Energy-saving magnetic medium deflocculation and separation integrated machine

A magnetic medium and energy-saving technology, applied in the field of water treatment, can solve the problems of affecting the floc recovery effect of the magnetic separation unit, not being able to be adsorbed cleanly by the magnetic medium, and reducing the recovery rate of the magnetic medium. , reduce the effect of specification design and configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

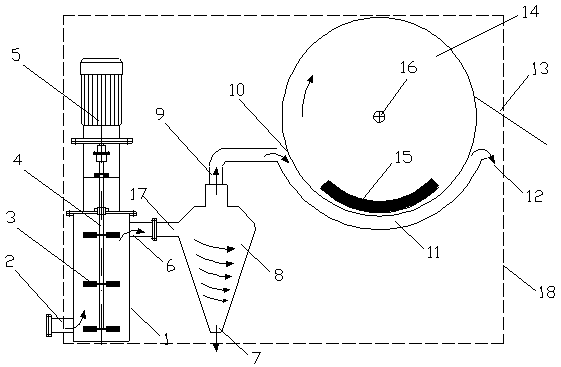

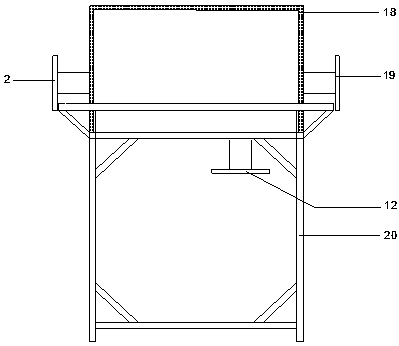

[0028] Such as figure 1 As shown, an energy-saving magnetic medium deflocculation and separation integrated machine, the main body is a deflocculation unit 1, a sand-water separator 8 and a magnetic separation unit 14, the deflocculation unit 2 is placed vertically or horizontally in the axial direction, and the motor of the deflocculation unit 5 drives the rotating shaft 4 of the deflocculating unit, the rotating shaft 4 of the deflocculating unit is fixedly connected with the blade 3, the feed port 2 of the deflocculating unit is set at the bottom of the cylinder, the discharge port 6 of the deflocculating unit is set at the top of the other side, and the sand-water separator enters The feed port 17 is flange-connected with the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com