Patents

Literature

31results about How to "Lower Upfront Costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra low density cementitious slurries for use in cementing of oil and gas wells

InactiveUS20050166803A1Accurate measurementLower Upfront CostsSolid waste managementDrilling compositionMicrospherePlasticizer

The storable, low-density, hydraulically-active, cementitious slurry of the invention is suitable for cementing within a subterranean formation for oil or gas wells. The low-density slurry comprises a hydraulically-active cementitious material, a set retarder, a plasticizer, glass or ceramic micro-spheres, and a strengthening agent. Further the slurry is substantially free of a suspension agent. The storable, low-density, hydraulically-active, cementitious slurry is made by adding glass or ceramic micro-spheres to a hydraulically-active cementitious material, adding a strengthening agent to the microsphere containing composition, and mixing the resulting composition with water, a set retarder, and a plasticizer to generate a slurry, wherein the set retarder is present in an amount sufficient to allow storage of the slurry.

Owner:BAKER HUGHES INC

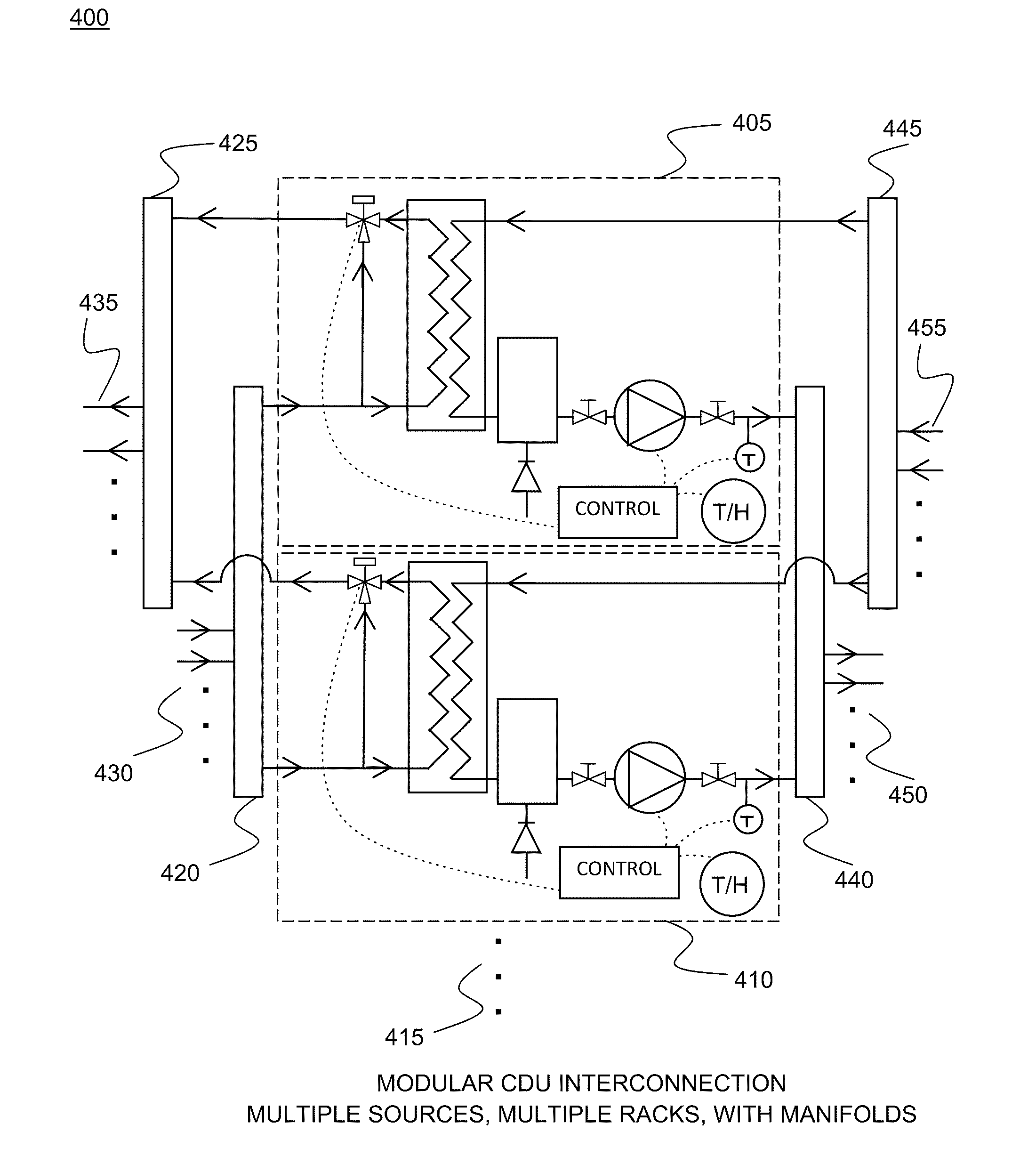

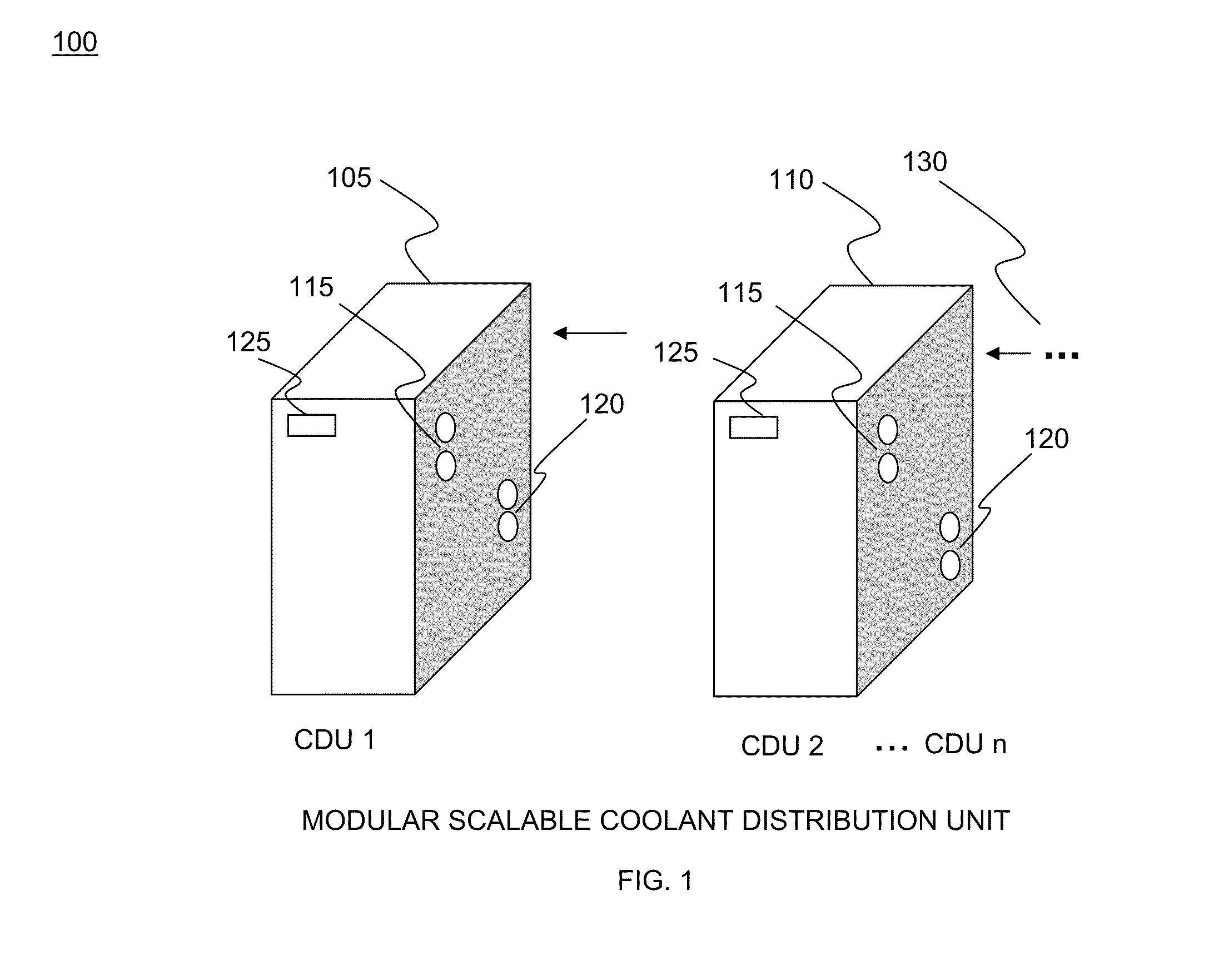

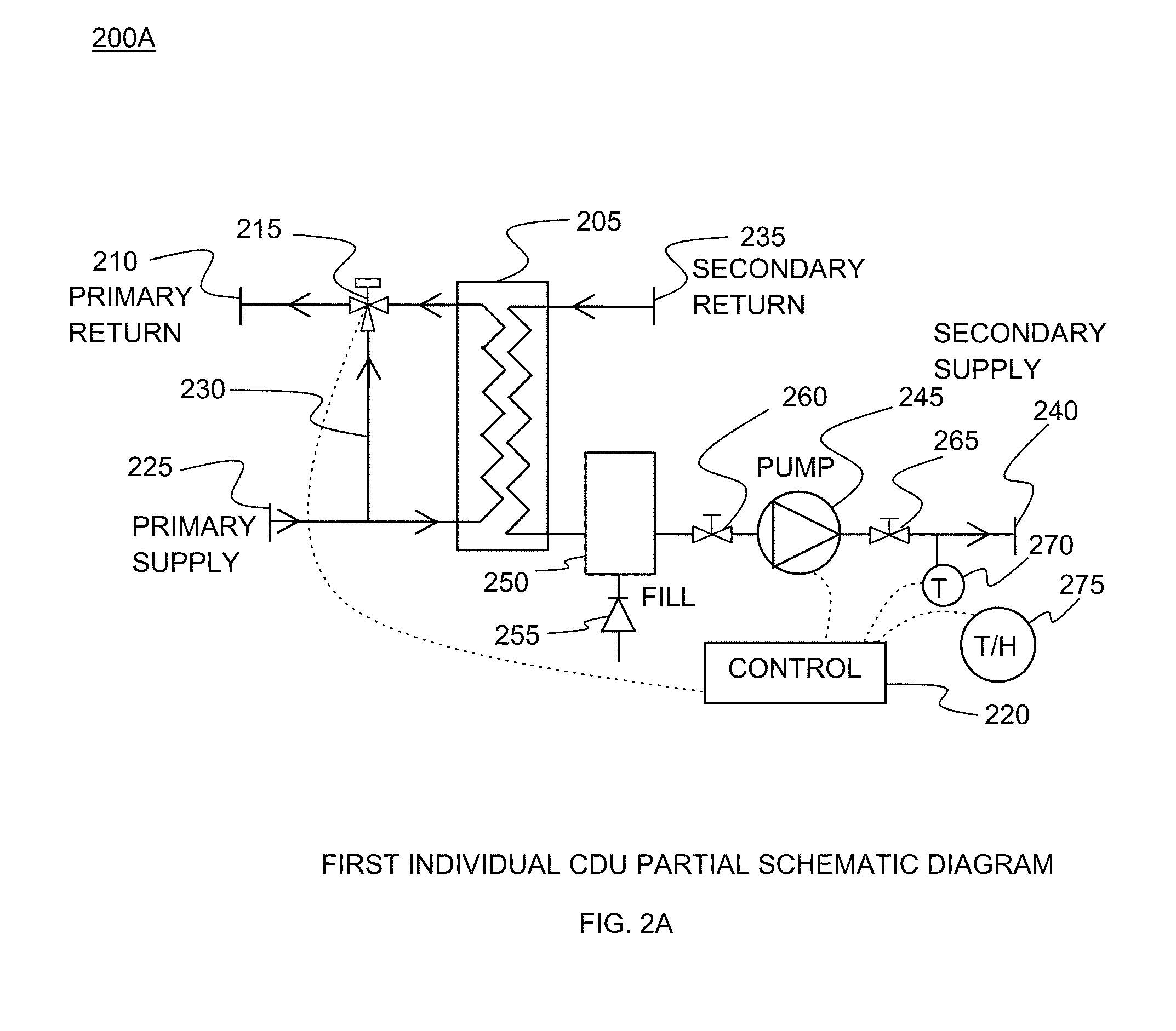

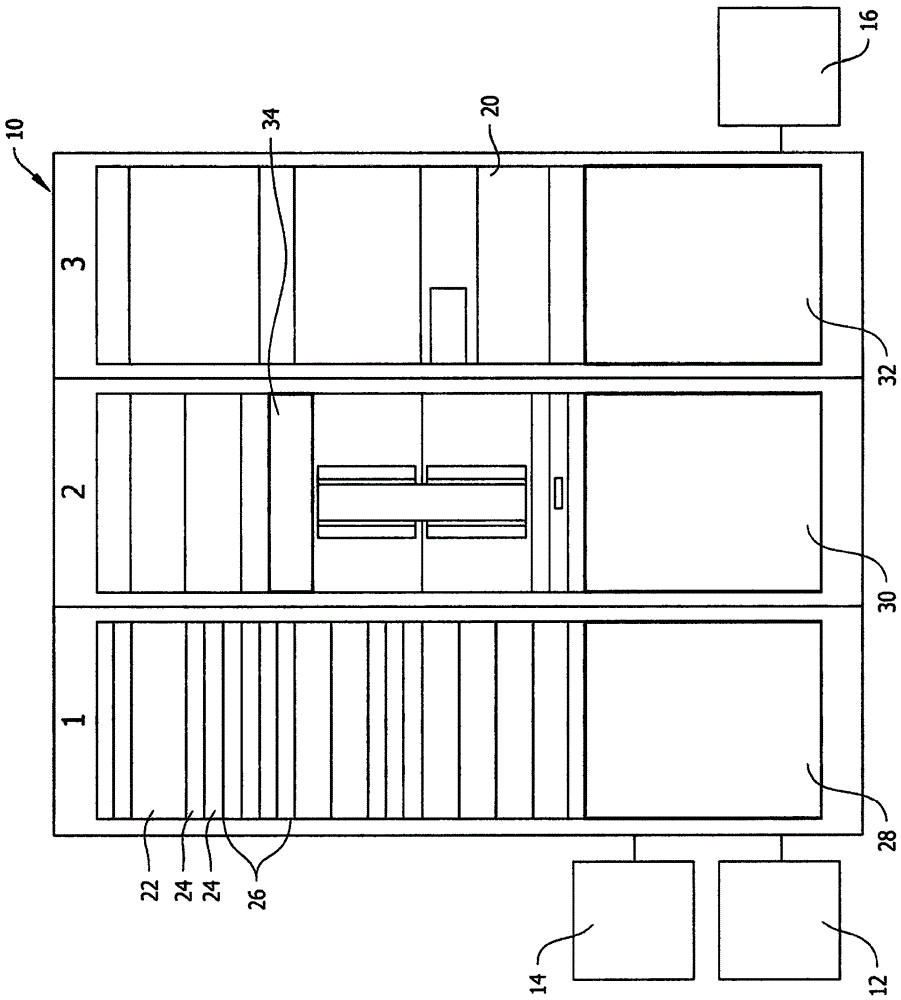

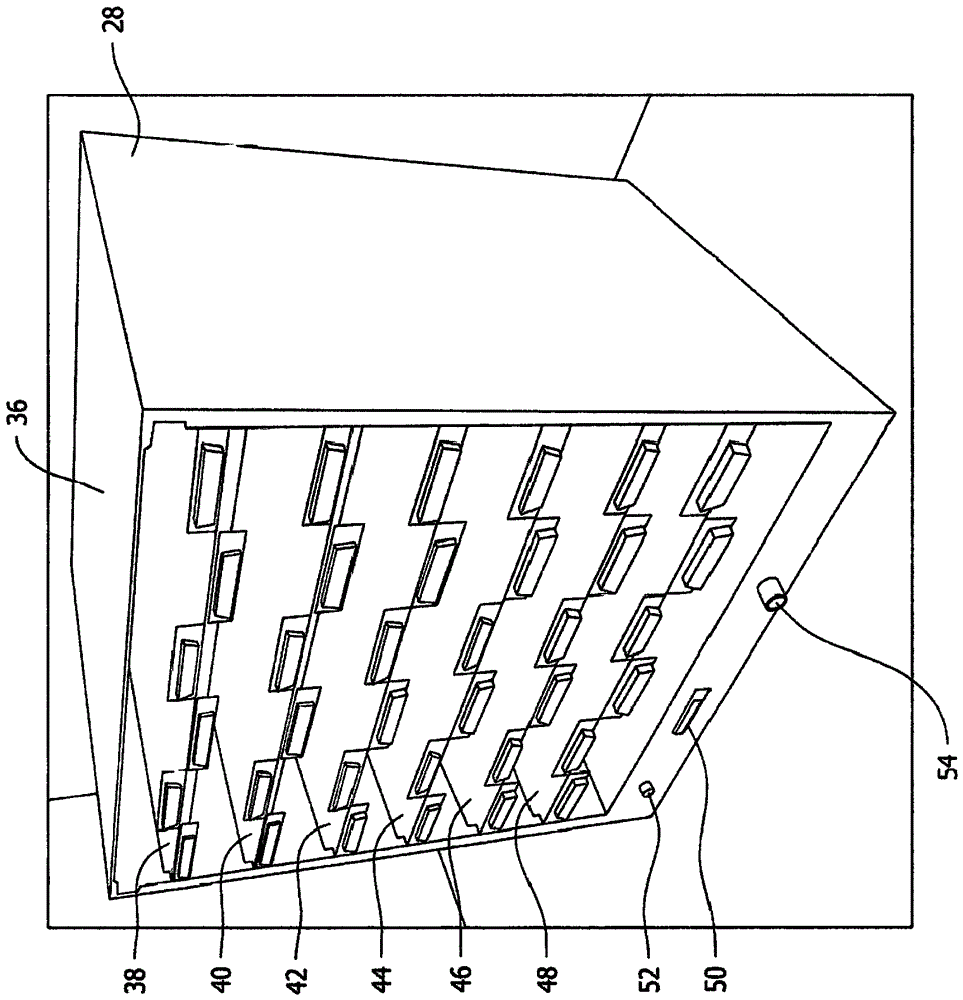

Modular scalable coolant distribution unit

InactiveUS8297069B2Lower Upfront CostsLarge load variationLighting and heating apparatusTemperatue controlData centerModularity

An equipment cooling system and method employing modular scalable coolant distribution units that interface with each other to provide liquid cooling for computer data centers. The coolant distribution unit (CDU) permits the use of elevated water temperatures without increasing the load on the computer room air conditioning. A control unit processes environment data to control pump and valve components supporting redundancy and multiple primary and secondary coolant loops.

Owner:VETTE TECH

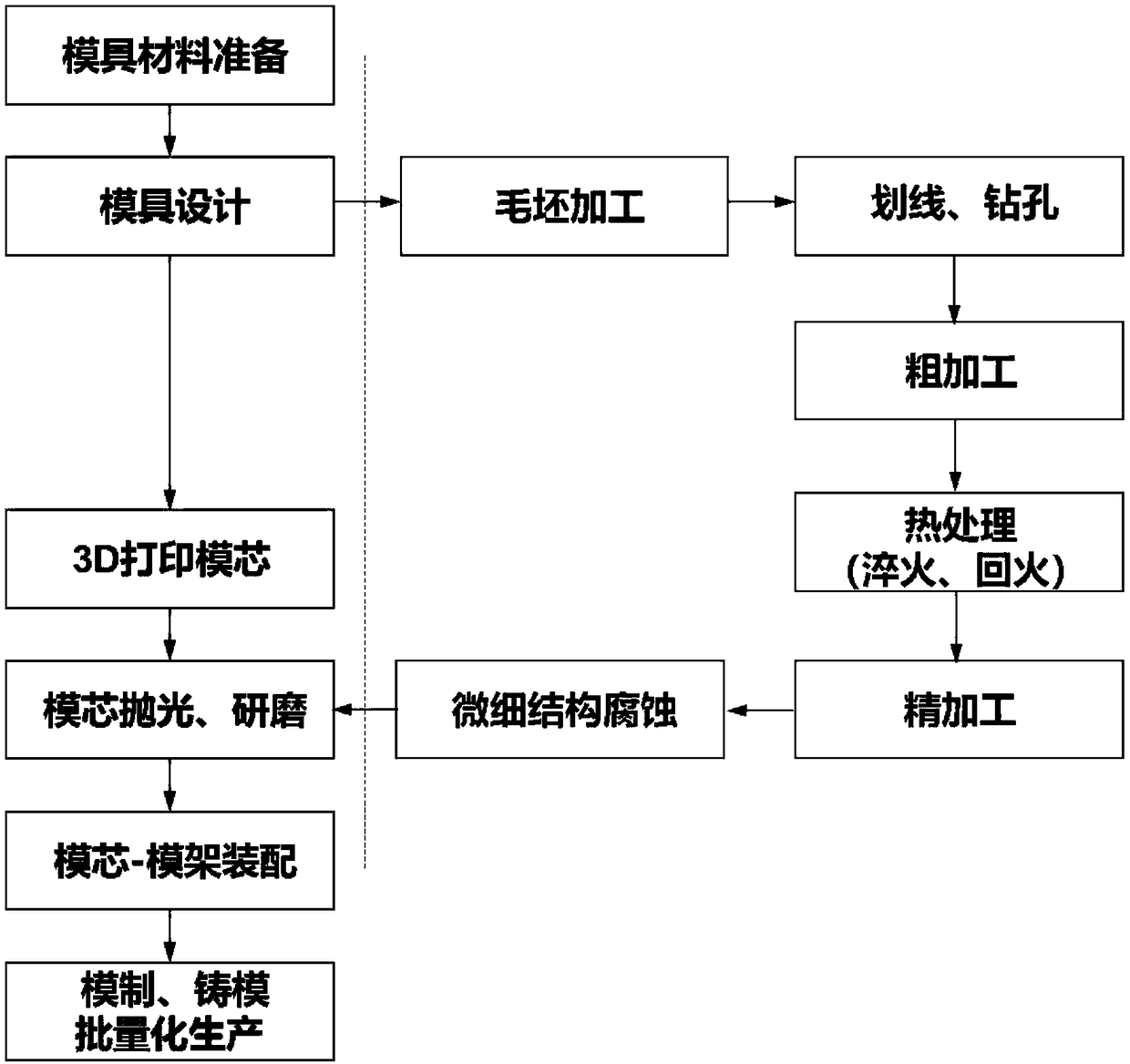

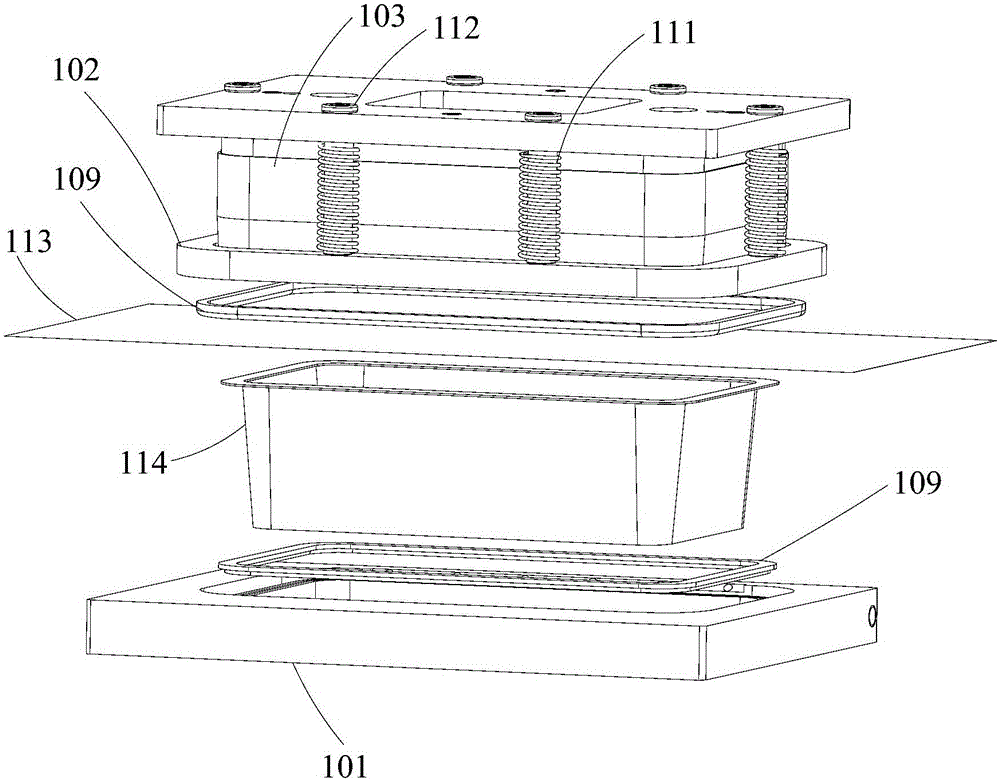

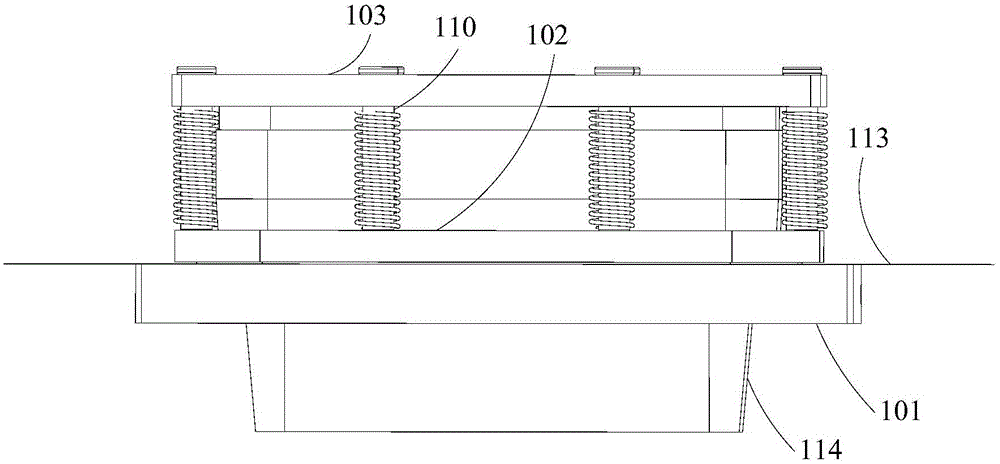

Mold rapid machining method based on 3D printing mold core

InactiveCN109128165AShorten the processing cycleRealize green and intelligent transformation and upgradingAdditive manufacturing apparatusCeramic shaping apparatusCasting moldRapid tooling

The invention discloses a mold rapid machining method based on a 3D printing mold core. The mold rapid machining method based on the 3D printing mold core is characterized by comprising the followingsteps of S1, preparing needed raw materials; S2, designing a geometric structure of the mold core, and converting the geometric structure of the mold core into a format matched with a format in a control equipment system; S3, using a 3D printing technology to print the mold core after S2 is finished; S4, polishing and grinding the mold core in S3 to a desired size and surface accuracy; S5, assembling the mold core in a mold base after S4 is finished; and S6, carrying out follow-up molding or casting mold batch production. By directly and rapidly performing 3D printing on the mold core, polishing the surface of the mold core and fastening the mold core on the mold base, the follow-up molding or casting mold batch production of the mold core is carried out and realized. According to the moldrapid machining method based on the 3D printing mold core, an optimal design is realized, the efficiency or function of a terminal product is enhanced, a difficult problem of traditional machining technologies such as CNC during machining the complicated geometric structures is solved, the design is free, the manufacturing is rapid and green, and green and intelligent transformation and upgradingof the traditional mold industry are really realized.

Owner:HUAZHONG UNIV OF SCI & TECH

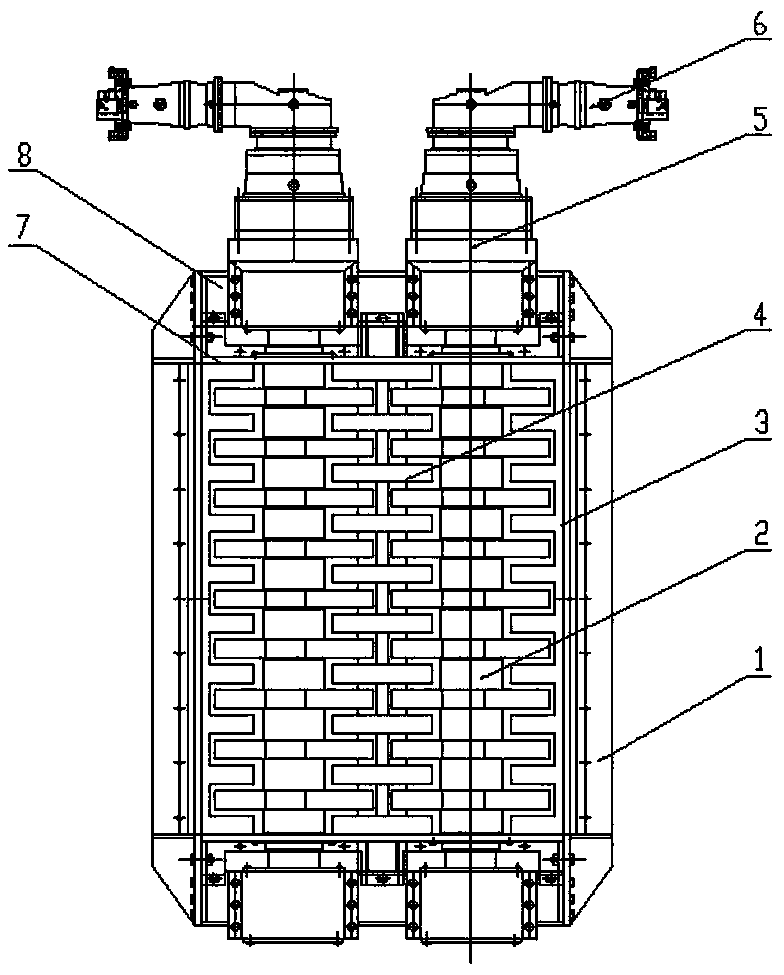

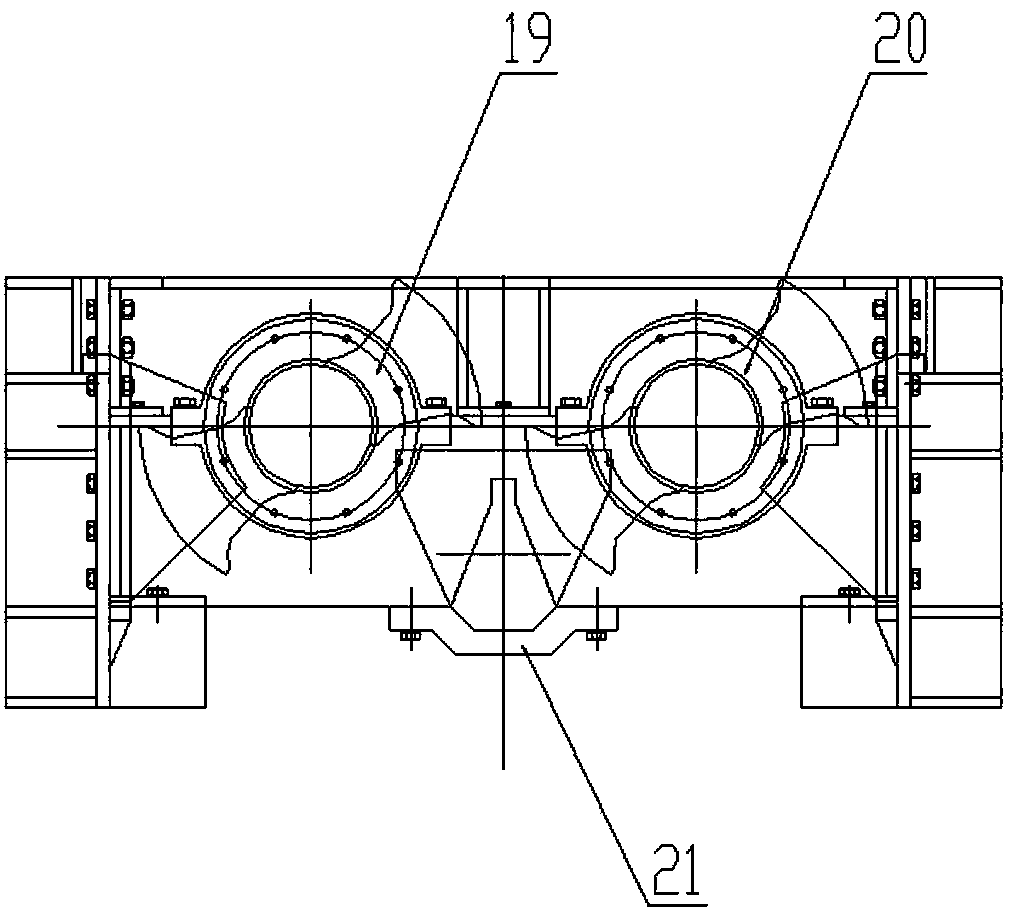

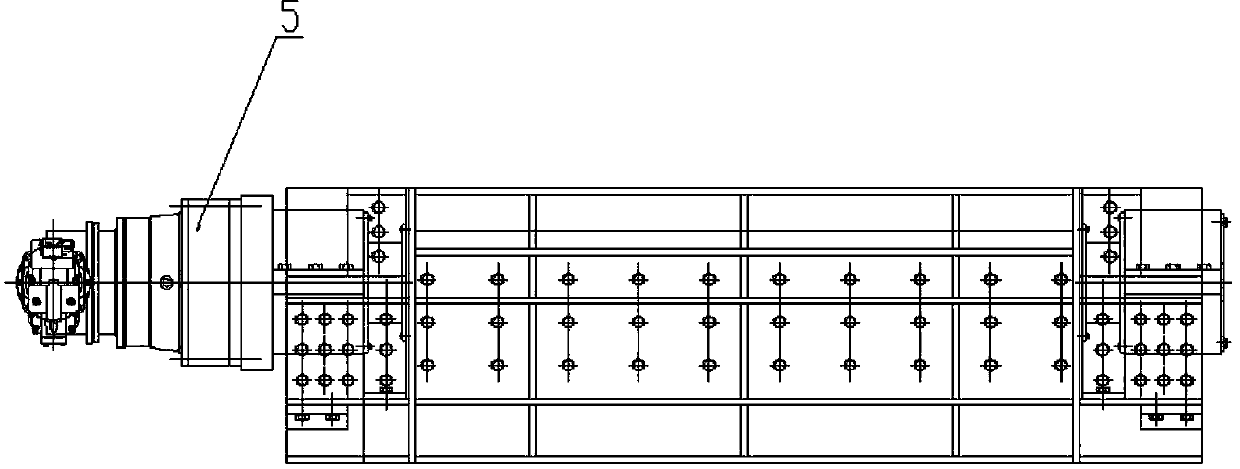

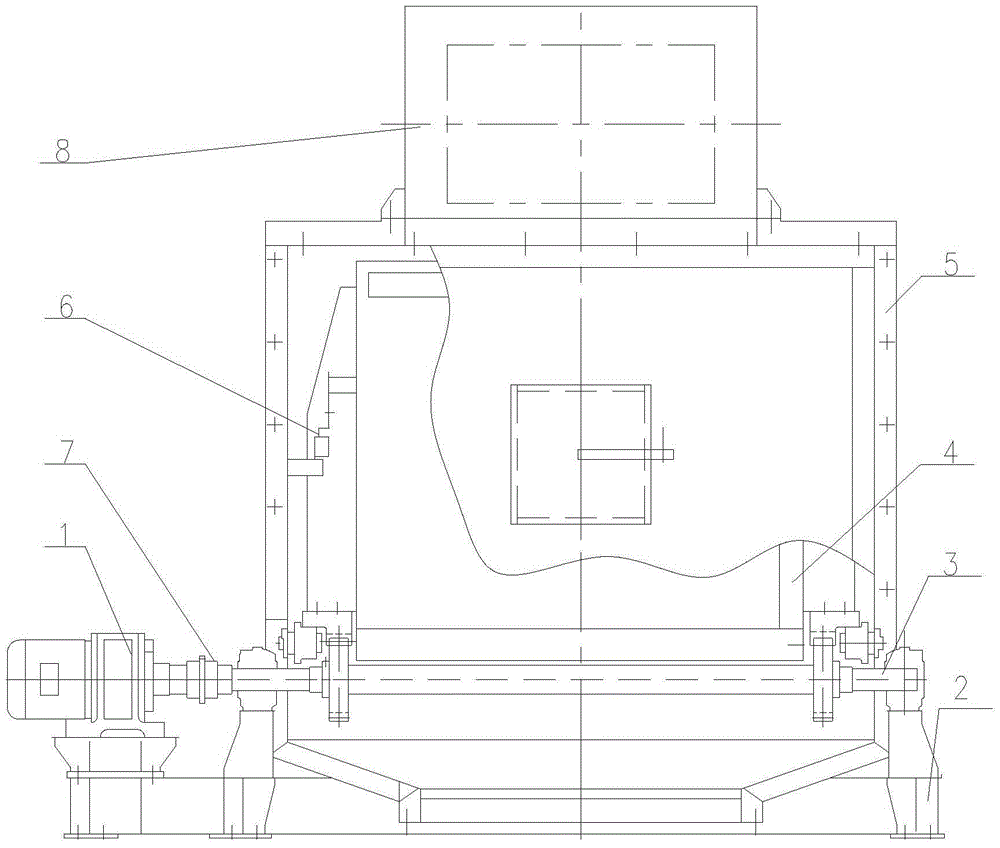

Hydraulic garbage crusher

The invention discloses a hydraulic garbage crusher, belongs to the technical field of garbage crushing, and mainly solves the problem that a conventional garbage crusher introduced from abroad has the defects that the price and the after-sales service expense are high, and the spare part period is longer. The hydraulic garbage crusher is mainly characterized by comprising a crusher box body, hydraulic power stations, rotary arbors, rotary blades, a side fixed cutter, a middle fixed arbor and a middle fixed blade. The crusher box body comprises an end plate I and an end plate I; the rotary arbors comprises a middle arbor I and a middle arbor II which are vertically mounted; the rotary blades comprises a middle rotary blade I and a middle rotary blade II which are vertically mounted; the hydraulic power station comprises a first hydraulic power station and a second hydraulic power station respectively connected with the middle arbor I and the middle arbor II; the side fixed cutter comprises a side fixed blade I on one side and a side fixed blade on the other side. The hydraulic garbage crusher has the characteristics of large crushing torque, good cutting effect and no garbage twining. The hydraulic garbage crusher is mainly used for municipal domestic waste crushing in a garbage incineration generation plant.

Owner:XIANGYANG HUIBO MECHANICAL EQUIP

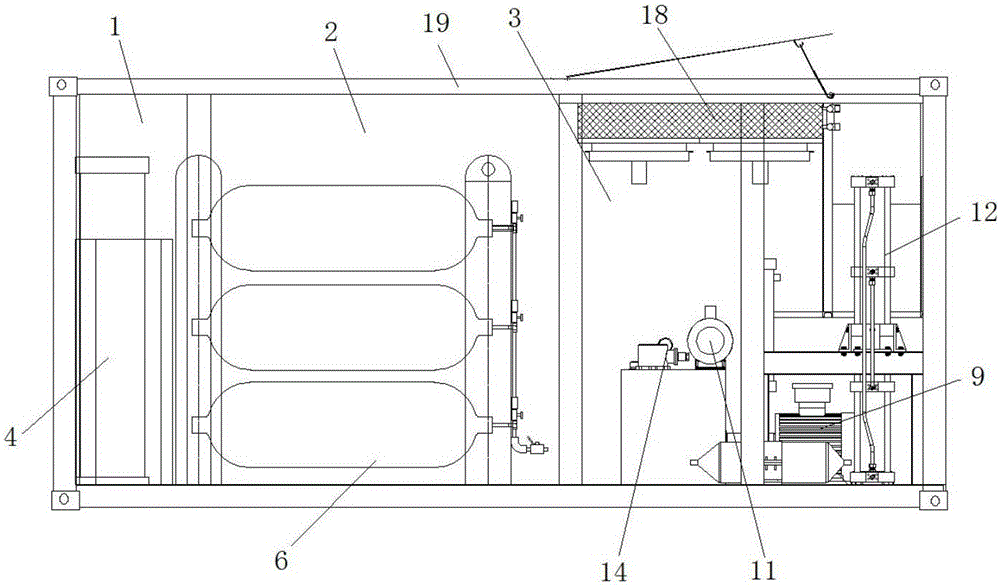

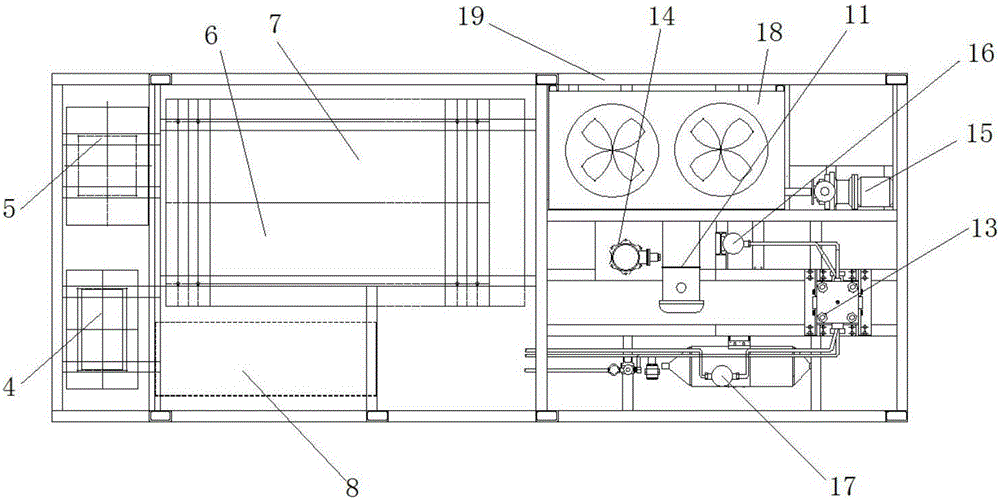

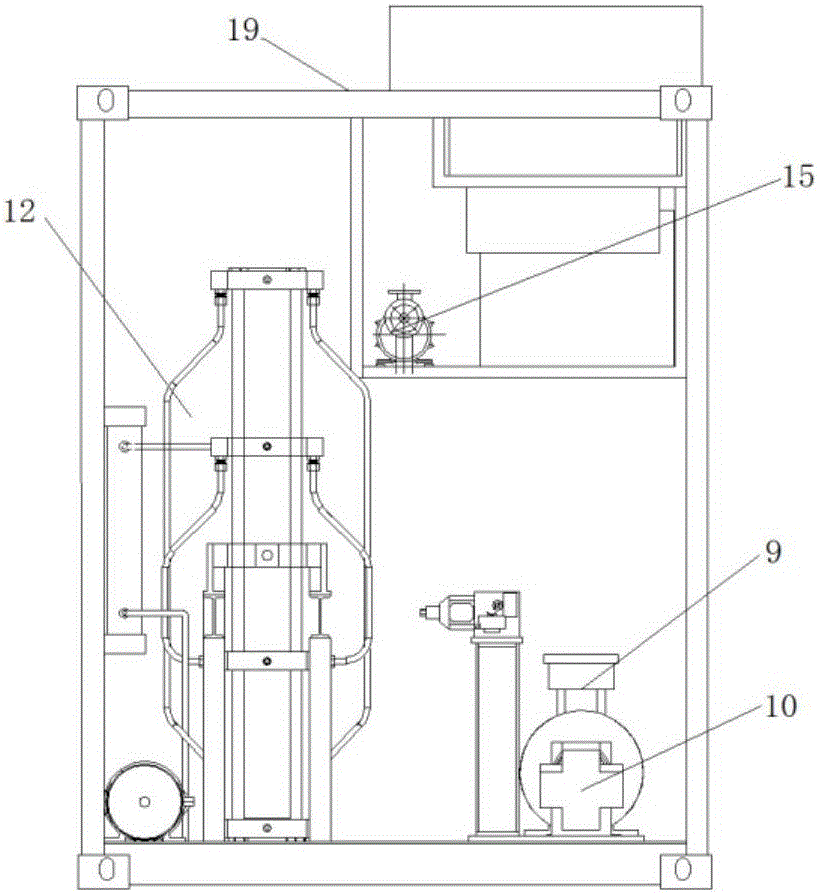

CNG integrated mobile gas supply system

InactiveCN106090600ASmall footprintLess investmentGas handling applicationsFluid transferredElectrical controlProcess engineering

The invention discloses a CNG integrated mobile gas supply system which comprises an unloading device and a mobile box body. The unloading device includes a CNG long-tube trailer and a pressurizer, the mobile box body is sequentially divided into a gas-entrapping section, a buffering section and a compression section in the length direction. A gas-entrapping unit is arranged in the gas-entrapping section, and a pressure buffering unit and an electrical control unit are arranged in the buffering section. A compression unit and an upper computer industrial control unit are mainly arranged in the compression section. A gas filtering device is mounted at a gas inlet of the compression unit. Part of CNG low-pressure gas directly enters the gas-entrapping unit, the other part of CNG low-pressure gas enters the compression unit through the gas filtering device to be pressurized, and then goes through the pressure buffering unit to the gas-entrapping unit. The electrical control unit and the upper computer industrial control unit control automatic running and stopping of the mobile gas supply system.

Owner:ZHONGYOU GENERAL LUXI NATURAL GAS EQUIP

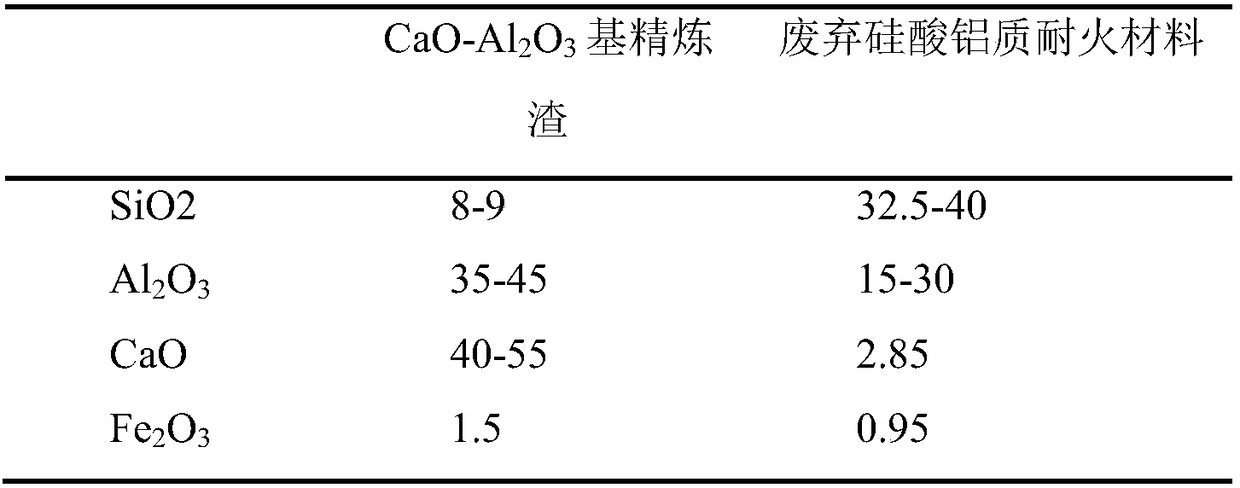

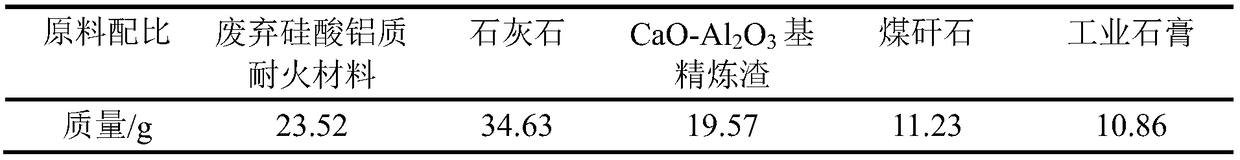

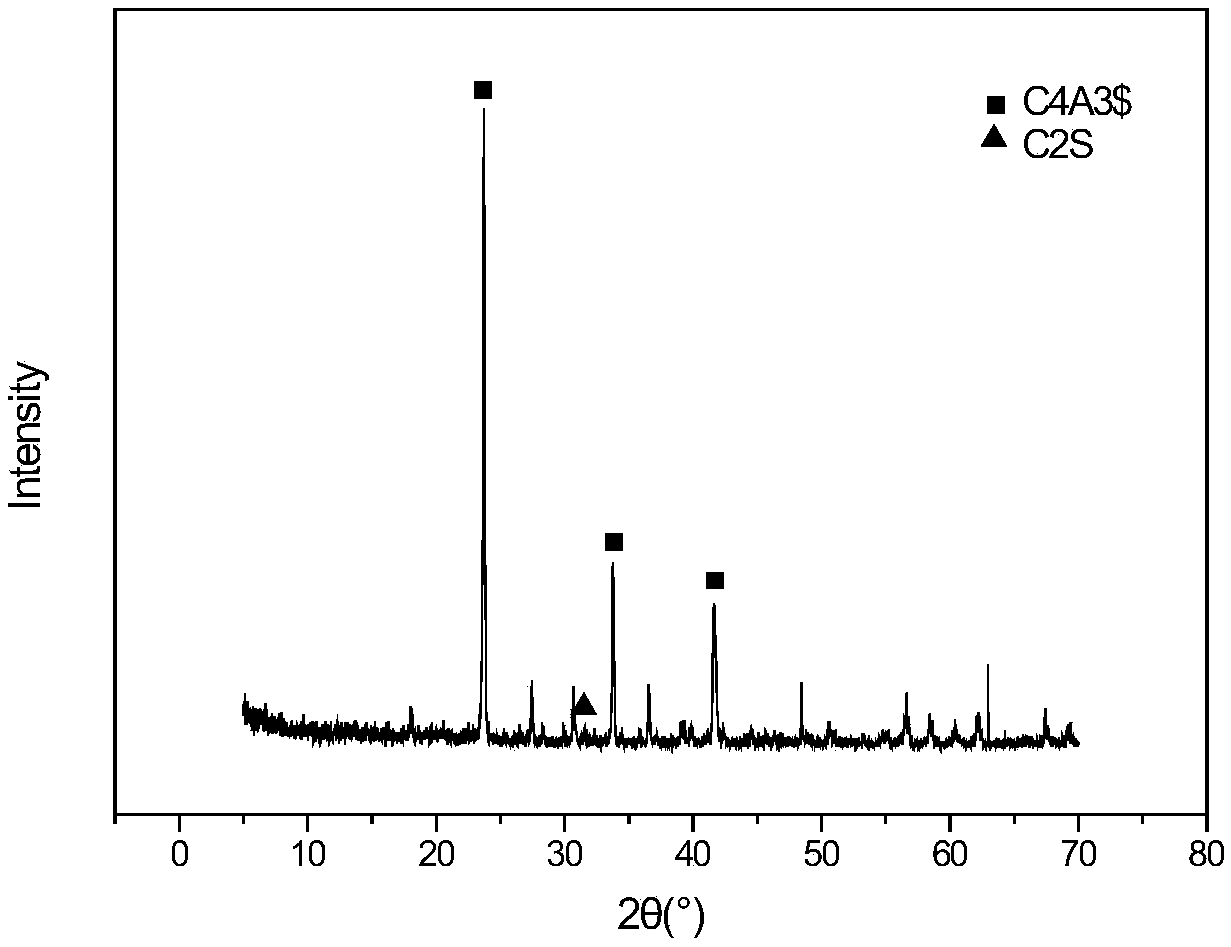

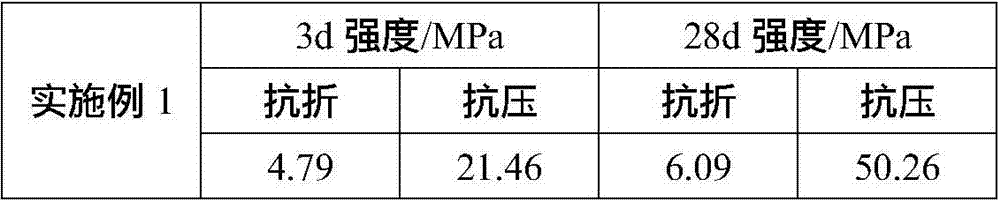

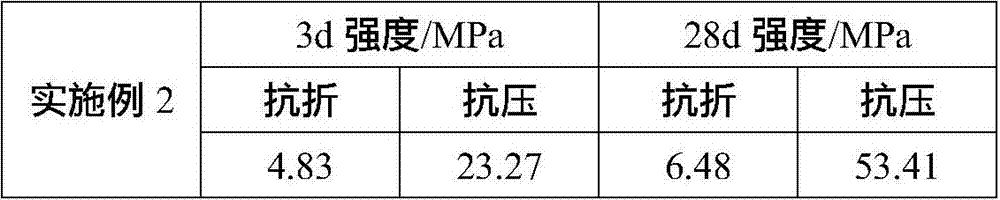

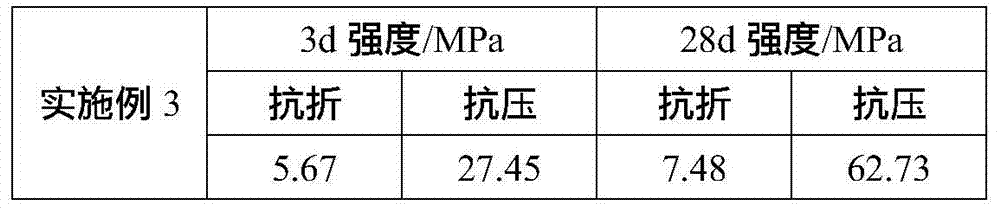

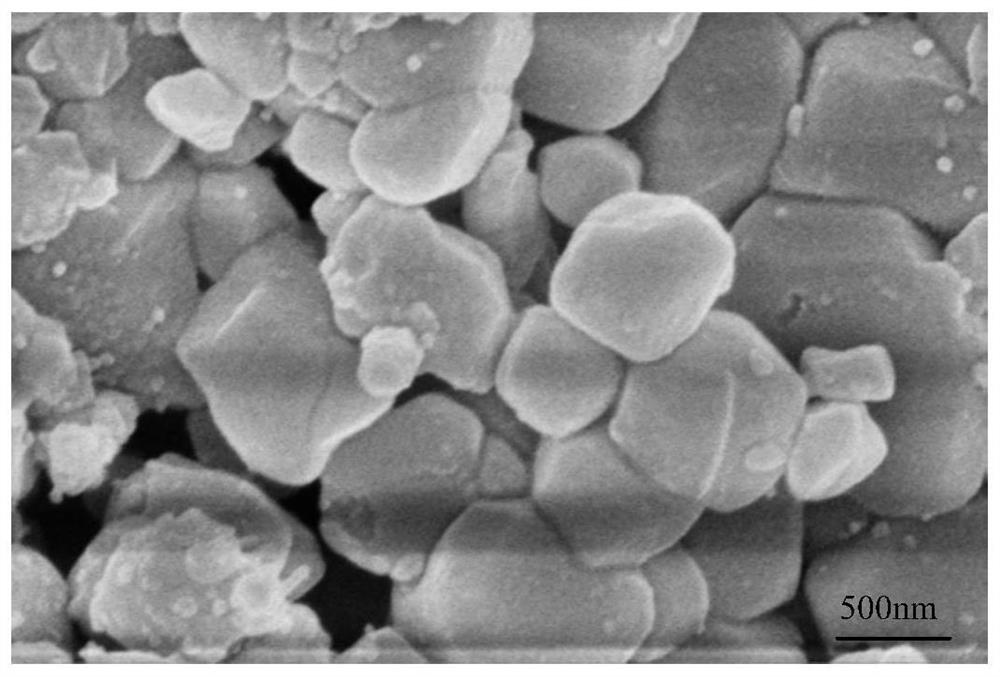

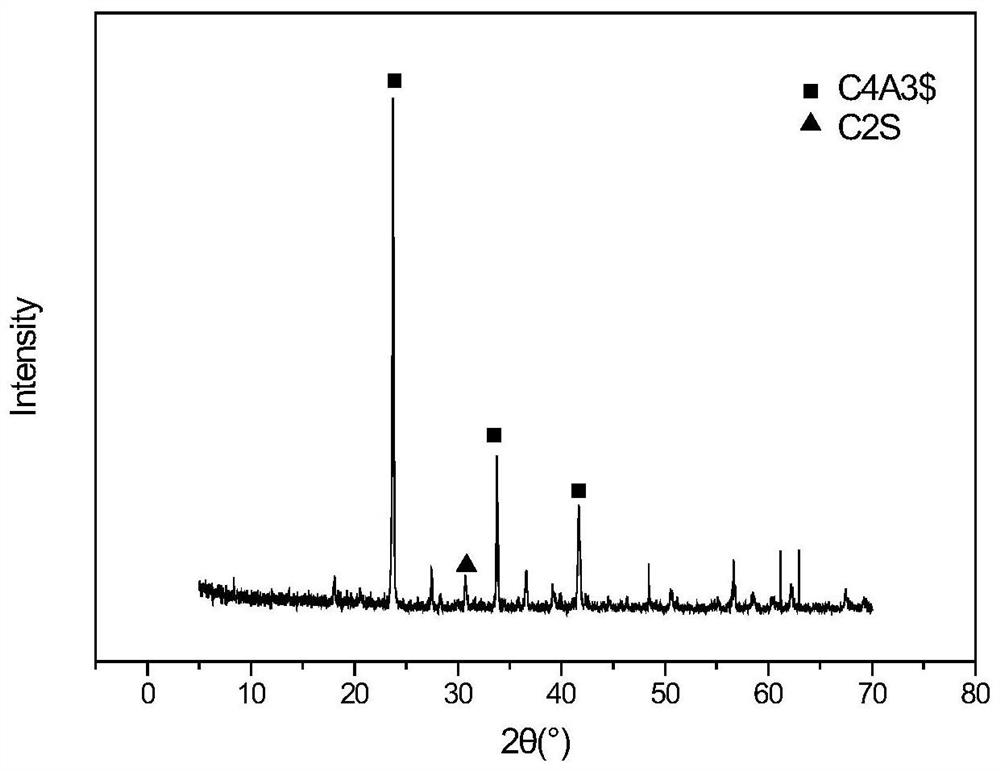

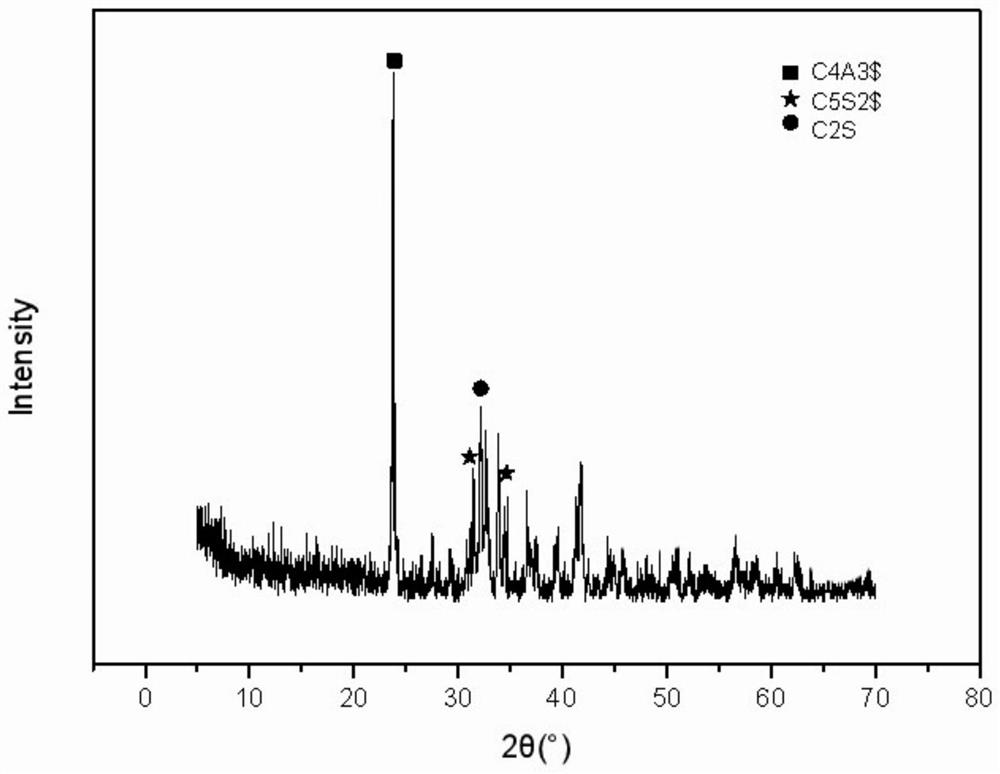

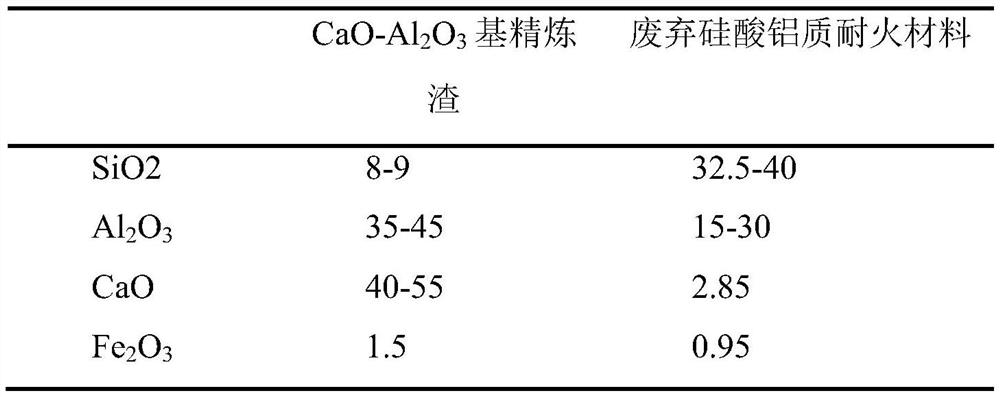

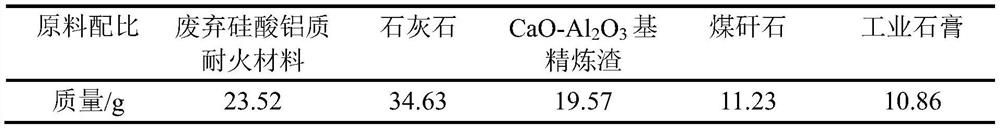

Low-temperature preparation method of sulfur silicate-belite-sulphoaluminate cement

The invention discloses a low-temperature preparation method of sulfur silicate-belite-sulphoaluminate cement. The low-temperature preparation method comprises the following steps: (1) putting raw materials into a planetary ball mill and uniformly mixing and finely grinding, wherein the raw materials comprise an aluminum-silicon raw material, an aluminum raw material, a calcium raw material, a silica raw material and industrial gypsum; (2) pressing the raw materials mixed in step (1) into a cake and placing the cake into a high-temperature electric furnace; calcining at the temperature of 700to 1200 DEG C; then taking out and quenching; (3) grinding a product obtained by step (2) into powder; (4) uniformly mixing the product obtained by step (3) with dihydrate gypsum and finely grinding to prepare the cement. According to the low-temperature preparation method disclosed by the invention, common wastes including gehlenite containing an intermediate product phase and other aluminate aredirectly used as the raw materials and the raw materials do not need to be subjected to modification or other treatment; the treatment cost is reduced and the utilization rate of the raw materials isimproved. The early-stage cost is greatly reduced; meanwhile, the environment problem cased by industrial wastes is solved.

Owner:YANCHENG INST OF TECH

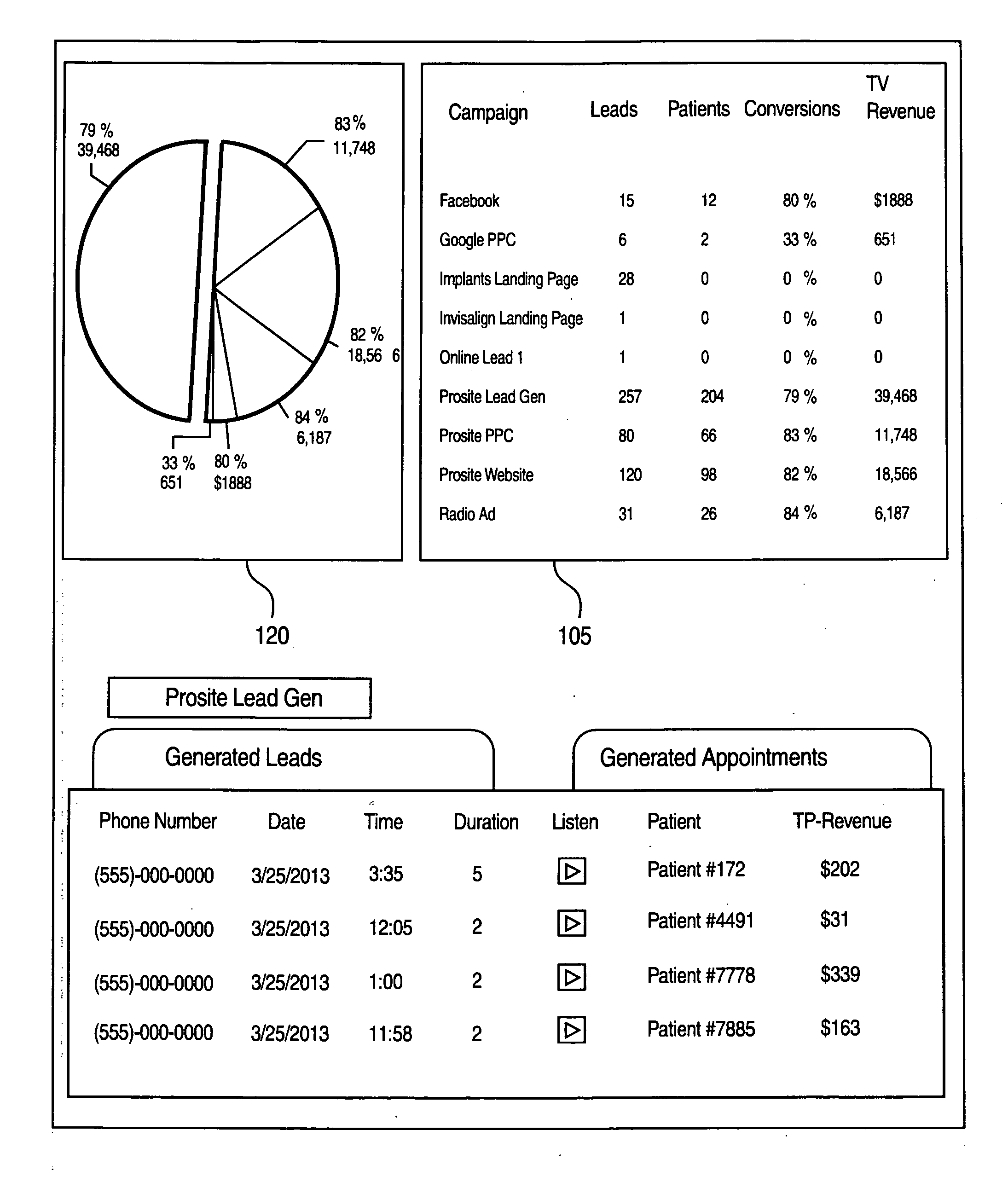

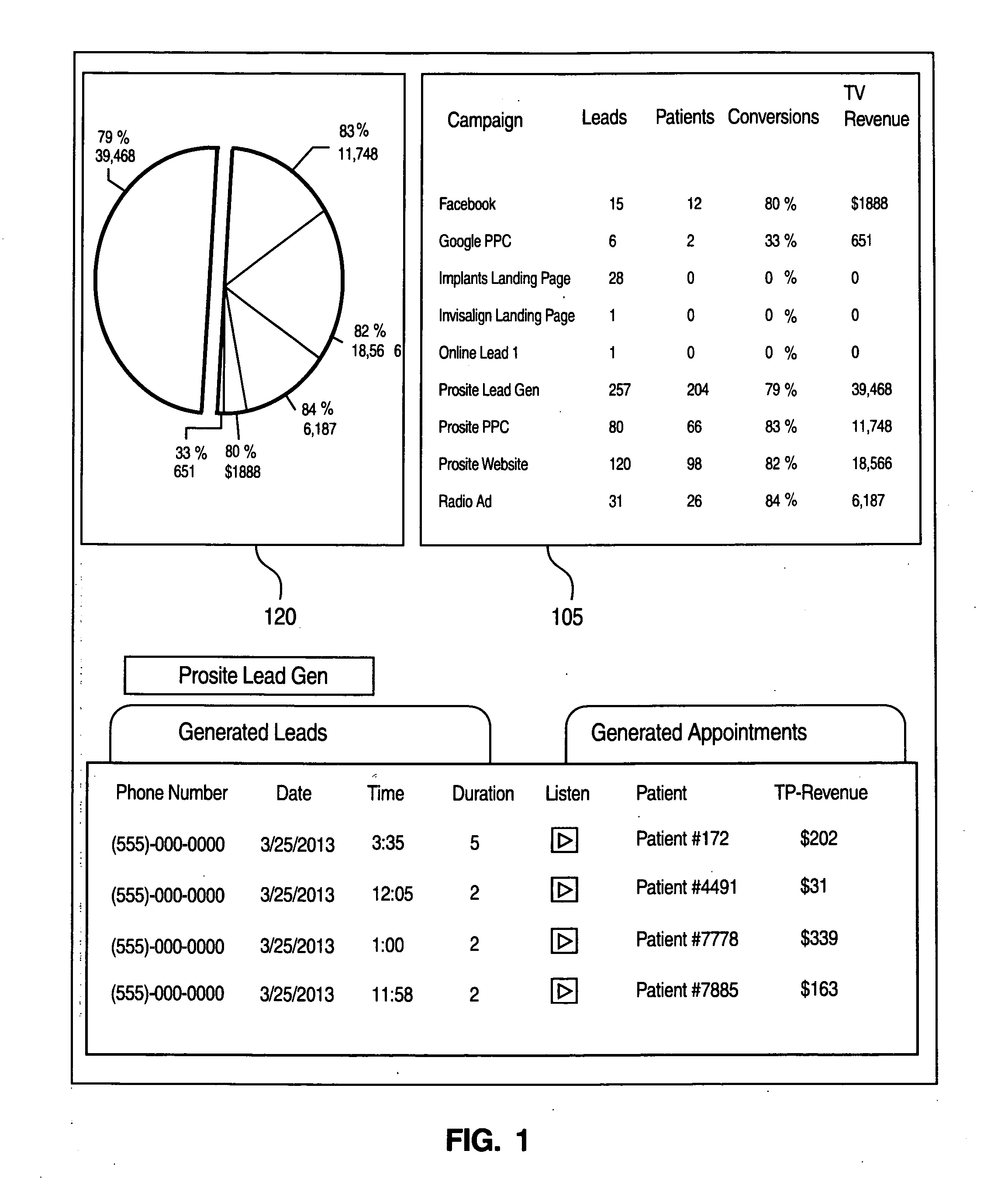

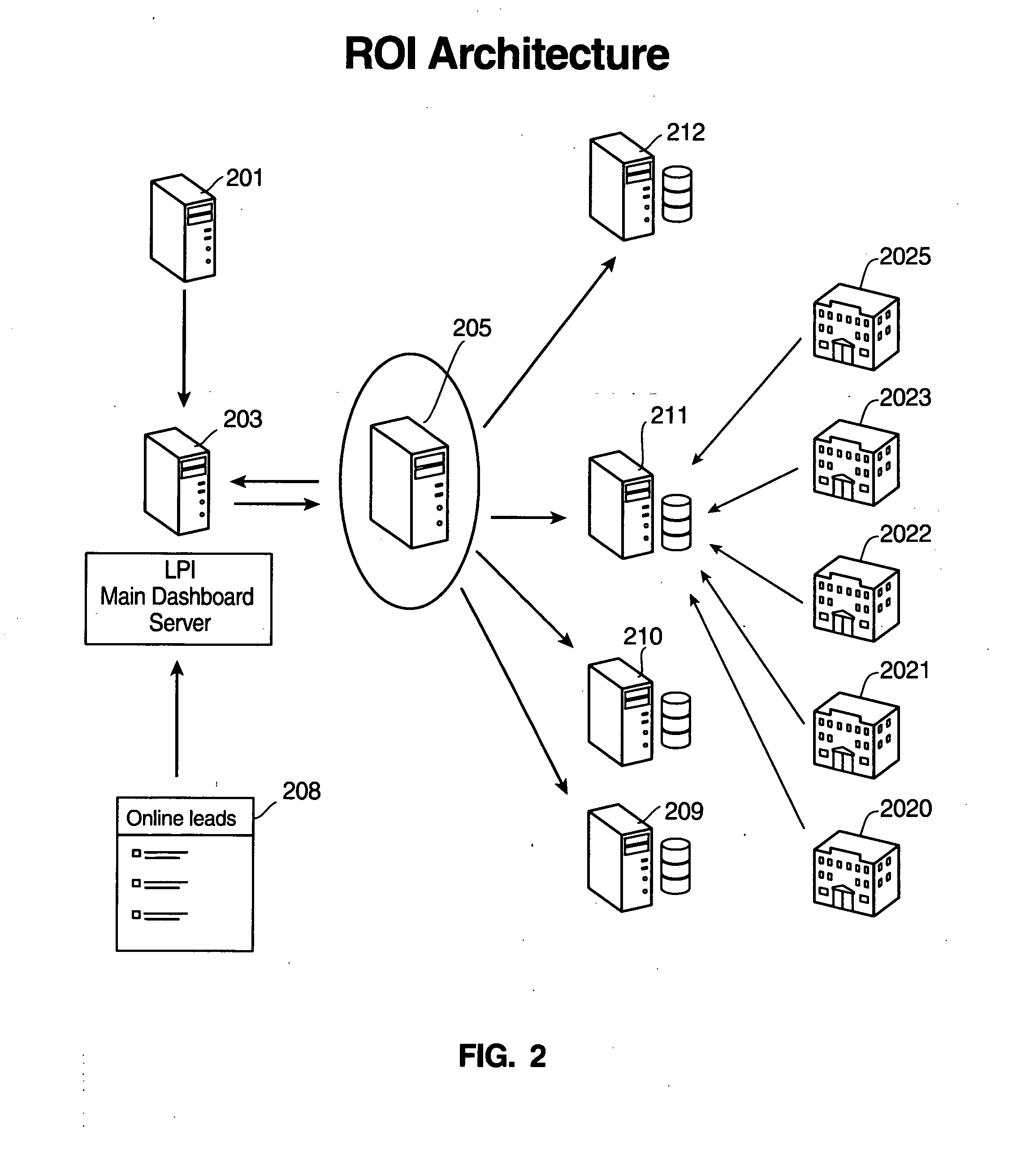

System and Method to Collect, Correlate and Display Customer Origination Data with Customer Revenue Data

A customer or patient management system implemented on a computer or computer network is disclosed that includes at least one electronic device having a display; a memory; and a processor operating in accordance with software for receiving a unique identifier associated with a customer and the identifier is associated with a predefined marketing campaign. The system captures and stores data that allows for the calculation of payment history for each customer and the cost data relating to the advertising and promotion expenditures for each customer that originates from each predefined marketing campaign and correlating the revenue and expenditure data for each customer in a visual display.

Owner:DREW AARON

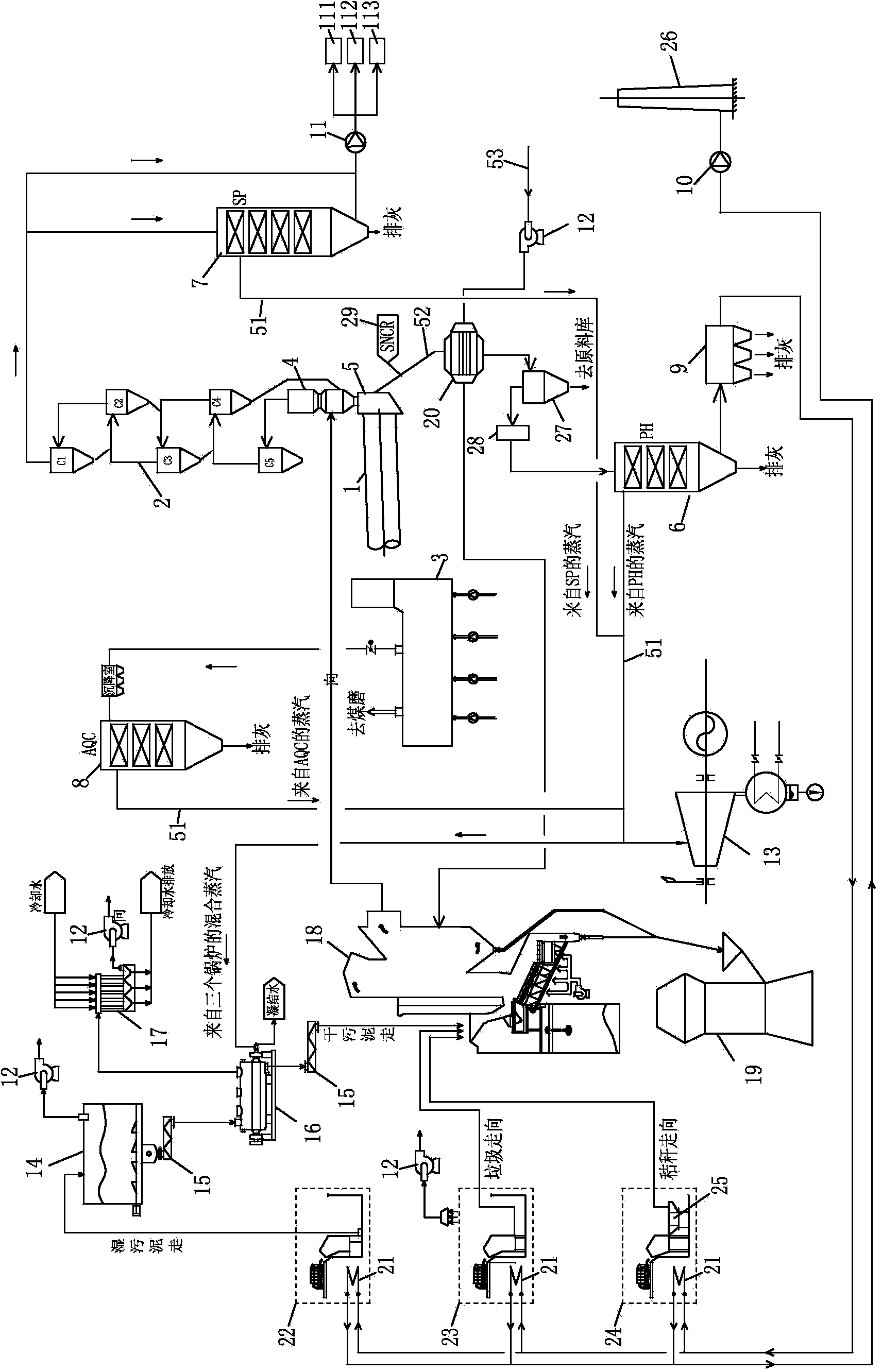

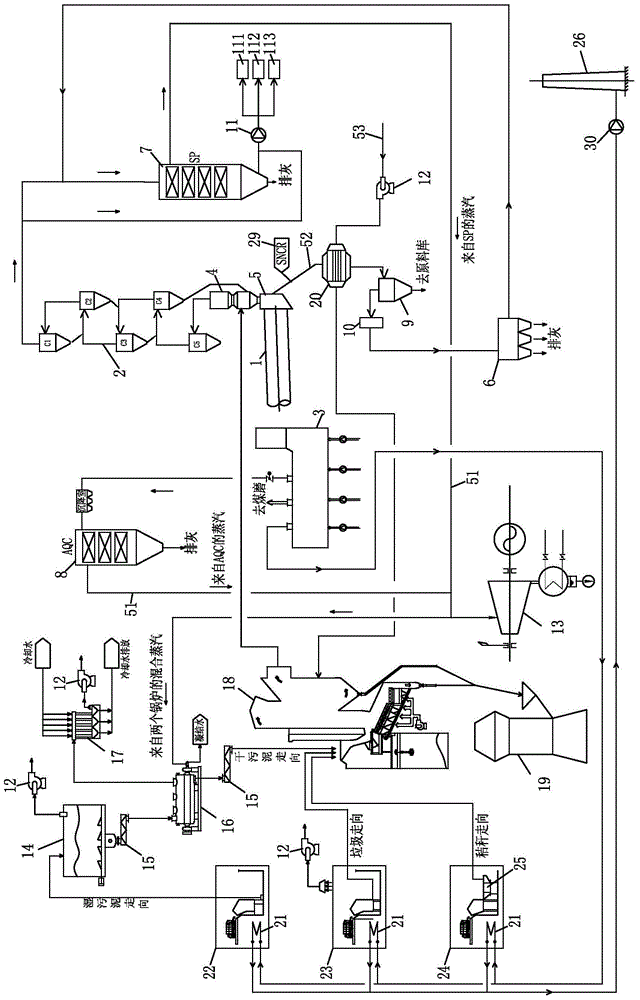

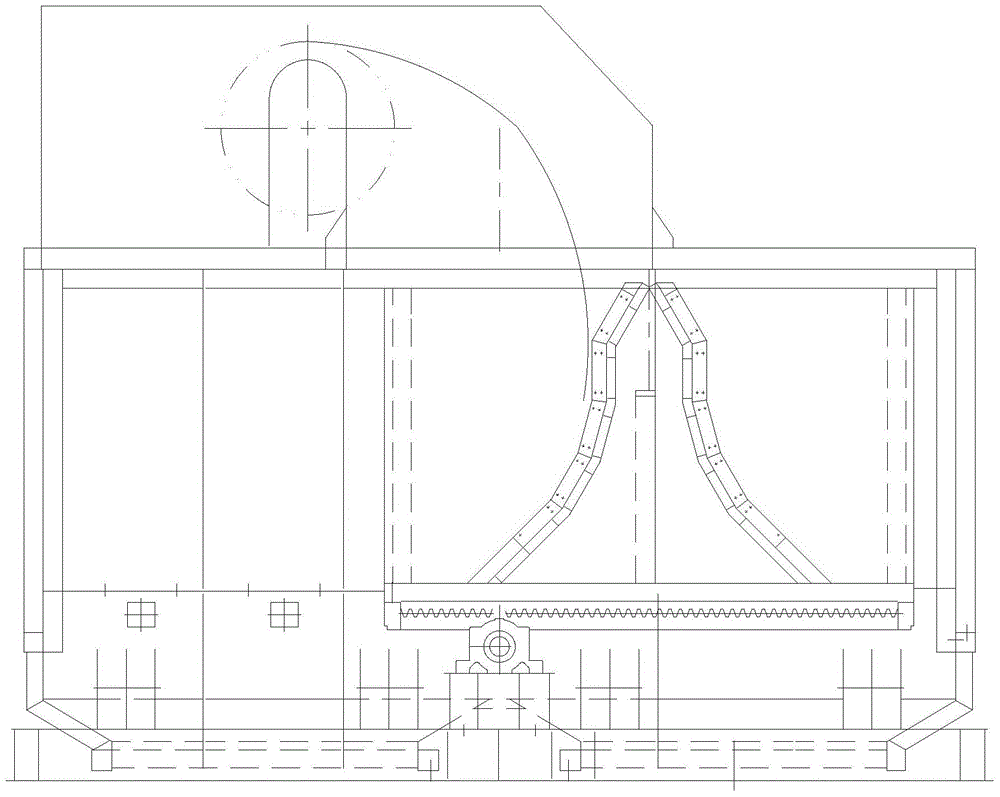

Cement kiln cooperative processing combustible waste and by-pass exhaust power generation complementary system

ActiveCN104048297AReduce the link of pre-processingLower Upfront CostsCement productionSteam engine plantsWaste processingEngineering

The invention relates to a cement kiln cooperative processing combustible waste and by-pass exhaust power generation complementary system. The cement kiln cooperative processing combustible waste and by-pass exhaust power generation complementary system aims to have higher combustible waste processing capacity and can guarantee the production quality of cement. According to the technical scheme, the cement kiln cooperative processing combustible waste and by-pass exhaust power generation complementary system comprises a power generation device, a kiln tail preheater, a kiln head waste heat boiler and a kiln tail waste heat boiler, wherein the kiln head waste heat boiler and the kiln tail waste heat boiler are connected with the power generation device through a steam circulation loop; an air inlet of the kiln head waste heat boiler is connected with an exhaust gas outlet of a clinker cooler; an exhaust gas outlet of the kiln tail preheater is connected with an air inlet of the kiln tail waste heat boiler; a discharge outlet of the kiln tail preheater is connected with a feed inlet of a feed-end chamber in a rotary kiln. The cement kiln cooperative processing combustible waste and by-pass exhaust power generation complementary system further comprises a collection device, an incinerator, a raw material vertical mill and a by-pass exhaust device, and an exhaust gas outlet of the incinerator is connected into a decomposing furnace of the kiln tail preheater.

Owner:福建龙麟环境工程有限公司

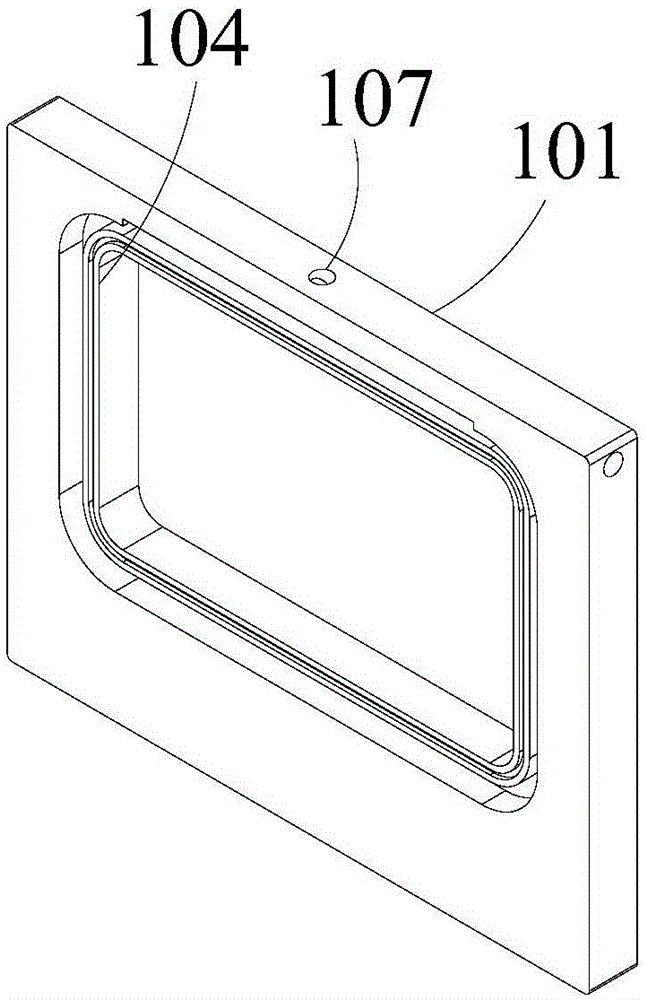

Fresh-keeping gas replacement device and method

InactiveCN105059592AFor quick replacementLower Upfront CostsPackaging by pressurising/gasifyingWrapper twisting/gatheringFood sectorProduct gas

The invention provides a fresh-keeping gas replacement device and method and belongs to the field of packaging equipment. The fresh-keeping gas replacement device comprises a positioning die, a pressing plate and a sealing film cutting device, wherein a positioning cavity for holding a packaging box is arranged on the positioning die; an air inlet hole and an air outlet hole which are communicated with the positioning cavity are formed in the positioning die; the pressing plate and the sealing film cutting device are connected through an elastic device; holes are formed in the pressing plate; the sealing film cutting device comprises a sealing film cutting mechanism; when the elastic device performs compression, the sealing film cutting mechanism can penetrate through the holes. By means of the fresh-keeping gas replacement device and method, fresh gas can be rapidly fed into the packaging box; a vacuum pump is not required; compared with the prior art, the fresh-keeping gas replacement device and method is more environmentally friendly and economical, higher in replacement accuracy, simple in structure and extremely convenient to maintain, the cost is greatly reduced, the machine purchase cost is also reduced for a user, and the influence on the whole food industry is profound.

Owner:成都市罗迪波尔机械设备有限公司

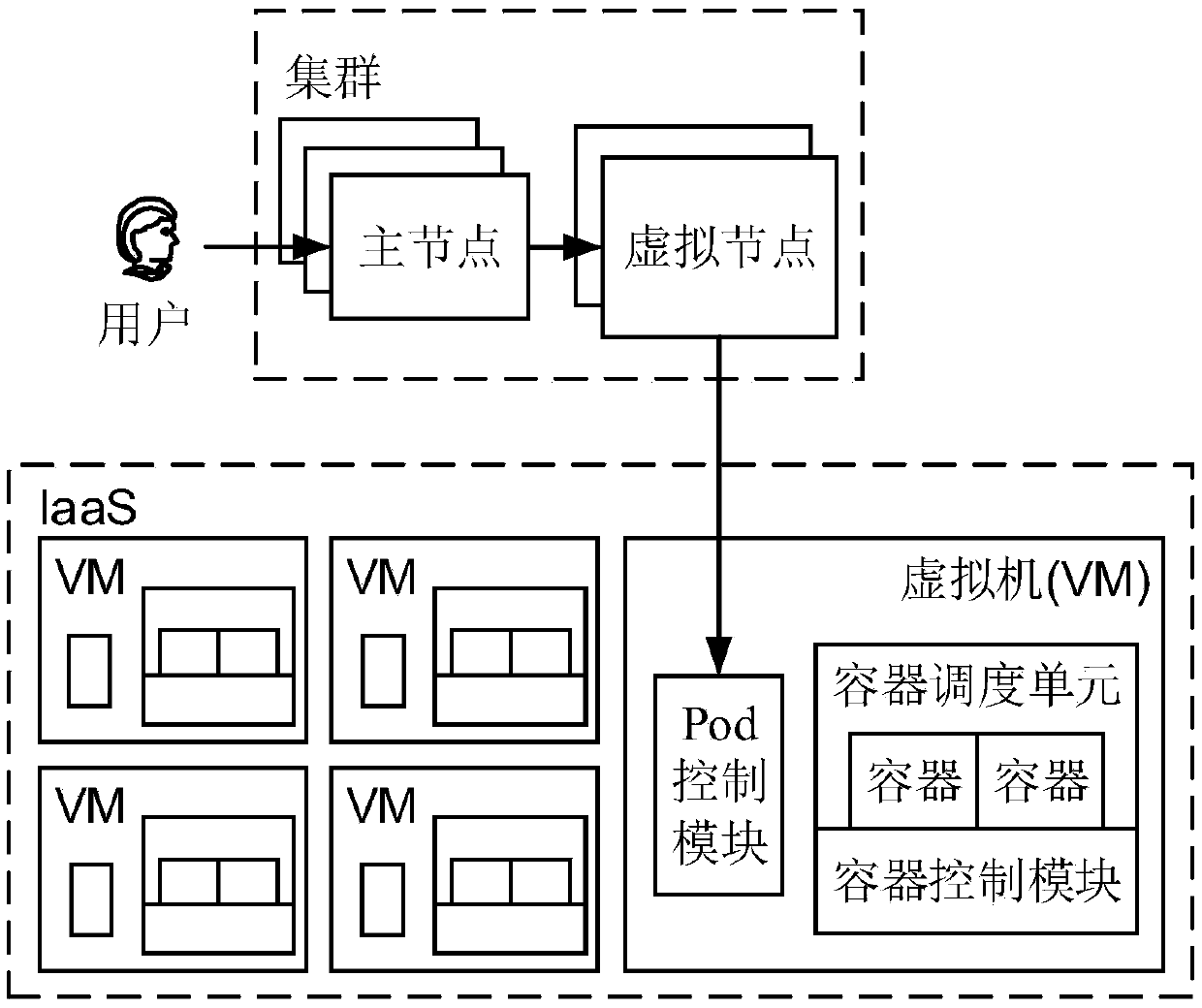

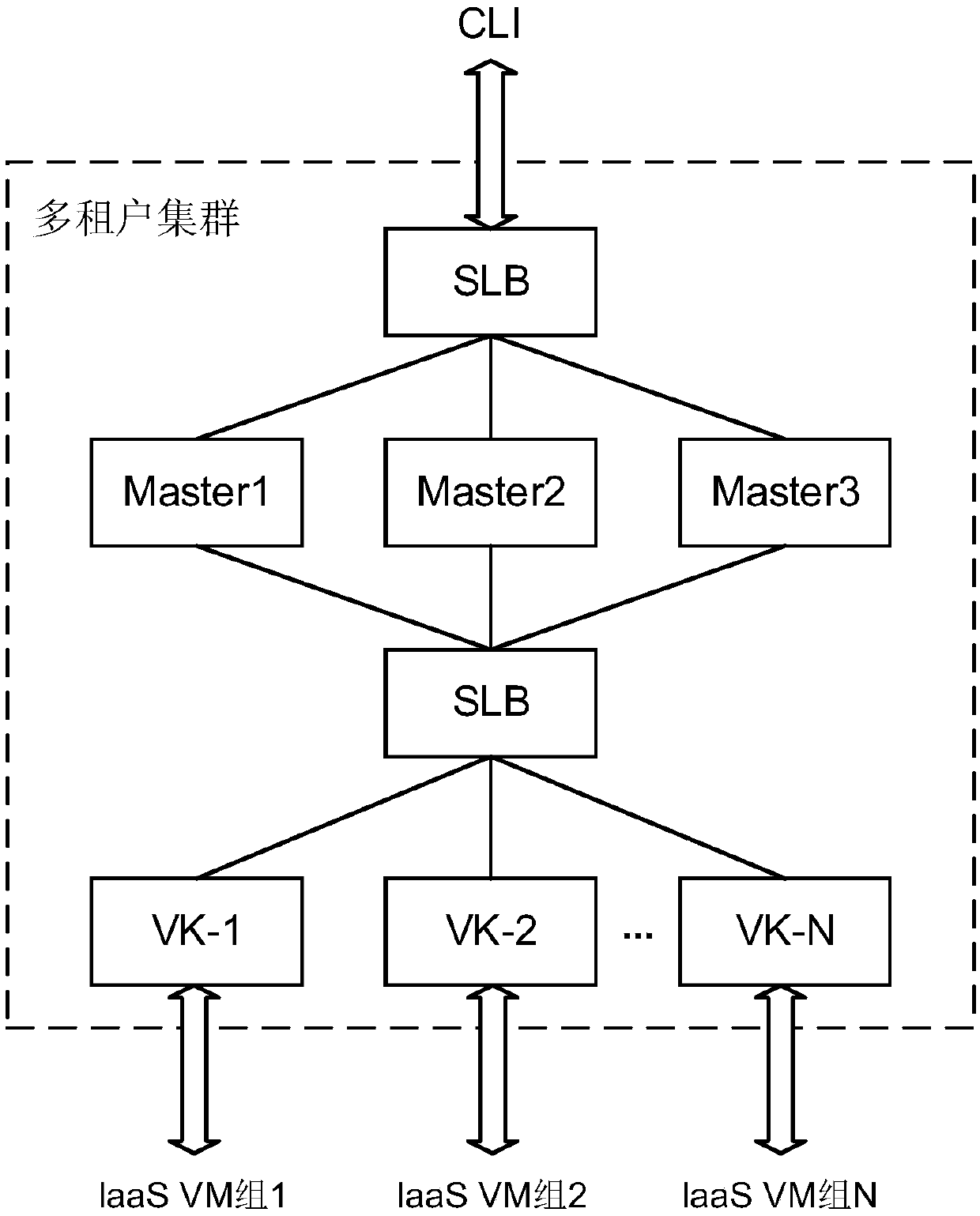

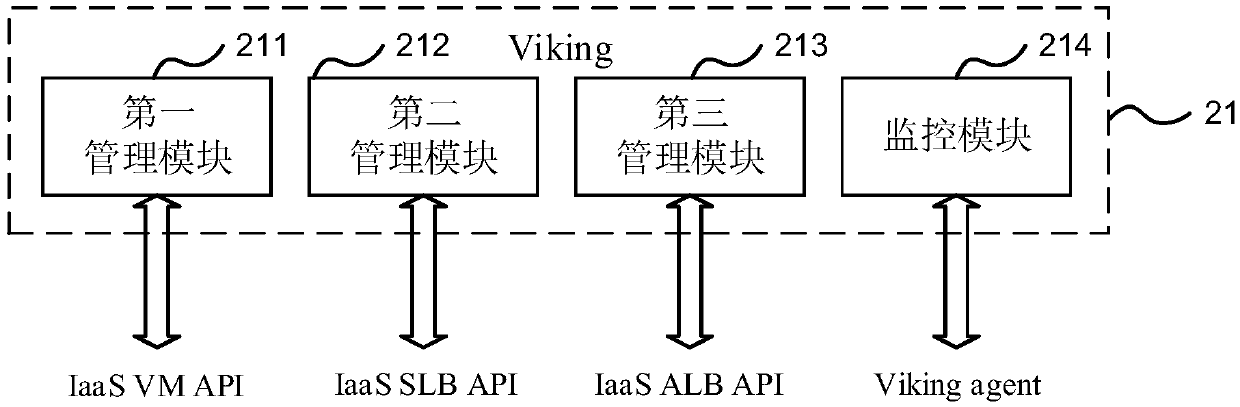

Server-free cloud service system, resource management method thereof and electronic equipment

ActiveCN110837407AImplement event managementLower Upfront CostsSoftware simulation/interpretation/emulationResource poolResource management

The embodiment of the invention provides a server-free cloud service system, a resource management method thereof and electronic equipment. Virtual nodes used for managing virtual machines are arranged in a cluster of the system, and container group control modules and container control modules are arranged in the virtual machines. The virtual node is used for acquiring a resource change event ina user demand, forming a resource management instruction according to the resource change event, communicating with the container group control module and issuing the resource management instruction;and the container group control module is used for performing event management on the container group according to the resource management instruction. According to the embodiment of the invention, the virtual nodes are matched with the container group control module and the container control module, so that the event management of the container group is realized, the existing cloud service resources are reused, the high isolation and high elasticity of the existing cloud service virtual machine are fully utilized, and the defects caused by the establishment of an independent physical machineresource pool are avoided.

Owner:ALIBABA GRP HLDG LTD

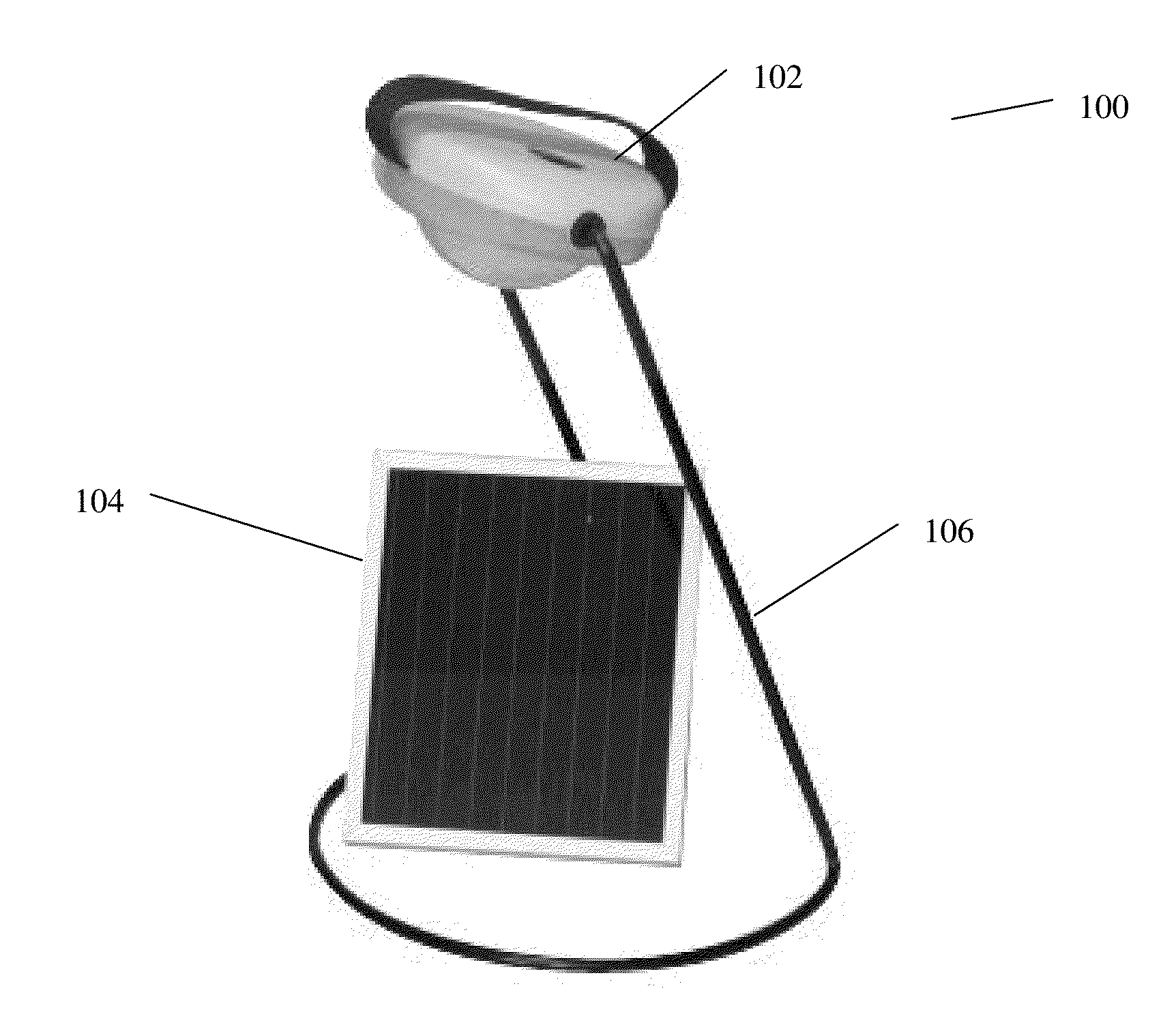

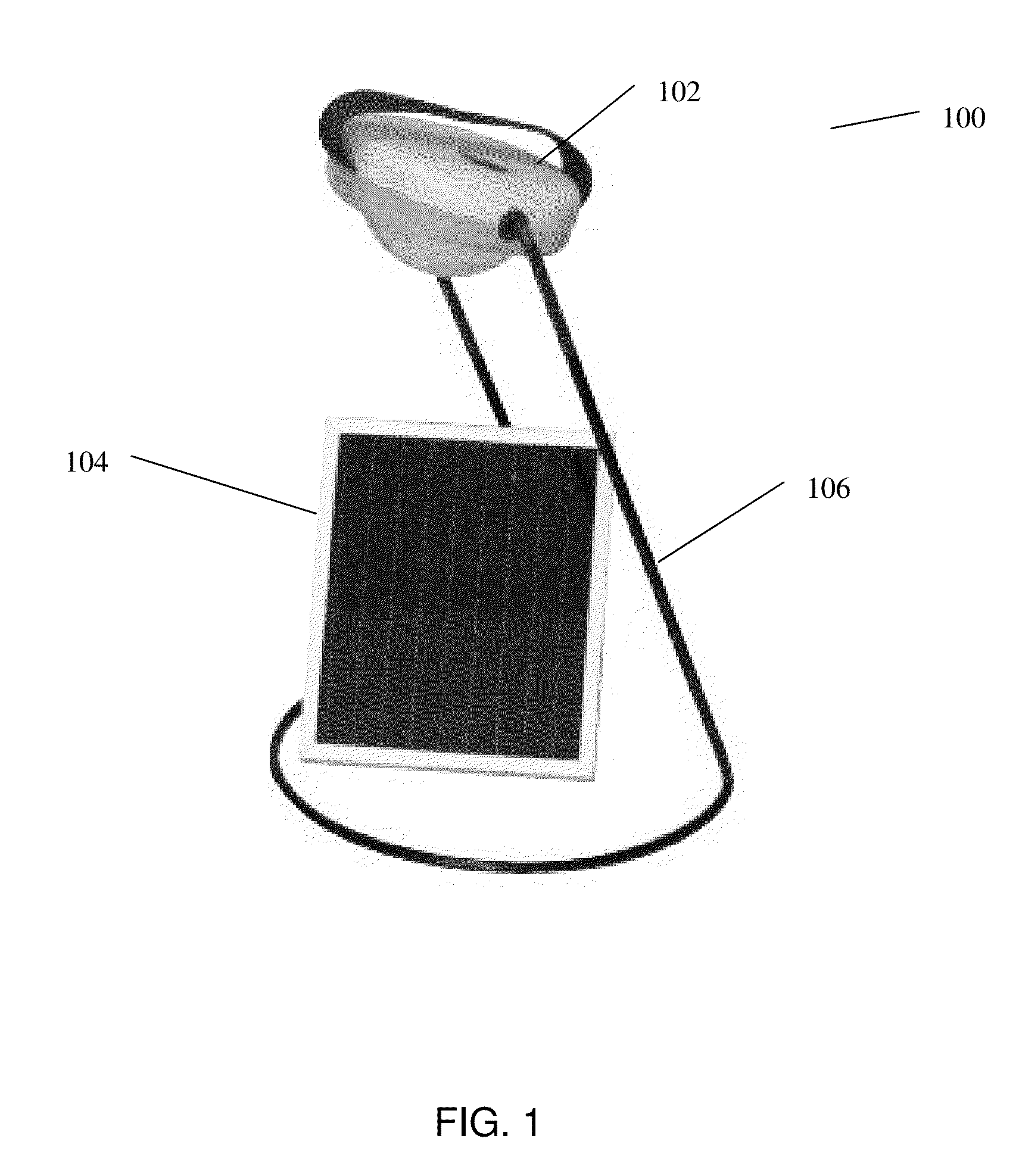

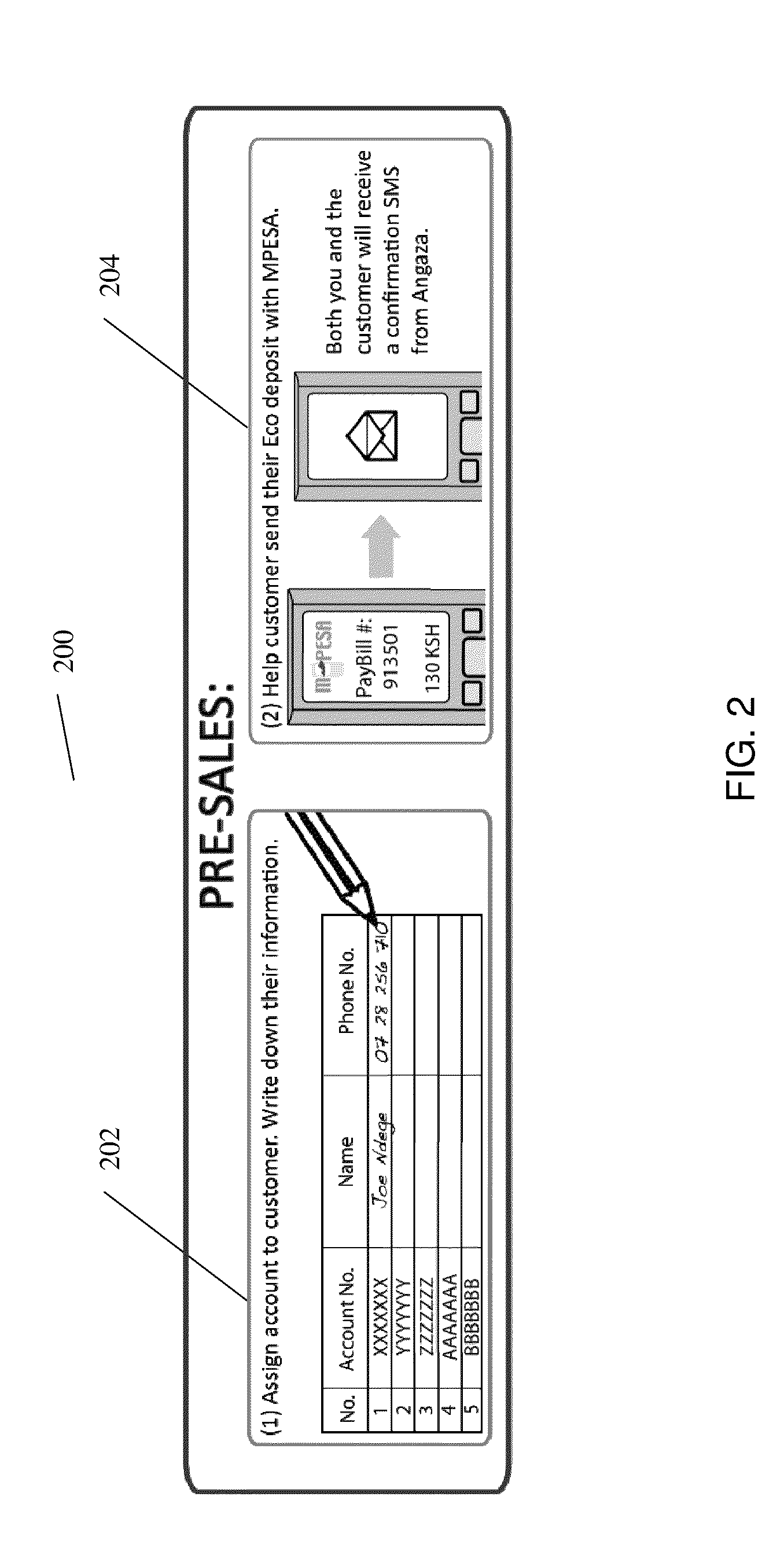

Solar lighting with pay-as-you go technology

ActiveUS20150287263A1Lower Upfront CostsEasy to manageModulated-carrier systemsCoin-freed apparatusPaymentSmart lighting

Disclosed are systems, devices and methods for providing solar lighting and power to a customer by using pay-as-you-go (PAYG) technology. The PAYG technology allows a customer to make incremental payments for a solar energy system that includes a lighting unit. The payments can be made through a smartphone. A cable is used to connect an audio jack of the smartphone and a PV power jack of the lighting unit. Analog AC signals including data about activation, payment, usage and status are transmitted over the cable between the service provider and lighting unit, through a smartphone. The power jack of the lighting unit is also used to connect to a solar panel of a charging unit and a battery of the lighting unit.

Owner:ANGAZA DESIGN

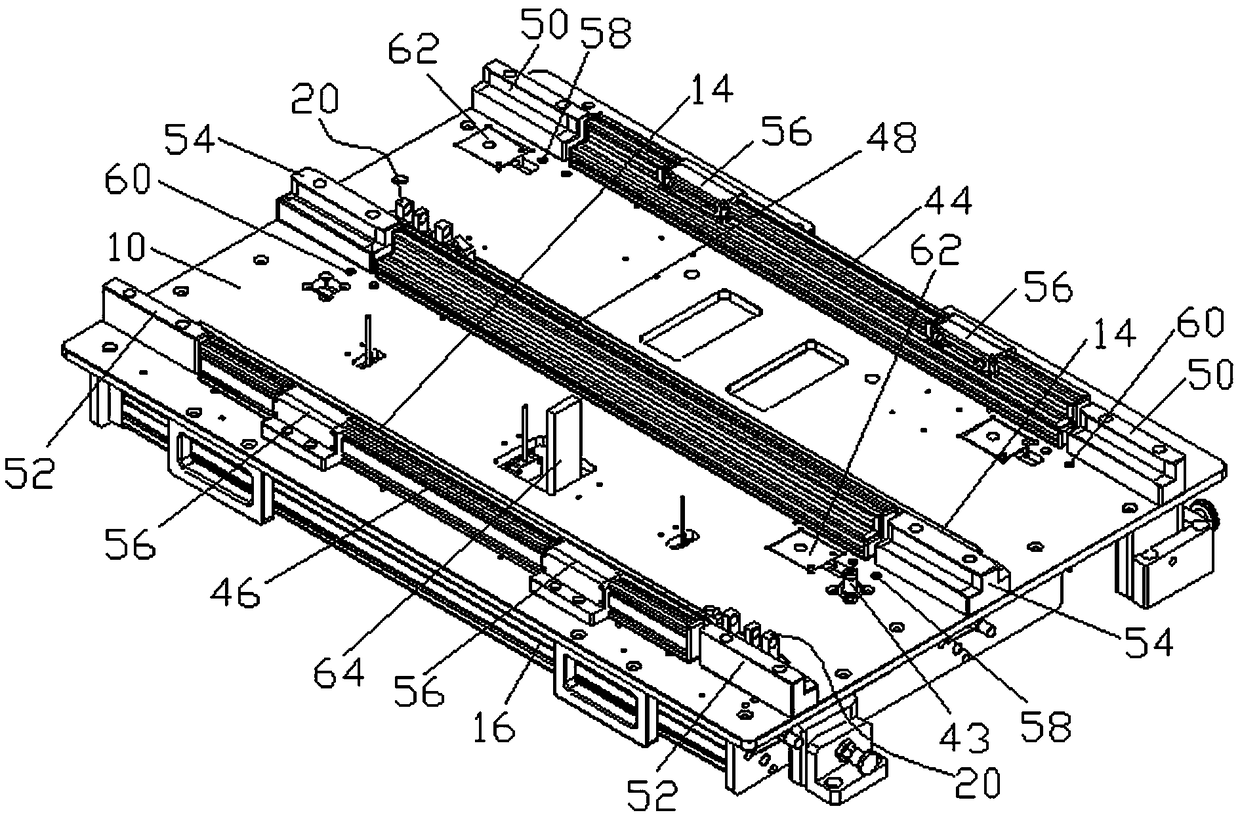

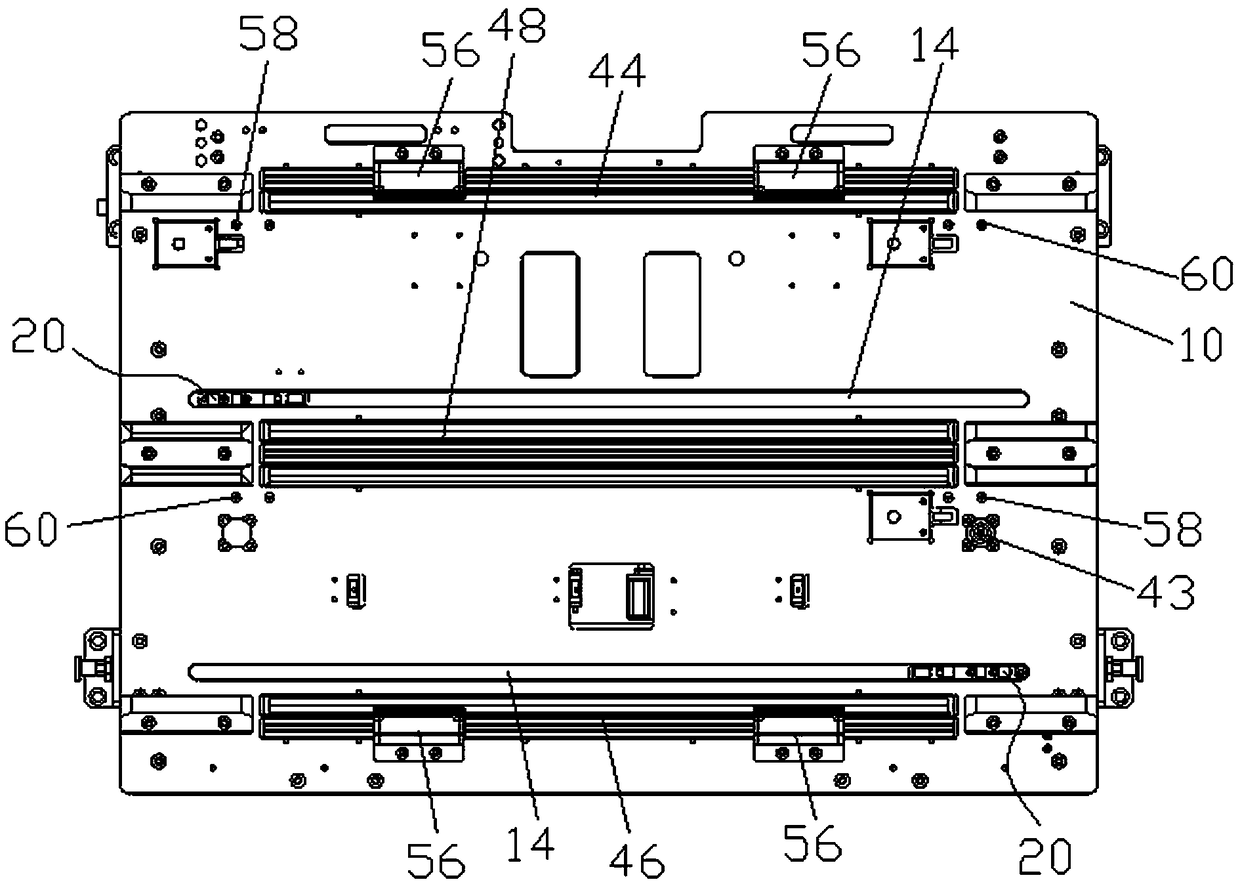

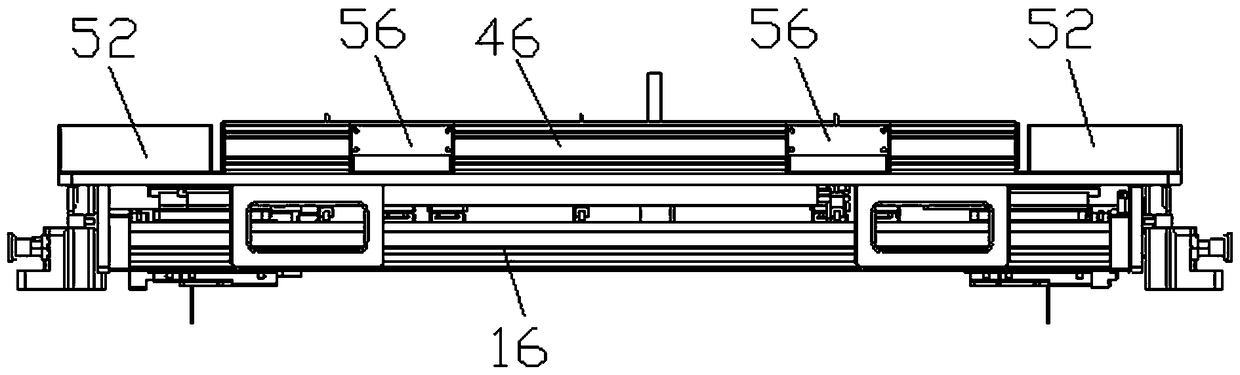

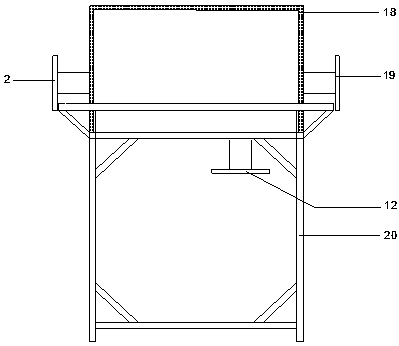

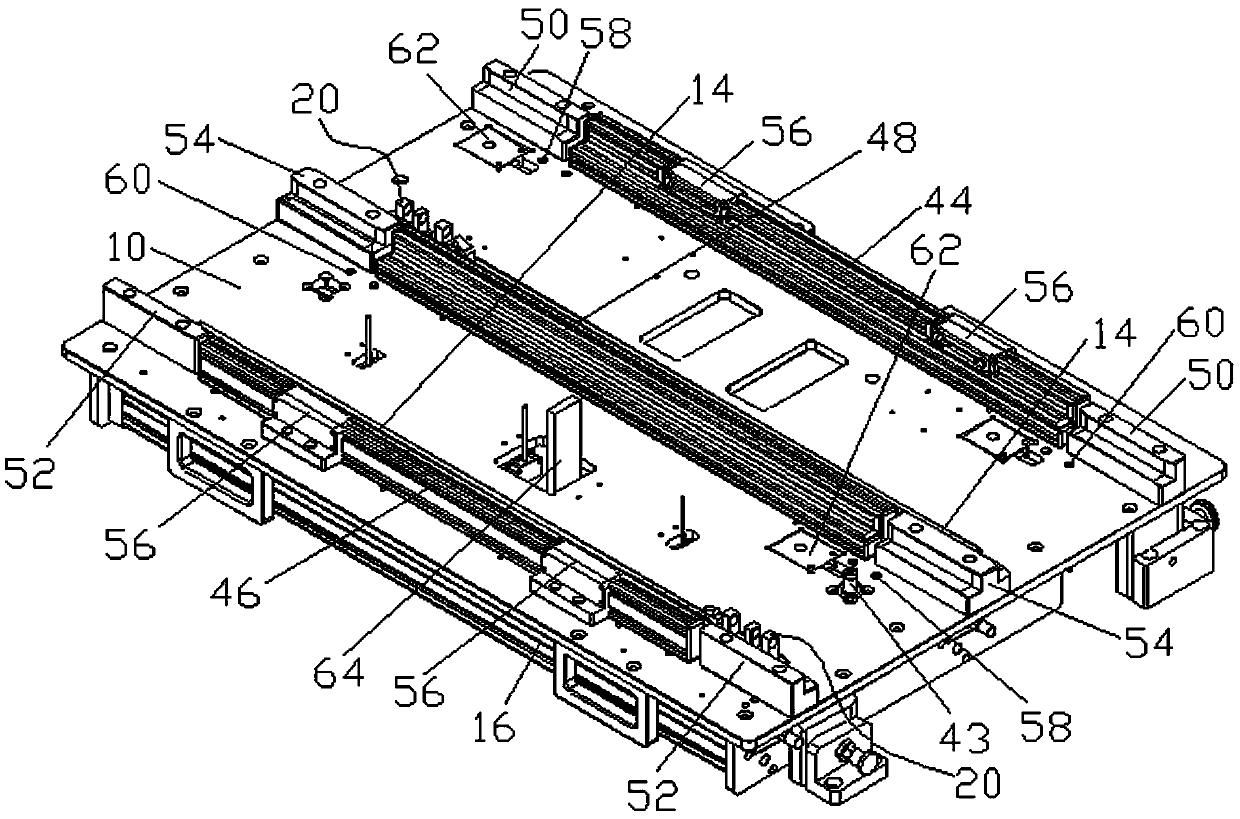

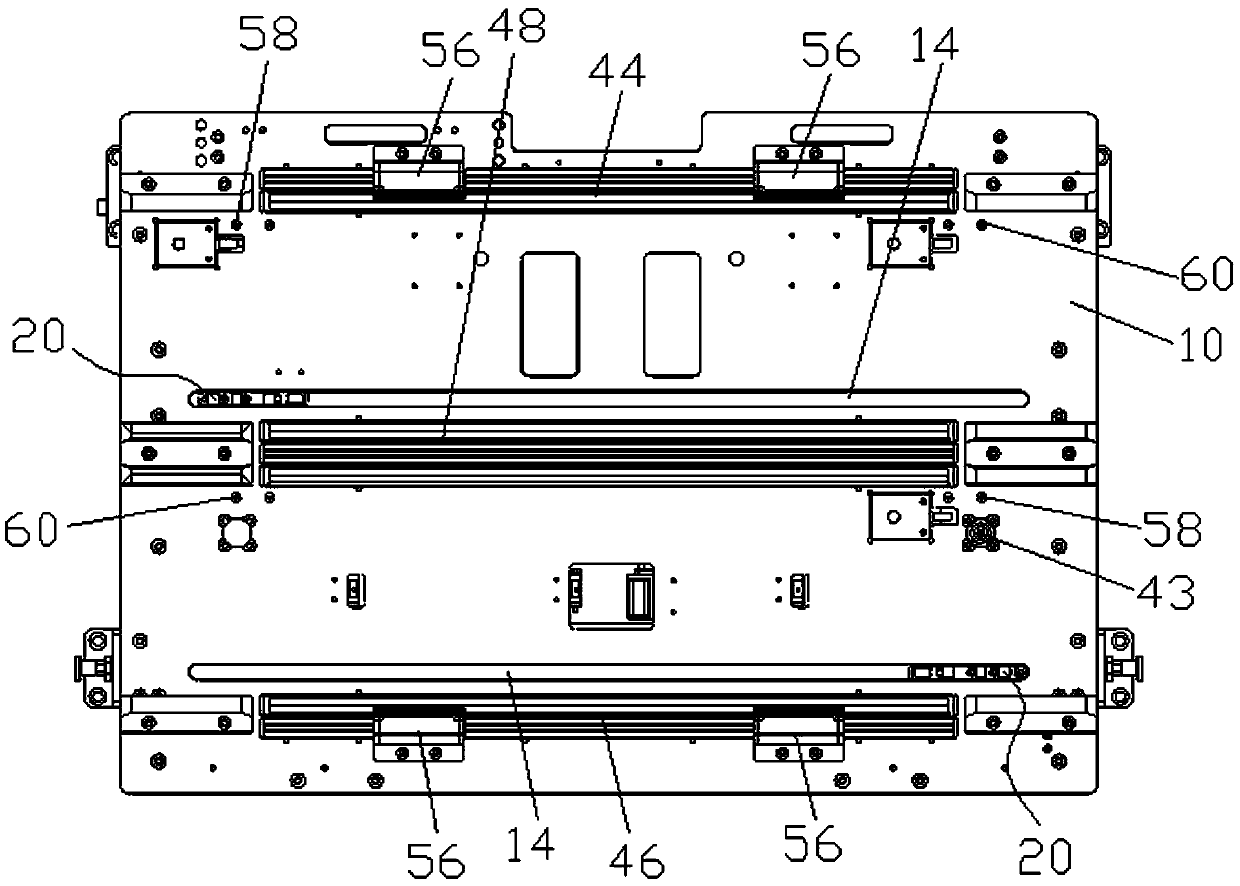

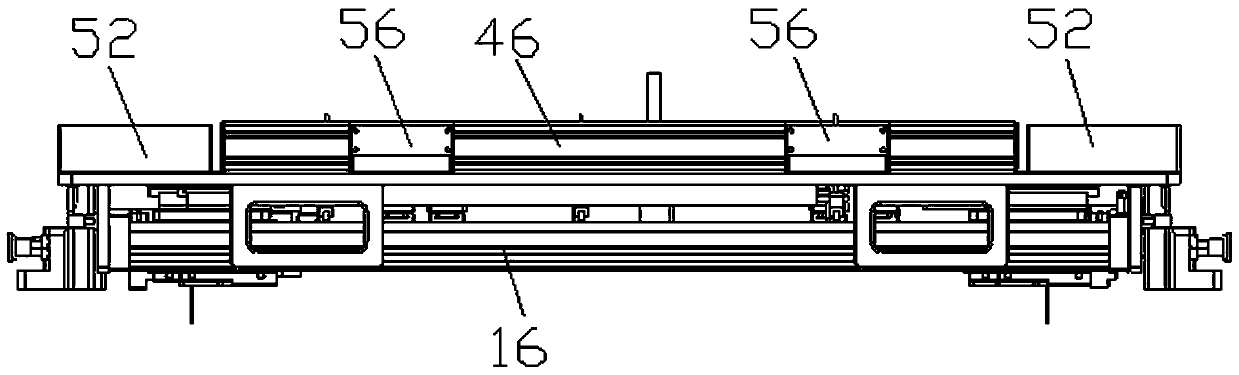

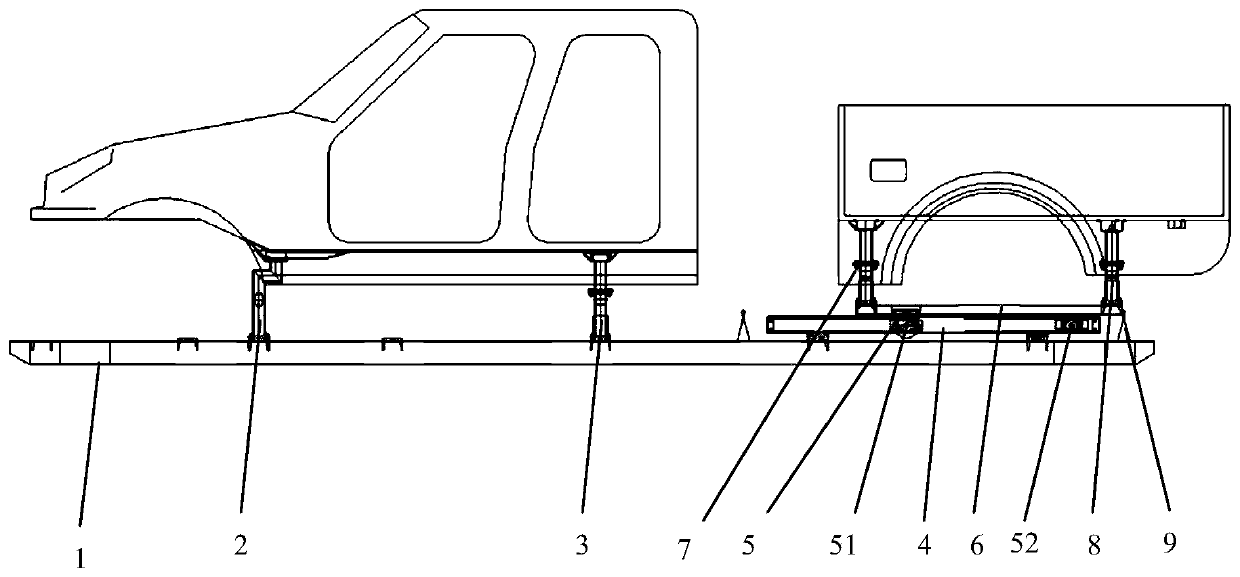

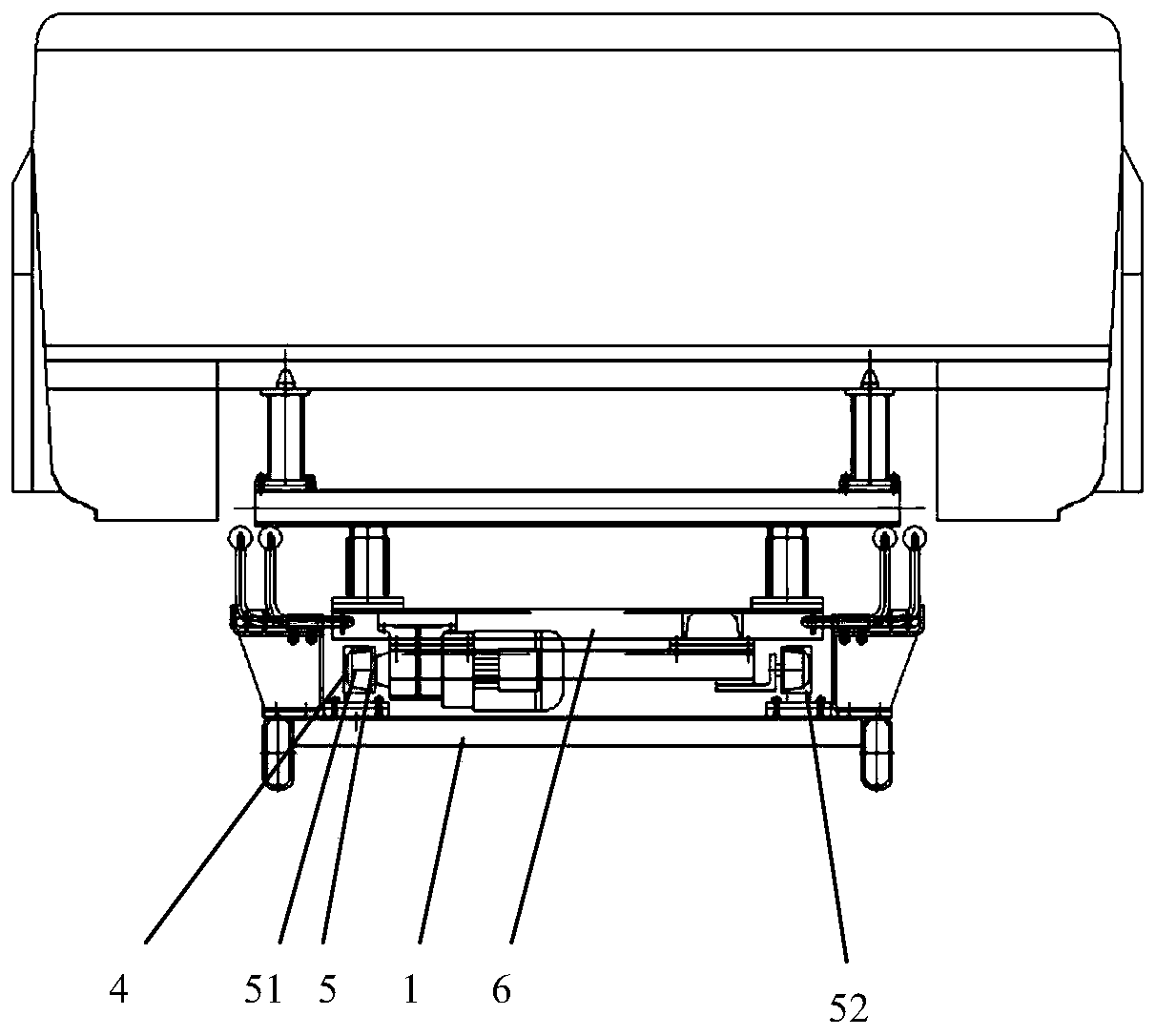

Conveying device for automobile electronic assembly line

ActiveCN108861504ALower Upfront CostsQuick and easy disassemblyConveyorsConveyor partsPush and pullEngineering

The invention relates to a conveying device for an automobile electronic assembly line. The conveying device for the automobile electronic assembly line comprises a deskboard, at least one tray, horizontal drive mechanisms arranged at the bottom end of the deskboard, a track assembly arranged at the upper end of the deskboard, and at least one group of clamping air cylinders. At least one long strip-shaped through hole is formed in the deskboard in a way of extending along the horizontal direction; each horizontal drive mechanism comprises a rodless cylinder, and a jacking assembly driven by the rodless cylinder so as to move horizontally; each jacking assembly comprises a jacking air cylinder, and a jacking claw connected with the output end of the jacking air cylinder; and each jacking claw penetrates through the corresponding long strip-shaped through hole. According to the conveying device for the automobile electronic assembly line provided by the invention, the conveying manner is realized by pushing and pulling the trays through the air cylinders instead of dragging through a belt, so that products can be accurately positioned, and the earlier-stage cost input of the belt isreduced; and meanwhile, the deskboard can be quickly disassembled, so that a line body can be disassembled into a single machine and a conveying part with specific capabilities, production schedulingis realized conveniently, the line body can be quickly conveyed and assembled, and later maintenance and part replacement can be further carried out conveniently.

Owner:SUZHOU IND PARK NESTAR AUTOMATION TECH

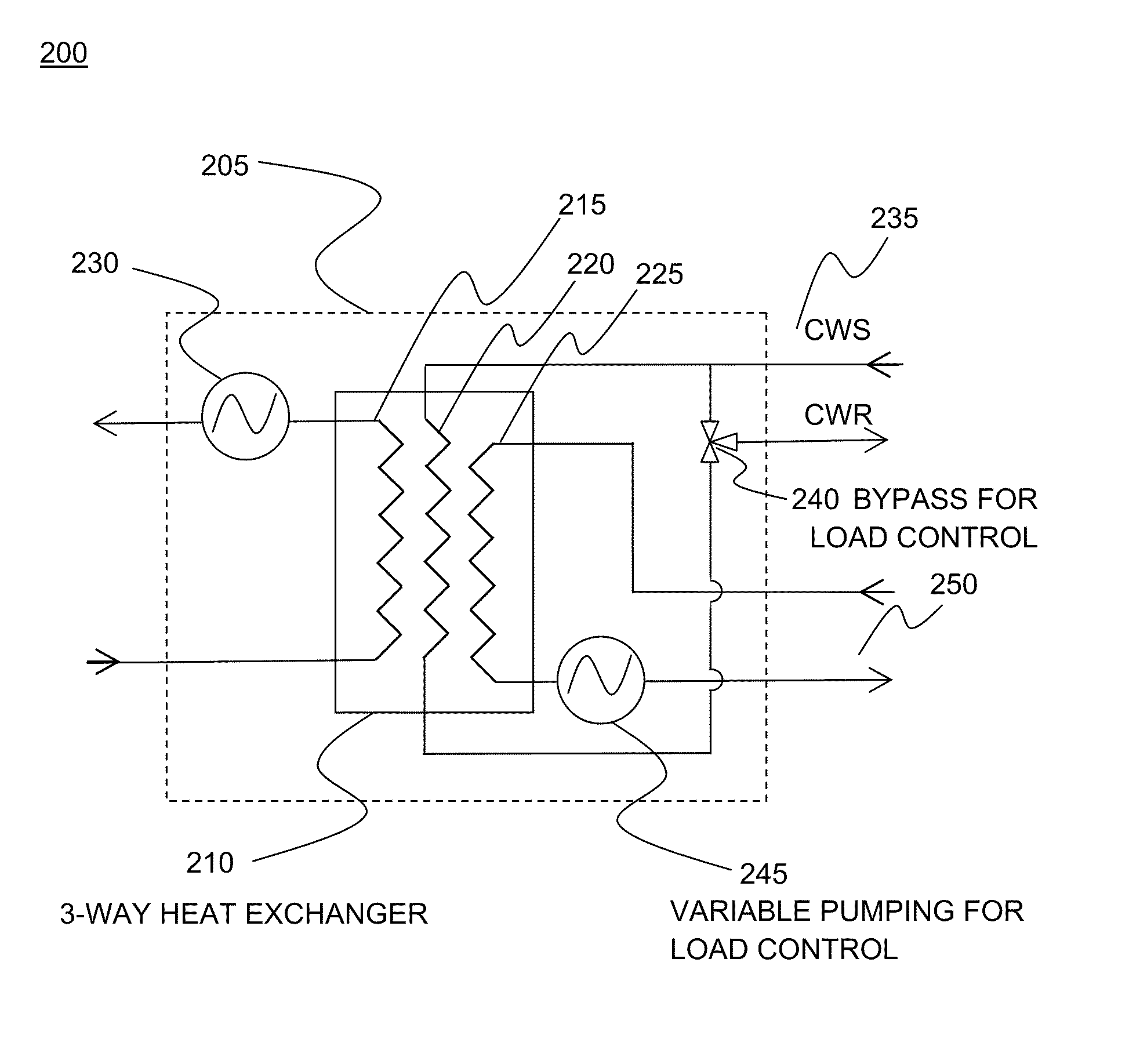

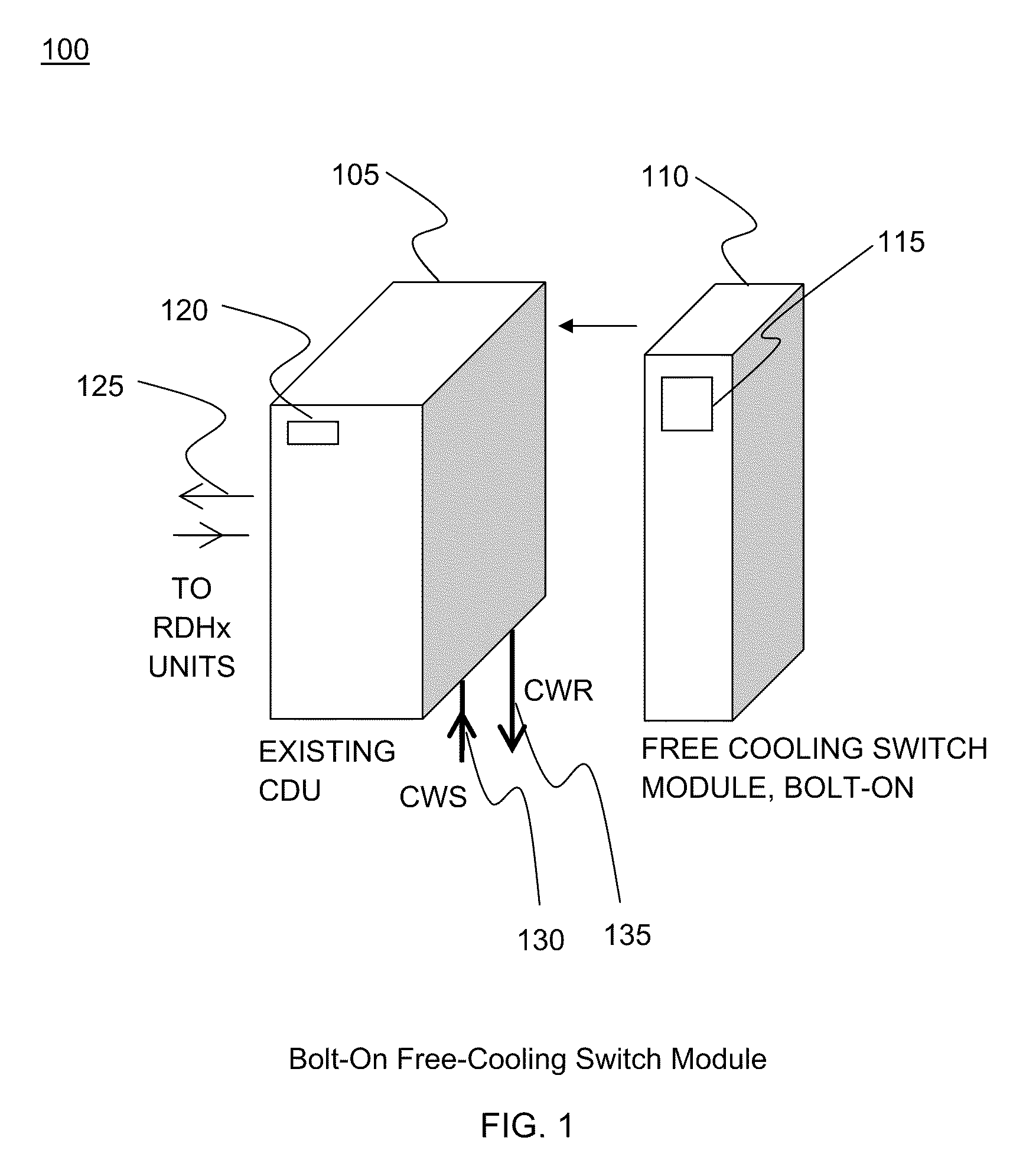

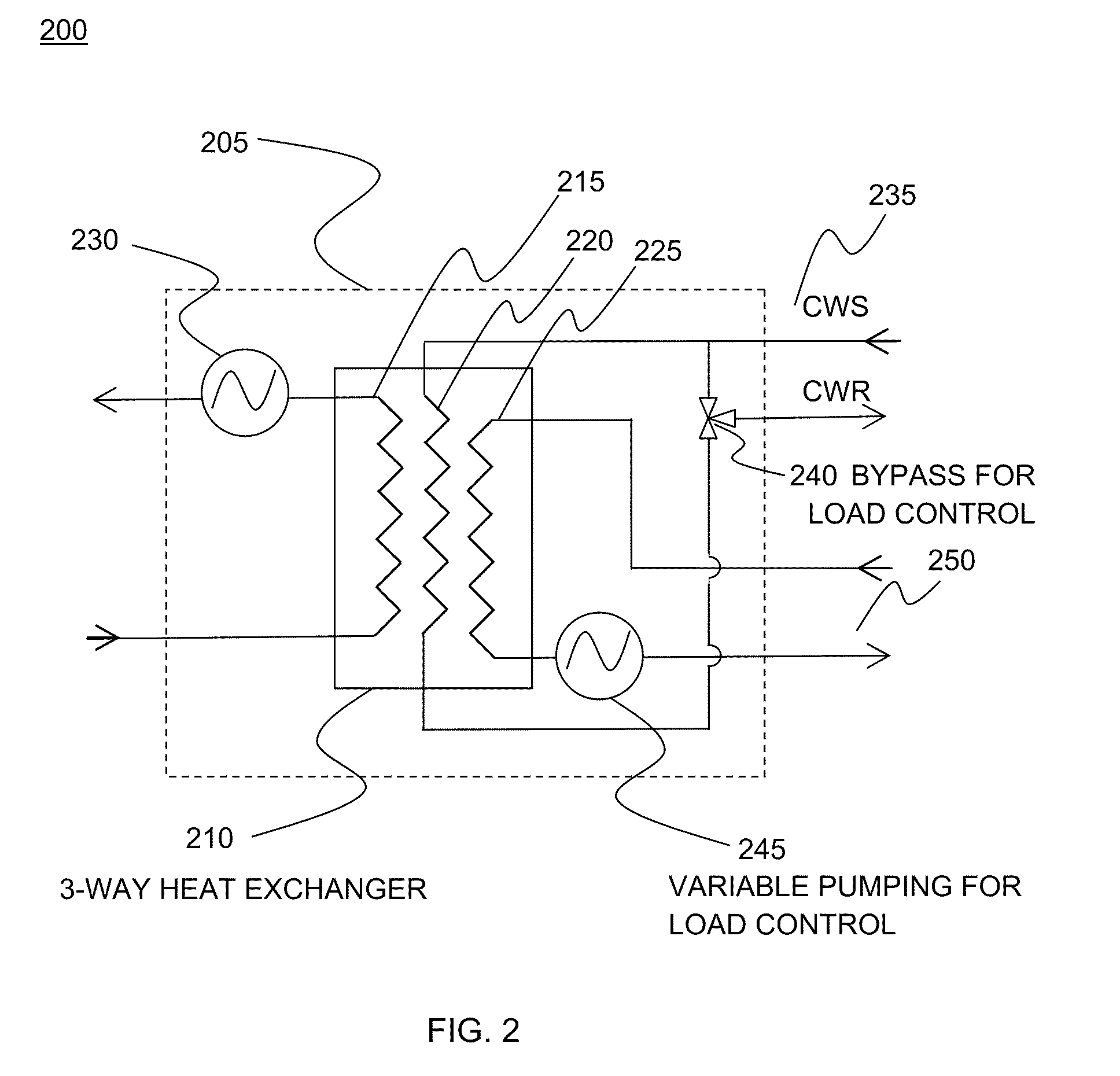

Free-cooling including modular coolant distribution unit

ActiveUS9285129B2Lower Upfront CostsEfficiently accommodatedOther heat production devicesStationary plate conduit assembliesData centerModularity

A system and method for liquid-liquid free-cooling that may include a modular coolant distribution unit (CDU) is provided. CDUs can incorporate integral free-cooling or bolt on free-cooling switch modules. The free-cooling flow can be either direct or indirect. Units can interface with each other to provide scalable cooling for computer data centers. Embodiments of the system can integrate with electronics rack passive rear door liquid heat exchangers.

Owner:VETTE TECH

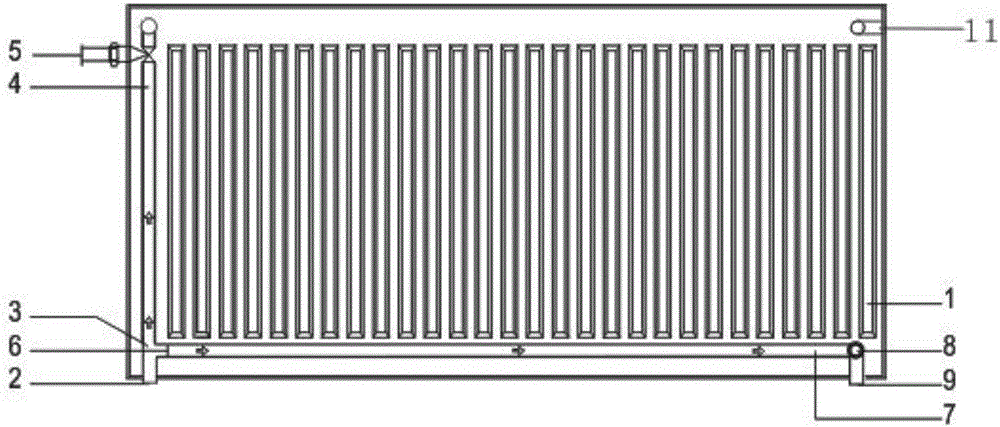

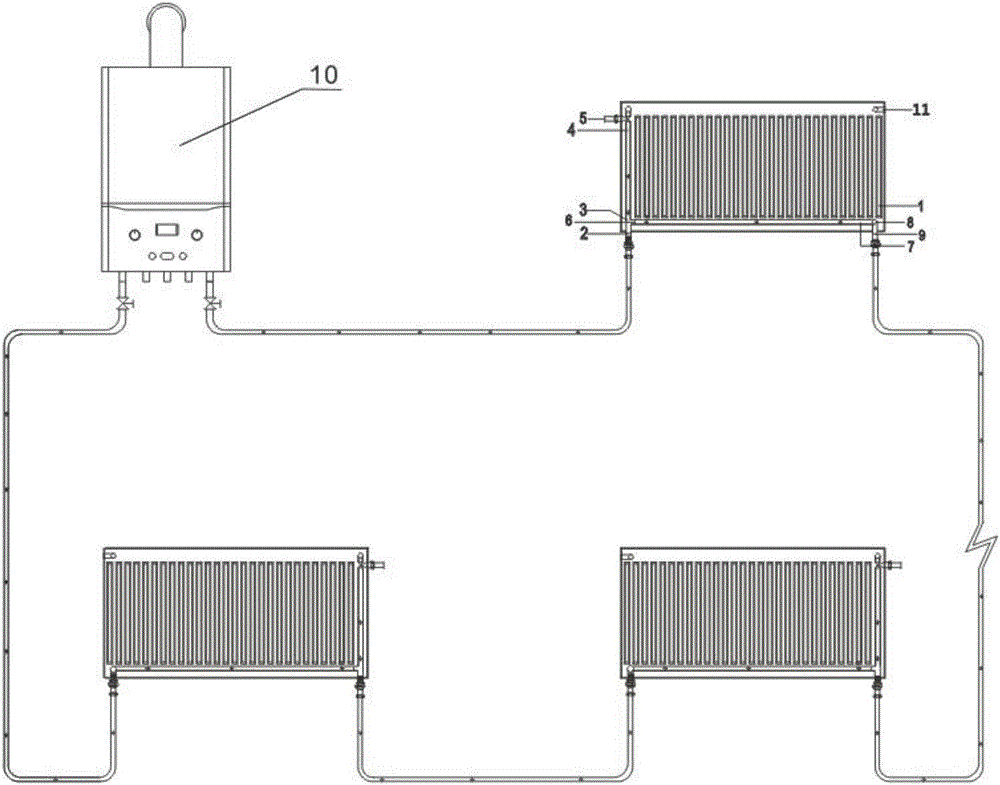

Singe-tube controllable radiator adopting serial connection

InactiveCN106196261ASave materialReduce the number of partsLighting and heating apparatusCentral heating componentsTemperature controlEngineering

The invention discloses a single-tube controllable radiator adopting serial connection. The single-tube controllable radiator adopting serial connection comprises a radiator body, a water supply port and a water return port, and is characterized in that a water supply tee joint and a water return tee joint are arranged inside the radiator body; one end of the water supply tee joint communicates with the radiator body through a water supply tube and a temperature control valve; the other end of the water supply tee joint communicates with the water return tee joint through a flow choking ring and a water return tube; the water return tee joint communicates with a next set of radiator or hear source through the water return port; and the water supply port further communicates with the heat source through a pipeline. The heat source is hot water or steam. The single-tube controllable radiator adopting serial connection is mainly used for serial connection of single-tube controllable radiators.

Owner:许劲松

Cement kiln co-processing combustible waste system that can bypass waste heat power generation

ActiveCN104033905BReduce the link of pre-processingLower Upfront CostsSludge treatment by de-watering/drying/thickeningCement productionCogenerationCo-processing

Owner:福建龙麟环境工程有限公司

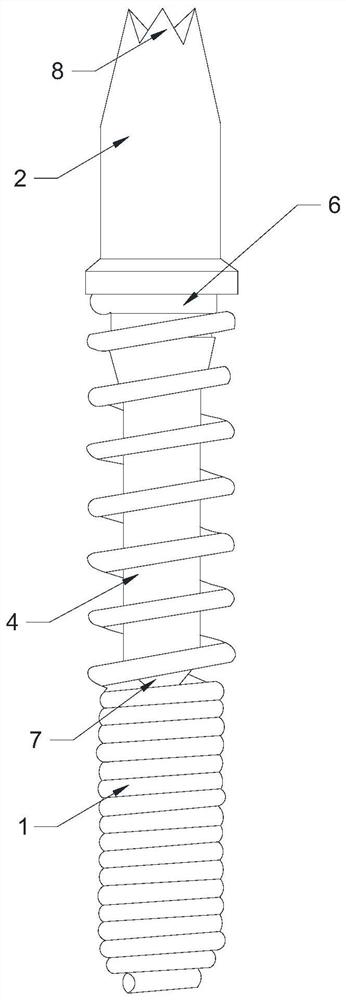

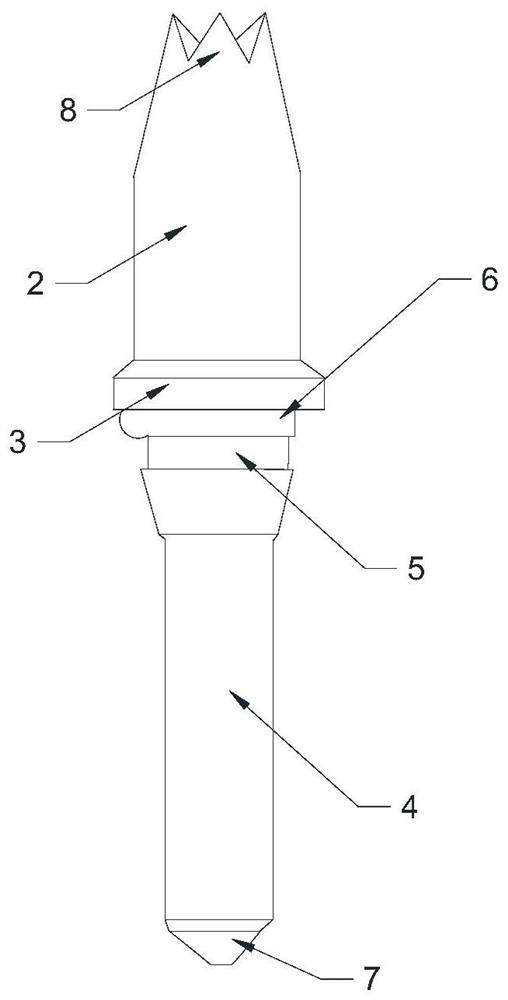

Single-head spring test probe

InactiveCN113447681ANot easy to separateEnhanced electronic signal deliveryElectrical measurement instrument detailsElectrical testingEngineeringSpring Test

A single-head spring test probe disclosed by the present invention comprises a TOP probe head and a center spring, the TOP probe head comprises a front section part, a middle section part and a tail section part which are integrally formed, wherein the front section part, the middle section part and the tail section part are all of a cylinder structure, the upper end of the front section part is provided with a probe head structure, the middle part of the middle section part is provided with a flange clamping groove. The diameter of the center spring is decreased from the middle to the two ends, the middle section is clamped to any end of the center spring through a flange clamping groove, the upper end of the front section and the upper end of the middle section are both located outside the end, and the lower end of the middle section part and the tail section part are both located inside a spring ring at the end and can both make contact with the spring ring at the end. The invention aims to provide the single-head spring test probe which is simple in structure and few in assembly parts, the difficulty of an assembly process is reduced, and the assembly efficiency is further improved; and meanwhile, the early-stage cost is also reduced.

Owner:苏州迪克微电子有限公司

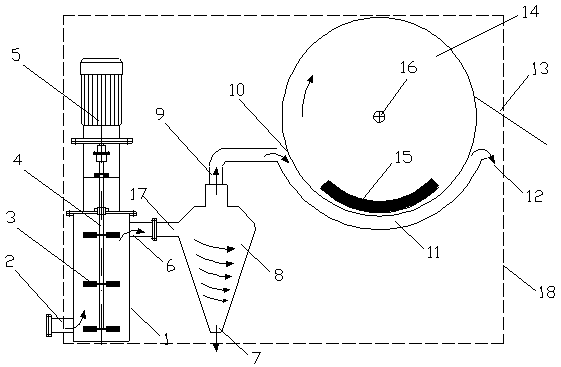

Energy-saving magnetic medium deflocculation and separation integrated machine

PendingCN109133483ACompact structureReduces the likelihood of flocculation over timeWater/sewage treatment by centrifugal separationSpecific water treatment objectivesMagnetic mediaIntegrated design

The invention provides an energy-saving magnetic medium deflocculation and separation integrated machine. A main body consists of a deflocculation unit, a magnetic separation unit and a sand-water separator. According to the energy-saving magnetic medium deflocculation and separation integrated machine provided by the invention, a sand-water separator is arranged between the deflocculation unit and the magnetic separation unit, so that flocs after deflocculation by the deflocculation unit can be immediately subjected to solid-liquid separation, the processing load of the magnetic separation unit in a subsequent section can be reduced, the energy consumption during operation of the magnetic separation unit can be reduced, the recovery rate of magnetic medium powder can be improved, and theoperation cost of water treatment can be reduced; and by adopting an integrated design, only a feed port and a discharge port need to be provided during field mounting, so that complicated mounting processes are saved, and the use is simpler and more convenient.

Owner:贾伯林

Low-temperature preparation method of anti-cracking agent of concrete

The invention discloses a low-temperature preparation method of an anti-cracking agent of concrete. The low-temperature preparation method comprises the following steps: (1) putting raw materials intoa planetary ball grinder for uniform mixing and grinding, wherein the raw materials comprise an aluminum calcium raw material, an aluminum raw material, a calcium raw material and industrial gypsum;(2) pressing the raw materials mixed in the step (1) into a cake, putting the cake into a high-temperature electric furnace, calcining cake at the temperature of 700 to 1,200 DEG C, and taking out andquenching the cake; (3) grinding a product obtained in the step (2) to obtain the sulfoaluminate anti-cracking agent. According to the low-temperature preparation method disclosed by the invention, common wastes containing an intermediate phase CA (mono calcium aluminate), CA2 (calcium dialuminate) and other aluminates are used as the raw materials, and the raw materials are not required to be modified or subjected to other treatment processes, so that the treatment cost is reduced, and the utilization rate of the raw materials is increased. The early cost is greatly reduced, and the environmental problems caused by industrial waste slag are solved.

Owner:YANCHENG INST OF TECH

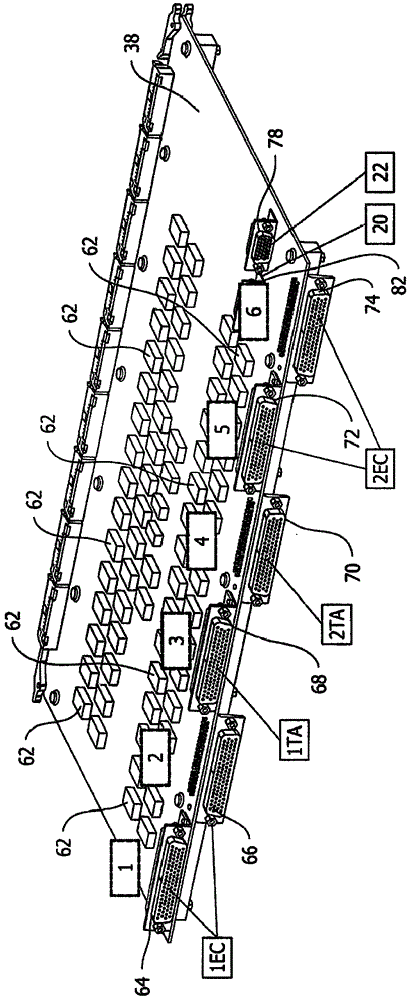

Large scale automated test system reconfiguration

ActiveCN106018886AWays to Simplify ConfigurationIncrease the number ofTesting electric installations on transportAircraft components testingSystem reconfigurationFlight vehicle

A large scale automated test system employs one or more relay boxes that contain and support one or more relay boards. Each relay board is operated to selectively communicate an item being designed, for example a cell phone, an automobile, or an aircraft, with two or more electrical components being considered in the design of the item to evaluate the performance of each electrical component in the item being designed.

Owner:THE BOEING CO

Conveyors for automotive electronics assembly lines

ActiveCN108861504BLower Upfront CostsQuick and easy disassemblyConveyorsConveyor partsPush and pullEngineering

The invention relates to a conveying device for an automobile electronic assembly line. The conveying device for the automobile electronic assembly line comprises a deskboard, at least one tray, horizontal drive mechanisms arranged at the bottom end of the deskboard, a track assembly arranged at the upper end of the deskboard, and at least one group of clamping air cylinders. At least one long strip-shaped through hole is formed in the deskboard in a way of extending along the horizontal direction; each horizontal drive mechanism comprises a rodless cylinder, and a jacking assembly driven by the rodless cylinder so as to move horizontally; each jacking assembly comprises a jacking air cylinder, and a jacking claw connected with the output end of the jacking air cylinder; and each jacking claw penetrates through the corresponding long strip-shaped through hole. According to the conveying device for the automobile electronic assembly line provided by the invention, the conveying manner is realized by pushing and pulling the trays through the air cylinders instead of dragging through a belt, so that products can be accurately positioned, and the earlier-stage cost input of the belt isreduced; and meanwhile, the deskboard can be quickly disassembled, so that a line body can be disassembled into a single machine and a conveying part with specific capabilities, production schedulingis realized conveniently, the line body can be quickly conveyed and assembled, and later maintenance and part replacement can be further carried out conveniently.

Owner:SUZHOU IND PARK NESTAR AUTOMATION TECH

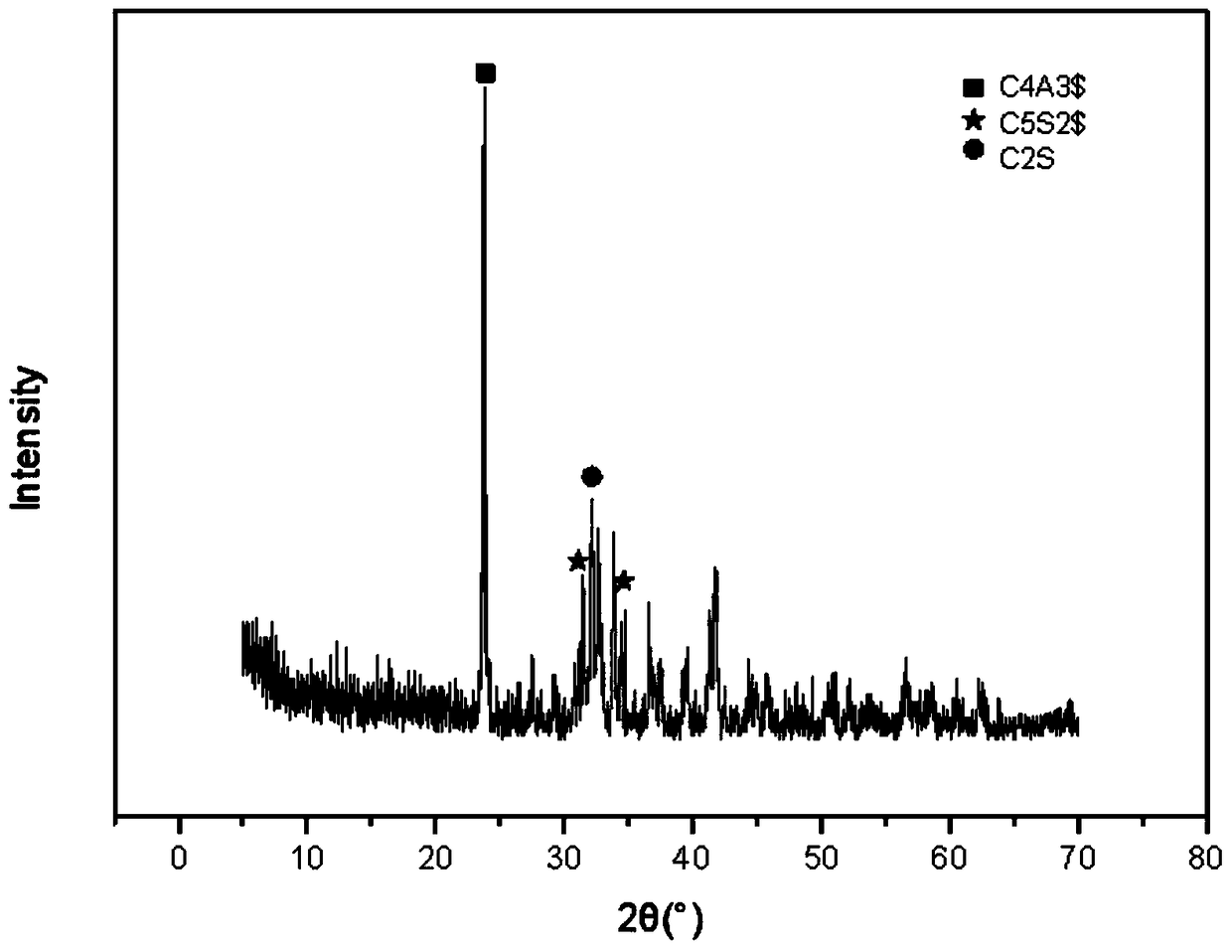

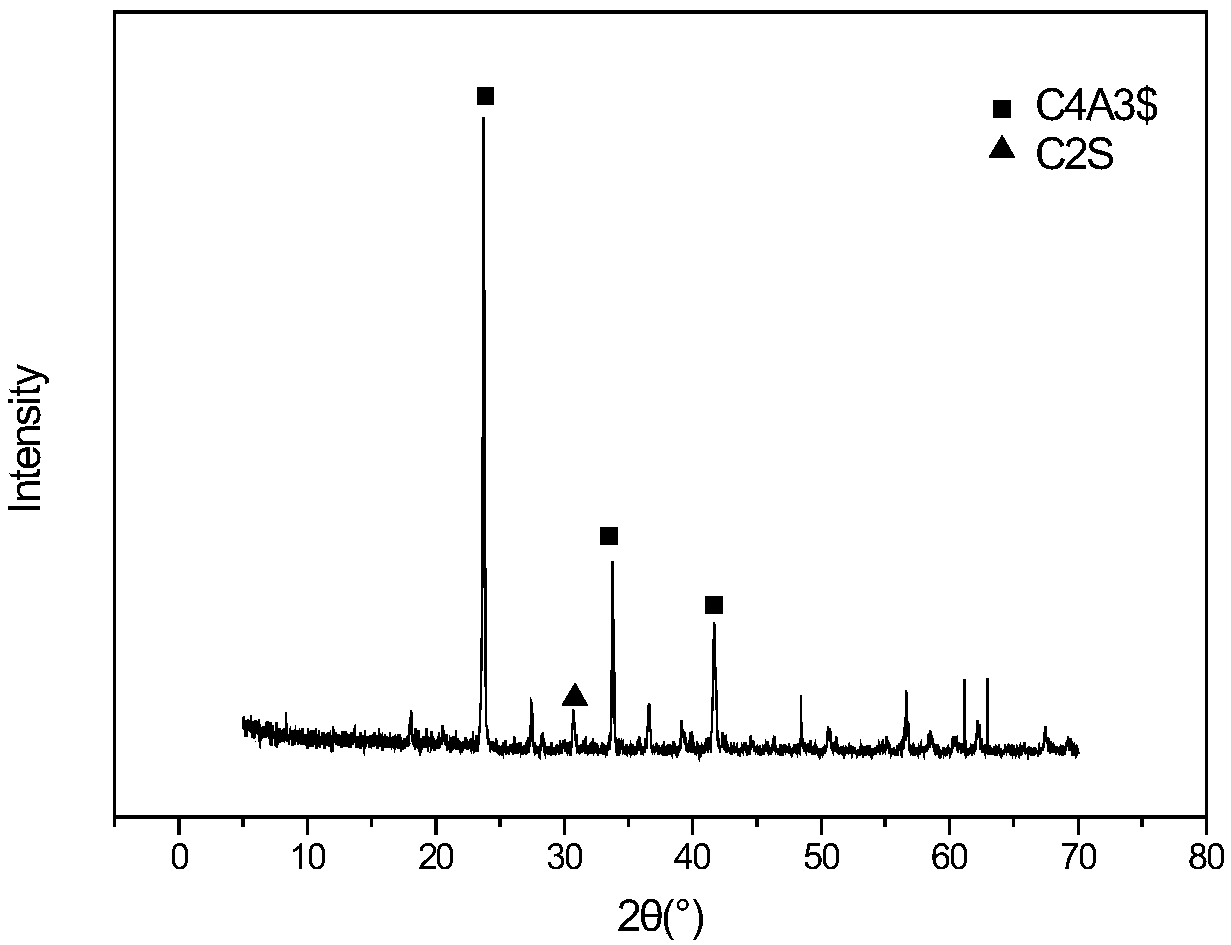

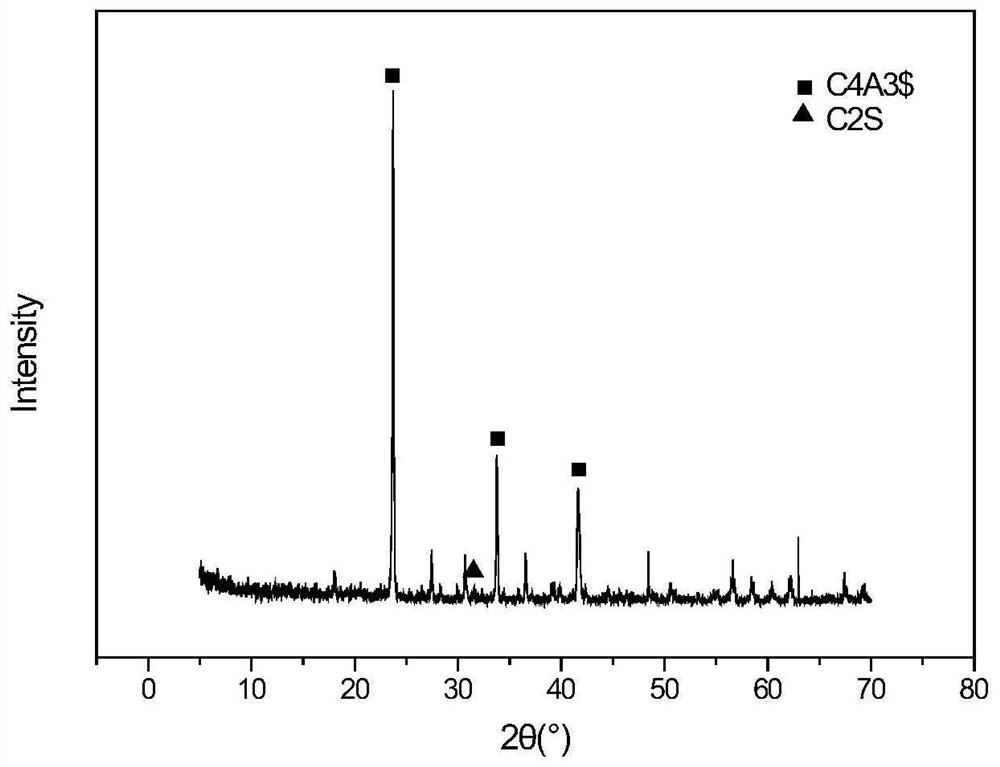

A kind of preparation method of belite sulphoaluminate cement

ActiveCN105060744BLow firing temperatureImprove performanceCement productionToxic industrial wasteCalcination

The invention discloses a preparation method of sulfoaluminate Belite cement. The preparation method comprises the following steps: taking industrial waste residues and industrial gypsum as raw materials, taking bauxite or bauxite tailings as a corrective material, adding water for grinding after mixing, molding, carrying out hydrothermal reaction, and then, smashing, calcining and grinding, so as to obtain sulfoaluminate Belite cement, wherein the main components of the sulfoaluminate Belite cement are C4A3S<-> and beta-C2S. According to the invention, the sintering temperature of the sulfoaluminate Belite cement is reduced through the hydrothermal reaction performed in advance, the energy consumption is reduced, the performance of the sulfoaluminate Belite cement is improved through a proper ratio and a proper technology, and the fact that the low-carbon sulfoaluminate Belite cement is prepared under low temperature; besides, limestone is not used, the generation of carbon dioxide is avoided, the environmental pressure is increased, and the energy consumption is low due to low calcination temperature; therefore, the preparation method of the sulfoaluminate Belite cement is low-carbon and environment-friendly.

Owner:YANCHENG INST OF TECH

A kind of low-temperature preparation method of concrete anti-cracking agent

The invention discloses a low-temperature preparation method of a concrete anti-cracking agent, which comprises the following steps: (1) Putting raw materials into a planetary ball mill, mixing and grinding; wherein, the raw materials include aluminum-calcium raw materials, aluminum raw materials, calcium Raw materials, industrial gypsum; (2) Press the raw materials mixed in step (1) into cakes, place them in a high-temperature electric furnace, calcinate them at a temperature of 700°C-1200°C, and then take them out for rapid cooling; (3) Take out the mixture obtained in step (2) The product is ground to obtain a sulphoaluminate anti-cracking agent. The present invention directly utilizes and contains intermediate product phase CA (monoaluminate calcium), CA 2 (Calcium dialuminate) and other common wastes of aluminates are used as raw materials, and the raw materials do not need to be modified or otherwise treated, which saves processing costs and improves the utilization rate of raw materials. The initial cost is greatly reduced, and the environmental problems caused by industrial waste residues are solved at the same time.

Owner:YANCHENG INST OF TECH

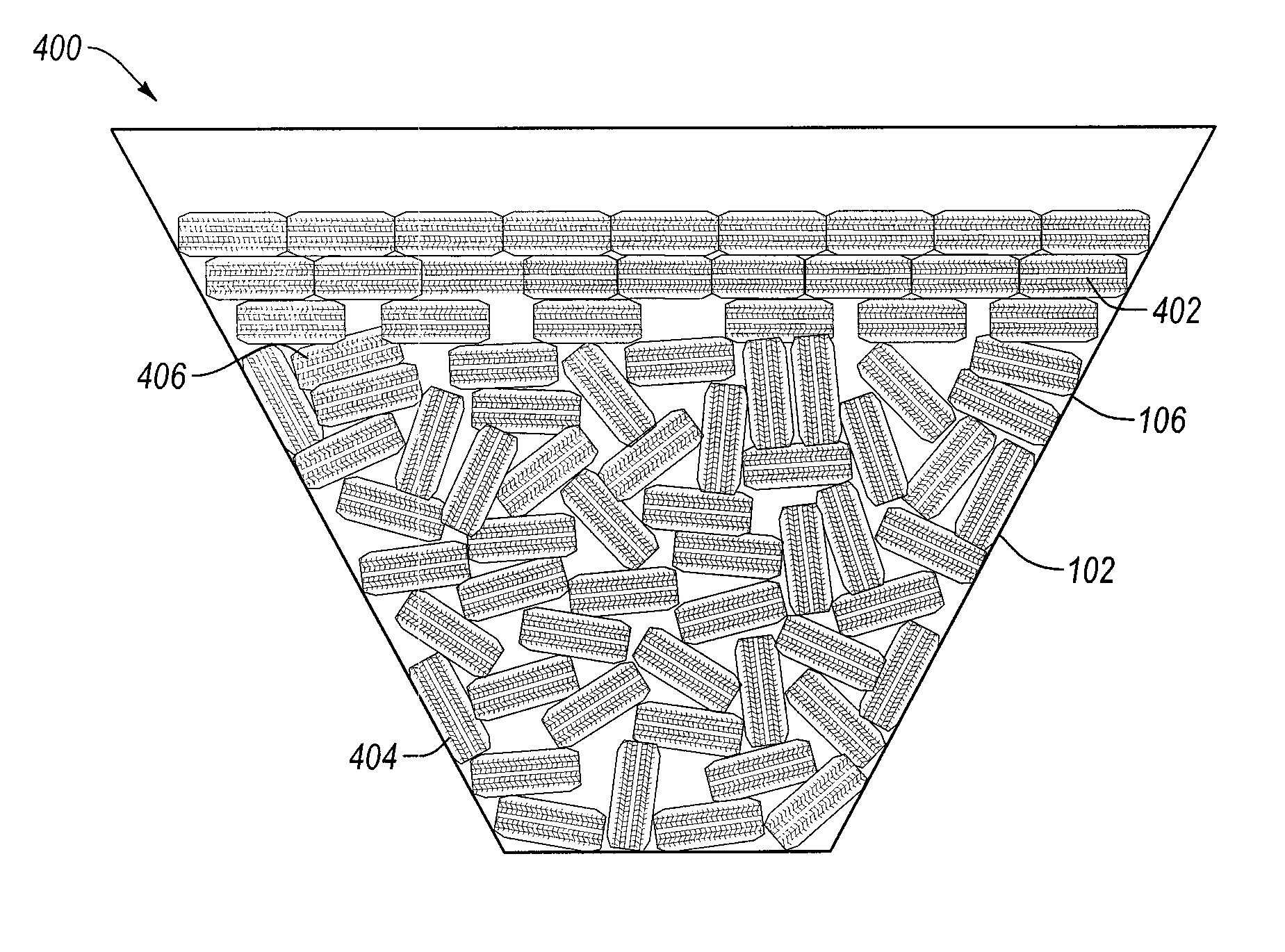

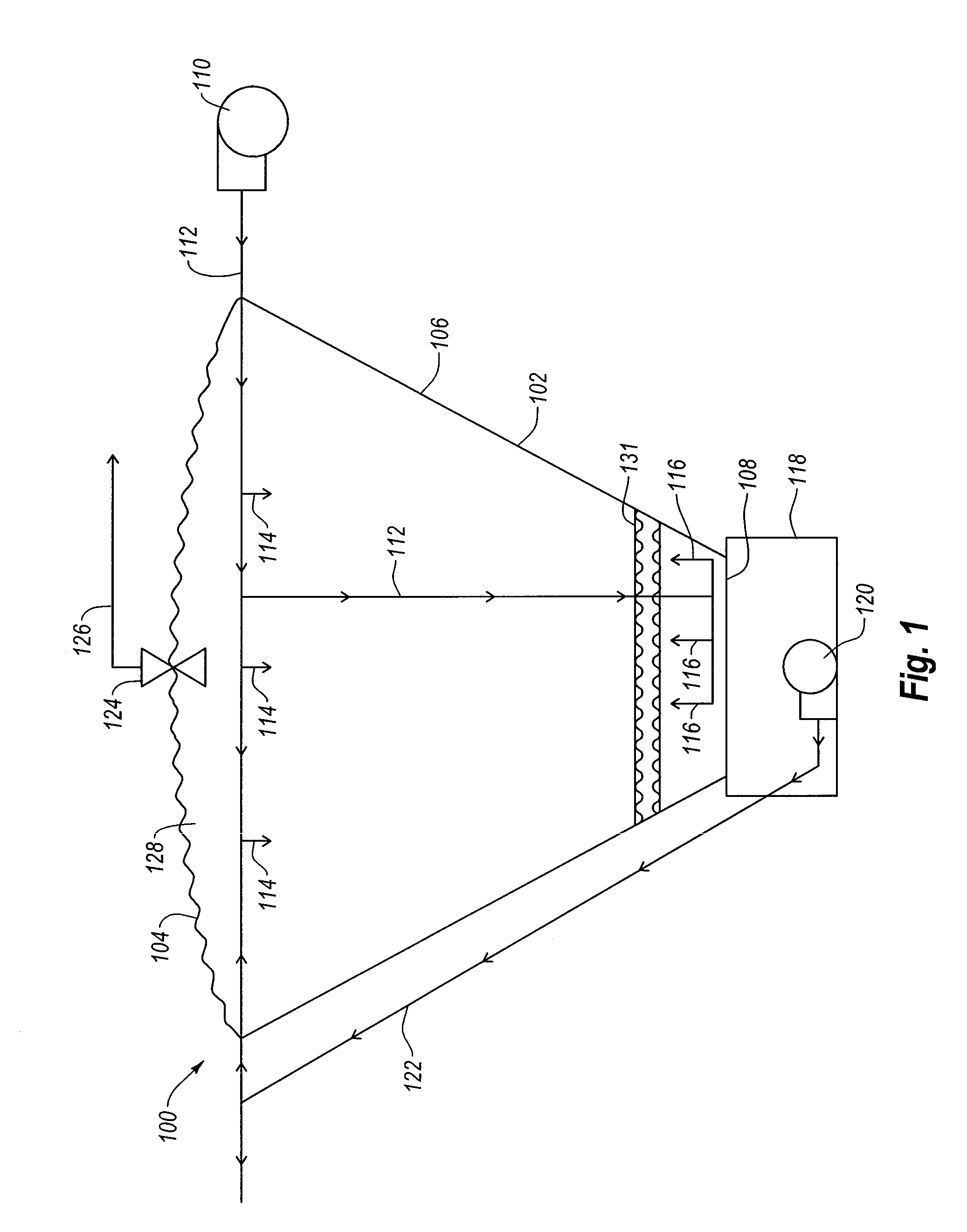

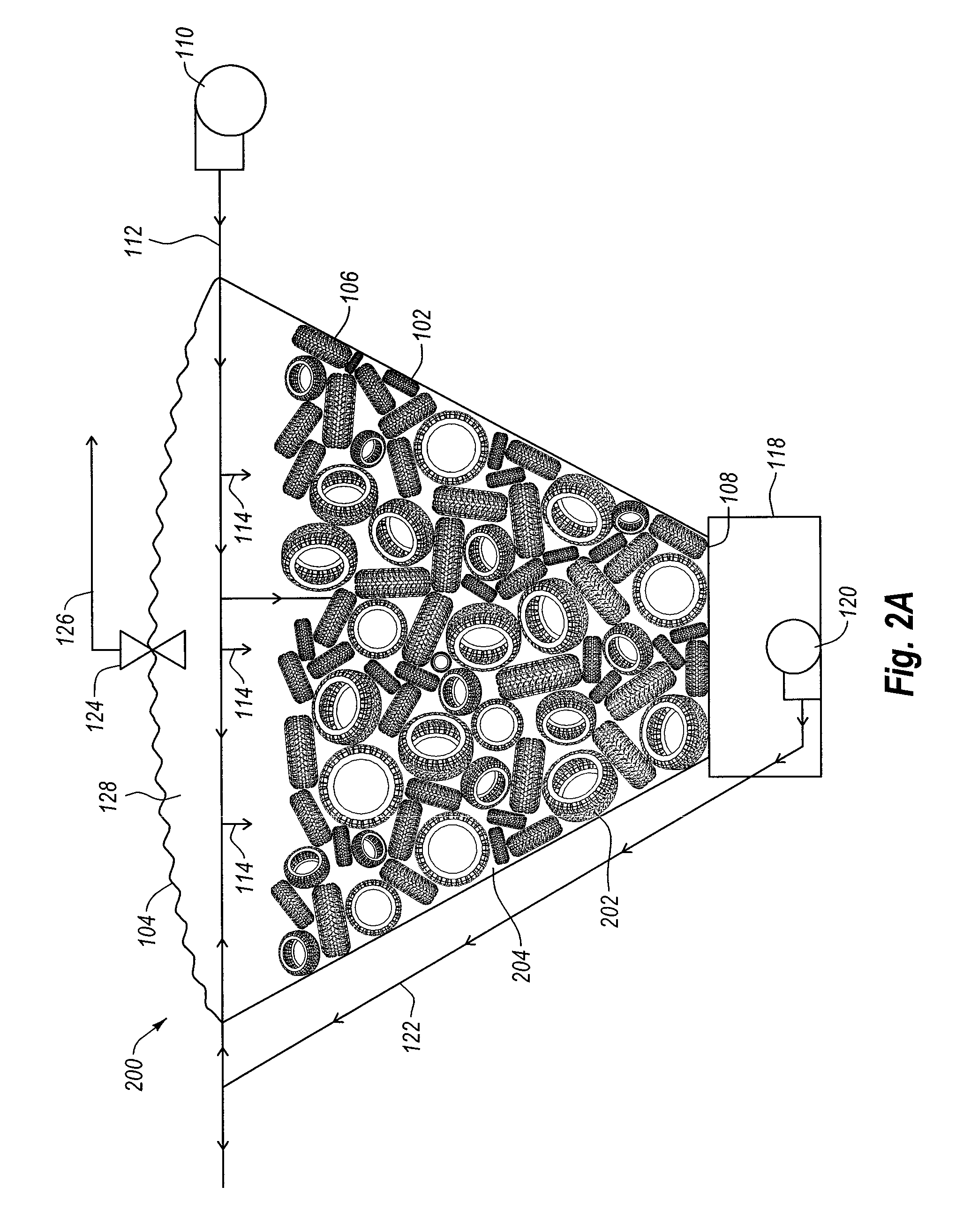

Anaerobic waste treatment apparatus

InactiveUS8691093B2Low costLower Upfront CostsSpecific water treatment objectivesTreatment with anaerobic digestion processesProximateWaste treatment

An anaerobic waste treatment apparatus comprises a container wherein randomly oriented bio-film media are disposed. An example waste treatment apparatus includes a container and optionally has at least two zones of bio-film media that are disposed within the container. In one example, the bio-film media includes torus-shaped materials, or other materials with voids therein, and the container is a dug out portion of earth. Moreover, the anaerobic waste treatment apparatus may additionally comprise a waste pump that is coupled to a waste pipe and configured to introduce waste into the container at one or more locations. When two zones are included, one zone may be randomly oriented, while a proximate zone may be substantially horizontal and / or an organized zone. The random zone may also have a transition layer thereon that supports the organized zone or that provides an interface between the organized and random zones.

Owner:J U B ENGINEERS

A low-temperature preparation method of sulfosilicate-belite-sulfoaluminate cement

The invention discloses a low-temperature preparation method of sulfosilicate-belite-sulfoaluminate cement, which comprises the following steps: (1) putting raw materials into a planetary ball mill, mixing and grinding; wherein, the raw materials include aluminum Silicon raw materials, aluminum raw materials, calcium raw materials, silicon raw materials, industrial gypsum; (2) press the raw materials mixed in step (1) into cakes, place them in a high-temperature electric furnace, and calcinate at a temperature of 700°C-1200°C, Then take out the rapid cooling; (3) grind the product obtained in step (2); (4) mix and grind the product obtained in step (3) with dihydrate gypsum to make cement. The present invention directly utilizes the common wastes containing the intermediate product phase calcium-aluminum feldspar and other aluminates as raw materials, and the raw materials do not need to be modified or treated in other ways, and the utilization rate of the raw materials is improved while saving the processing cost. The initial cost is greatly reduced, and the environmental problems caused by industrial waste residues are solved at the same time.

Owner:YANCHENG INST OF TECH

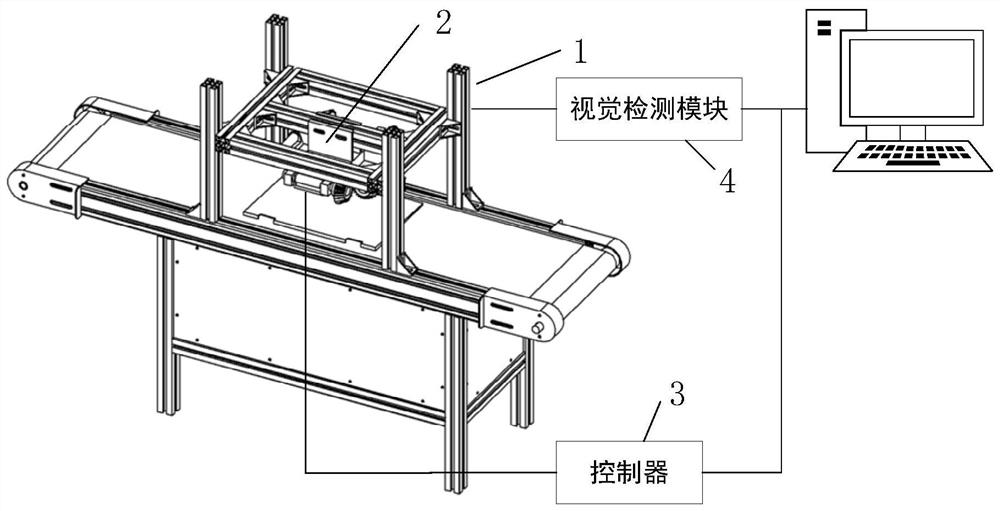

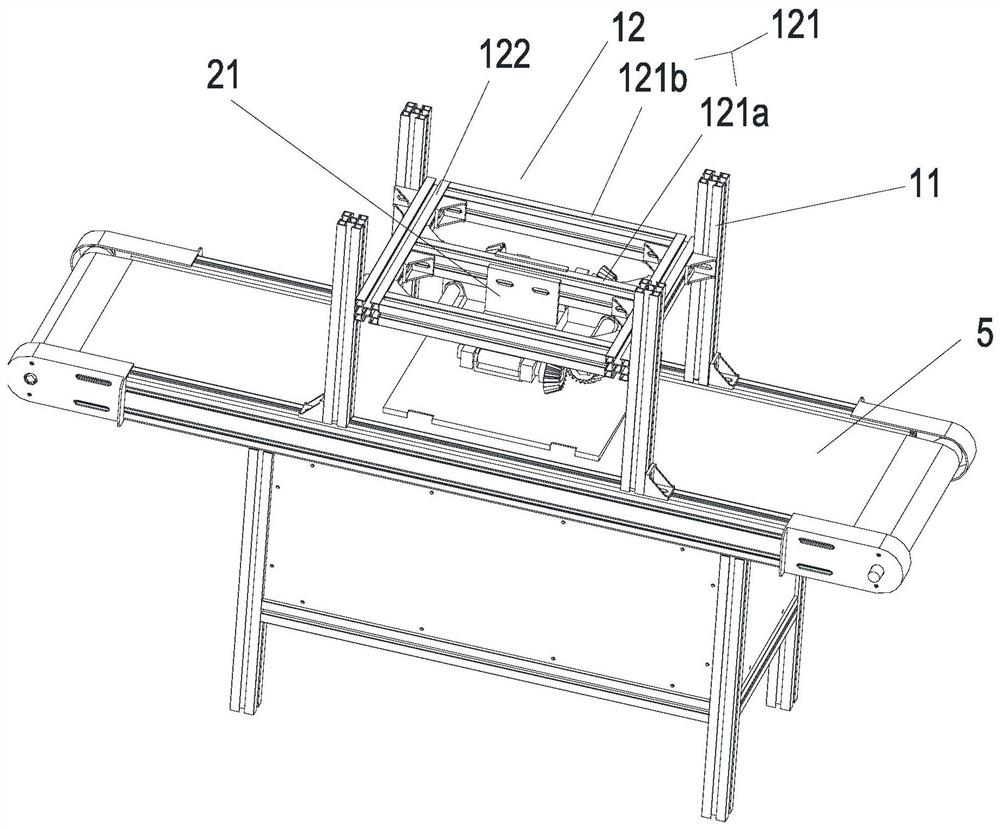

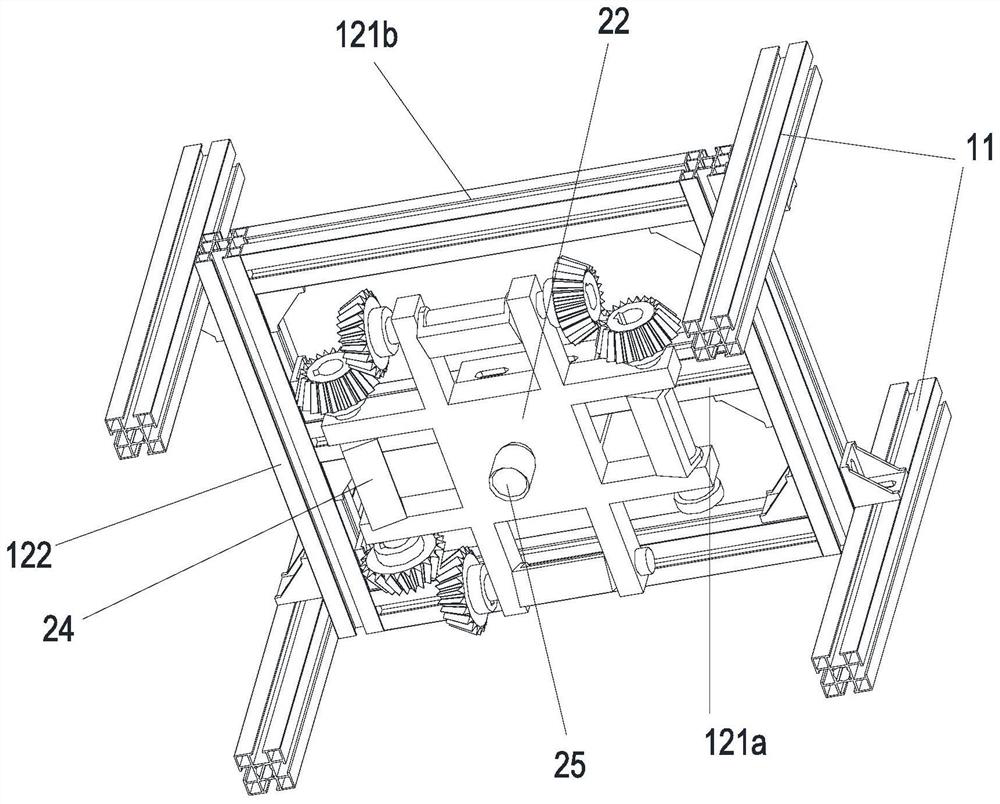

Rectangular multi-light source lighting device and defect detection method for its application

ActiveCN110231342BRealize modular installationLower Upfront CostsTelevision system detailsColor television detailsMachine visionEngineering

The invention discloses a rectangular multi-light source lighting device and a defect detection method for its application. The lighting device includes: an adjustment bracket, including a z-direction bracket and a movable frame that can move vertically along the z-direction bracket; the lighting bracket , including a "well"-shaped frame, the "well"-shaped frame extends in the circumferential direction to form four pairs of cantilevers, the inner sides of the two opposite cantilevers are used to erect the light source, and the outer sides of the two opposite cantilevers are used to set the angle adjustment device; The "well"-shaped frame is also provided with a shooting component at the bottom; an object stage is formed at the bottom of the lighting bracket to be measured; a controller is used to control each of the light sources to be turned on or off according to preset rules, and Controlling the shooting component to acquire the image of the workpiece to be tested; the machine vision detection module is used to generate a composite image according to the images of the workpiece to be measured acquired by the shooting component under all lighting environments. The defect detection method is applied to the above-mentioned lighting device. The modular assembly of the invention guarantees the detection reliability.

Owner:GUANGDONG UNIV OF TECH

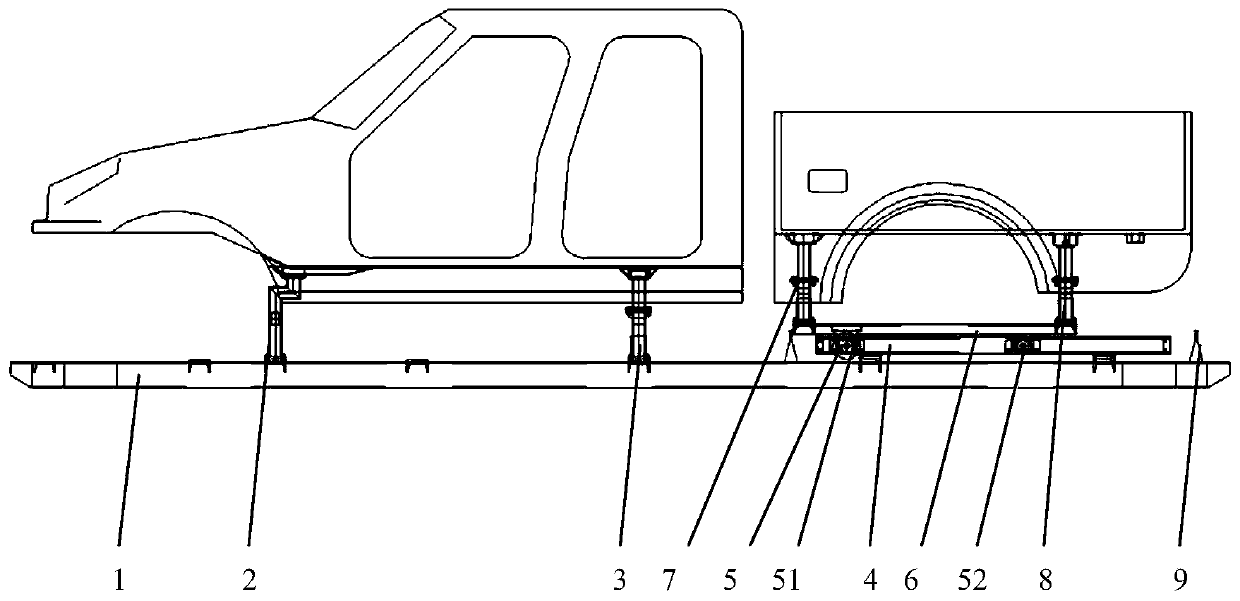

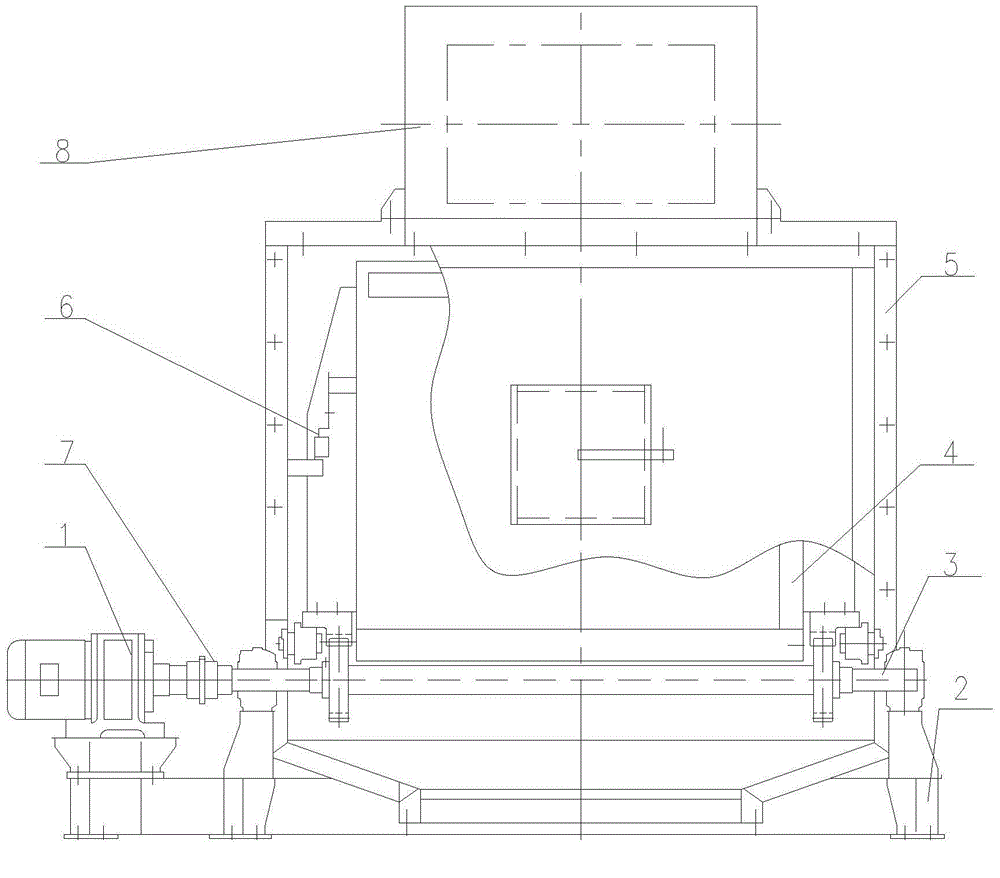

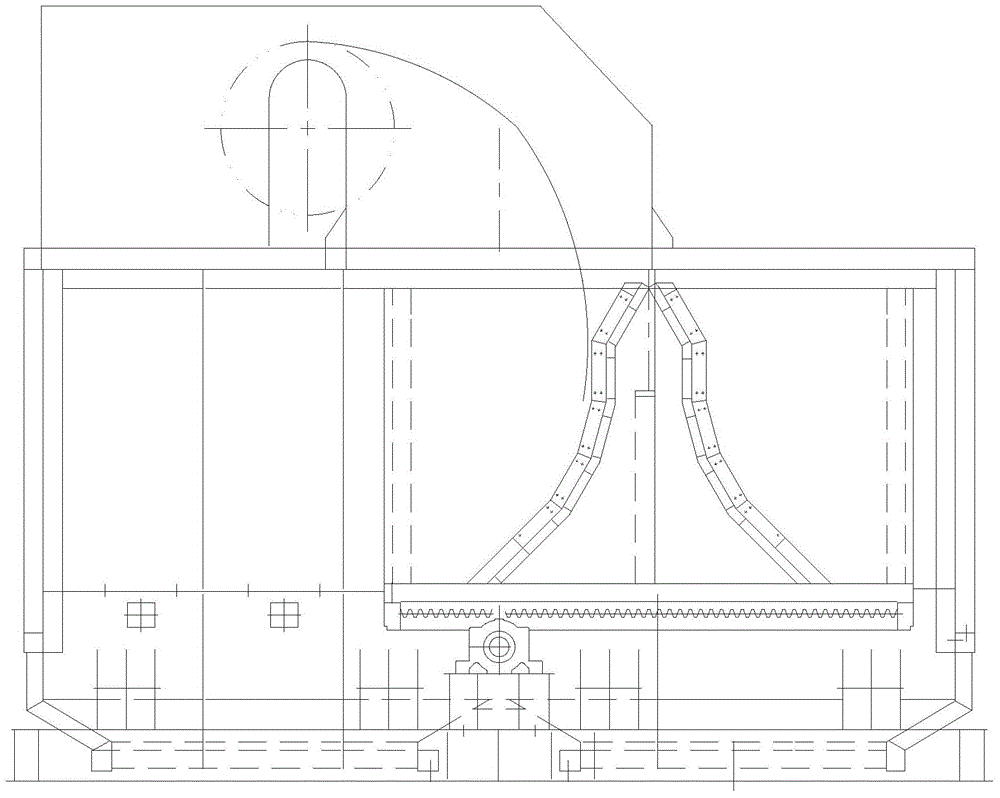

Device and method for automatically adjusting distance between cab and container for coating line

The invention discloses a device and a method for automatically adjusting the distance between a cab and a container for a coating line. The device comprises a skid, a track device, a rolling wheel moving device and a movable framework, wherein a cab front support and a cab rear support are arranged at the front end of the skid, the track device is arranged at the rear end of the skid, the rollingwheel moving device is arranged on the track device, and the movable framework is arranged on the rolling wheel moving device; and the movable framework is provided with a container front support anda container rear support. According to the device and the method, the distance between the cab and the container can be automatically adjusted, an coating operation is facilitated, the production pitch can be reduced, the operation is simple, the whole and local coating procedures of a truck can be ensured smoothly, the overall occupied space of a production line can be reduced as well, the early-stage cost investment and the later-stage energy loss are saved for enterprises.

Owner:NANTONG BEST MACHINE CO LTD

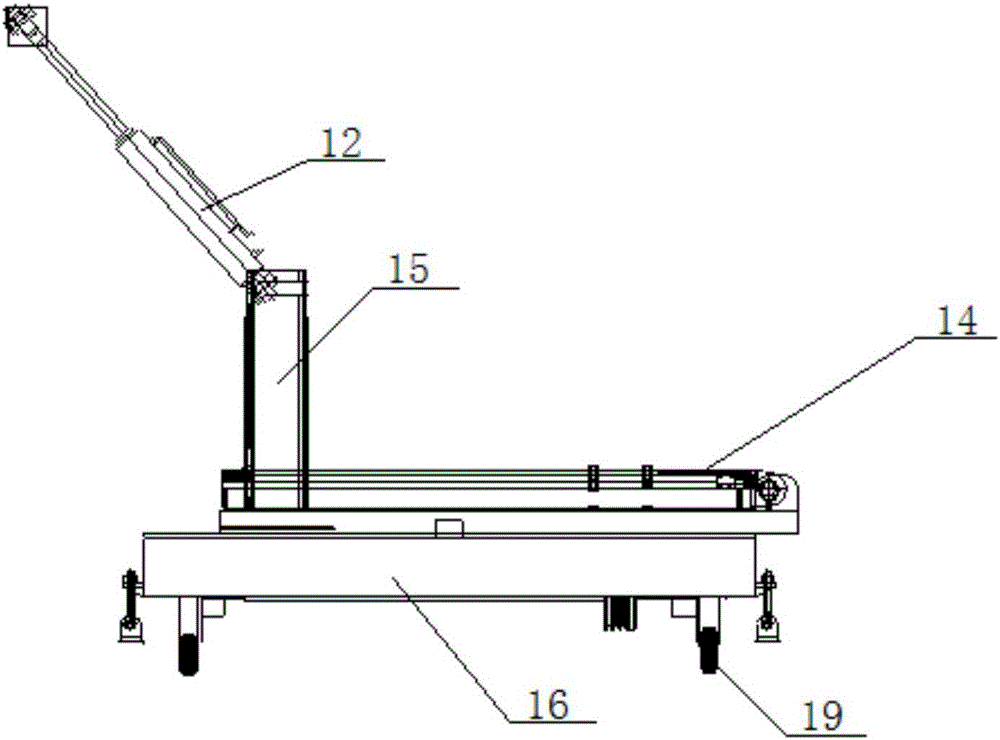

Movable discharge device of belt conveyor

A movable discharge device of a belt conveyor is applied to the technical field of power, ports, metallurgy and mines and comprises a driving device, a base, a transmission device, a reversing baffle, a funnel, travel switches, a coupler and a head protection cover. The driving device is connected with the base through a thread. The transmission device penetrates through the funnel and is connected with the base through a thread. A shaft extension at one end of the transmission device is connected with the driving device through the coupler. The funnel is connected with the base through a thread. The reversing baffle is arranged in the funnel and engaged with the transmission device through a chain on the reversing baffle, and the head protection cover is connected with the funnel through a flange. The travel switches are arranged at the two ends of the movable discharge device of the belt conveyor. The discharge device is simple in structure, the failure rate is lowered, the equipment structure is more compact, and vertical space is saved. A PLC control system is utilized for monitoring the discharge condition in real time, intelligent equipment control is truly achieved, and operation is convenient, easy and fast.

Owner:NORTHERN HEAVY IND GRP CO LTD

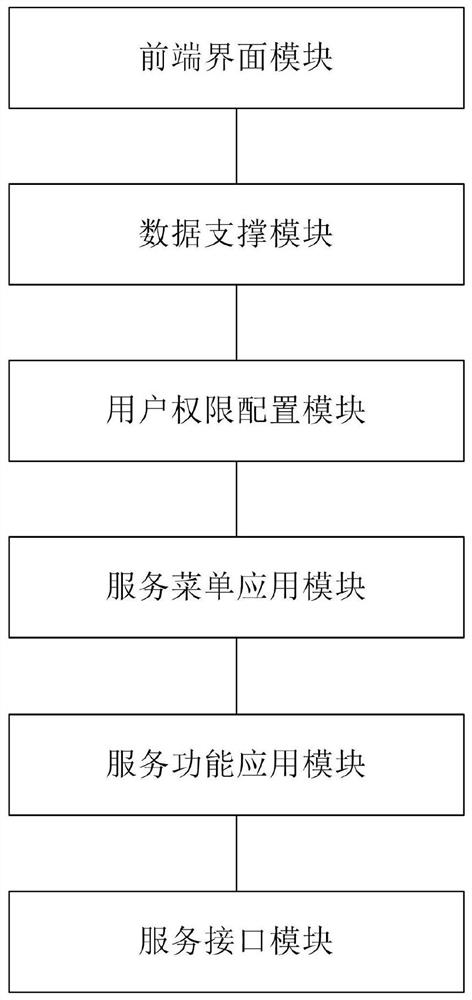

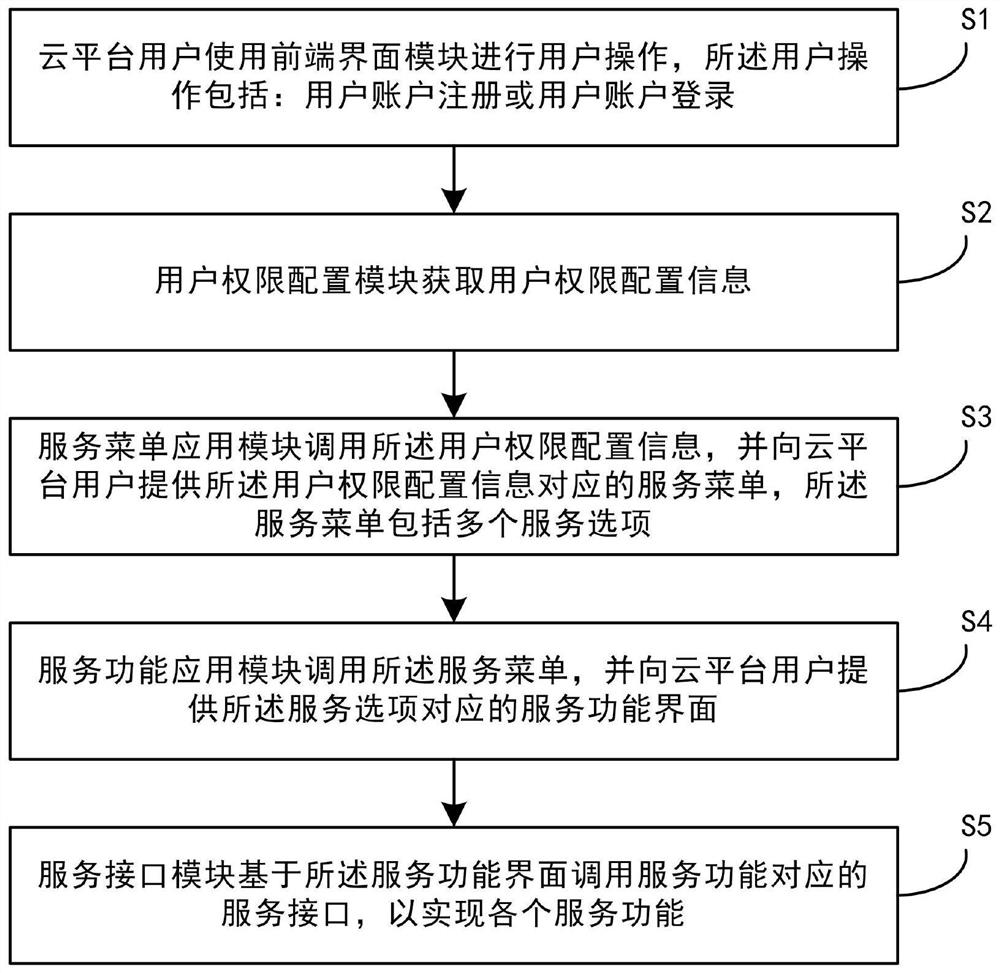

KYC safety service system and method

PendingCN112861085ARealize the service functionLower Upfront CostsFinanceDigital data authenticationUser PrivilegeBusiness enterprise

The invention provides a KYC safety service system and method. The system comprises a front-end interface module, a data support module, a user permission configuration module, a service menu application module, a service function application module and a service interface module. Wherein the front-end interface module provides a user operation interface; the data support module responds to a request of a cloud platform user, performs user account registration or user account login and stores user account data; the user permission configuration module obtains user permission configuration information; the service menu application module calls the user permission configuration information and provides a service menu corresponding to the user permission configuration information for the cloud platform user; the service function application module calls the service menu and provides a service function interface corresponding to the service option for the cloud platform user; and the service interface module calls a service interface corresponding to the service function based on the service function interface so as to realize each service function. According to the application, the personal KYC service process and the enterprise KYC service process are integrated, and the service process efficiency is high.

Owner:北京通付盾人工智能技术有限公司 +1

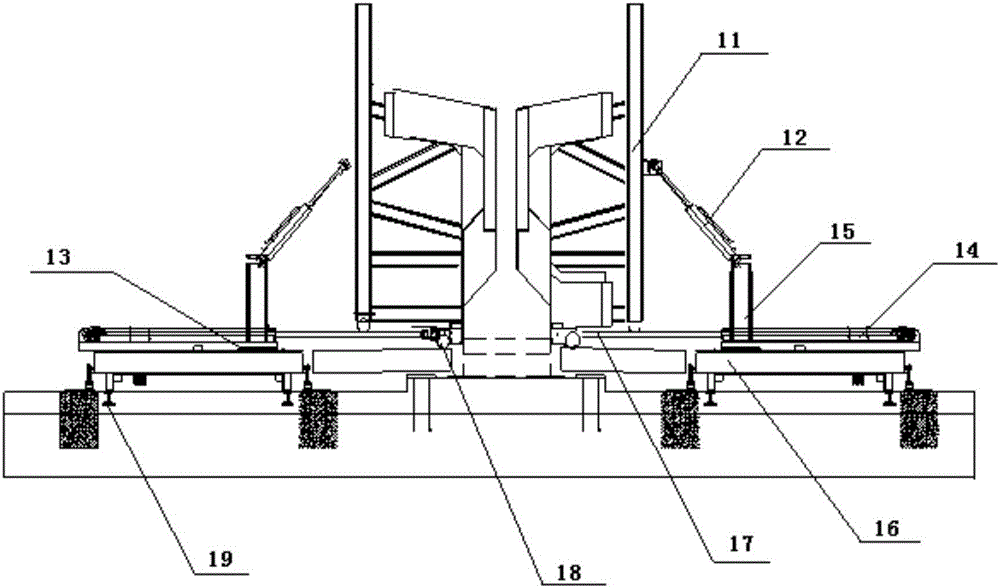

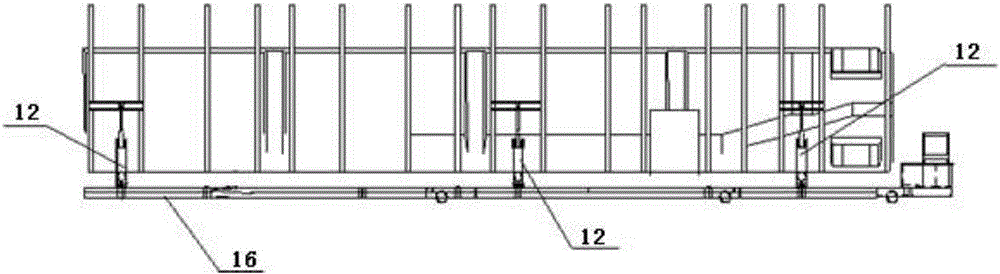

T-beam mold shifting device and method of use thereof

The invention discloses a T beam mould moving device and a specific use method thereof. A track is laid on each side of a T beam side mould; each track is provided with a mould moving trolley; the upper surface of each mould moving trolley is provided with a plurality of bidirectional adjustment devices; each horizontal drawing oil cylinder is arranged at a position adjacent to the corresponding bidirectional adjustment devices. According to the T beam mould moving device and the specific use method, the demoulding and mould clamping efficiency of the T beam side mould is improved due to each mould moving trolley and the parts which are arranged on the upper portion of the mould moving trolley and the bottom of the T beam side mould is provided with a pulley block, the surface of a lapping plate is provided with a sliding channel, the pulley block and the sliding channel are corresponding to each other, the friction force in the movement process of the T beam side mould is converted into the rolling friction, and accordingly the service life of the T beam side mould is extended.

Owner:JIANGSU SHENGLE CONSTR ENG CO LTD

A belt conveyor mobile unloading device

A movable discharge device of a belt conveyor is applied to the technical field of power, ports, metallurgy and mines and comprises a driving device, a base, a transmission device, a reversing baffle, a funnel, travel switches, a coupler and a head protection cover. The driving device is connected with the base through a thread. The transmission device penetrates through the funnel and is connected with the base through a thread. A shaft extension at one end of the transmission device is connected with the driving device through the coupler. The funnel is connected with the base through a thread. The reversing baffle is arranged in the funnel and engaged with the transmission device through a chain on the reversing baffle, and the head protection cover is connected with the funnel through a flange. The travel switches are arranged at the two ends of the movable discharge device of the belt conveyor. The discharge device is simple in structure, the failure rate is lowered, the equipment structure is more compact, and vertical space is saved. A PLC control system is utilized for monitoring the discharge condition in real time, intelligent equipment control is truly achieved, and operation is convenient, easy and fast.

Owner:NORTHERN HEAVY IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com