Method for purifying dichloromethyl phenylsilane by chemical coordination effect

A technology of methylphenyldichlorosilane and phenyltrichlorosilane, which is applied in the field of purification of methylphenyldichlorosilane, can solve the problems of large by-products, strict requirements on the stability of distillation aids, etc., and achieves low reaction loss , The effect of fast reaction speed and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

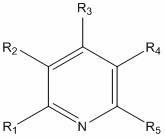

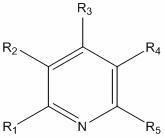

Image

Examples

Embodiment 1

[0027] Embodiment 1: in the 2000mL three-neck flask that stirring and constant pressure dropping funnel are housed, add 1000g purity and be 74.3% MePhSiCl 2Put the crude product in a low-temperature bath at 0°C, and then add a mixture of 219g N-methylimidazole and 250g acetonitrile dropwise through a constant-pressure dropping funnel, and soon a white precipitate will form. , the white precipitate gradually increased. After the dropwise addition, the reaction was stirred at room temperature for 0.5 h. Then filter to remove the white precipitate, and the obtained filtrate is subjected to fractional distillation at normal pressure through a distillation column (specification 700×24mm, glass spring packing). MePhSiCl is obtained between ~204°C 2 , the purity is 96.4%, and the yield is 85.3%.

Embodiment 2

[0028] Embodiment 2: in the 2000mL three-neck flask that stirring and constant pressure dropping funnel are housed, add 1000g purity and be 85.8% MePhSiCl 2 Put the crude product in a low-temperature bath at -10°C, and then add a mixture of 133g N-methylimidazole and 150g toluene dropwise through a constant-pressure dropping funnel, and soon a white precipitate will form. Carried out, the white precipitate gradually increased. After the dropwise addition, the reaction was stirred at room temperature for 2 h. Then centrifuge and decant to obtain the supernatant, and then through the distillation column (specification 700×24mm, glass spring packing) fractional distillation at normal pressure, the temperature at the top of the column is between 109 and 111°C to obtain toluene (yield is 96.5%), the column The top temperature is between 202 and 204°C to obtain MePhSiCl 2 , the purity was 98.2%, and the yield was 90.6%.

Embodiment 3

[0029] Embodiment 3: in the 2000mL three-neck flask that stirring and constant pressure dropping funnel are housed, add 1000g purity and be 92.3% MePhSiCl 2 Put the crude product in a low-temperature bath at -30°C, and then add a mixture of 83g N-methylimidazole and 100g toluene dropwise through a constant-pressure dropping funnel, and soon a white precipitate will form. Carried out, the white precipitate gradually increased. After the dropwise addition, the reaction was stirred at room temperature for 2 h. Then filter to remove the white precipitate, and the obtained filtrate is subjected to fractional distillation at atmospheric pressure through a distillation column (specification 700×24mm, glass spring packing). MePhSiCl is obtained between ~204°C 2 , the purity is 99.7%, and the yield is 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com