Large-scale preparation method of niobium pentoxide nanowires and hydrogen-sensitive element thereof

A niobium pentoxide nanometer, large-area technology, applied in chemical instruments and methods, electrical components, nanotechnology, etc., can solve the problems of high cost, low repeatability, disadvantage, etc., to reduce equipment and production costs, improve The effect of surface area, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare Nb according to the previous steps 2 o 5 Nanowires, where the Nb foils are cut into small pieces of 5mm×10mm in steps 1 and 2, and after cleaning, place 3-5 pieces of cut Nb foils in a ceramic burning boat and place them in the furnace tube for heating The center of the zone, other steps are the same as above, and the specific process conditions are shown in the table below:

[0039]

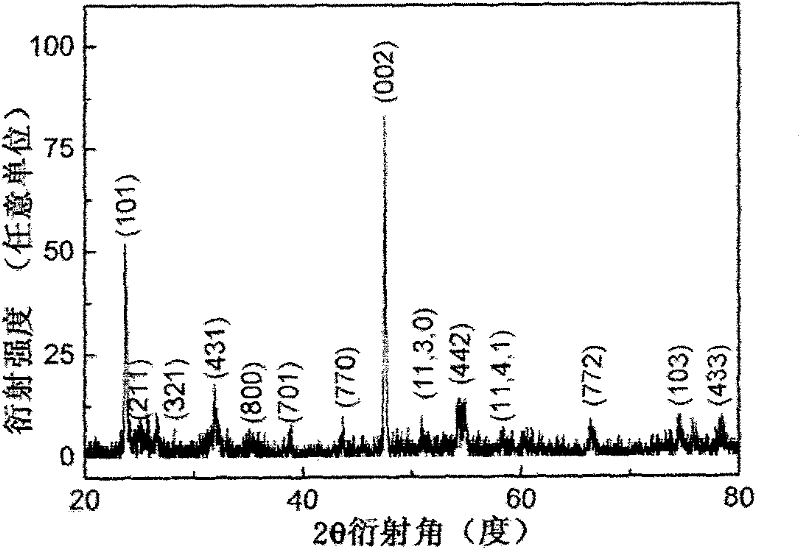

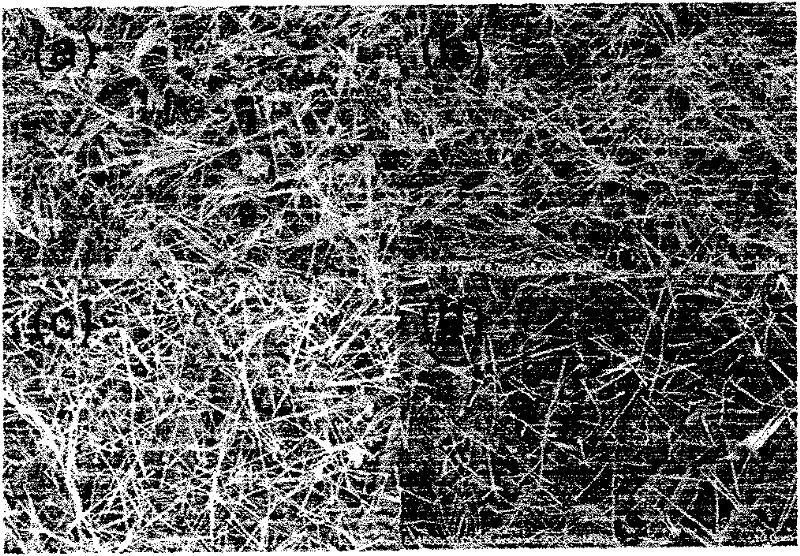

[0040] In the first embodiment above, on the basis of ensuring that the flow rate of Ar is constant, change O 2 flow rate, the surface morphology of the obtained sample is as attached image 3 shown. In order to obtain large area, high aspect ratio Nb 2 o 5 For nanowires, the oxygen flow rate should be controlled not to exceed 20 sccm, and the Nb prepared by too high oxygen flow rate 2 o 5 The aspect ratio and density of nanowires are both low. Nb prepared under the conditions of No. 2 2 o 5 With the best surface morphology, its phase and microstructure are as attache...

Embodiment 2

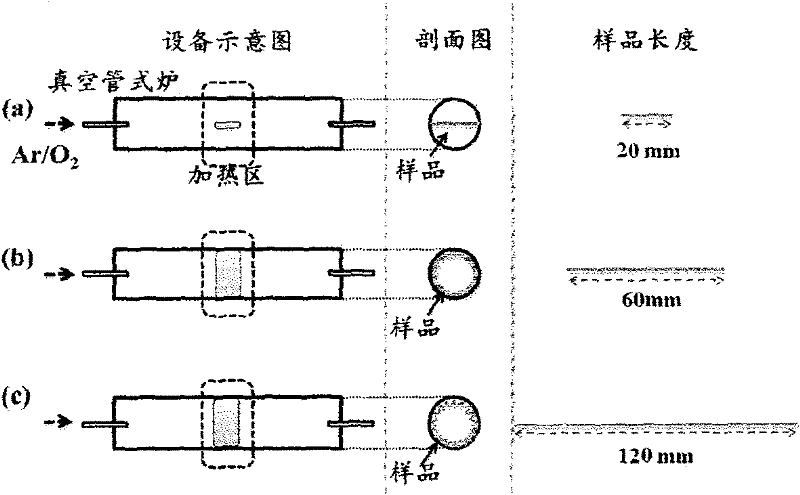

[0042] Prepare Nb according to the previous steps 2 o 5 Nanowires, wherein in steps 1 and 2, the Nb foil is cut into a strip-shaped foil of 60mm×30mm-60mm×50mm, and after the cleaning process is completed, it is bent into a cylindrical shape and attached to the furnace of the vacuum tube furnace The inner wall of the tube and placed in the center of the heating zone, if attached figure 1 (b) shown.

[0043] Other steps are all the same as above, and the specific process conditions are shown in the table below:

[0044]

[0045] In above-mentioned embodiment two, determine that Ar flow rate, heating rate and holding temperature are constant, at lower O 2 The heat preservation and oxidation time under the flow rate is longer, with the O 2 The flow rate is gradually increased, and the holding oxidation time is gradually reduced to 60min. In this example, a large area of uniformly grown Nb can be obtained 2 o 5 nanowire film structure.

Embodiment 3

[0047] Prepare Nb according to the previous steps 2 o 5 Nanowires, where in steps 1 and 2, the Nb foil is cut into 120mm×30mm-120mm×50mm strip foil and the cleaning process is completed, and it is folded and bent every 2-4mm to form an organ shape and rolled into a circle The cylindrical shape makes it attached to the inner wall of the furnace tube of the vacuum tube furnace and placed in the center of the heating area. Other steps are all the same as above, and the specific process conditions are shown in the table below:

[0048]

[0049] In the above example three, it is determined that the Ar flow rate, heating rate and holding temperature are constant, and at a lower O 2 The heat preservation and oxidation time under the flow rate is longer, with the O 2 The flow rate is gradually increased, and the holding oxidation time is gradually reduced to 60min. In this example, a large area of uniformly grown Nb can be obtained 2 o 5 nanowire film structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com