Method for improving bonding quality of silicon carbide seed crystals

A silicon carbide seed and bonding technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of poor bonding quality of seed crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

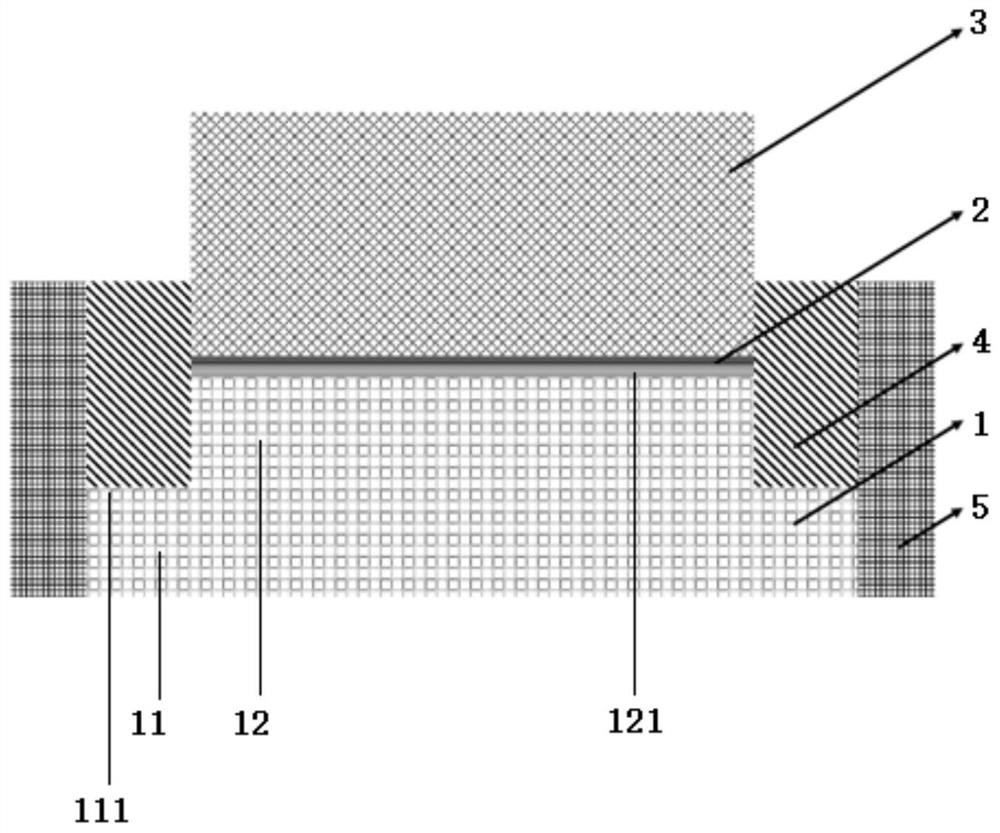

[0029] A silicon carbide seed crystal bonding structure is characterized in that it includes the following parts: a graphite plate 1, a seed crystal 2, a weight 3, a fixing ring 4, and a thermal insulation felt 5.

[0030] Graphite plate 1 is in the shape of a "convex" in cross-section, with a base 11 and a protrusion 12, the cross-sectional area of the protrusion 12 is smaller than that of the base 11, and the outside of the protrusion 12 is the shoulder 111 of the base 11; the horizontal surface of the protrusion 12 is bonded Surface 121.

[0031] The seed crystal 2 is a layer bonded on the bonding surface 121 .

[0032] The cross section of the weight 4 is the same as that of the protrusion 12 and is cylindrical, and is located above the seed crystal 2 .

[0033] The fixed ring 4 is a hollow cylinder made of high-purity graphite, and the hollow part thereof fits with the weight 4 and the convex part 12 .

[0034] The thermal insulation felt 5 is one or more layers of gr...

Embodiment 2

[0037] A silicon carbide seed crystal bonding structure is characterized in that it includes the following parts: a graphite plate 1, a seed crystal 2, a weight 3, a fixing ring 4, and a thermal insulation felt 5.

[0038] Graphite plate 1 is in the shape of a "convex" in cross-section, with a base 11 and a protrusion 12, the cross-sectional area of the protrusion 12 is smaller than that of the base 11, and the outside of the protrusion 12 is the shoulder 111 of the base 11; the horizontal surface of the protrusion 12 is bonded Surface 121.

[0039] The seed crystal 2 is a layer bonded on the bonding surface 121 .

[0040] The cross section of the weight 4 is the same as that of the protrusion 12 and is cylindrical, and is located above the seed crystal 2 .

[0041] The fixed ring 4 is a hollow cylinder made of high-purity graphite, and the hollow part thereof fits with the weight 4 and the convex part 12 .

[0042] The thermal insulation felt 5 is one or more layers of grap...

Embodiment 3

[0045] A silicon carbide seed crystal bonding structure is characterized in that it includes the following parts: a graphite plate 1, a seed crystal 2, a weight 3, a fixing ring 4, and a thermal insulation felt 5.

[0046] Graphite plate 1 is in the shape of a "convex" in cross-section, with a base 11 and a protrusion 12, the cross-sectional area of the protrusion 12 is smaller than that of the base 11, and the outside of the protrusion 12 is the shoulder 111 of the base 11; the horizontal surface of the protrusion 12 is bonded Surface 121.

[0047] The seed crystal 2 is a layer bonded on the bonding surface 121 .

[0048] The cross section of the weight 4 is the same as that of the protrusion 12 and is cylindrical, and is located above the seed crystal 2 .

[0049] The fixed ring 4 is a hollow cylinder made of high-purity graphite, and the hollow part thereof fits with the weight 4 and the convex part 12 .

[0050] The thermal insulation felt 5 is one or more layers of gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com