Method for achieving optical visualization of low-dimensional nanomaterials

A low-dimensional nanometer and nanomaterial technology, applied in the field of nanomaterial characterization, can solve problems such as narrow scope of application, complex methods and equipment, and no visualization of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

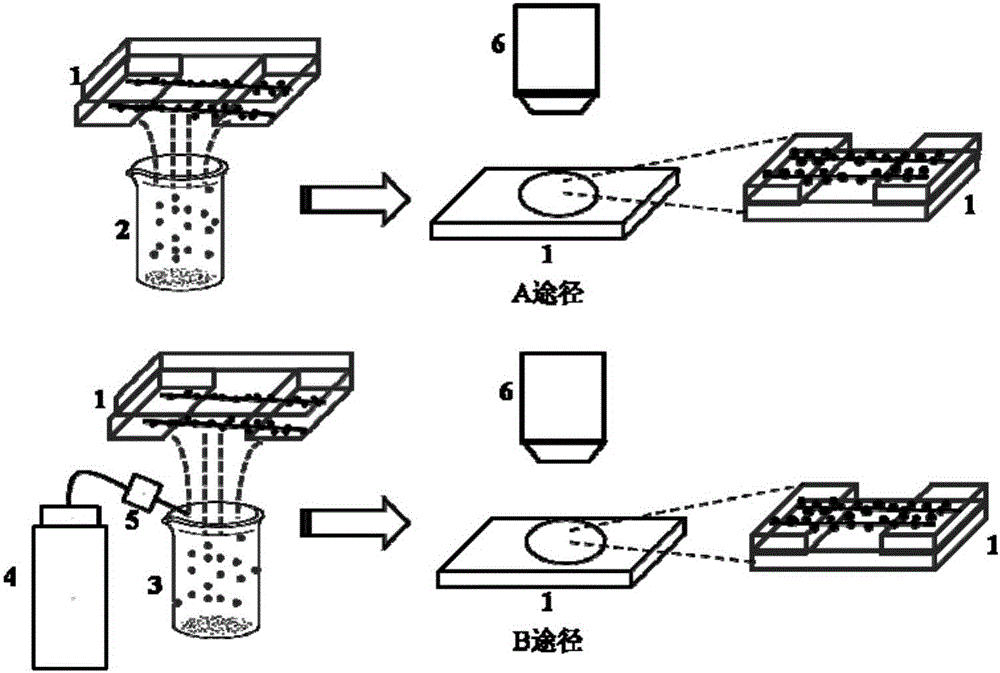

[0041] Example 1. Optical visualization of a single carbon nanotube on a silica / silicon substrate using sublimated sulfur

[0042] Specific process such as figure 1 As shown, the horizontal array of ultra-long carbon nanotubes grown on the silica / silicon substrate is prepared first, and then the sublimated sulfur is heated to 120 ° C by a heating platform. After the temperature is stable, the substrate with carbon nanotubes is turned upside down. Above the sublimated sulfur, take it off after 5 minutes, and observe it with an optical microscope.

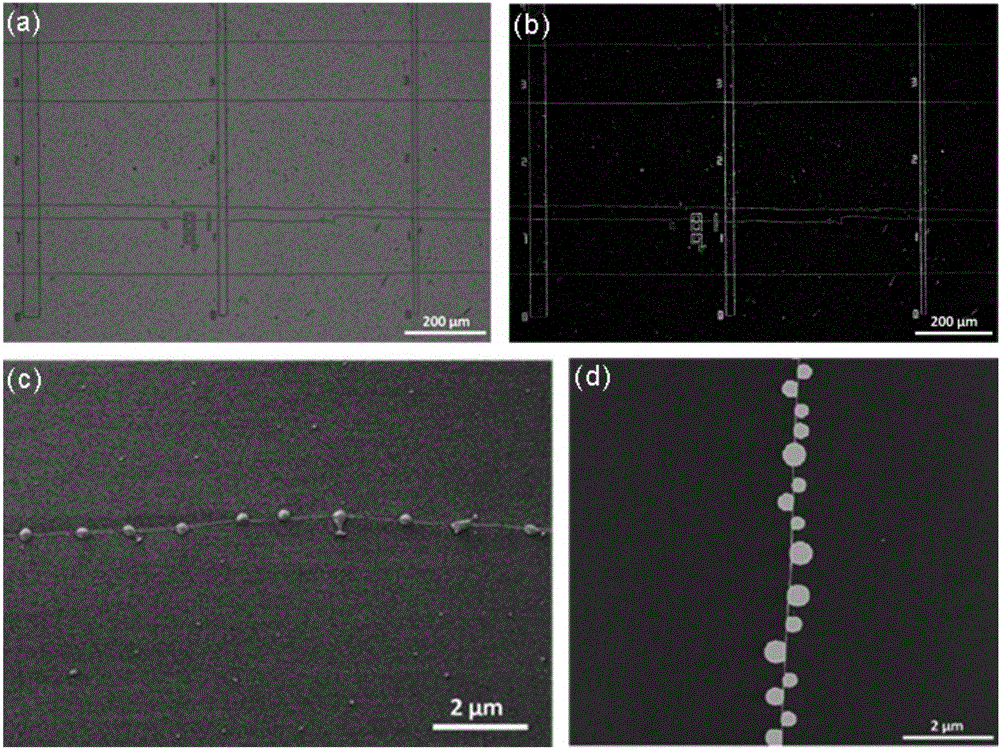

[0043] The optical photo of the sublimed sulfur-loaded carbon nanotubes prepared in this example is as follows figure 2 As shown, through optical photographs, scanning electron microscope photographs, and atomic force microscope photographs, it can be seen that sublimated sulfur is effectively supported on carbon nanotubes, and optical visualization of carbon nanotubes on a silica / silicon substrate is realized.

[0044] In this em...

Embodiment 2

[0046] Example 2. Optical visualization of suspended carbon nanotubes using sublimated sulfur

[0047] The specific process flow is the same as in Example 1. In this example, a substrate with slits is selected to grow carbon nanotubes, and the carbon nanotubes are in a suspended state at the slits, and the suspended carbon nanotubes are helpful for subsequent controllable manipulation. Place the substrate with suspended carbon nanotubes on top of sublimated sulfur at 120°C for 5 minutes, and then remove the sample for observation.

[0048] Optical photographs of the sublimed sulfur-loaded suspended carbon nanotubes prepared in this example are as follows Figure 4 As shown, it can be seen from optical photos and scanning electron microscope photos that the sublimated sulfur is effectively loaded on the suspended carbon nanotubes, and the optical visualization of the suspended carbon nanotubes is realized.

[0049] The suspended carbon nanotubes loaded with sublimed sulfur pre...

Embodiment 3

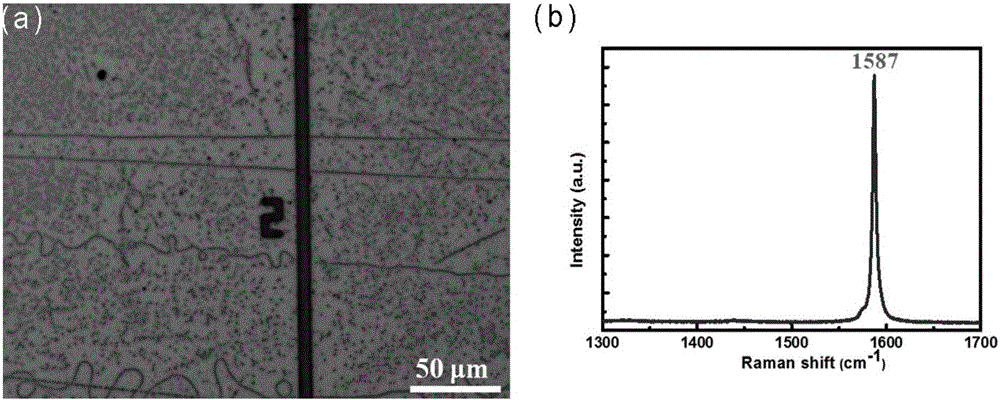

[0050] Example 3. Optical visualization of carbon nanotubes on a pure silicon substrate using sublimated sulfur

[0051] The specific process flow is the same as in Example 1. First, the horizontal array of ultra-long carbon nanotubes grown on a pure silicon substrate is prepared, and then the sublimated sulfur is heated to 120°C by a heating platform. The pure silicon substrate was placed upside down on the sublimated sulfur, removed after 5 minutes, and then observed with an optical microscope.

[0052] The optical photo of the sublimed sulfur-loaded carbon nanotubes prepared in this example is as follows Figure 5 As shown, the sublimated sulfur is effectively supported on the carbon nanotubes through the optical photographs, and the optical visualization of the carbon nanotubes on the pure silicon substrate is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com