Method for regenerating vanadium-titanium SCR denitration catalyst by utilizing regeneration activity complementing solution

The technology of denitration catalyst and deactivation catalyst is applied in the field of regeneration of vanadium-titanium series SCR denitration catalyst, which can solve the problems of increasing the amount of regeneration and reactivation liquid, increasing the regeneration cost, difficult to control the dispersion degree, etc. The effect of less raw material consumption and lower dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to clearly illustrate the present invention, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. Those skilled in the art understand that the following content does not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

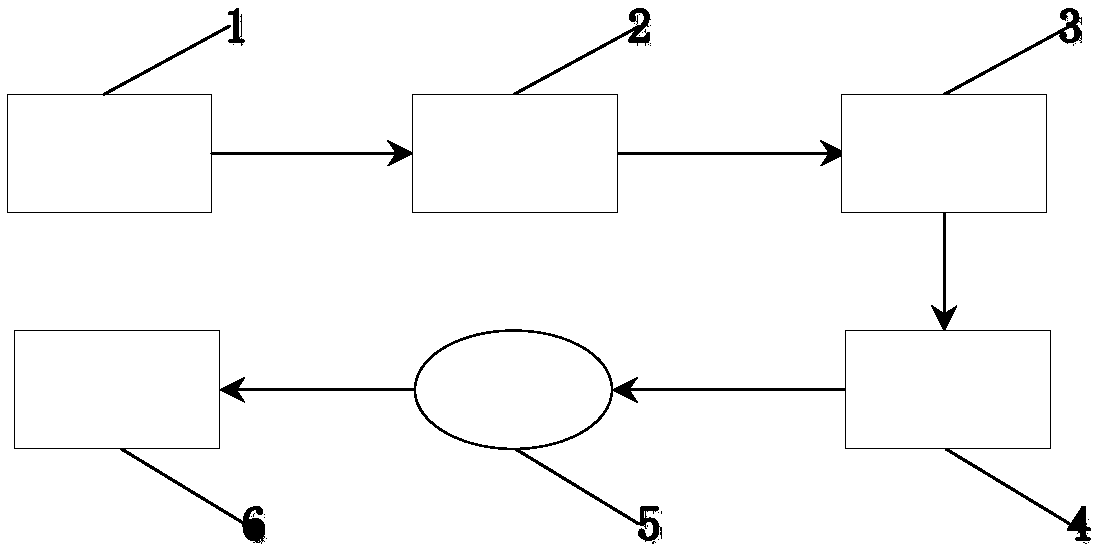

[0043] According to a preferred embodiment of the present invention, the system used in the deactivated catalyst regeneration process is as figure 1 As shown, it includes: deactivated catalyst 1, soot blowing and slagging system 2, water washing system 3, pickling system 4, organic complex impregnation system 5 and catalyst drying and calcination system 6, and the six systems are sequentially connected in series .

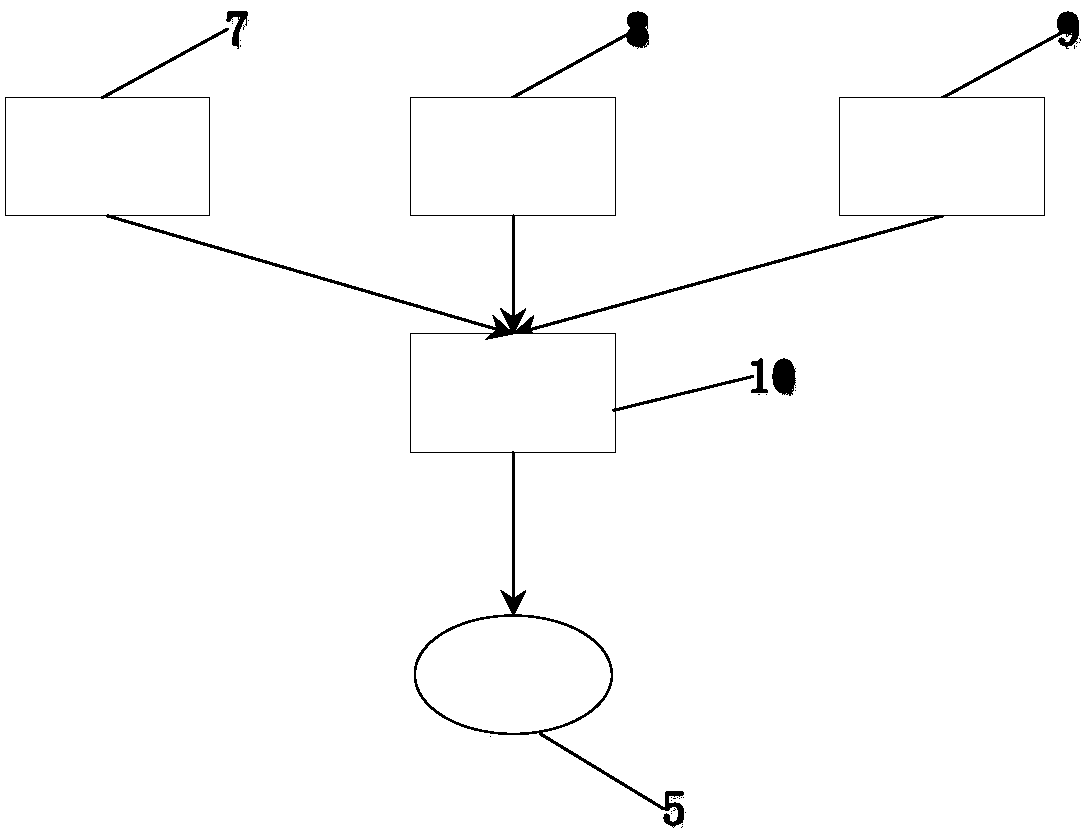

[0044] Based on the organic complex preparation system of the present invention such as figure 2 shown. In addition to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com