. The wrap-up device is simple in structure, is convenient to operate, and is additionally equipped with an electrostatic-elimination and distance-sensing device, so that hands of a worker do not easily generate an aching feeling, follow-up use of cloth is not affected, working efficiency is improved, compacting effect is more ideal, and wrapped textile fabric is more flat.

Owner:响水县奕杰制衣有限公司

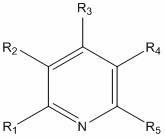

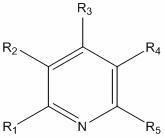

Method for purifying dichloromethyl phenylsilane by chemical coordination effect

InactiveCN101845055AFast responseMild reaction conditionsGroup 4/14 element organic compoundsPyrroleQuinoline

The invention relates to a method for purifying dichloromethyl phenylsilane by chemical coordination effect, which aims at solving the technical problems to realize the effects that the MePhSiCl2 in a raw material mixture can be effectively purified, and the purity and the yield are higher. The purifying method of the invention comprises the following steps: slowing adding coordination agents or the solution of the coordination agents into the dichloromethyl phenylsilane / phenyl trichlorosilane mixture during the stirring; and stirring the materials after the material adding so that the reaction is sufficient, or carrying out distilling purification after the sediment is removed to obtain the dichloromethyl phenylsilane, or directly carrying out distilling purification without removing the sediment to obtain the dichloromethyl phenylsilane. The valent weight ratio of the coordination agents to the phenyl trichlorosilane is 100 to 300 percent. The coordination agents are selected from imidazole, pyrrole, paradiazine, quinoline, isoquinolin, imidazole derivatives and pyridine derivatives.

Owner:HANGZHOU NORMAL UNIVERSITY

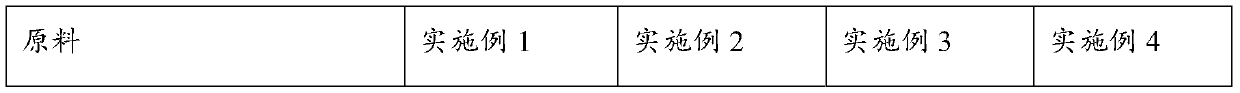

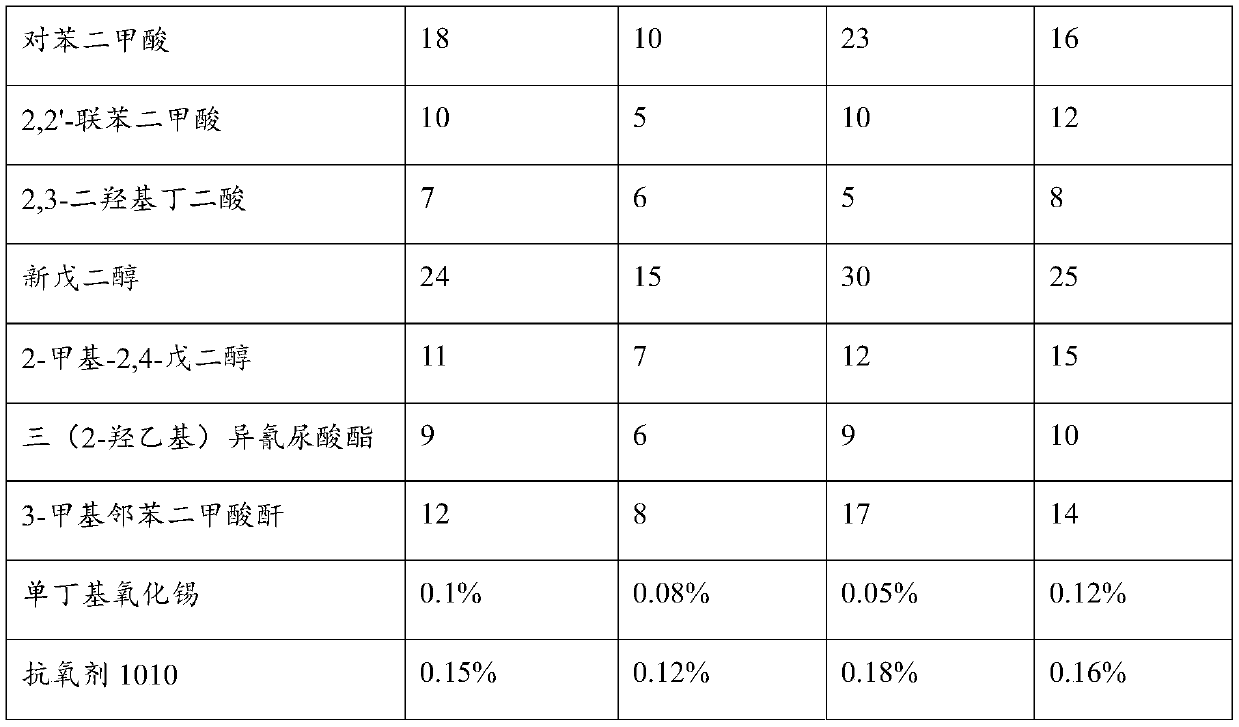

Polyester resin with high hardness and high storage stability for 60/40 mixed powder and preparation method thereof

ActiveCN111333827AHigh hardnessGood storage stabilityPowdery paintsPolyester coatingsPolymer scienceButanedioic acid

The invention, which belongs to the technical field of preparation of polyester resin, particularly relates to polyester resin with high hardness and high storage stability for 60 / 40 mixed powder anda preparation method thereof. According to the polyester resin for 60 / 40 mixed powder, the polyester resin is characterized by being prepared from the following main raw materials: terephthalic acid,2, 2 '-biphenyldicarboxylic acid, 2, 3-dihydroxy succinic acid, neopentyl glycol, 2-methyl-2, 4-pentanediol, tris (2-hydroxyethyl) isocyanurate and 3-methyl phthalic anhydride. According to the invention, the performances such as impact resistance, coating film appearance, caking resistance, hardness, gloss and the like of polyester resin products are guaranteed, the influence on subsequent spraying use and coating film quality due to crosslinking of the powder coating in the storage period is eliminated, the polyester resin can be stored in an environment of 45 DEG C for a long time without influencing subsequent use, and the polyester resin has excellent high storage stability.

Owner:黄山市源润新材料科技有限公司

Building brick cutting machine

InactiveCN110328762ASame lengthAvoid knockingWorking accessoriesStone-like material working toolsBrickArchitectural engineering

The invention relates to a brick cutting machine, in particular to a building brick cutting machine. The invention aims to provide the building brick cutting machine, wherein the building brick cutting machine is characterized by being capable of replacing workers to cut off bricks, so that labor is saved, and hands cannot be knocked and hurt by a tool. According to the technical description scheme, the building brick cutting machine comprises a base, a workbench, a first mounting plate, an elastic plate, a mounting rod, a pressing cutter, a first limiting block, a motor, a first rotating shaft, a swing rod, rollers and the like; and the workbench for placing the bricks is fixedly connected to the middle of the top of the base, the first mounting plate is fixedly connected to the rear partof the right side of the top of the base, and the first mounting plate is located on the rear side of the workbench and is in contact with the workbench. According to the building brick cutting machine, the bricks are placed on the workbench, the motor is started to rotate forwards, so that the bricks can be pressed and fixed by a pressing plate, then the pressing cutter moves downwards to cut off the bricks, so that the bricks are fixed without holding the tool with the hands by people, more labor is saved, and the hands can be prevented from being knocked and hurt by the tool.

Owner:周忆梅

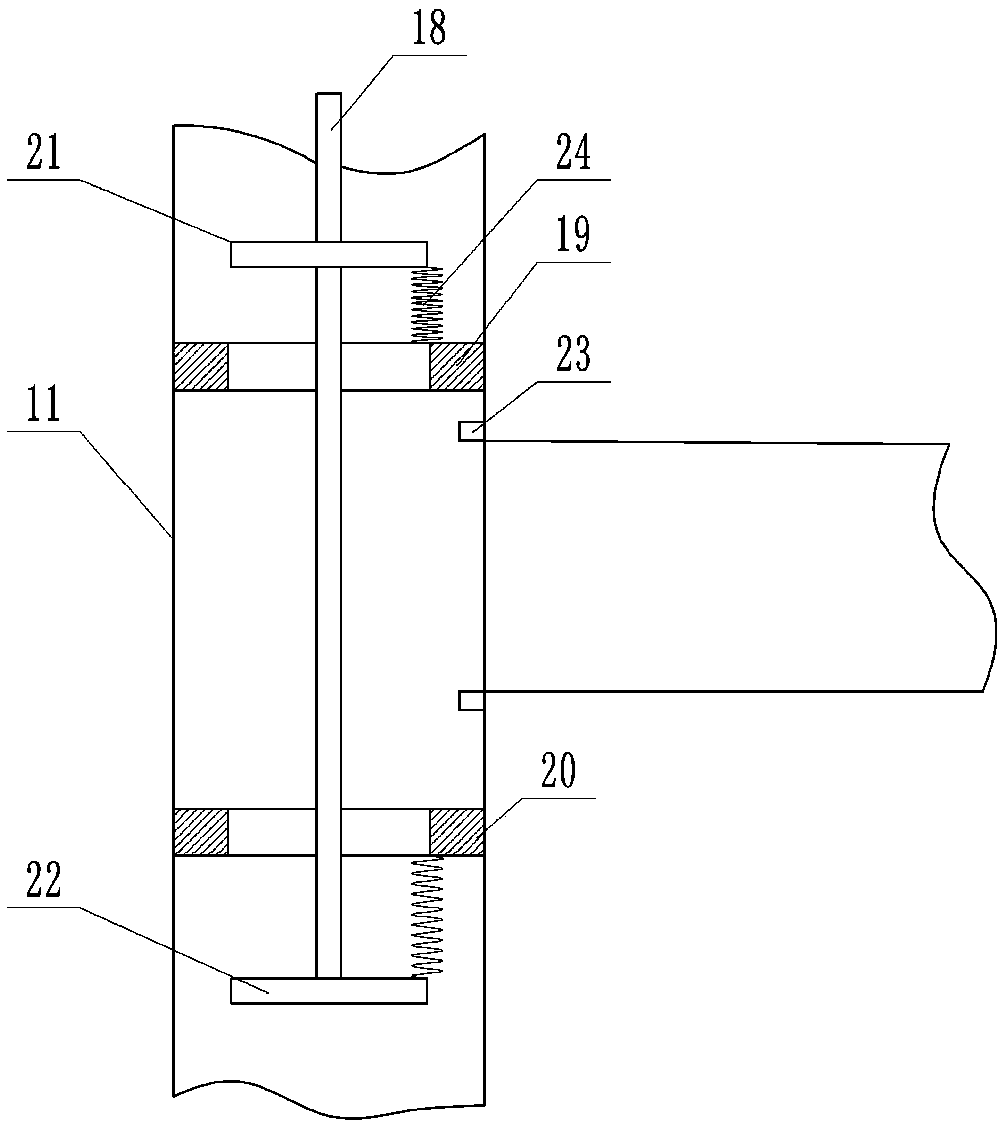

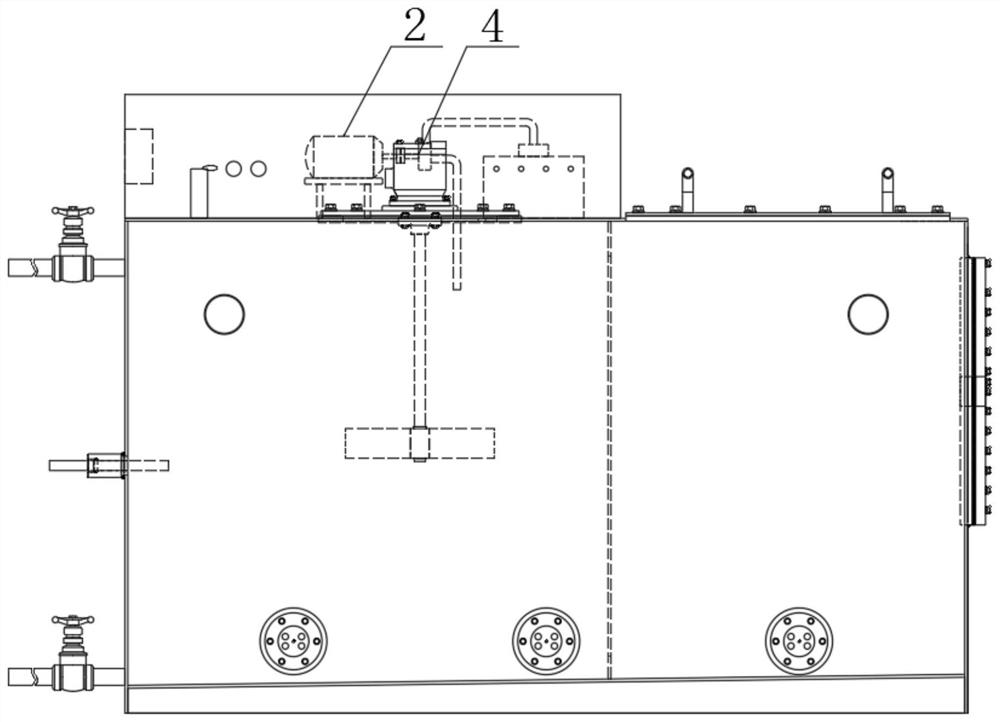

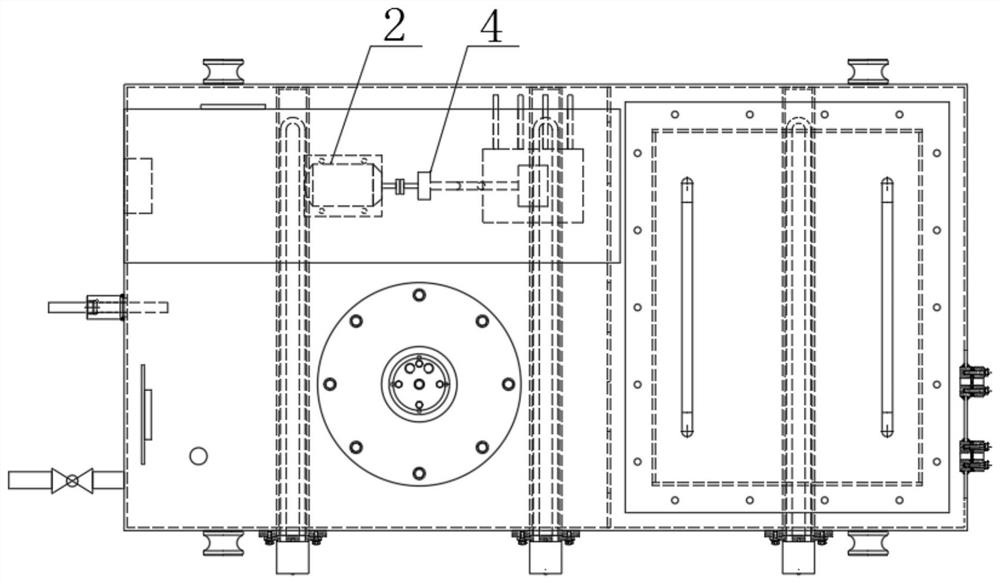

Hydraulic device

ActiveCN108266428AThe adjustment process is timelyGood support effectFluid-pressure actuatorsHydraulic equipmentHydraulic pressure

The invention belongs to the technical field of hydraulic equipment, and particularly discloses a hydraulic device. The hydraulic device comprises a base and a first sleeve. A big piston rod is arranged on the base. A big piston is arranged on the big piston rod. A second sleeve and a third sleeve are separately arranged on the two sides of the first sleeve. A hemispherical support which is rotatably connected with the first sleeve in a sealing mode is arranged at the upper end of the first sleeve. Sealing plates with sliding holes are arranged at the upper ends of the two sleeves correspondingly. A supporting plate is arranged on the support. The second sleeve and the third sleeve are each internally provided with a small piston and a small piston rod. An upper pipeline, a lower pipelineand a tee joint are arranged on each of the first sleeve and the second sleeve. Valves are arranged on the tee joints. Supporting rods are connected between the valves and the supporting plate. The first sleeve is connected with an oil pump through an oil inlet pipe. The hydraulic device is mainly used for supporting a weight, and the problem that the service life of a hydraulic supporting deviceis shortened due to unbalanced stress is solved.

Owner:CHONGQING WEIQING HYDRAULIC MACHINERY CO LTD

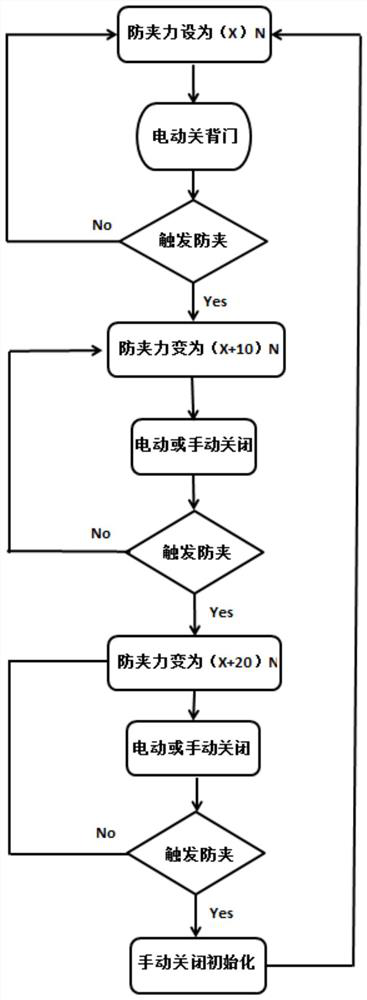

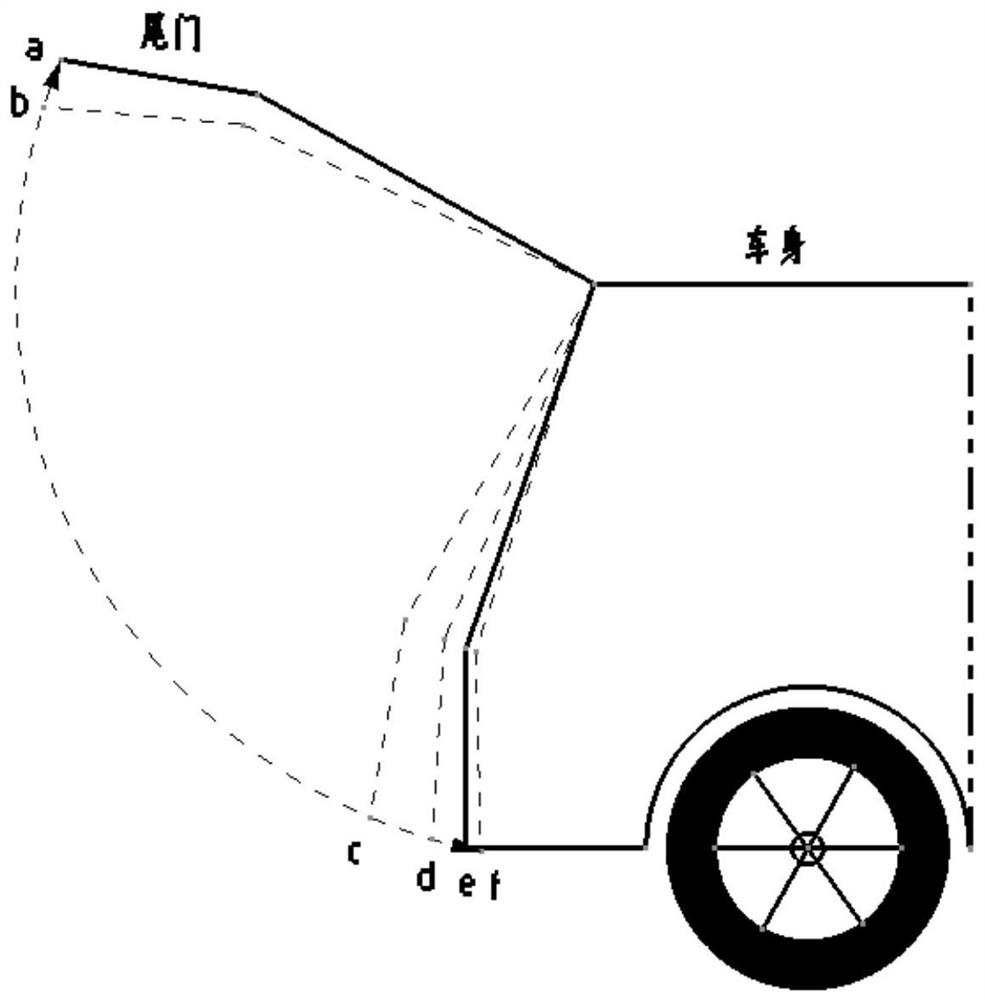

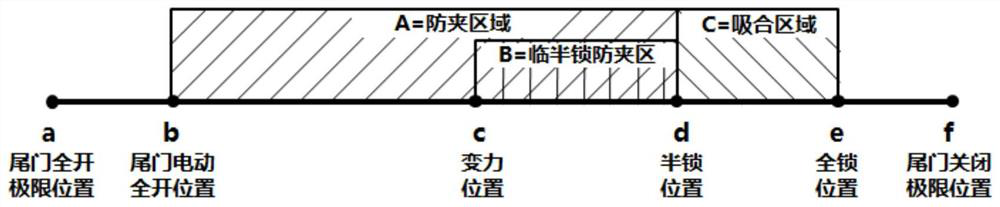

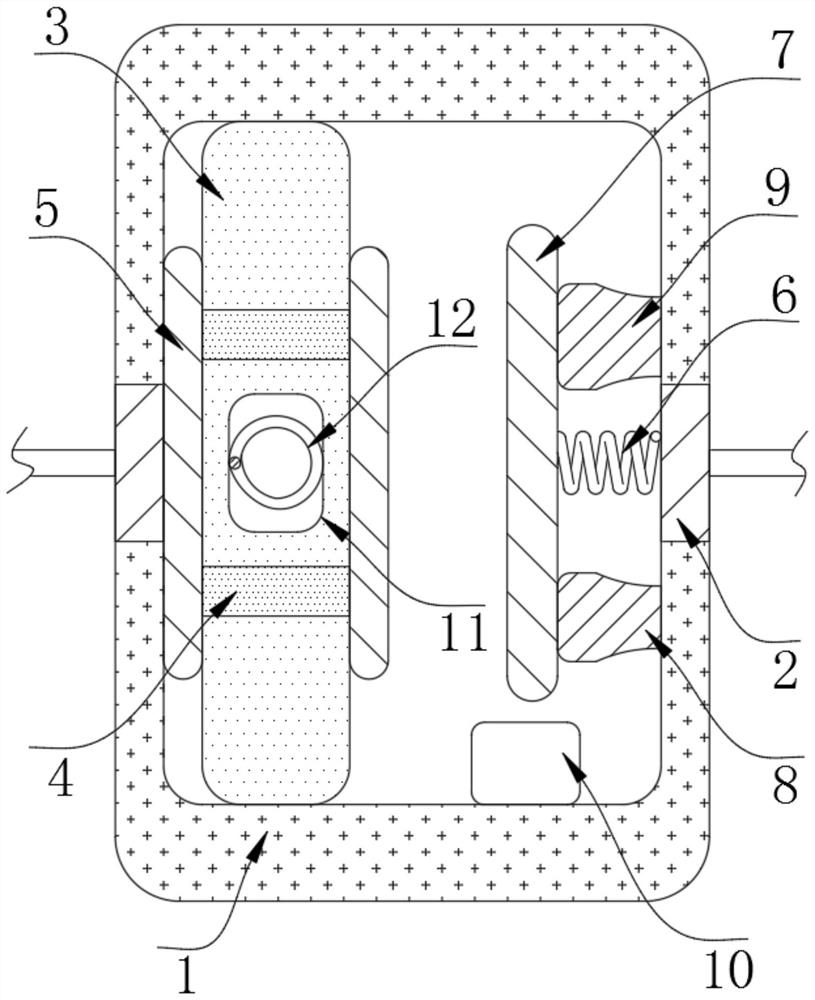

Electric closing anti-pinch control method for automobile back door

InactiveCN111877906AGuarantee the normal anti-pinch functionIncreased anti-pinch forceMan-operated mechanismPower-operated mechanismBack doorMotronic

The invention discloses an electric closing anti-pinch control method for an automobile back door. The electric closing anti-pinch control method comprises the following steps: under initially-set anti-pinch force, the automobile back door is electrically closed and enters an approach semi-lock anti-pinch area, and the anti-pinch force is increased after anti-pinch is triggered until the back dooris closed; the number of times of increasing the anti-pinch force does not exceed two, and if the anti-pinch force is increased twice, anti-pinch is triggered, and the back door is closed manually; the approach semi-lock anti-pinch area is an area between a variable force position and a semi-lock position; and the variable force position is the position where the back door starts to make contactwith an automobile body side counter-force part. The anti-pinch force is increased by several times in the approach semi-lock anti-pinch area, so that the problem that the back door cannot be electrically closed due to accidental change of the side counter force of the automobile body is solved on the technical basis of ensuring the normal anti-pinch function of the automobile back door.

Owner:FAW CAR CO LTD

Time-delay fuse

InactiveCN111627773AAvoid shockEnough to handleProtective switch terminals/connectionsProtective switch operating/release mechanismsElectrical batteryHemt circuits

The invention discloses a time-delay fuse. The fuse comprises an outer box, power connection sheets penetrate through and are inserted into two symmetrical side walls of the outer box, and an adsorption plate is fixed to the inner wall of the outer box. A conductive rod is inserted into the side wall of the adsorption plate in a penetrating manner, power connection plates are fixed to the two endsof the conductive rod, and a battery is fixed to the inner wall of the outer box. A contraction spring is fixed to the side wall, away from the adsorption plate, of the power connection plate, and aconductive plate is fixed to the end, close to the adsorption plate, of the contraction spring. The time-delay fuse has the advantages that the conductive plate is in contact with the power connectionplate, an external power utilization circuit is electrified through the connection of the contraction spring, when a fault current of the circuit is increased, the contraction spring can complete contraction action at the moment when the current is increased, so that the conductive plate is separated from the power connection plate, the external circuit is rapidly disconnected, the external circuit and an electric appliance are prevented from being impacted by a high current, and the external circuit and the electric appliance are protected.

Owner:杨伟

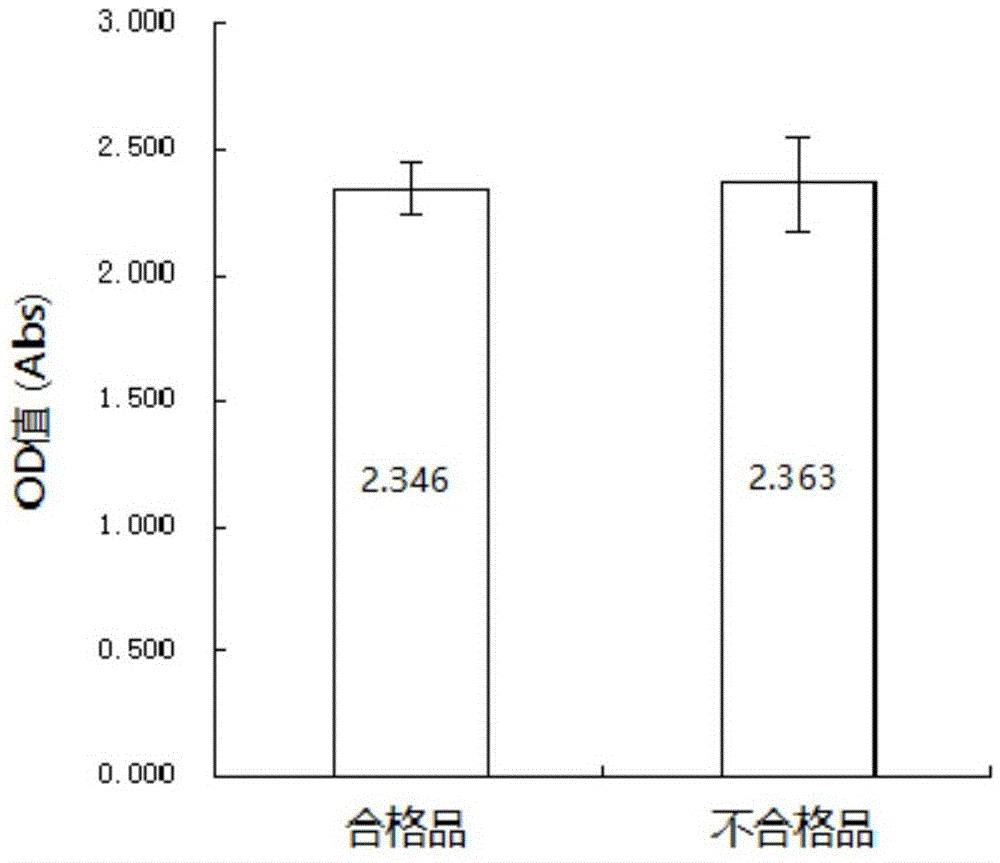

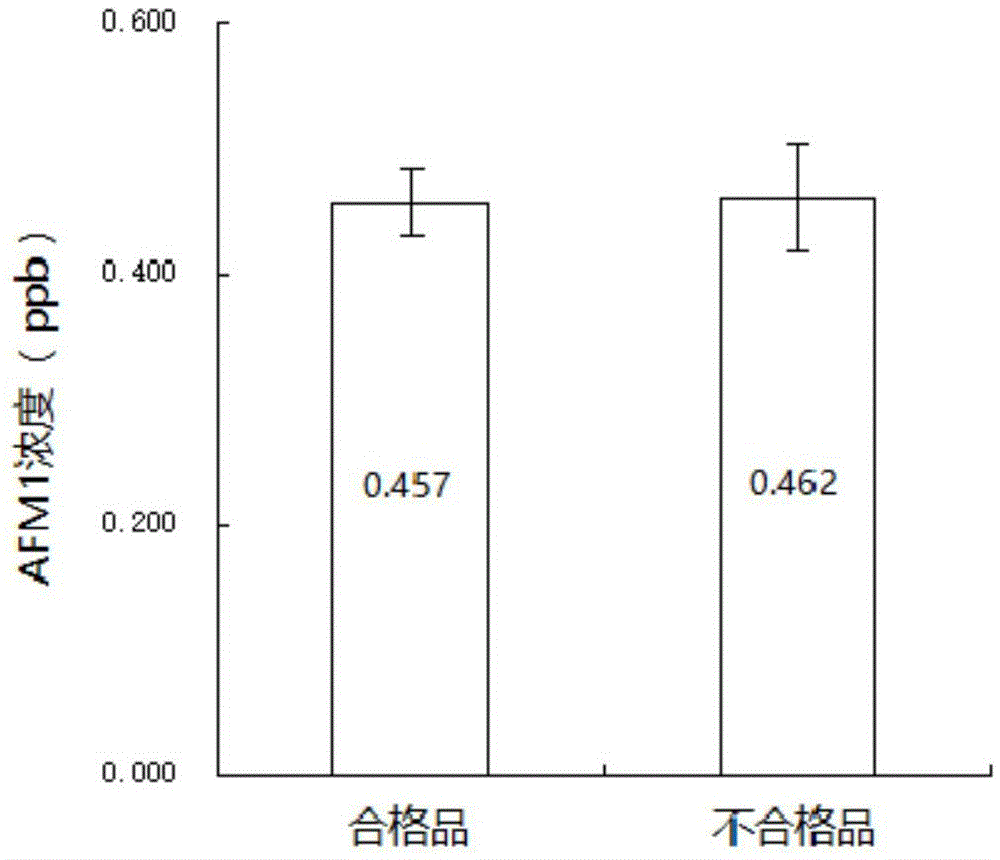

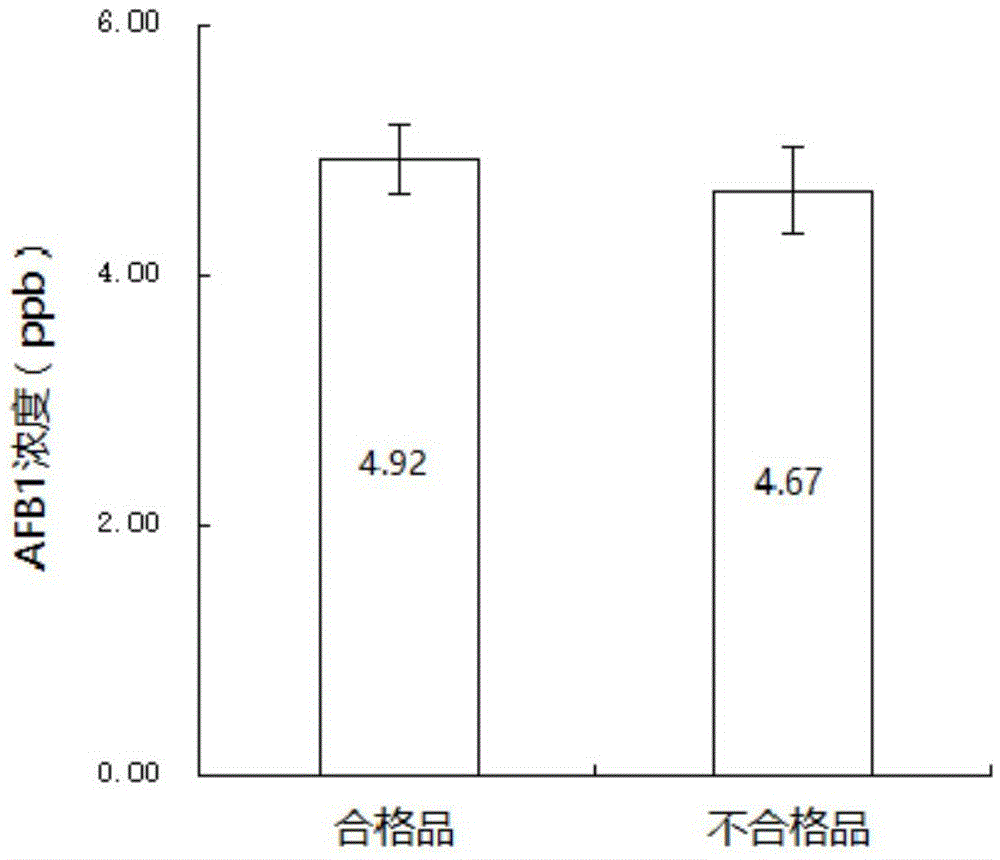

ELISA (enzyme-linked immunosorbent assay) plate coating liquid, confining liquid and ELISA plate manufacturing method

ActiveCN105588937AGuaranteed qualityDoes not affect subsequent useColor/spectral properties measurementsAntigenPhosphate

The invention discloses an ELISA (enzyme-linked immunosorbent assay) plate coating liquid and an ELISA plate confining liquid. The ELISA plate coating liquid contains a carbonate buffer solution with pH of 9.6 and G-6-PD, and the ELISA plate confining liquid contains a phosphate buffer solution with pH of 8.0, NADP<+> and G-6-P. The invention further discloses a method for manufacturing a pre-coated ELISA plate through matching use of the ELISA plate coating liquid and the ELISA plate confining liquid. According to the method for manufacturing the pre-coated ELISA plate, G-6-PD and a to-be-coated antigen or antibody are coated together in the coating process, NADP<+> can be reduced into NADPH during closing, coating uniformity of G-6-PD can be indirectly detected through detection of NADPH, then the coating uniformity of the antigen or antibody is reflected, accordingly, an unqualified pre-coated ELISA plate is identified in a manufacturing process, and the quality of the pre-coated ELISA plate can be guaranteed.

Owner:馥申生命科学(上海)有限公司

Spraying device for copper rod and online spraying system

PendingCN111617916ASolve the problem of being oxidized when exposed to the airGuaranteed appearanceSpray boothsStructural engineeringContinuous rolling

The invention discloses a spraying device for a copper rod. The spraying device comprises a storage box and a spraying mechanism connected with the storage box, wherein the spraying mechanism comprises a hollow columnar shell; an upper connecting and guiding opening is formed in the top of the shell; a lower connecting and guiding opening is formed in the bottom of the shell; the upper connectingand guiding opening and the lower connecting and guiding opening are coaxially arranged; a nozzle connected with the storage box is arranged in the shell; and a power mechanism is arranged on the storage box. According to the spraying device, a thin anti-oxidation layer can be formed on the surface of the copper rod, the problem that the copper rod is exposed in air for a long time and is oxidizedcan be effectively solved, and the appearance and quality of subsequent products are guaranteed. The invention further discloses an online spraying system. The anti-oxidation spraying device is arranged between a traction mechanism and a rod throwing mechanism, transferring labor is saved, transferring time is shortened, transferring cost is reduced, and efficiency is improved. Meanwhile, the whole process is continuous, under the condition that normal production of a copper rod continuous rolling machine is not affected, the problem that the copper rod is exposed in air for a long time and is prone to being oxidized is solved, efficiency is high, and cost is low.

Owner:CHENGDU SHUHONG EQUIP MFG

VR home page popup implementing method and system

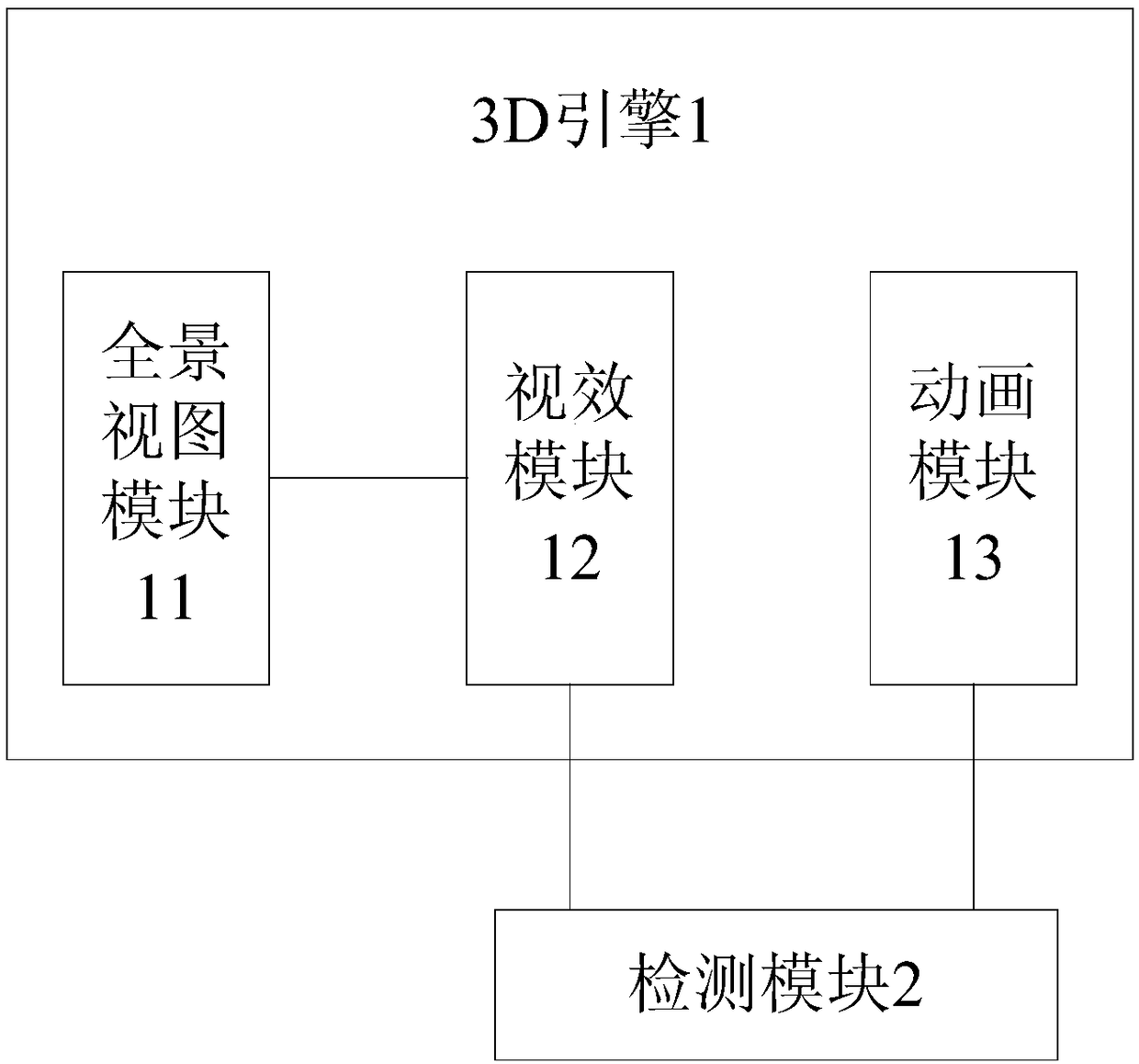

ActiveCN108334324AImprove display effect3D experience is goodSoftware engineering3D-image renderingInterface designAnimation

The invention discloses a VR home page popup implementing method and system and relates to the field of VR interface design. The method comprises steps as follows: after a VR APP is started, a panoramic view of a 3D space is constructed, and a target object is suspended in the panoramic view; after the virtual focus of a VR head display stays in the center of the target object for a preset time, achanging visual effect is produced through texture of the target object; the texture of the target object is deleted, and meanwhile, a dynamic effect picture is loaded to produce an animation effectof deletion of the target object. After VR APPs are started, VR home is entered, related information, cautions and the like of VR product brands are displayed through the VR home, and the generalization performance of VR products is improved.

Owner:FENGHUO COMM SCI & TECH CO LTD

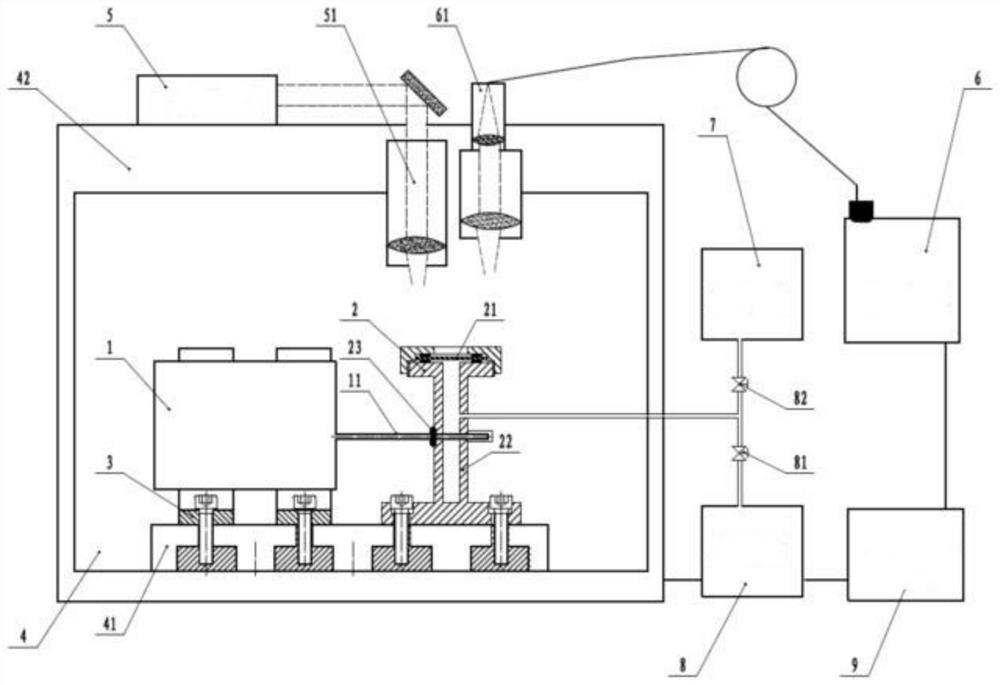

Device and method for in-situ laser drilling sampling and solder sealing of small pipe

InactiveCN112620938AHigh aspect ratioGood mechanical propertiesLaser beam welding apparatusErbium lasersLaser drilling

The invention discloses a device and method for in-situ laser drilling sampling and solder sealing of a small pipe, and belongs to the technical field of ultrafast laser drilling and quasi-continuous laser welding methods. Firstly, a laser machining part is installed on a special workbench, the part needing laser drilling is placed in a sampling container, and interface sealing is achieved; vacuumizing is carried out on the sampling container, a sampling valve is closed after the vacuum reaches 10<-3>Pa, and micropores penetrating through the wall thickness of a sampling pipe is machined at a specified part through a picosecond laser; then the atmosphere in the interior of a product is slowly released into the sampling container through a micropore channel; and after the internal air pressure of the product is balanced with the air pressure of the sampling container, a solder sealing laser head is moved to the micropore, and solder sealing is carried out on the micropore in a long-pulse laser welding mode. Laser in-situ near-lossless punching and solder sealing of the sampling pipe in a narrow space are met, near-lossless sampling is carried out on the atmosphere in the interior of a sealed container, and the use performance of a sealed container product is not affected.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

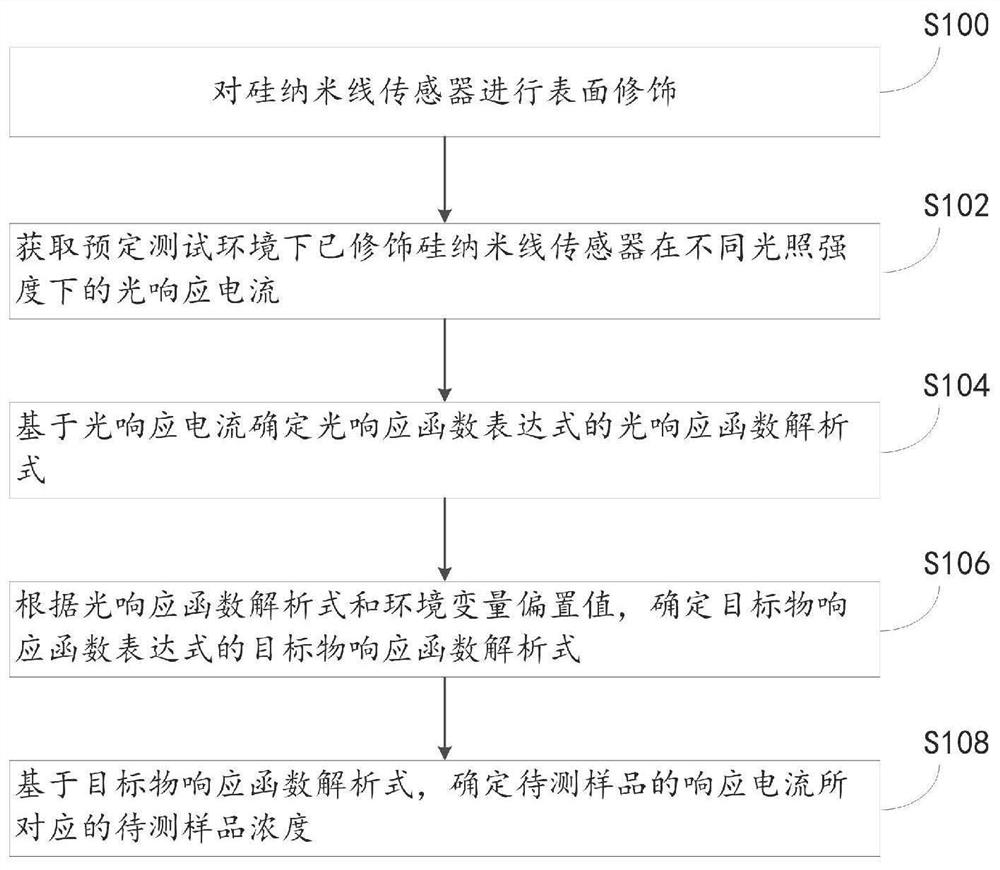

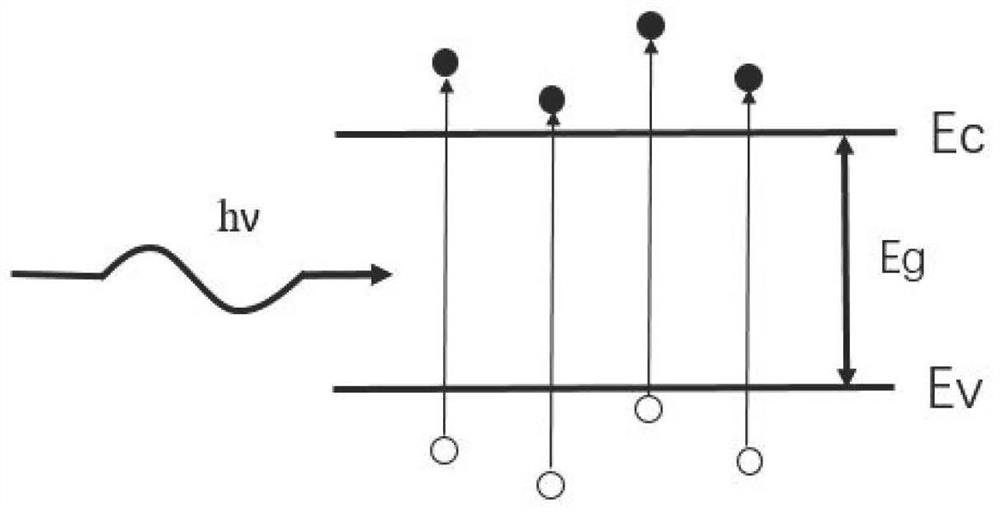

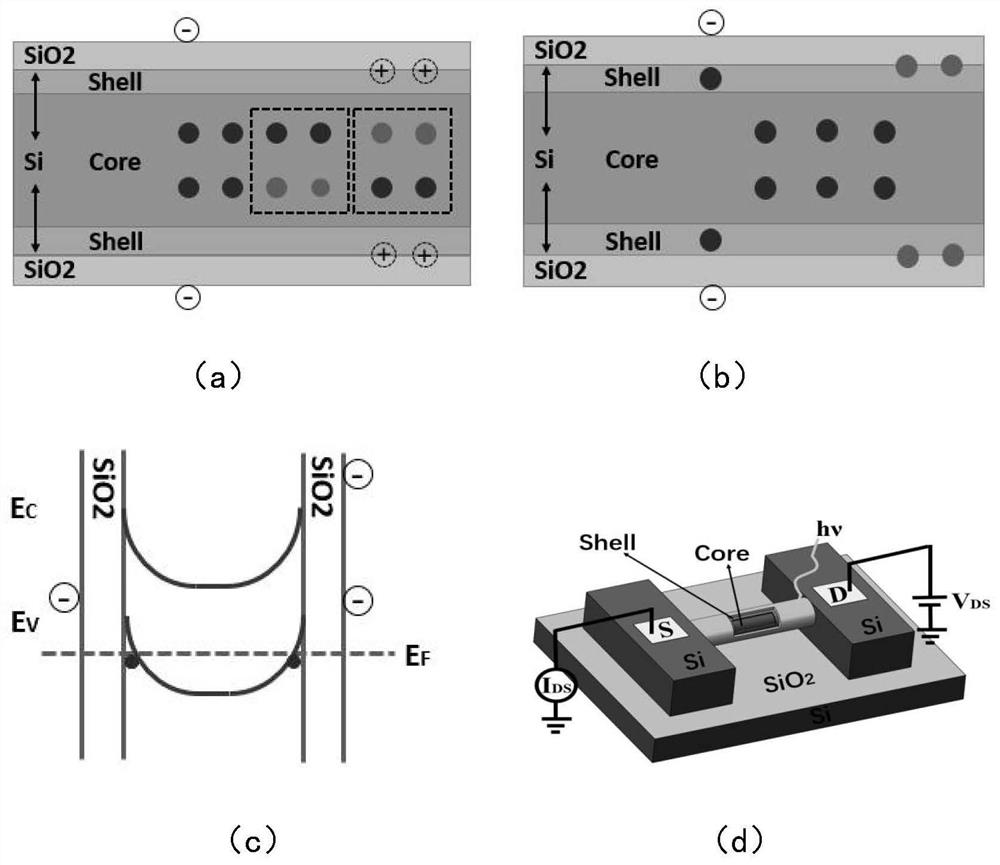

Method for calibrating silicon nanowire sensor by using cursor

ActiveCN111721710AEasy to measureTest results are stableMaterial analysis by electric/magnetic meansMaterial analysis by optical meansComputational physicsSurface modification

The invention provides a method for calibrating a silicon nanowire sensor by using a cursor. The method comprises the steps of carrying out surface modification on the silicon nanowire sensor; acquiring photoresponse current of the modified silicon nanowire sensor under different illumination intensities in a predetermined test environment; determining a photoresponse function analytic expressionof a photoresponse function expression based on the photoresponse current; determining a target object response function analytic expression of a target object response function expression according to the light response function analytic expression and the environment variable offset value; and determining the concentration of the to-be-detected sample corresponding to the response current of theto-be-detected sample based on the target object response function analytic expression. According to the method, the performance of the silicon nanowire sensor is evaluated by utilizing the light absorption efficiency of the silicon nanowire, and the problem of inconsistent response efficiency of a sensing device caused by difference of sensing units is solved. The calibration method has the advantages of simplicity, high efficiency, low cost, no damage to the device and no interference to the use of subsequent devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Blade tip clamping device

InactiveCN108555430AAvoid damageReduce welding stressNon-electric welding apparatusEngineeringWeld strength

The invention discloses a blade tip clamping device. The blade tip clamping device structurally comprises a rotating clamping seat, a sliding seat, a blade clamping plate, an ultrasonic wave welding protecting device, castors, at least two cushion blocks, a control panel, a device main body and a transmission lead, wherein the cushion blocks are in same shape and size and are welded to four corners of the lower surface of the device main body, and the castors are movably connected to the lower ends of the cushion blocks. By arranging the ultrasonic wave welding protecting device, the lower endof a blade is supported through the cooperation with a lifting support plate during the welding, so that the situation that the tip of the blade is damaged due to an overhigh clamping stress when theblade is overweight is prevented; and the welded part of the blade is supported, so that the welding stress borne by the blade is reduced, the deformation of the formation of the blade is controlledwithin a tolerance range, the welding strength of the welded blade can approximate to the strength of a raw material, the welding precision is high, and the subsequent use of the blade is not influenced.

Owner:余燕

Tritium-contaminated optical film non-destructive removal method based on inert ion beam etching

ActiveCN110013999AEfficient removalDoes not affect subsequent useCleaning processes and apparatusAcid etchingNon destructive

The invention belongs to the technical field of optical element manufacturing, and particularly relates to a tritium-contaminated optical film non-destructive removal method based on inert ion beam etching. In order to overcome the shortcoming that acid etching is used in the prior art to remove tritium-contaminated optical films, the method in the technical scheme comprises the steps that the thickness of optical films made according to the technology the same as that of the optical elements to be subjected film removing is firstly measured; then the etching rate of ion beams on the optical films on the element surfaces is calibrated; and finally inert ion beams with the energy being 100 eV to 1500 eV, the beam current being 100 mA to 500 mA and the ion beam incident angle being -90 degrees to 90 degrees are adopted to accurately etch and remove the tritium-contaminated optical films on the element surfaces. By means of the method, the shortcoming existing in an existing acid etchingtechnology for removing the tritium-contaminated optical films can be effectively overcome, and meanwhile, it is ensured that the surface quality, the optical performance and the laser damage resistance of an optical substrate are not affected.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Cotton thread winding device for textile

ActiveCN108557566BDoes not affect subsequent useWind evenlyFilament handlingAgricultural engineeringElectric machinery

The invention relates to a winding device, in particular to a spinning cotton thread winding device, and aims at achieving the technical purpose of providing the spinning cotton thread winding devicewhich is capable of saving time and labor and uniform in winding and does not influence later usage of a cotton thread. The spinning cotton thread winding device is provided and comprises a bottom plate, an n-shaped frame, guide sleeves, a connecting plate, a first bearing block, an inner thread sleeve, a screw, a first belt wheel, a vertical plate, a fixing plate, a first motor and the like. Then-shaped frame is arranged on the right side of the top of the bottom plate, the guide sleeves are arranged on the left side and the right side of the n-shaped frame, the connecting plate is arrangedbetween the inner side faces of the guide sleeves on the left side and the right side, and the first bearing block is embedded in the middle of the top of the n-shaped frame. Through a triggering device, the cotton thread amount of a coiling block reel can be controlled, and the needed amount is achieved; through a guiding device, the cotton thread is not loose and is better wound around a coilingblock, and the effects that the time and labor are saved, winding is uniform, and the later usage of the cotton thread is not influenced are achieved.

Owner:JIANGSU XIANGHE TEXTILE

Flue gas mercury oxidation catalyst and application thereof

ActiveCN106693980AImprove catalytic oxidation performanceSimple preparation processGas treatmentDispersed particle separationSlagFixed bed

The invention discloses a flue gas mercury oxidation catalyst and application thereof. The flue gas mercury oxidation catalyst is metal smelting water quenched slag based on copper smelting or nickel smelting. The flue gas mercury oxidation catalyst has a very strong capability of catalytically oxidating elemental mercury in coal-fired flue gas, has a very high elemental mercury oxidating rate even under the condition that the concentration of hydrogen chloride in the flue gas is relatively low, can be recycled and reused by virtue of own magnetism, and does not affect the subsequent utilization of fly ash after entering the fly ash. The flue gas mercury oxidation catalyst is in contact with the flue gas through particle spraying, a fluidized bed or a fixed bed or other ways, and can achieve high-efficiency oxidation of the elemental mercury in the flue gas. The flue gas mercury oxidation catalyst and the application thereof have the advantages of simplicity, feasibility, less investment, no secondary pollution and the like, and have a wide market application prospect.

Owner:CENT SOUTH UNIV

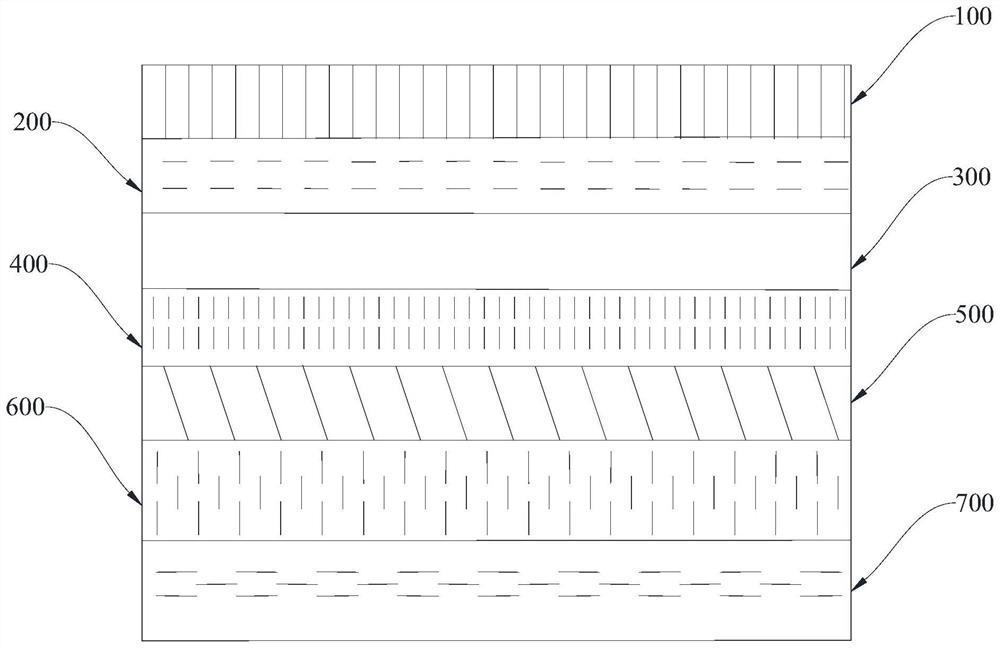

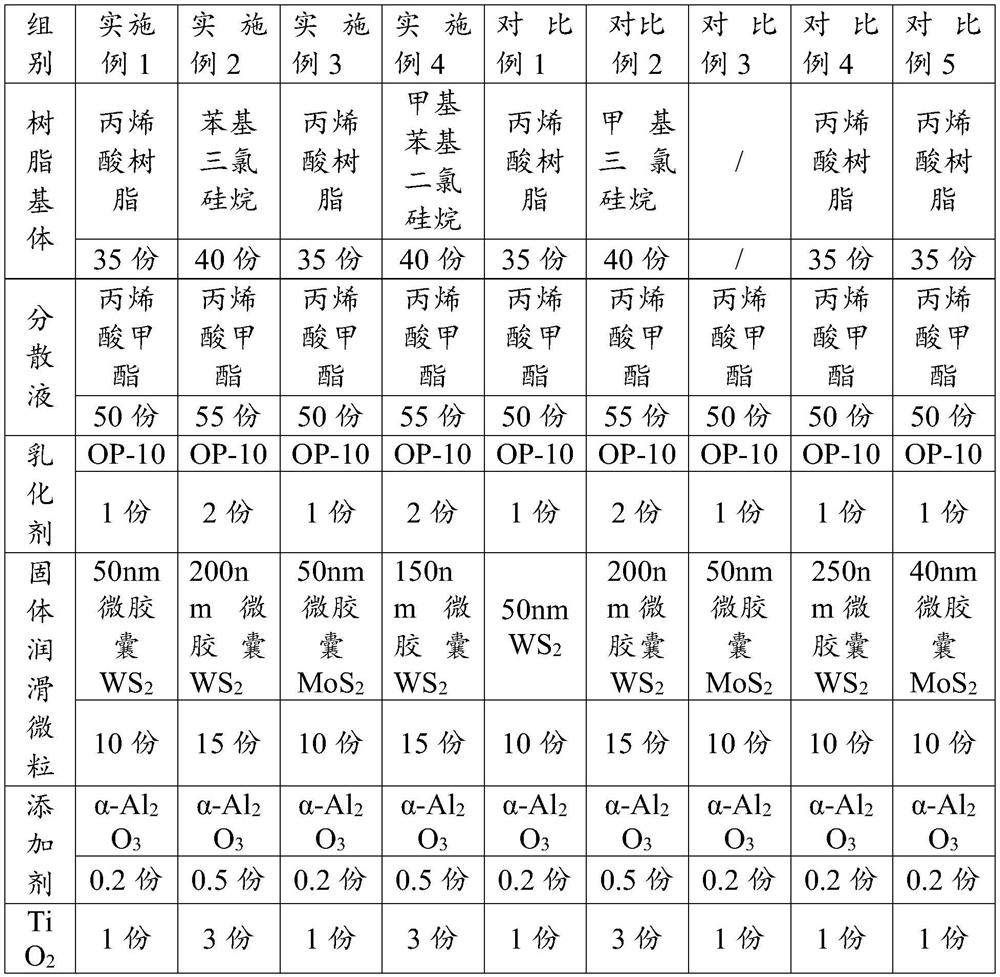

Wear-resistant coating, preparation method thereof and decorative membrane

PendingCN114181574ADoes not affect subsequent usePromote safe productionFilm/foil adhesive primer layersCoatingsCellulosePolymer science

The embodiment of the invention provides a wear-resistant coating, a preparation method thereof and a decorative membrane, and relates to the technical field of decorative membrane production. The wear-resistant coating provided by the embodiment of the invention comprises the following components in parts by weight: 35-40 parts of a resin matrix; 50 to 55 parts of dispersion liquid; 10 to 15 parts of microcapsule lubricating particles; the resin matrix is at least one of acrylic resin or organic silicon resin, the microcapsule lubricating particles are solid lubricating particles with the surfaces coated with cellulose, and the solid lubricating particles are at least one of WS2 or MoS2. All the components in the wear-resistant coating cooperate with one another and have a synergistic effect, and the wear-resistant coating has good wear resistance and weather resistance; the decorative membrane prepared from the wear-resistant coating has good wear resistance and weather resistance, and the friction coefficient of the surface is small.

Owner:上海华工艾马尔新材料有限公司

Bobbin paper length measuring device

InactiveCN106907975ADoes not affect subsequent useAccurate measurementMechanical measuring arrangementsBobbinPulp and paper industry

The invention provides a bobbin paper length measuring device. The device comprises a bracket. A paper pay-off roller used for installing to-be-detected bobbin paper and making the to-be-detected bobbin paper release paper gradually and a paper take-up roller synchronously rotating with the paper pay-off roller and used for gradually receiving paper are rotationally assembled on the bracket. The bracket is further equipped with a counting roller which is used for always rotating in contact with paper in the process of paper pay-off and has a rotation speed detection function. During use, the head of the bobbin paper on the paper pay-off roller is fixed to the paper take-up roller, and the paper take-up roller drives the paper pay-off roller to rotate synchronously through paper when rotating. As the perimeter of the counting roller is fixed, the length of paper released is calculated according to a formula: the rotation speed times the perimeter of the counting roller is the length of paper. Thus, length detection of the bobbin paper is completed. According to the device, the length of bobbin paper is measured accurately based on a simple mathematical principle. Measurement is convenient and highly accurate. After measurement, a coil of bobbin paper is reformed on the paper take-up roller. Therefore, length detection is completed, and subsequent use of bobbin paper is not affected.

Owner:CHINA TOBACCO HENAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com