Electric closing anti-pinch control method for automobile back door

A control method and anti-pinch technology, applied in manual mechanisms, door/window accessories, power control mechanisms, etc., can solve the problem that the tailgate cannot be closed electrically, and achieve a more humanized control strategy and avoid accidental changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

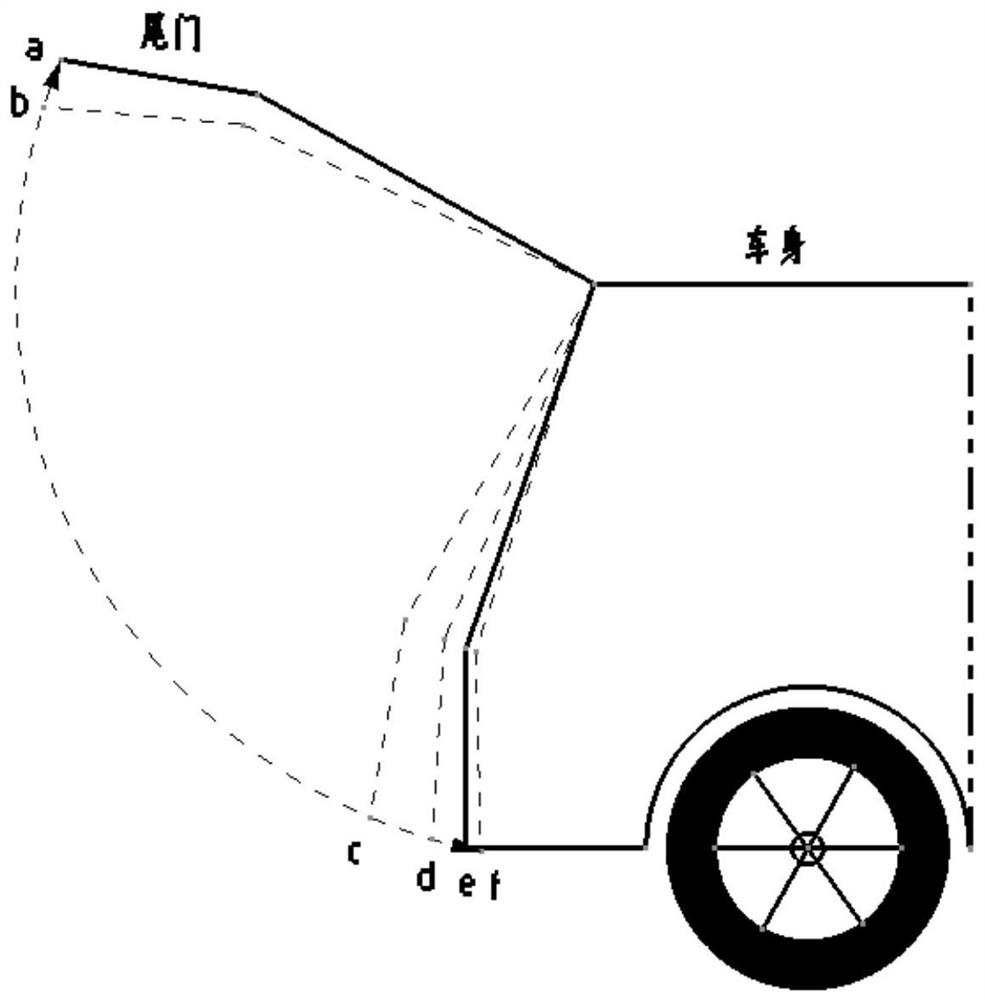

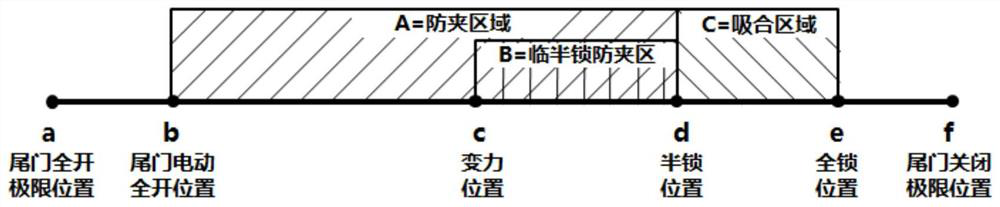

[0028] The invention discloses an automobile tailgate electric closing anti-pinch control method, such as figure 2 As shown, in the closing process of the existing automobile tailgate, the tailgate 1 first moves from the limit position a of the tailgate full opening to the direction close to the body 2 to the electric fully open position b of the tailgate, and then moves to the direction close to the body 2 to the half-lock position d, then continue to move toward the vehicle body 2 to the full-lock position e, and finally move to the tailgate closing limit position f to realize the complete closure of the tailgate 1.

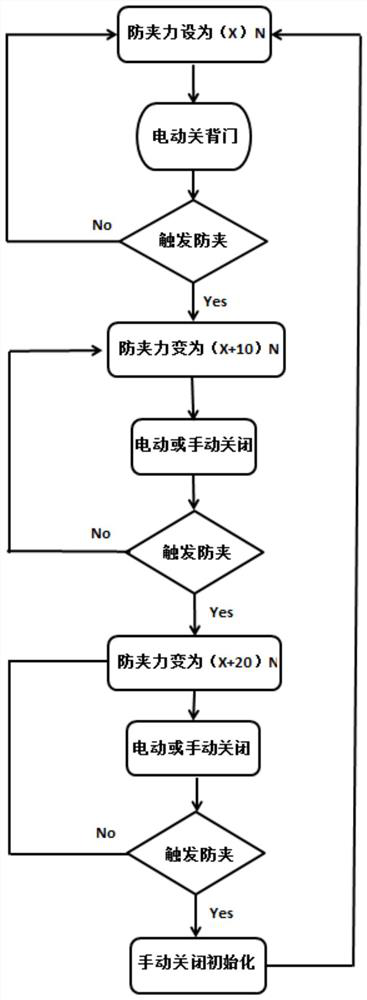

[0029] Such as figure 2 with image 3 As shown, in order to prevent the tailgate from being trapped during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com