Device and method for automatically adjusting distance between cab and container for coating line

An automatic adjustment and cab technology, applied in the field of painting lines, can solve the problems of increasing the space occupied by the painting production line, increasing the production pitch, cost waste, etc., so as to save the initial cost investment and later energy consumption, and reduce the cost. Occupies space and reduces the effect of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

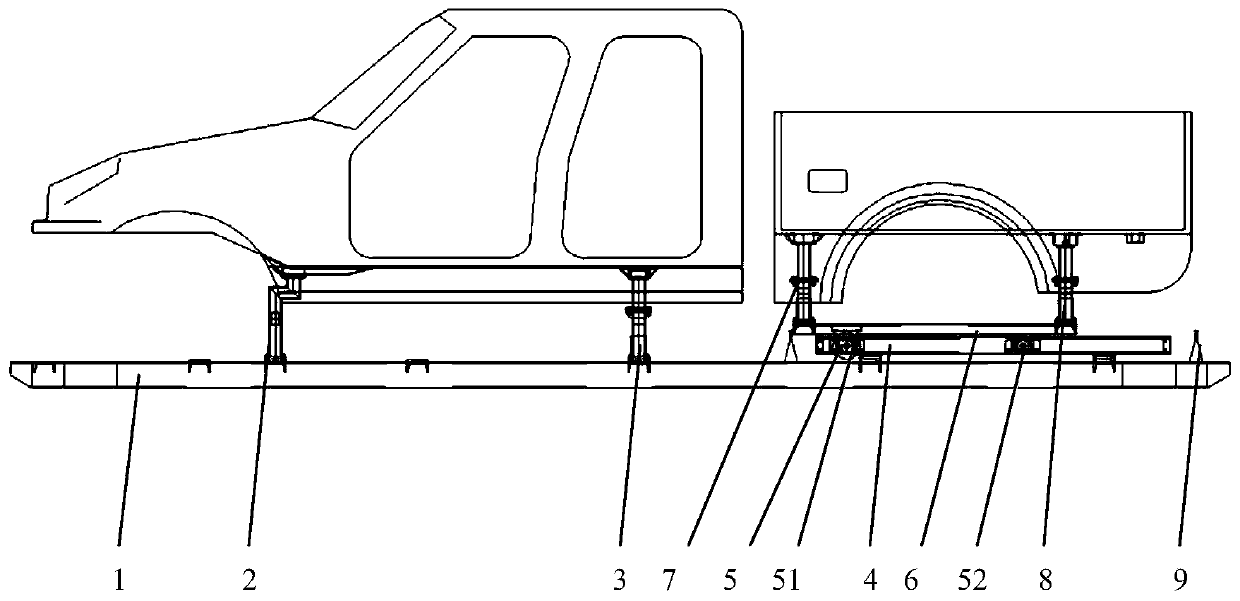

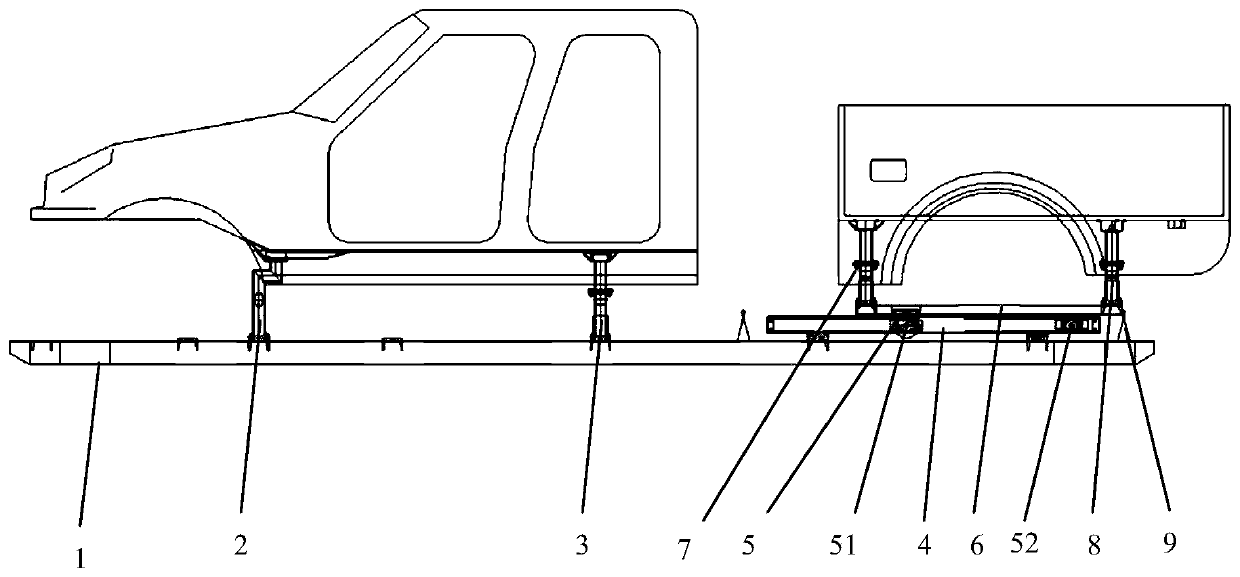

[0043] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 5 As shown, the skid 1 is provided with two position sensors 9 , and the two position sensors 9 are respectively located at two ends of the track device 4 . The position of the movable frame 6 is monitored by two position sensors 9 .

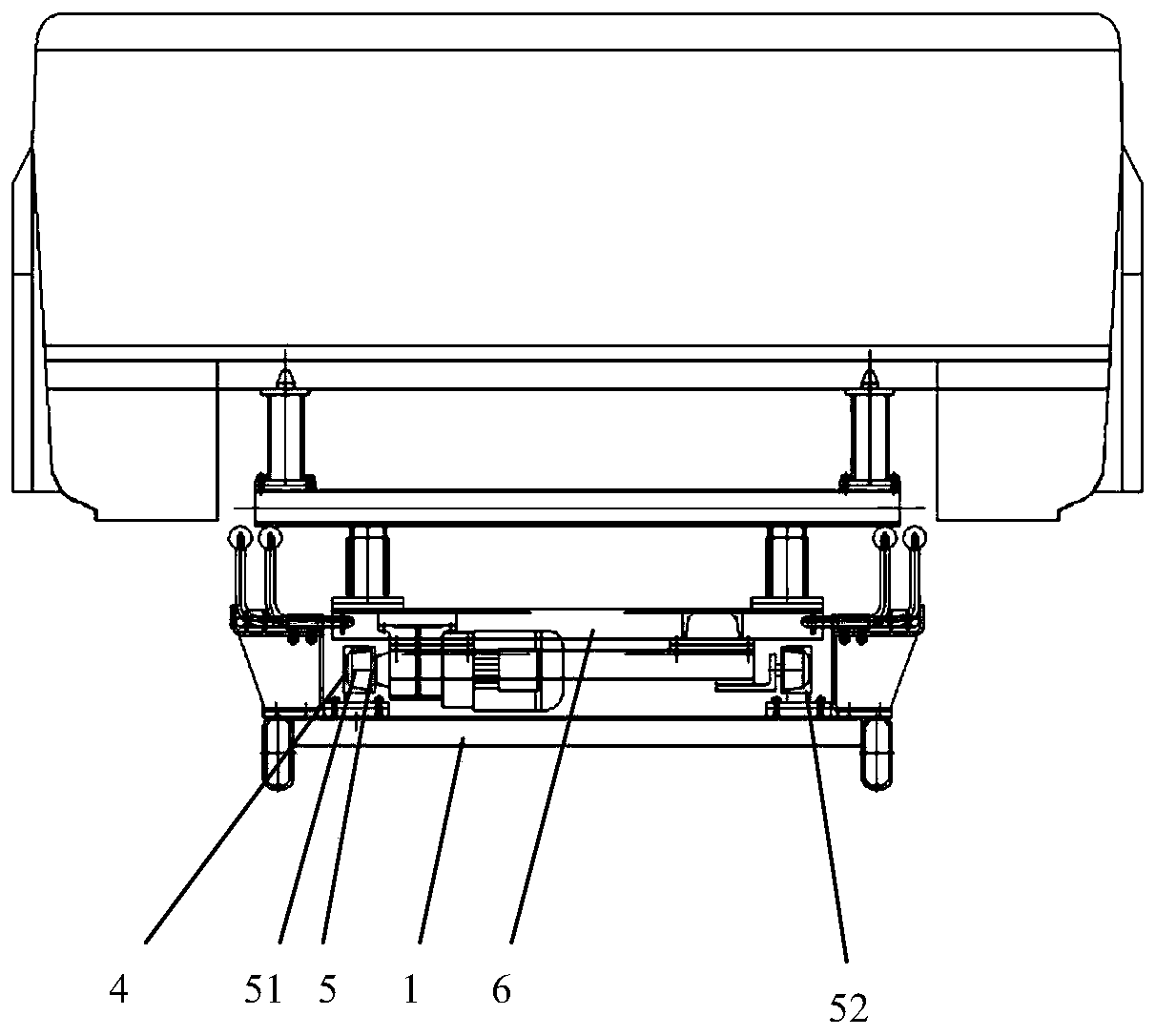

[0044] In a further embodiment of the present invention, the reduction motor 512 and the driving wheel 511 are fixed by flat keys and screws.

[0045] In a further embodiment of the present invention, the driven traveling wheel 521 and the driven wheel shaft 522 are limited by a round nut 524 .

[0046] In a further embodiment of the present invention, a deep groove ball bearing 525 and a shaft sleeve 526 are further provided between the driven road wheel 521 and the driven wheel shaft 522 .

[0047] The working method of the present invention is illustrated below:

[0048]Step S1: Load the car body onto the skid 1, the skid 1 enters the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com