ELISA (enzyme-linked immunosorbent assay) plate coating liquid, confining liquid and ELISA plate manufacturing method

A production method and technology of microtiter plate, which can be used in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to detect the uniformity of coating effectively, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Example 1 Preparation of Streptavidin pre-coated ELISA plate

[0030] 1.1 Reagent configuration

[0031] The reagents that need to be used in the production process include ELISA plate coating solution, washing solution and blocking solution, which can be configured according to the ingredients and parameters or contents in Table 1.

[0032] Table 1

[0033]

[0034] 1.2 Production steps

[0035] 1) Dissolve streptavidin with the ELISA plate coating solution, the concentration of streptavidin is 2μg / mL;

[0036] 2) Add streptavidin-dissolved ELISA plate coating solution (100 μL / well) to each microwell of the 96-well ELISA plate to be coated, and coat overnight at 4°C;

[0037] 3) Wash the plate 3 times with washing solution (350μL / well / time), and pat dry;

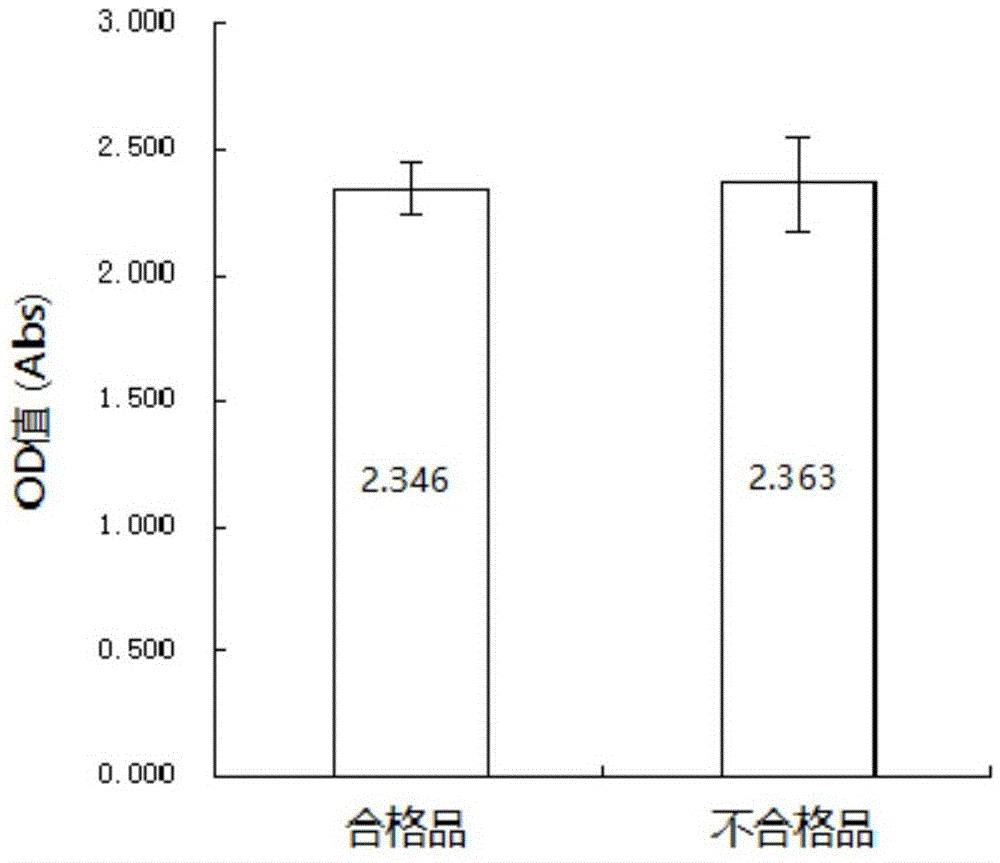

[0038] 4) Add blocking solution (250μL / well) and block at 37°C for 2 hours; use a microplate reader to detect the absorbance of the blocking solution in each microwell of the microtiter plate at a wavelength of 340nm, and calcula...

Embodiment 2

[0049] Example 2 Preparation of aflatoxin M1 monoclonal antibody pre-coated ELISA plate

[0050] 2.1 Reagent configuration

[0051] Configure the coating solution, washing solution and blocking solution of the microplate according to the ingredients and parameters or content in Table 2.

[0052] Table 2

[0053]

[0054] 2.2 Production steps

[0055] Referring to Example 1, the difference is that in step 1), streptavidin is replaced with AFM1 monoclonal antibody, and the concentration of AFM1 monoclonal antibody is 0.5 μg / mL.

[0056] 2.3 Effect test

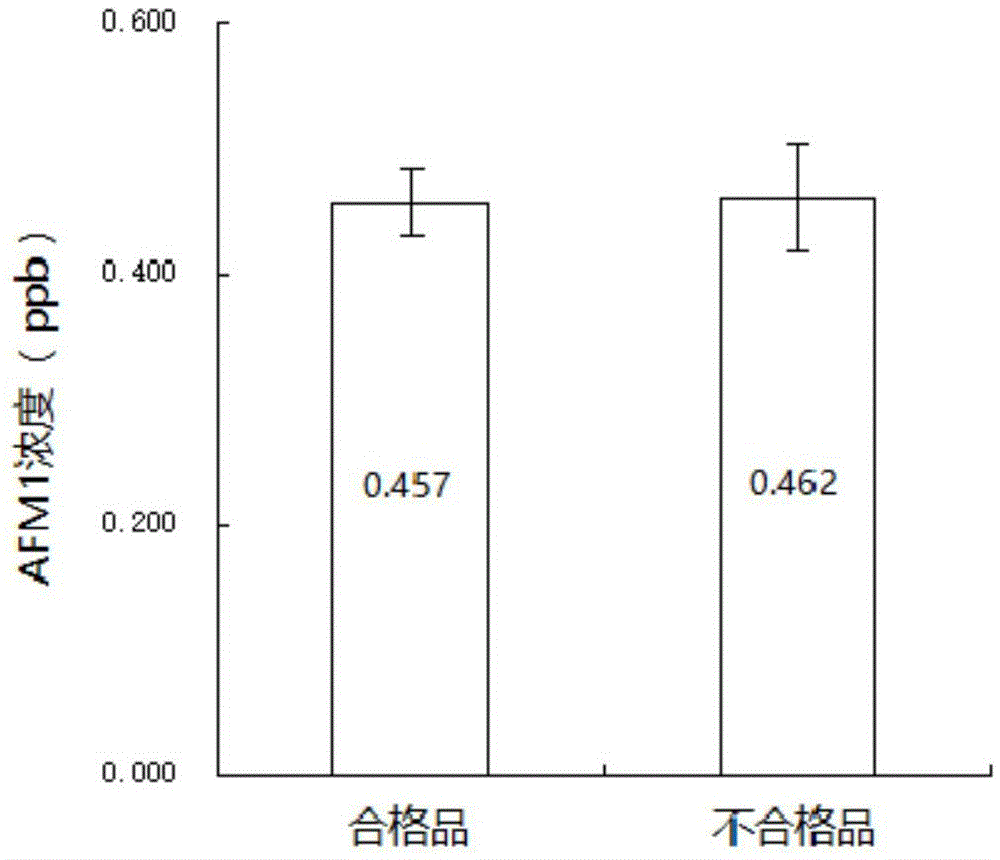

[0057] Detection of unqualified products: A total of 50 ELISA plates were coated, of which the coefficient of variation in 7 of the wells exceeded 5%, and the unqualified rate was 14%.

[0058] Take a qualified and unqualified pre-coated ELISA plate, respectively, to detect milk samples with an AFM1 content of 0.45ppb.

[0059] The steps are:

[0060] A. Add AFM1 to milk without AFM1 to prepare a milk sample with an AFM1 content of 0.45ppb.

[...

example 3

[0068] Example 3 Preparation of aflatoxin B1 (AFB1) monoclonal antibody pre-coated ELISA plate

[0069] 3.1 Reagent preparation:

[0070] Configure the coating solution, washing solution and blocking solution for the ELISA plate according to the ingredients and parameters or content in Table 3.

[0071] table 3

[0072]

[0073] 3.2 Production steps

[0074] Referring to Example 1, the difference is that in step 1), streptavidin is replaced with AFB1 monoclonal antibody, and the concentration of AFB1 monoclonal antibody is 1 μg / mL.

[0075] 3.3 Effect test

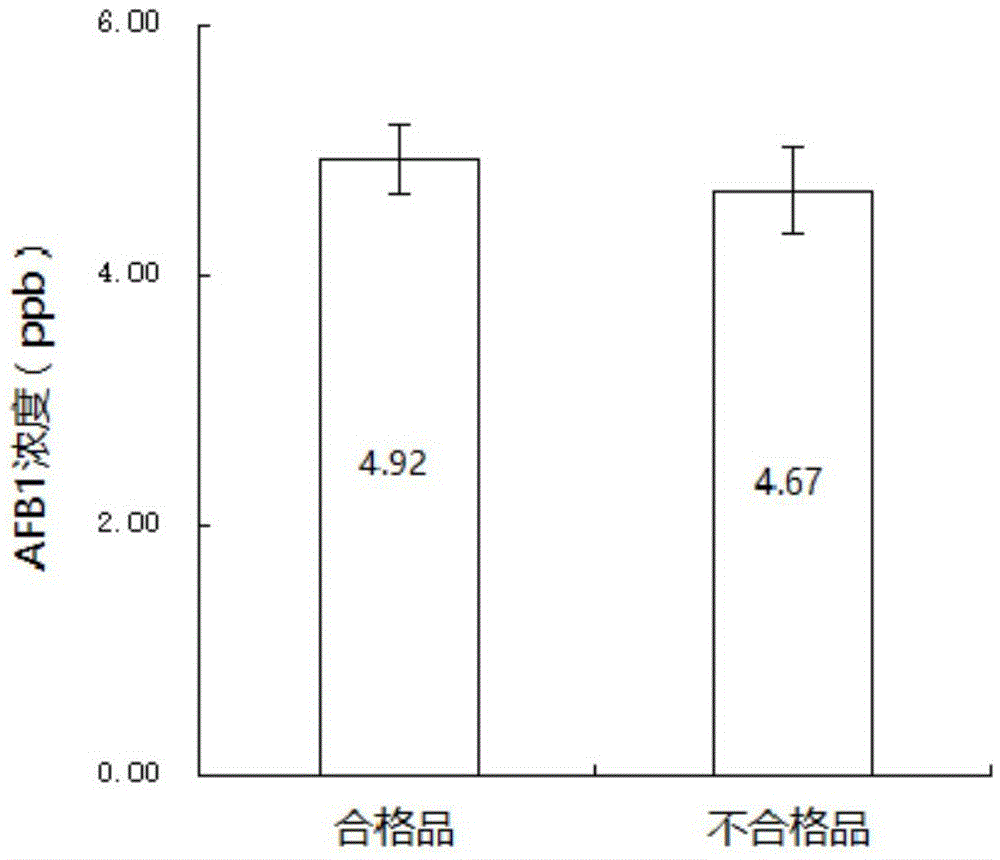

[0076] Detection of unqualified products: A total of 50 ELISA plates were coated, of which the coefficient of variation in 2 of the wells exceeded 5%, and the unqualified rate was 4%.

[0077] Take a qualified and unqualified pre-coated ELISA plate, respectively, and use them to detect the corn flour samples with AFB1 content of 5ppb.

[0078] The steps are:

[0079] A. Take a sample of corn flour with an AFB1 content of 5ppb verified by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com