A complementary system of cement kiln co-processing combustible waste and bypass ventilation power generation

A bypass ventilation and collaborative processing technology, applied in cement production, combustion types, combustion methods, etc., can solve the problems of limited and insufficient combustible waste, achieve the effect of increasing power generation, maintaining power consumption, and saving initial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

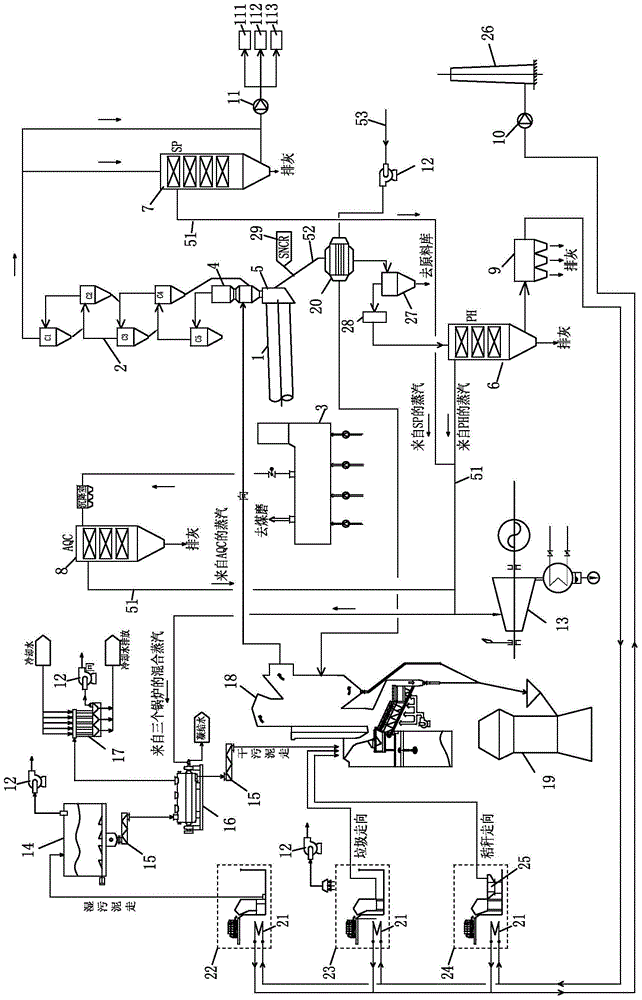

[0031] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

[0032] like figure 1 As shown, a cement kiln cooperative treatment of combustible waste and bypass ventilation power generation complementary system, including power generation device 13, kiln tail preheater 2, kiln head waste heat boiler 8, kiln tail waste heat boiler 7, used to accommodate combustible waste And the collection device for transporting combustible waste to the incinerator, the incinerator 18 for incineration and treatment of combustible waste, the raw material vertical mill 19 for processing the ash generated by the incinerator, and the bypass for leading out the exhaust gas from the kiln tail smoke chamber The air release device and the purification treatment device for feeding the air from the collection device into the incinerator.

[0033] The feed port of the kiln tail smoke chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com