Method and device for catalytic hydrolysis of urea

A urea catalyzed hydrolysis and urea hydrolysis technology, applied in the field of urea catalyzed hydrolysis, can solve problems such as not very mature, and achieve the effects of fast reaction speed, low operating cost and high superiority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

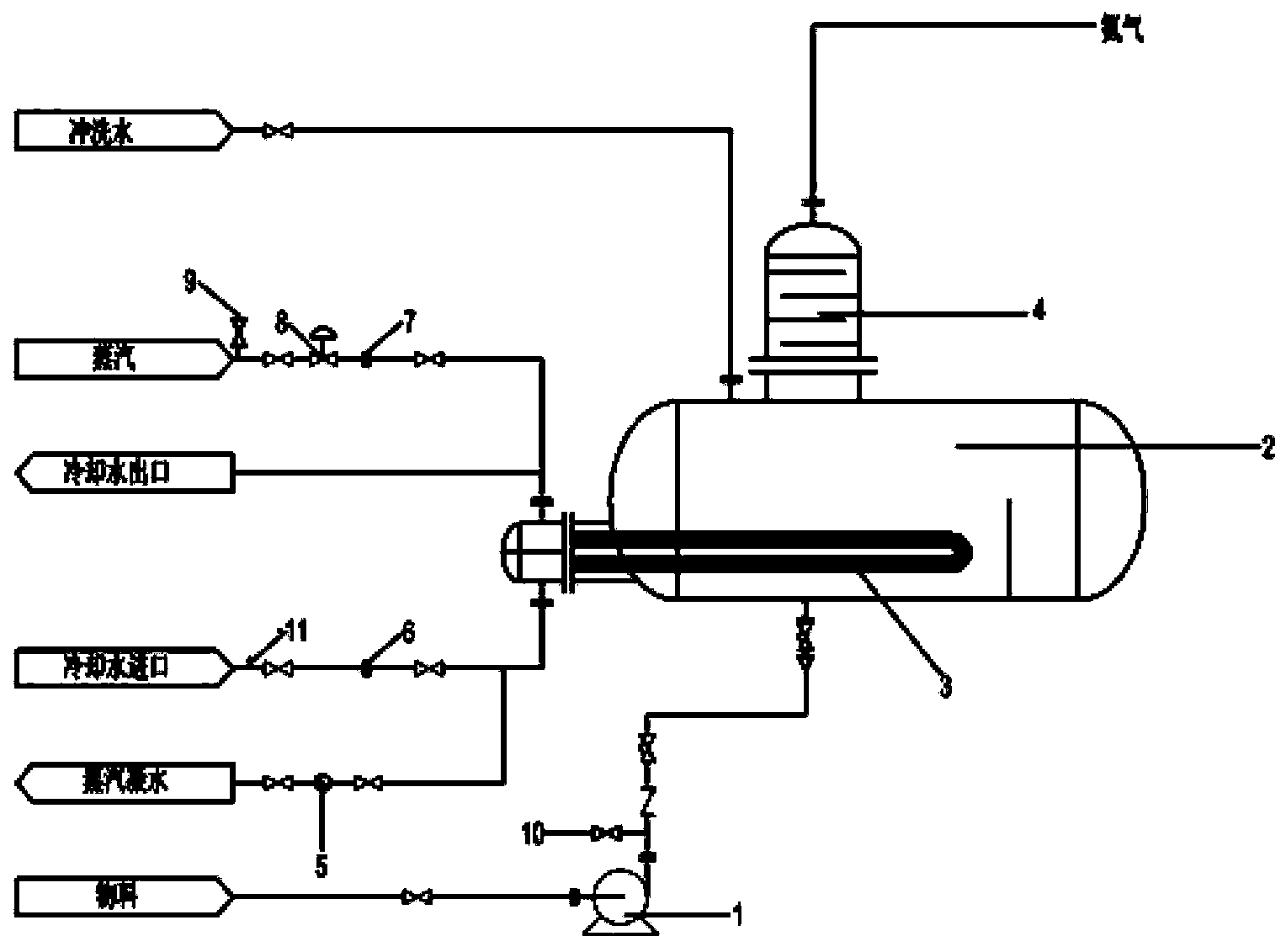

[0038] Urea catalytic hydrolysis device of the present invention, such as figure 1 As shown, it includes: feed pump 1, urea hydrolysis reactor 2, an on-site pressure gauge 10 is provided on the connecting pipeline between feed pump 1 and urea hydrolysis reactor 2, and a steam coil is inserted in the urea hydrolysis reactor 2 3. The steam inlet pipe is connected to the cooling water outlet pipe and connected to the top of the outer side of the steam coil 3. The steam inlet pipe is provided with a flow meter 7, a temperature regulating valve 8 and an on-site pressure gauge 9; the steam outlet pipe and the cooling water The inlet pipe is connected to the bottom of the outer side of the steam coil 3, and a steam trap 5 is provided on the steam outlet pipe, which can make the steam condense and release the condensation heat to be absorbed by the urea solution, saving steam to the greatest extent. A flow meter 6 and a thermometer 11 are provided to indicate the temperature and flow ...

Embodiment 2

[0053] 1) The dry urea powder is stored in the storage bin, transported to the dissolving tank by the screw feeder, the dry urea is dissolved into a 45% mass concentration urea solution with deionized water, and transported to the urea hydrolysis reactor through the feed pump;

[0054] 2) The catalyst diammonium hydrogen phosphate and ammonium dihydrogen phosphate are transported to the urea hydrolysis reactor through the feed pump according to different proportions, reaching 8% of the reactor volume; the urea solution and the catalyst are mixed evenly.

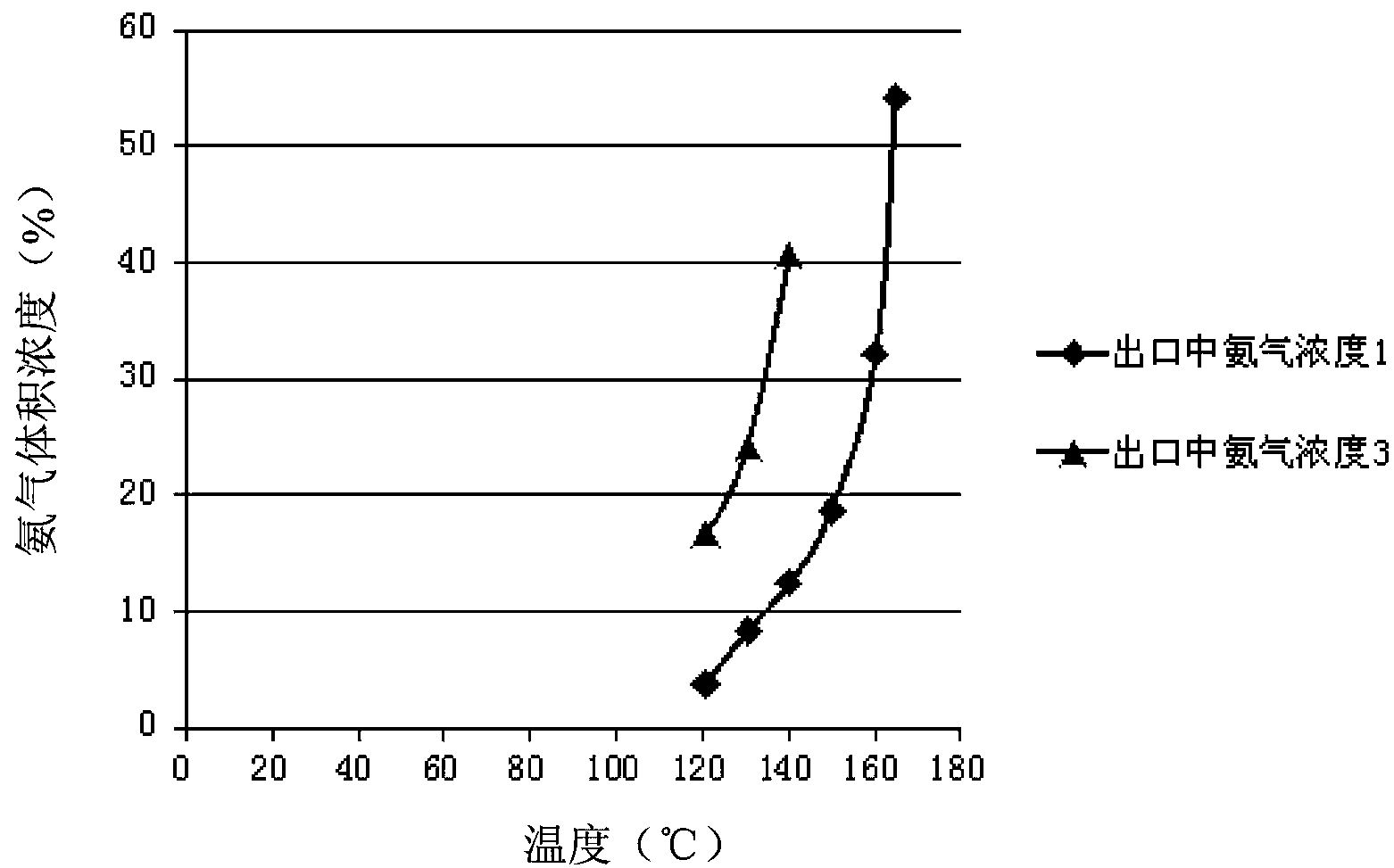

[0055] 3) The urea hydrolysis reactor is heated by means of airtight electric heat tracing. The heating temperature is 160°C and the pressure is 0.7MPa to realize the catalytic hydrolysis of urea.

Embodiment 3

[0057] 1) The dry urea powder is stored in the storage bin, transported to the dissolution tank by the screw feeder, and the dry urea is dissolved into a 50% mass concentration urea solution with deionized water, and transported to the urea hydrolysis reactor through the feed pump;

[0058] 2) The catalyst diammonium hydrogen phosphate and ammonium dihydrogen phosphate are transported to the urea hydrolysis reactor through the feed pump according to different proportions, reaching 10% of the reactor volume; the urea solution and the catalyst are mixed evenly.

[0059] 3) Use steam heating method to heat the urea hydrolysis reactor, heating temperature: 180°C, pressure: 0.8MPa, to realize catalytic hydrolysis of urea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com