Wear-resistant coating, preparation method thereof and decorative membrane

A wear-resistant coating, wear-resistant layer technology, applied in the direction of film/sheet adhesive, coating, film/sheet release coating, etc., can solve the problems of oxidation, easy wear of decorative patterns, loss of durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation steps of wear-resistant coating are as follows:

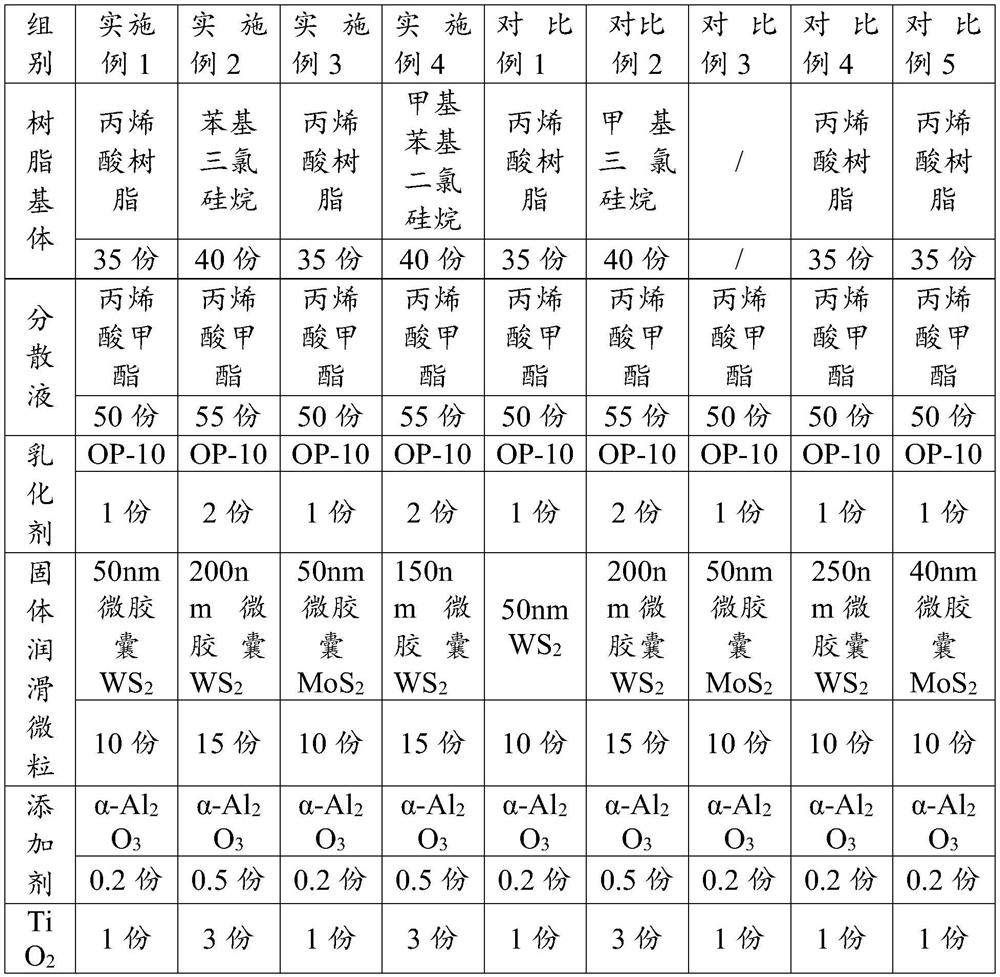

[0041] According to parts by weight, mix 35-40 parts of resin matrix, 1-2 parts of emulsifier and 50-55 parts of dispersion liquid to make a solvent; mix 10-15 parts of microcapsule lubricating particles, 0.2-0.5 parts of additives, 1 ~3 parts TiO 2 Mix well with solvent.

[0042] Wherein, the preparation steps of microcapsule lubricating particles are:

[0043] Mix the cellulose and liquid medium evenly, raise the temperature to 76-80°C to form a coating liquid; mix the solid lubricating particles and the coating liquid and ultrasonically disperse them for 15-30 minutes, then cool down to 0-30°C to precipitate the crude product, and then use The liquid medium washes the crude product.

[0044] The liquid medium is mixed with the cellulose to form a coating liquid, which facilitates subsequent coating of the solid lubricating particles. Since cellulose is a macromolecular organic matter, in order to a...

Embodiment 1

[0052] This embodiment provides a kind of wear-resistant coating, and its preparation method is specifically as follows:

[0053] Prepare microcapsule lubricating particles first: mix ethyl cellulose and glycerin, stir and heat up to 76°C to form a coating solution; WS with an average particle size of 50nm 2 Add it into the coating solution and ultrasonically disperse for 15 minutes, then cool the reaction system to 0°C until solids are precipitated, and then use glycerin to wash the precipitated solids to obtain microcapsule lubricating particles.

[0054] Then, in parts by weight, mix 35 parts of acrylic resin, 1 part of emulsifier OP-10, and 50 parts of methyl acrylate to make a solvent; then take 10 parts of microcapsule lubricating particles in the present embodiment, 0.2 part of α -Al 2 o 3 and 1 part rutile TiO 2 Add it to the solvent and mix well to get a wear-resistant coating.

Embodiment 2

[0056] This embodiment provides a kind of wear-resistant coating, and its preparation method is specifically as follows:

[0057] Prepare microcapsule lubricating particles first: mix carboxymethyl cellulose and glycerin in parts by weight, stir and heat up to 80°C to form a coating solution; WS with an average particle size of 200nm 2 Add it into the coating solution and ultrasonically disperse for 30 minutes, then cool down the reaction system to 30°C until solids are precipitated, and then wash the precipitated solids with glycerin to obtain microcapsule lubricating particles.

[0058] Then in parts by weight, 40 parts of phenyltrichlorosilane, 2 parts of emulsifier OP-10, 55 parts of methyl acrylate were mixed to make a solvent; 0.5 parts of α-Al 2 o 3 and 3 parts rutile TiO 2 Add it to the solvent and mix well to get a wear-resistant coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com