Spraying device for copper rod and online spraying system

A technology of spraying device and copper rod, which is applied in spraying device, paint spraying room and other directions, can solve the problems of copper rod oxidation, etc., and achieve the effect of low cost, high efficiency, and saving labor in transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

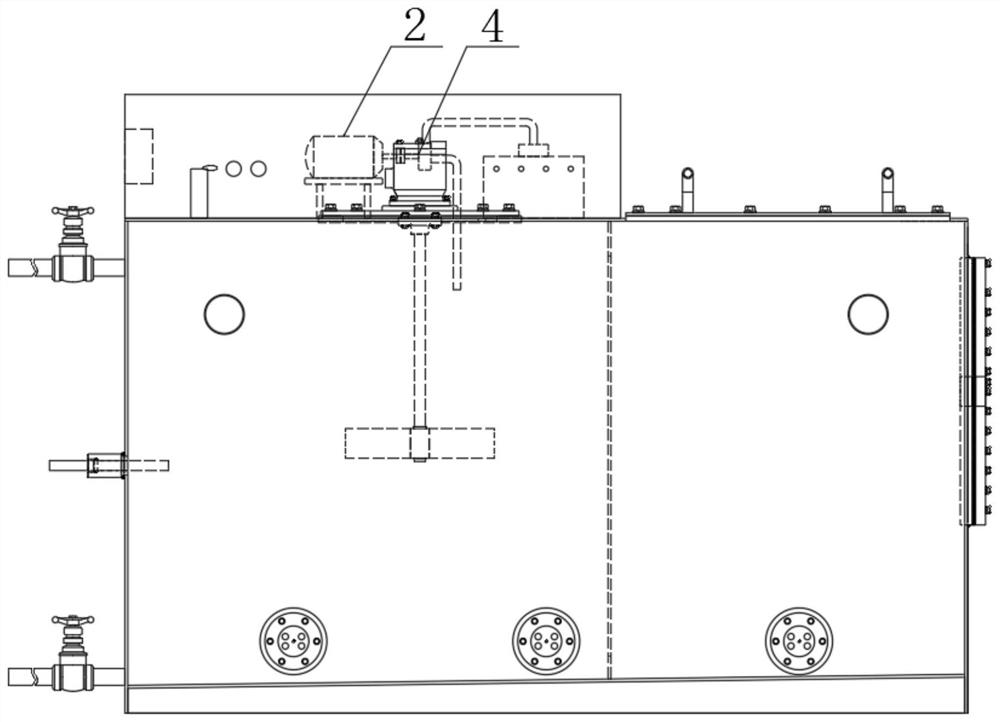

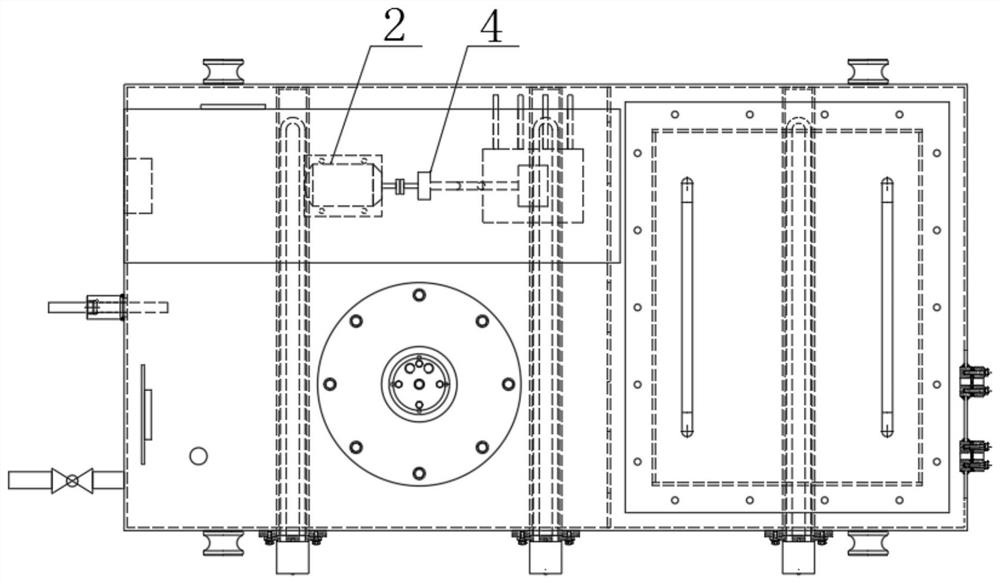

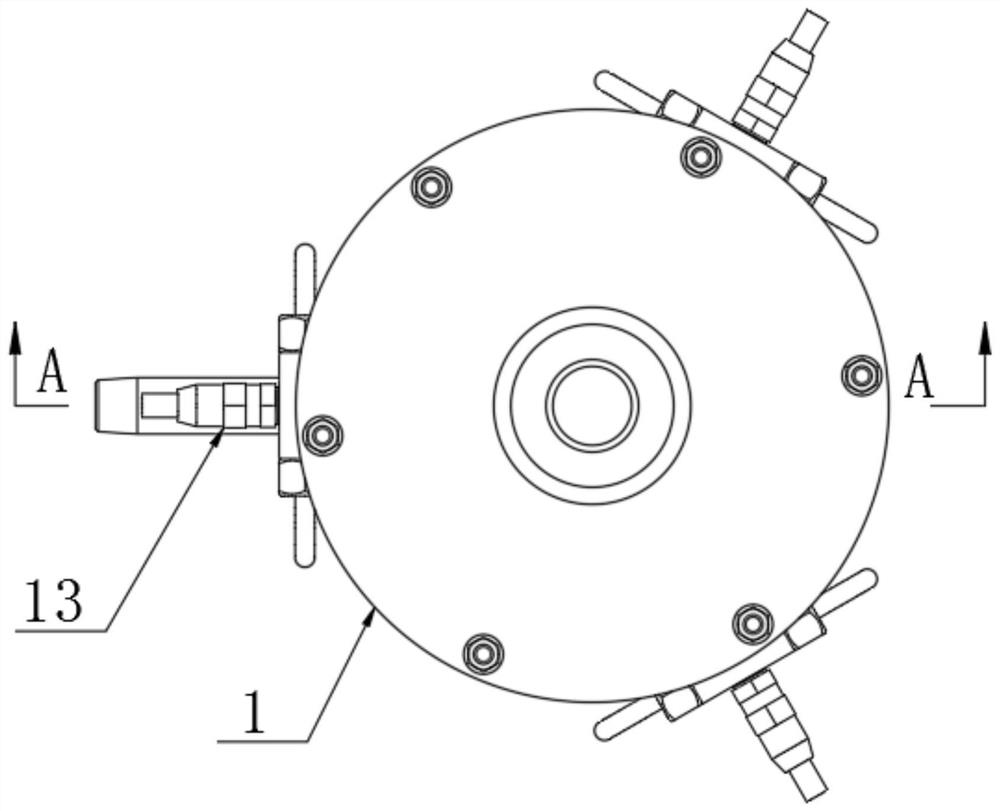

[0034] refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, the spraying device for copper rods of the present invention includes a storage box for storing an anti-oxidation medium and a spraying mechanism connected to the storage box; the spraying mechanism includes a hollow cylindrical shell 1, and the top of the shell 1 is arranged There is an upper connecting port 11, and a lower connecting port 12 is provided at the bottom of the housing 1; the upper connecting port 11 and the lower connecting port 12 are coaxially arranged; the housing 1 is provided with three nozzles 13 connected to the storage tank , and arranged on the same plane, the distance between two adjacent nozzles 13 is 120°; the storage tank is provided with a power mechanism 2 for transporting the anti-oxidation medium in the storage tank to the nozzles 13; the power mechanism 2 adopts an air pump. The copper rod of the present invention passes through the upper connecting port, the inside of ...

Embodiment 2

[0041]The on-line spraying system includes a copper rod continuous rolling mill, which includes a traction mechanism and a throwing rod mechanism, and also includes the spraying device for copper rods in Embodiment 1, and the anti-oxidation spraying device is arranged on the traction mechanism and the throwing rod mechanism. between rods. The present invention is ingeniously designed, and the anti-oxidation spraying device is arranged between the traction mechanism and the throwing rod mechanism, which is equivalent to being integrated into the copper rod continuous rolling mill, and there is no need to set up a special process to spray the copper rod again, saving the transfer labor, The transfer time and transfer cost have improved the efficiency; at the same time, the whole process is continuous, without affecting the normal production of the copper rod continuous rolling mill, it solves the problem that the copper rod is easily oxidized when it is exposed to the air for a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com