Cement kiln co-processing combustible waste system that can bypass waste heat power generation

A technology of bypass ventilation and waste heat power generation, applied in dehydration/drying/thickened sludge treatment, waste heat treatment, cement production, etc., can solve the problem of limited and insufficient combustible waste, and achieve increased power generation and constant power consumption , the effect of constant output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings, but the present invention is not limited to the following embodiments.

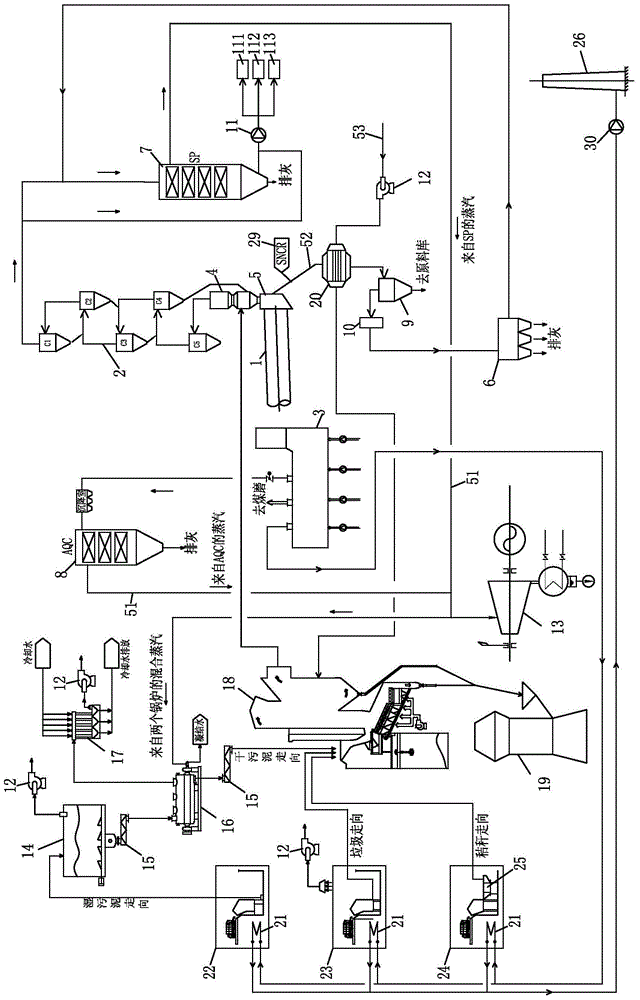

[0032] like figure 1 As shown in the figure, a cement kiln co-processing combustible waste system that can bypass waste heat and generate electricity includes a power generation device 13, a kiln end preheater 2, a kiln head waste heat boiler 8, and a kiln end waste heat boiler 7, which is used to store combustible waste and A collection device for transporting combustible waste to an incinerator, an incinerator 18 for incinerating and treating combustible waste, a raw material vertical mill 19 for treating ash produced by the incinerator, and a bypass vent for extracting exhaust gas from the kiln tail smoke chamber The device and the purification treatment device for feeding the air from the collection device to the incinerator.

[0033] The feed port of the kiln tail smoke chamber 5 in the rotary k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com