Clamp control device

A control device and fixture technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of automatic opening and closing, etc., achieve the effect of reducing load, compact control device, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

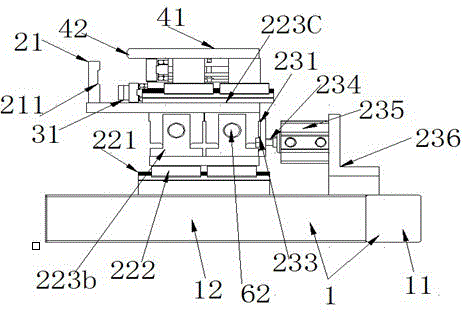

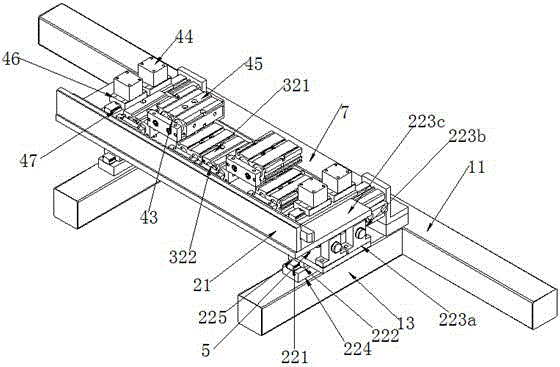

[0053] Such as figure 1 As shown, this embodiment provides a clamp control device, including a fixed bracket 1, the fixed bracket 1 includes a first fixed bracket 11 arranged along the running direction of the clamp, and vertically extending from the first fixed bracket 11 At least two second fixed mounts 12 and third fixed mounts 13 arranged at a certain distance, the first fixed mount 11, the second fixed mount 12 and the third fixed mount 13 are on the same height plane, and, The first fixing frame 11, the second fixing frame 12 and the third fixing frame 13 are all long slats, and the cooperation of the three forms the bottom supporting frame of the fixture control device of this embodiment. The supporting frame has the function of saving materials. specialty.

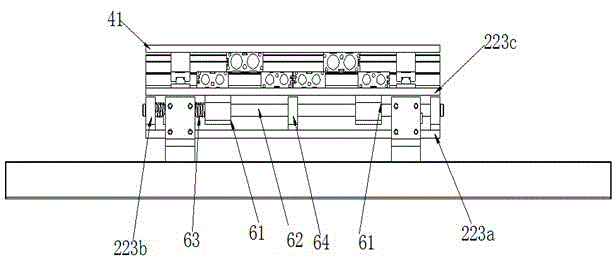

[0054] The core of this embodiment is that the gripper control device also includes a first movement device located on the fixed support 1, a second movement device, a third movement device arranged above the runn...

Embodiment 2

[0080] This embodiment provides a clamp control device, which is a modification based on Embodiment 1. In this embodiment, the telescopic device includes a device arranged between the first supporting plate 223a and the second supporting plate 223c and The slider fixed by the second support plate 223c is arranged on the track on the first support plate 223a, the slider is located in the track, and the first movement device, the second movement device or the third movement device are given to the clamp. When the driving force of the moving device is towards the front of the running direction, it can slide along the track with the slider to play the role of the above-mentioned elastic support member 63. When it needs to be reset, it can be reset by controlling the controller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com