Patents

Literature

34results about How to "Easy brushing operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast-drying solvent type epoxy resin intermediate paint

InactiveCN101386766AGood drying performanceSimple painting operationEpoxy resin coatingsSolventChemistry

The invention relates to fast-dry solvent type intermediate epoxy resin paint, which comprises a main agent and a curing agent, wherein the ratio of the main agent to the curing agent is between 20 to 1 and 5 (weight). Compared with the prior art, the intermediate epoxy resin paint has good drying property as well as simple and convenient coating operation, adapts to flow coating of the prior containers, can be thickly coated to the specified film thickness at one time, has good anticorrosion property, and has good binding force with a last-pass primer and a next-pass primer; and for thicker outer finish, particularly polyurethane finish, the intermediate epoxy resin paint has good usability, can not froth, and has good anticorrosion property.

Owner:中涂化工(上海)有限公司

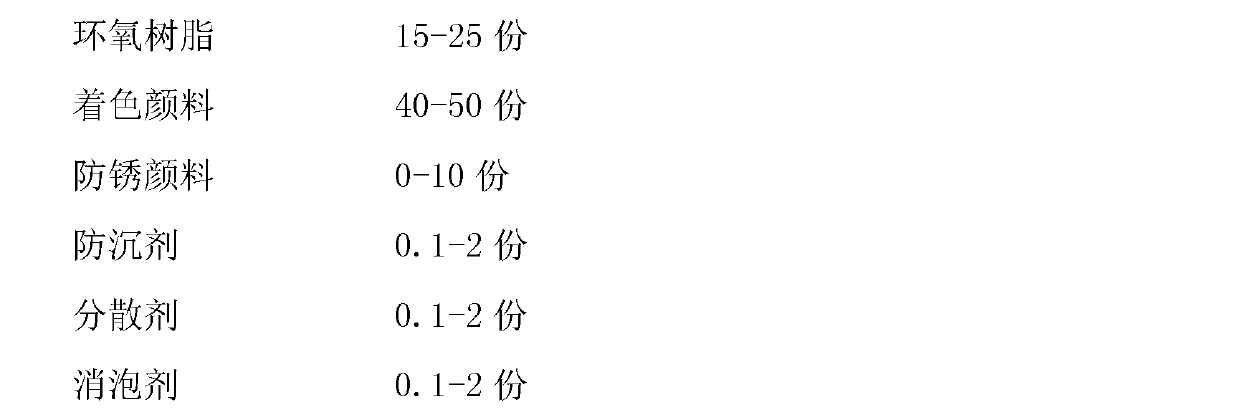

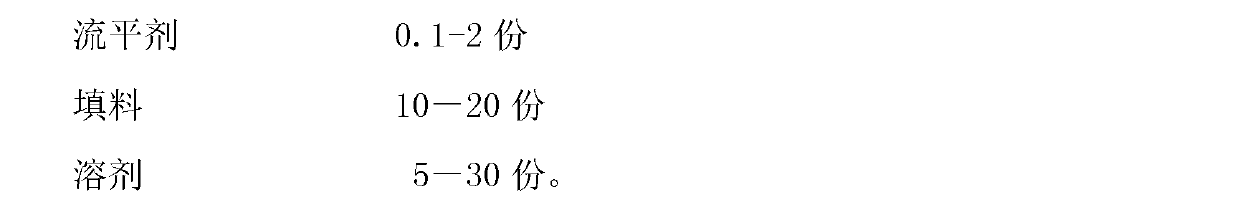

Quick-drying epoxy zinc rich shop primer

InactiveCN103342945AGood drying performanceSimple painting operationAnti-corrosive paintsEpoxy resin coatingsChemistryPolyamide

The invention provides a quick-drying epoxy zinc rich shop primer, which is composed of a main paint vehicle and a curing agent, wherein the weight ratio of the main paint vehicle to the curing agent is 15: (1-5); the curing agent is polyamide; and the main paint vehicle is composed of an epoxy resin, a tinting pigment, an anti-rust pigment, an anti-settling agent and the like. The epoxy zinc rich shop primer provided by the invention is formed by reacting the main paint vehicle with the polyamide curing agent and curing the reaction product into a film; and the epoxy zinc rich shop primer can be applied to the surfaces of steel structures in medium to heavy corrosive environments and water-based acrylic acid, water-based epoxy, water-based polyurethane and appropriate solvent paint can be applied to the surfaces. Besides, the quick-drying epoxy zinc rich shop primer is good in drying performance, simple and convenient in coating operating, and adapted to stream line coating of the existing steel structure materials; and the quick-drying epoxy zinc rich shop primer can be coated to a specified film thickness once and has excellent corrosion resistance.

Owner:TIANCHANG JULONG TRAVEL PAINT

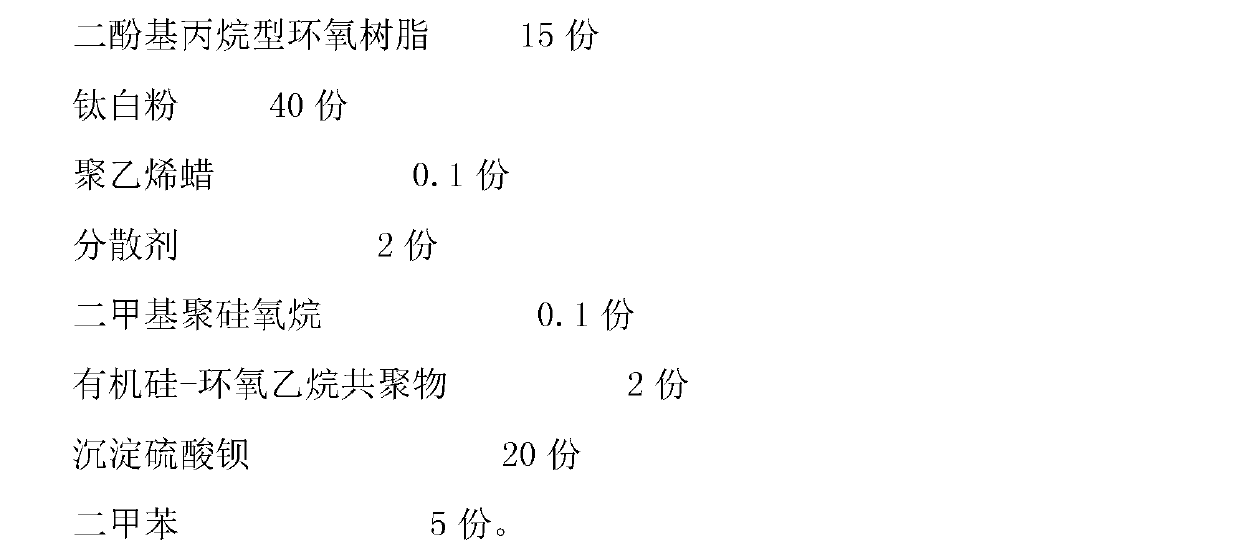

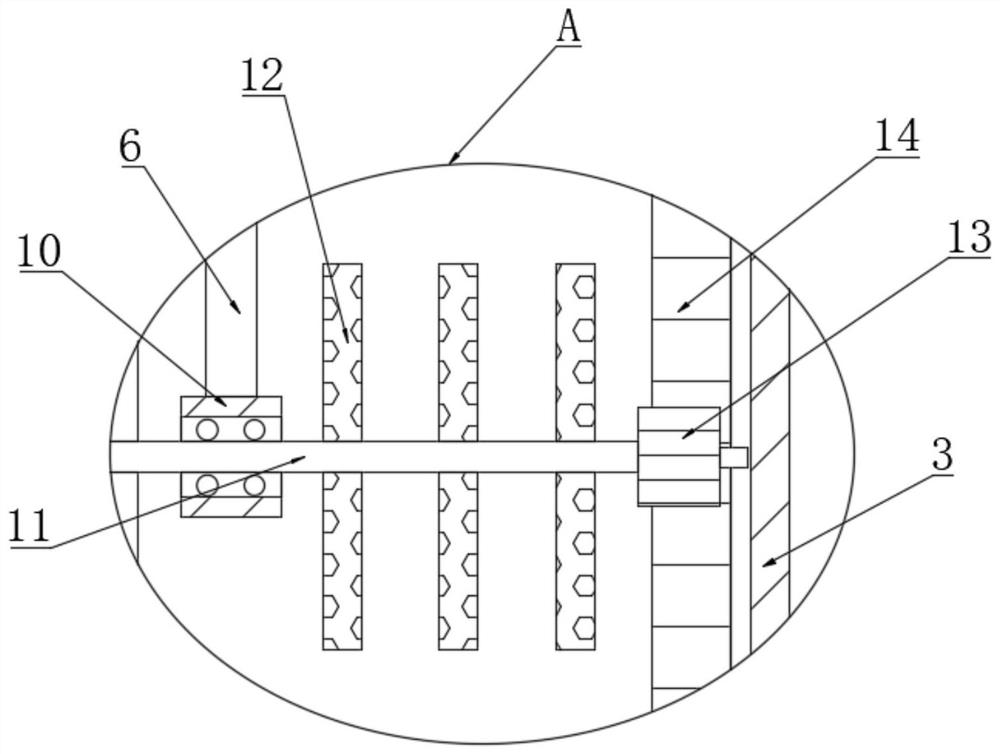

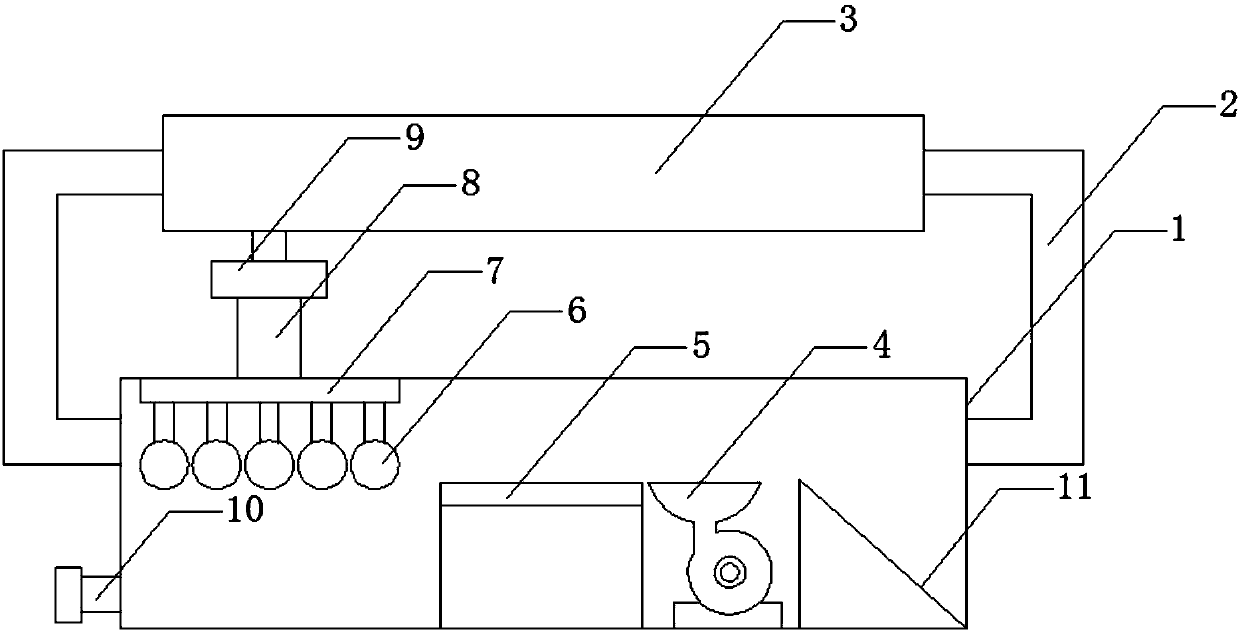

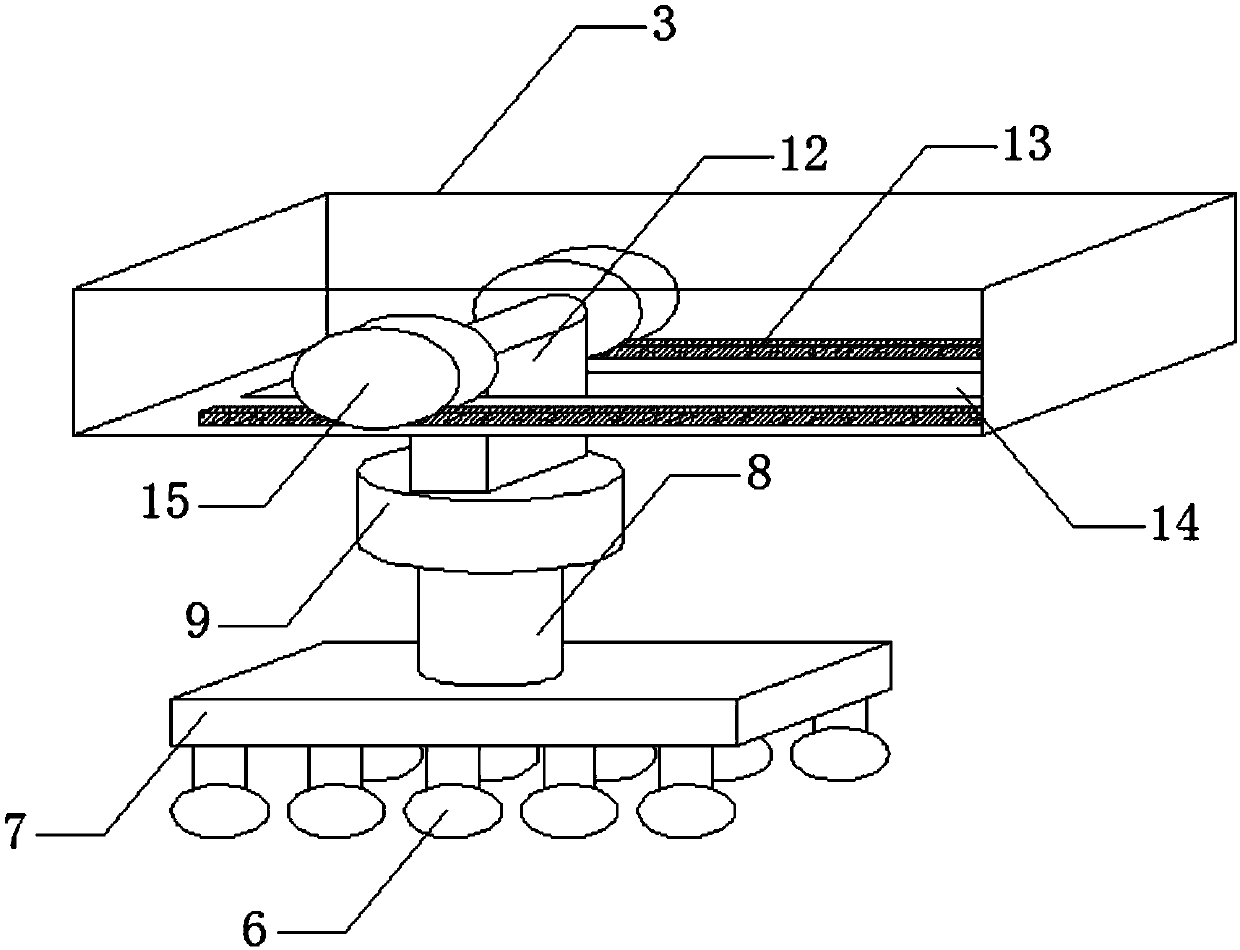

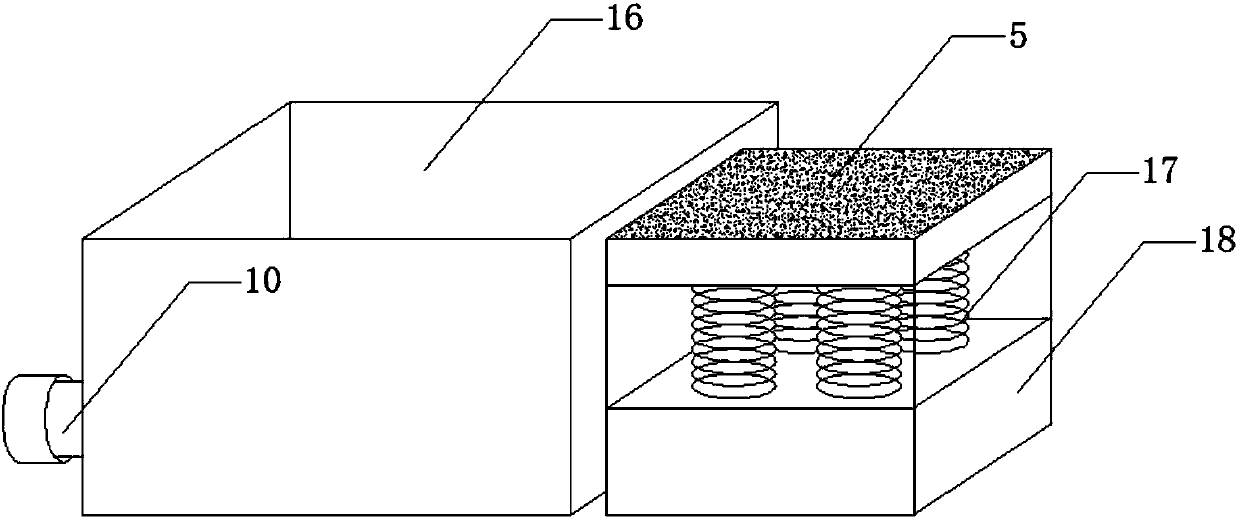

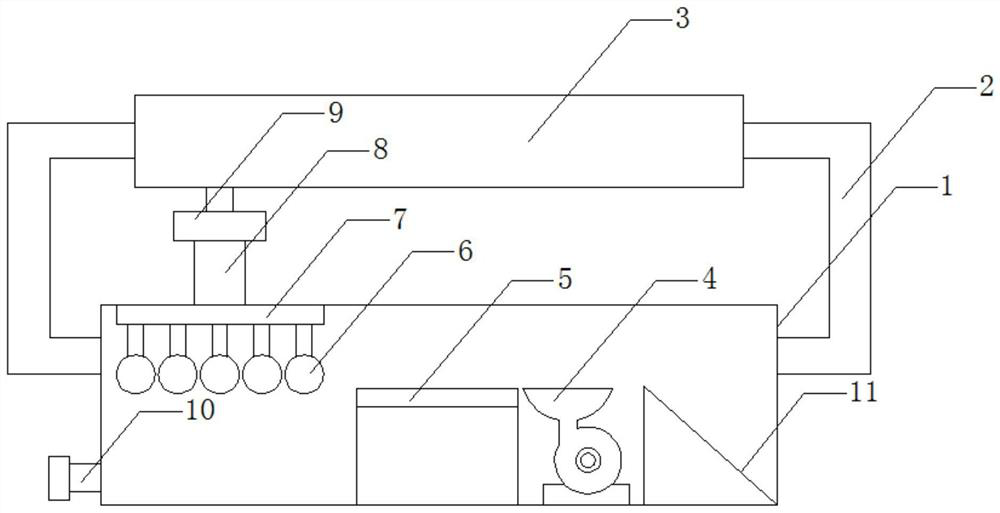

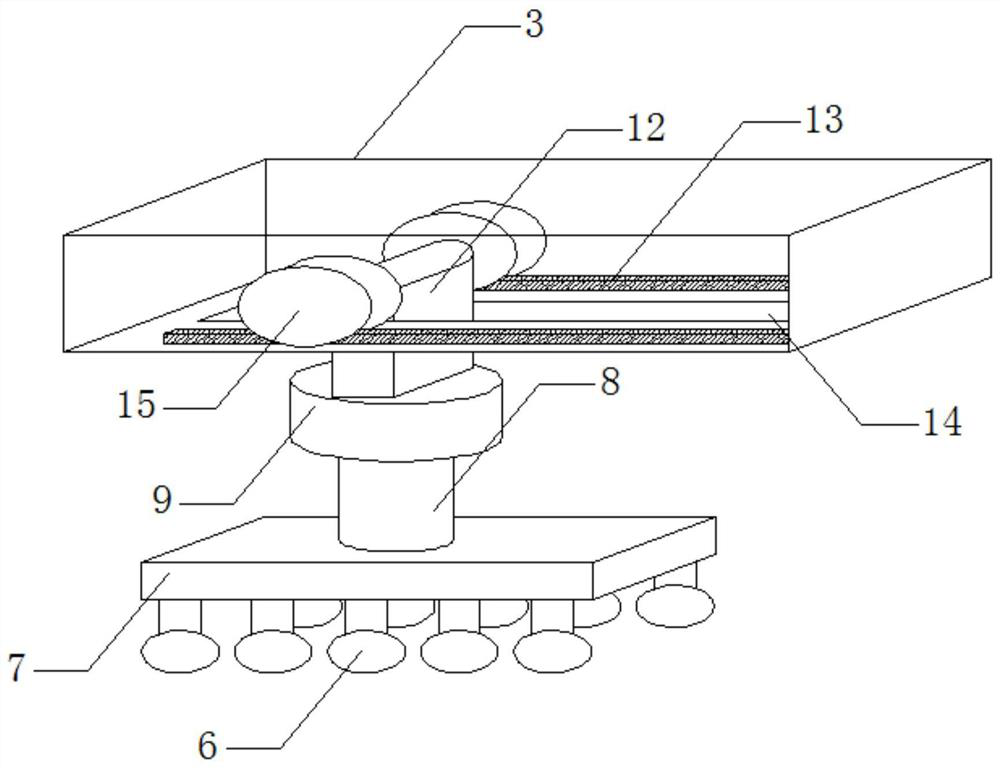

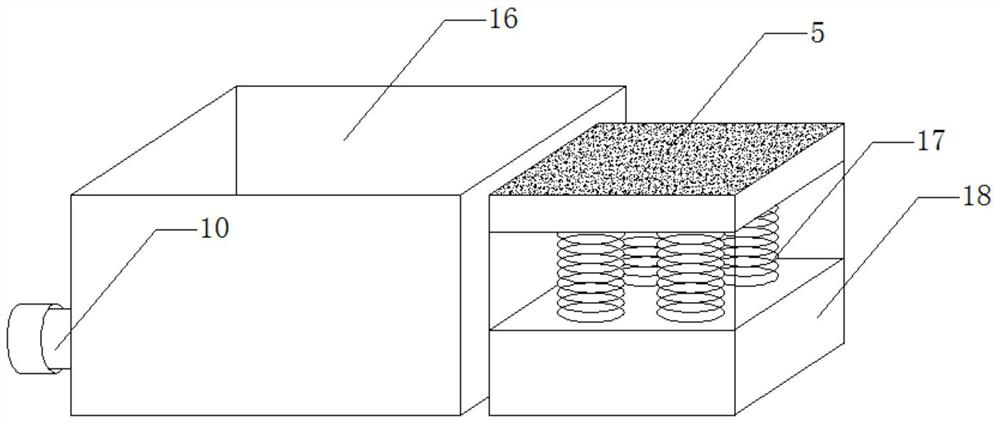

Wall painting device for constructional engineering

InactiveCN112709406AAvoid cakingAvoid damageRotary stirring mixersTransportation and packagingElectric machineAir blower

The invention discloses a wall painting device for constructional engineering, and belongs to the technical field of constructional engineering. The problem that an existing wall painting device is low in painting efficiency is solved. The wall painting device is characterized by comprising a base, wherein painting paint is stored in a painting paint storage box, during painting; the wall painting device moves through universal wheels; a first motor is started to drive a first connecting rod and a second connecting rod to extend and contract; stirring blades on a first rotating shaft rotate; caking of the painting paint is avoided; a piston plate conveys the painting paint in a conveying box to a spray head to be sprayed out for painting; a second motor is started to drive a second supporting frame to drive a painting roller to ascend and descend; a third motor is started to drive a semicircular gear to drive the painting roller to carry out left-right painting operation; a second spring carries out buffering to protect a wall and the painting roller; after painting, an air blower is started to generate hot air for drying treatment, the painting paint falling in the painting process can fall into a material receiving hopper to be collected and recycled; and the wall painting device has the advantage of being high in painting efficiency.

Owner:王涛

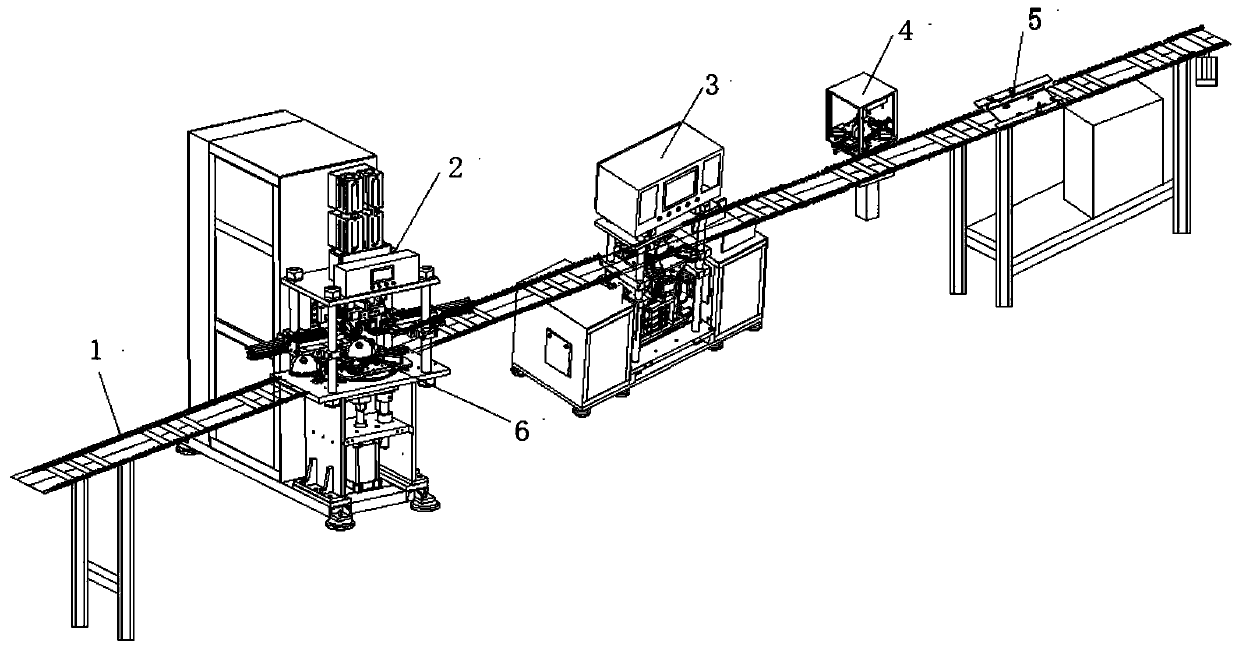

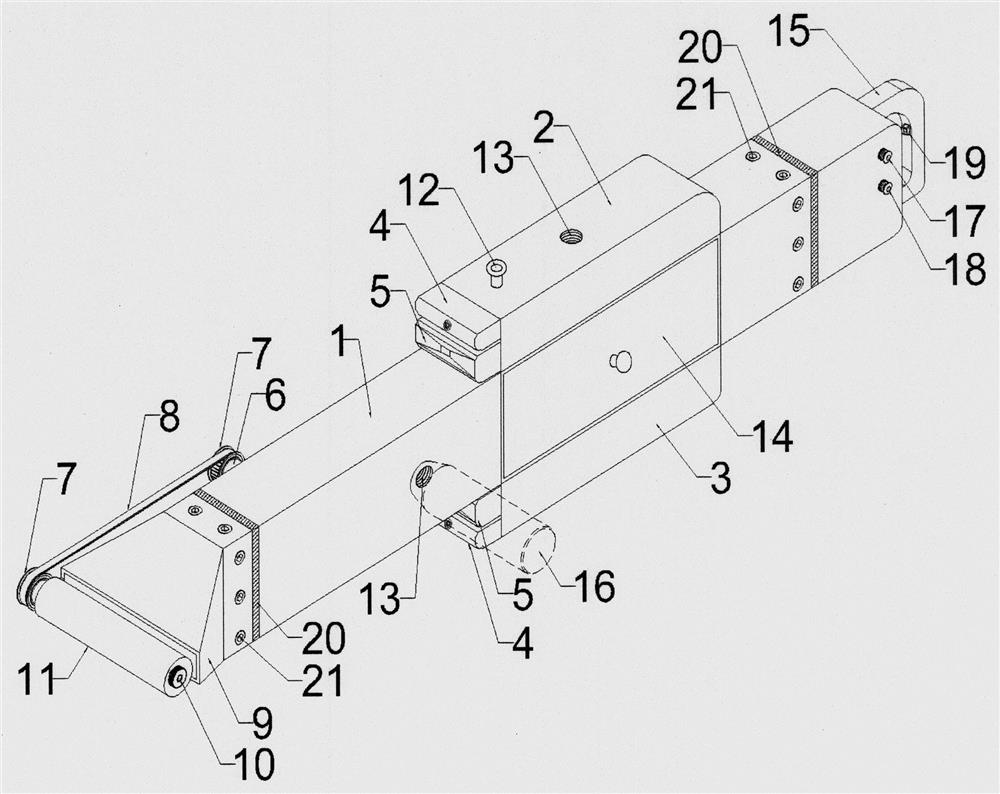

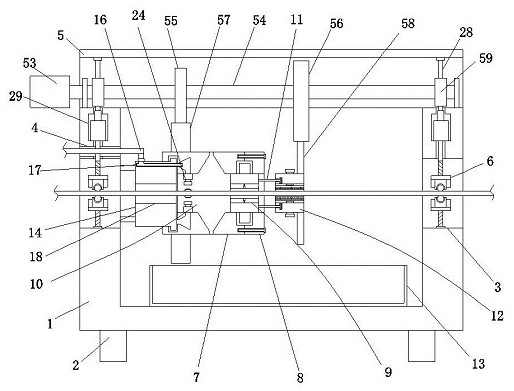

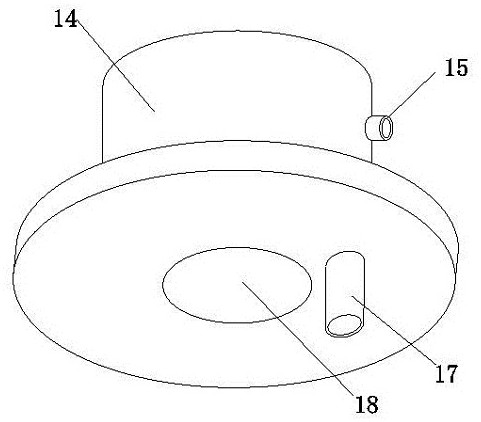

Full-automatic shell welding production line

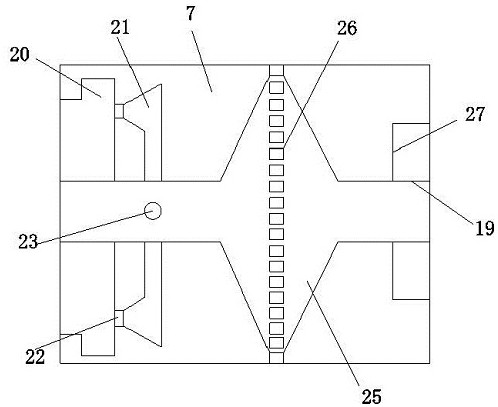

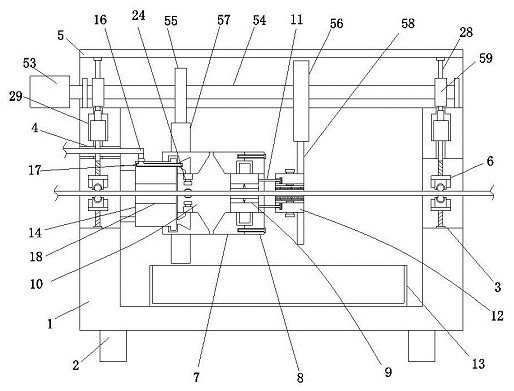

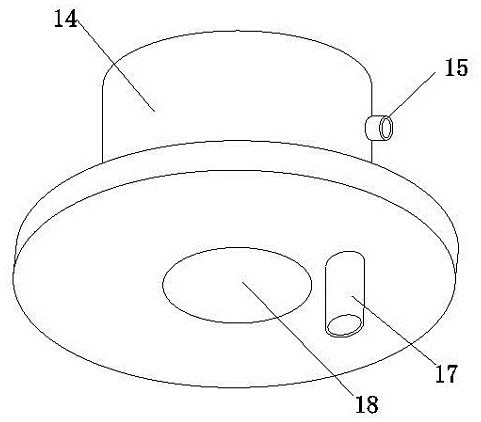

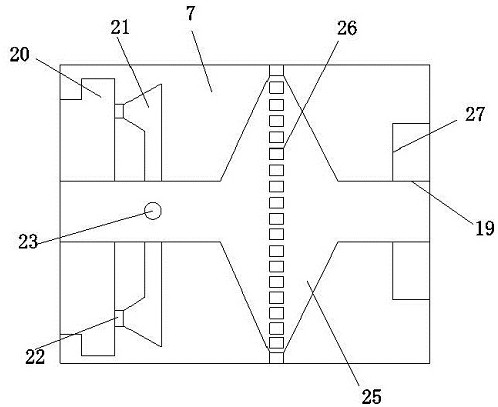

PendingCN111283344ADoes not hinder deliveryEasy brushing operationEdge grinding machinesWelding/cutting auxillary devicesProduction lineElectric machinery

The invention relates to the technical field of shell welding production, in particular to a full automatic shell welding production line comprises foot plate welding equipment, protruding nail welding equipment and position detecting equipment, wherein the foot plate welding equipment, the protruding nail welding equipment and the position detecting equipment are sequentially connected from leftto right of a conveying line body. A burnishing mechanism is arranged in the position detecting equipment. The burnishing mechanism comprises burnishing bottom plates, a burnishing side plate and burnishing motors. The burnishing motors of two stations are fixedly installed on the upper end faces of the two burnishing bottom plates correspondingly through fasteners. Two sliding grooves are formedin the upper surfaces of the burnishing bottom plates. Sliding blocks are installed in the two sliding grooves in a sliding manner. Clamping blocks are installed at the top ends of the sliding blocks.Anti-skid pads are installed on the outer walls of the clamping blocks. Clamping drive mechanisms are arranged at the bottom ends of the sliding blocks. According to the production line, in the burnishing process, a compressor shell is clamped conveniently, the compressor shell does not shake or deviate, oxide skin, rusting mark and burrs generated after machining on the surface of the compressorshell are cleared off beneficially, and the unglazed forge face appearance is obtained.

Owner:浙江加西贝拉科技服务股份有限公司

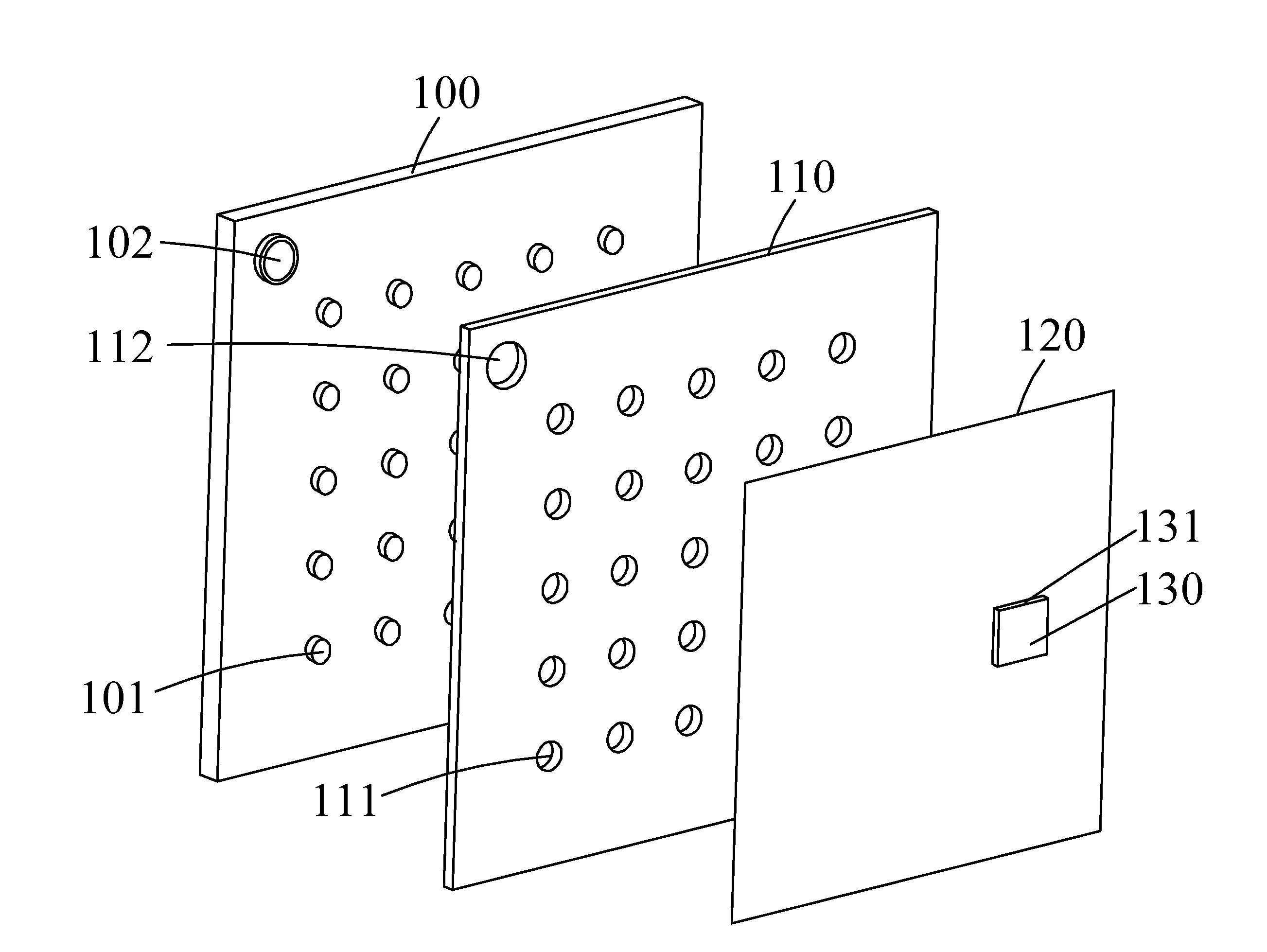

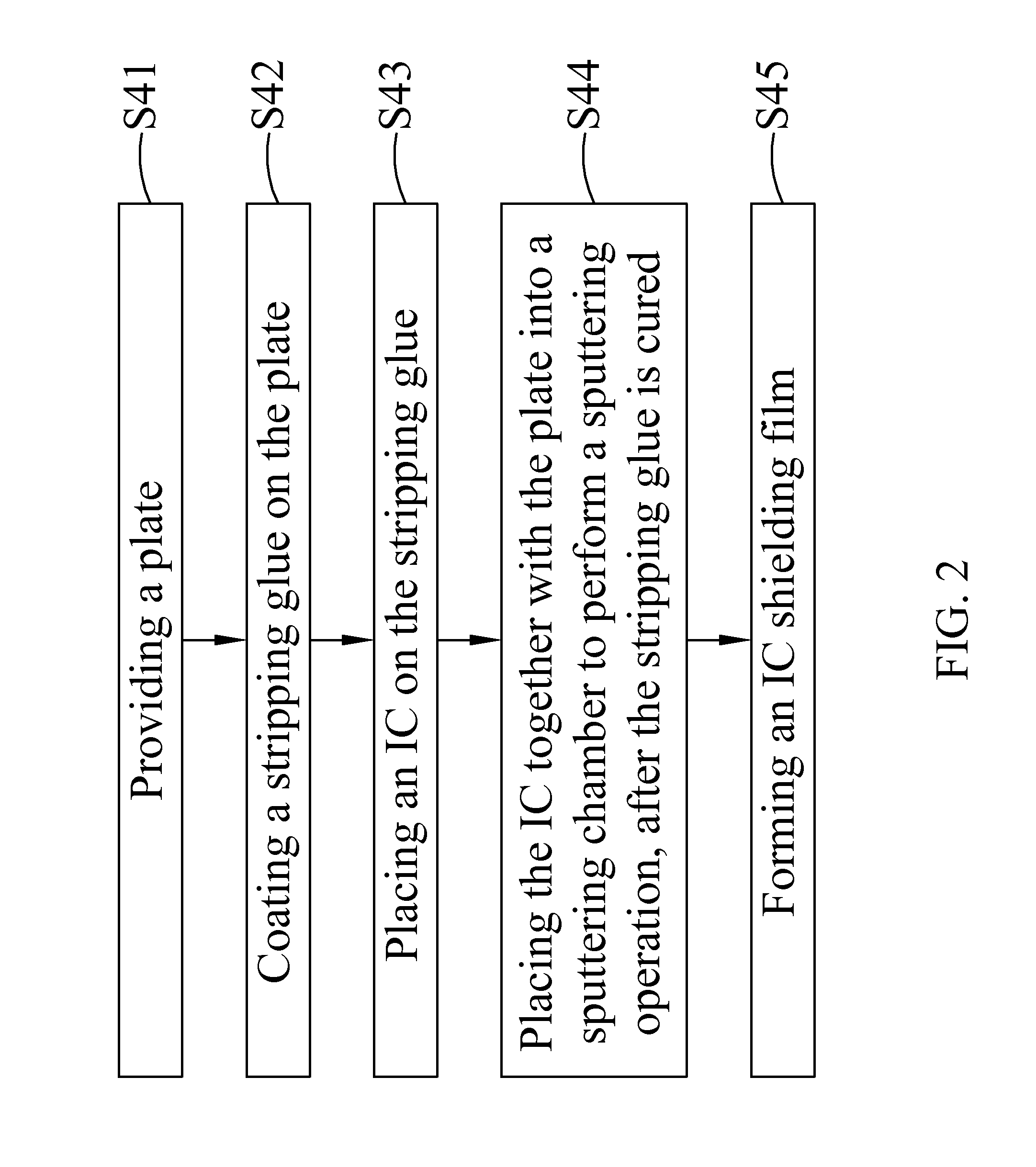

Integrated Circuit Shielding Film and Manufacturing Method Thereof

InactiveUS20130193566A1Improve the bonding force between layersEasy brushing operationSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitIntegrated circuit design

An integrated circuit shielding film and a manufacturing method thereof. The manufacturing method provides a plate. A stripping glue is coated on the plate. An integrated circuit is disposed on the stripping glue and the stripping glue is deposited on the surface of the integrated circuit. A shielding film is then formed on the integrated circuit by coating operations.

Owner:CHENMING MOLD IND CORP

Ageing technology for woodwork

The invention discloses an ageing technology for woodwork. The technology comprises steps as follows: (1) treatment with river mud; (2) drying treatment; (3) primary polishing; (4) bleaching treatment; (5) secondary drying; (6) secondary polishing; (7) brushing of primer; (8) waxing; (9) brushing of white paint; (10) ternary polishing; (11) brushing of glaze. The woodwork prepared with the technology is good in overall ageing effect, high in laying feeling, high in quality and realistic in effect, paint layers are uniform and do not fall off easily, and the use value of the woodwork is well increased.

Owner:阜南县永盛工艺品有限公司

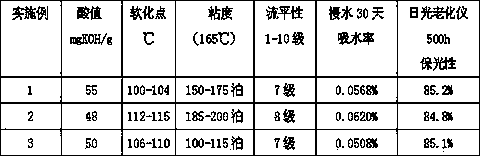

Anti-sunshine waterproof polyester resin and production process thereof

The invention discloses anti-sunshine waterproof polyester resin and a production process thereof. The process comprises the following steps that pure terephthalic acid and neopentyl glycol are subjected to esterification, condensation polymerization, vacuumizing and dehydration, end sealing, filtering, cooling, grinding and packaging and storing to obtain the anti-sunshine waterproof polyester resin; the characteristic parameters of the polyester resin are as follows: the acid value is 48-55mg KOH / g, the softening point is 100-115 DEG C, the viscosity is 100-200P (165 DEG C), the curing condition is 200 DEG C per 10 minutes, and the mass ratio of polyester resin to epoxy resin in the finished product is 90:10. The polyester resin disclosed by the invention is suitable for outdoor furniture or outdoor walls; the anti-ultraviolet property is improved by adding isophthalic acid; since the product is exposed outdoors for long time, the usage amount of the isophthalic acid is relatively large; meanwhile, by adding 2,2,4-trimethyl-1,3-pentanediol as an auxiliary additive of the isophthalic acid, the waterproof anti-stain performance is improved, the leveling property of the product is reduced at the same time, and the viscosity of the product is relatively low; the forming effect of the coating is good, the paint film is full, and the brushing operation of the finished product of the coating is convenient; meanwhile, the waste generated in the whole production process is convenient to treat.

Owner:滁州市全丰物资有限公司

Automobile glass surface waterproof agent and preparation technology and coating technology thereof

InactiveCN106221671AHigh transparencyImprove driving safetyOther chemical processesLong lastingChemistry

The invention discloses an automobile glass surface waterproof agent, which comprises silane, an acid catalyst and an organic solvent. The silane includes long chain silane and short chain silane in the weight ratio of 1:3-3:1; and the weight ratio of silane, organic solvent and acid catalyst is 1-40:100:0.5-10. The invention also discloses a preparation technology and a coating technology of the automobile glass surface waterproof agent. The waterproof agent uses the mixture of long chain silane and short chain silane; uneven level between the long and short chain molecules results in increase in the hydrophobicity. The waterproof agent of the invention forms hydrophobic effect in the automotive glass surface, can improve the transparency of automotive glass under rainy conditions, improve traffic safety. The waterproof agent of the invention has the advantages of simple coating process, long-lasting hydrophobic effect time, and no use of a fluoride repellent material.

Owner:杨得全

Painting device for processing paperboard strips

ActiveCN107931004AUniform treatmentEasy brushing operationLiquid surface applicatorsCoatingsPaperboardEngineering

The invention discloses a painting device for processing paperboard strips. The painting device comprises a processing groove, connecting columns, a sliding device, a drying machine, an adsorption pad, lantern rings, a painting plate, a hydraulic rod, a hydraulic base, an outlet pipe, a storage groove, a sliding block, sliding rails, a sliding groove, pulleys, a paint groove, springs and a foundation base. The painting device has the beneficial effects that the hydraulic rod and the hydraulic base are arranged above the paint coating plate so that the painting plate can freely extend up and down according to different painting steps; the multiple lantern rings are arranged below the painting plate, and the diameters of the lantern rings are matched with the diameters of the paperboard strips so that a user can fix and clamp the paperboard strips on the lantern rings according to the painting requirement; the springs and the adsorption pad are arranged above the foundation base so thatpaint on the paperboard strips can be more uniformly applied through the treatment of the adsorption pad; and the storage tank of a triangular structure is arranged on one side of the drying machine so that the processed paperboard strips can be further aired in the storage tank.

Owner:佛山市万良商贸有限公司

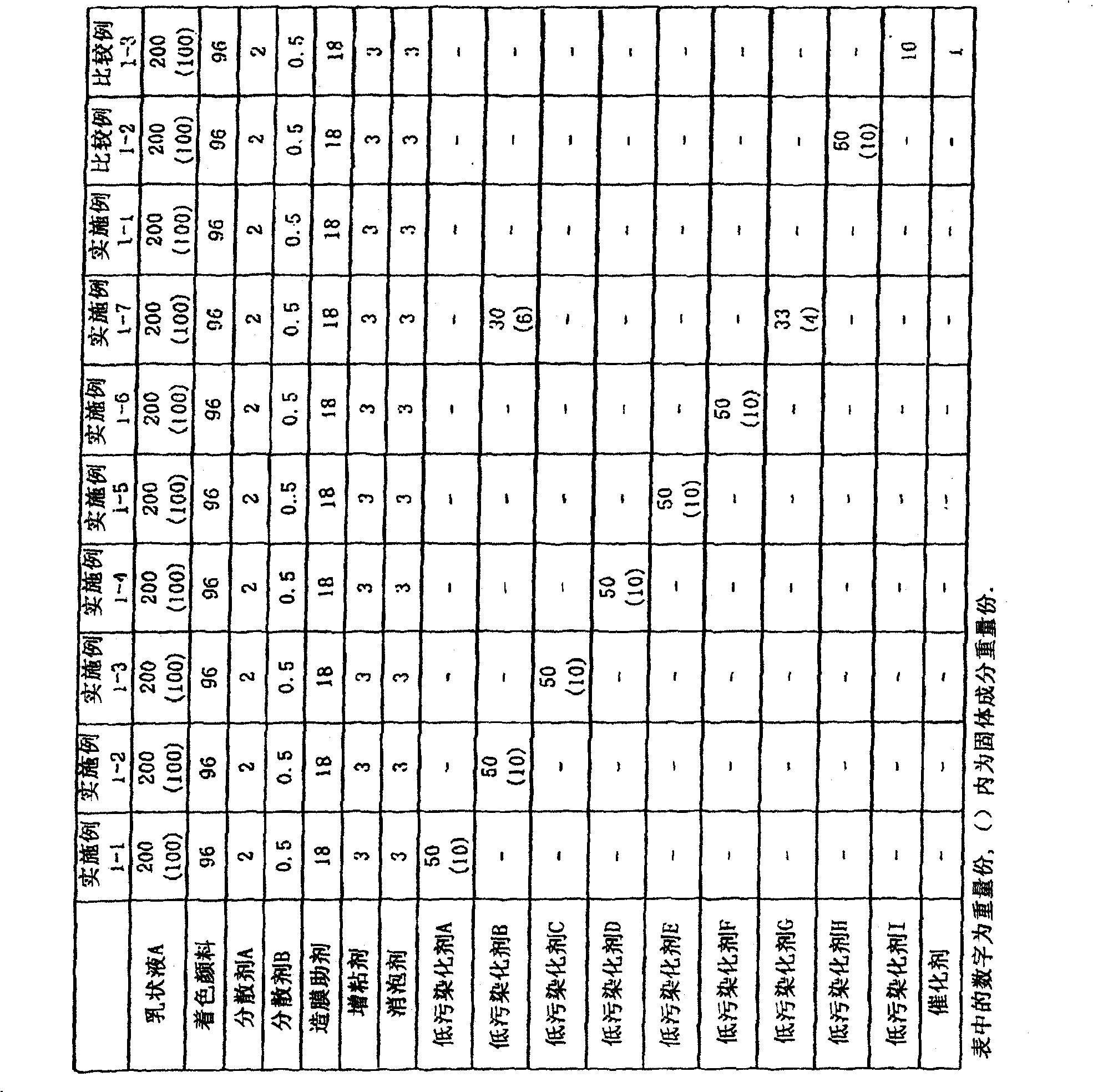

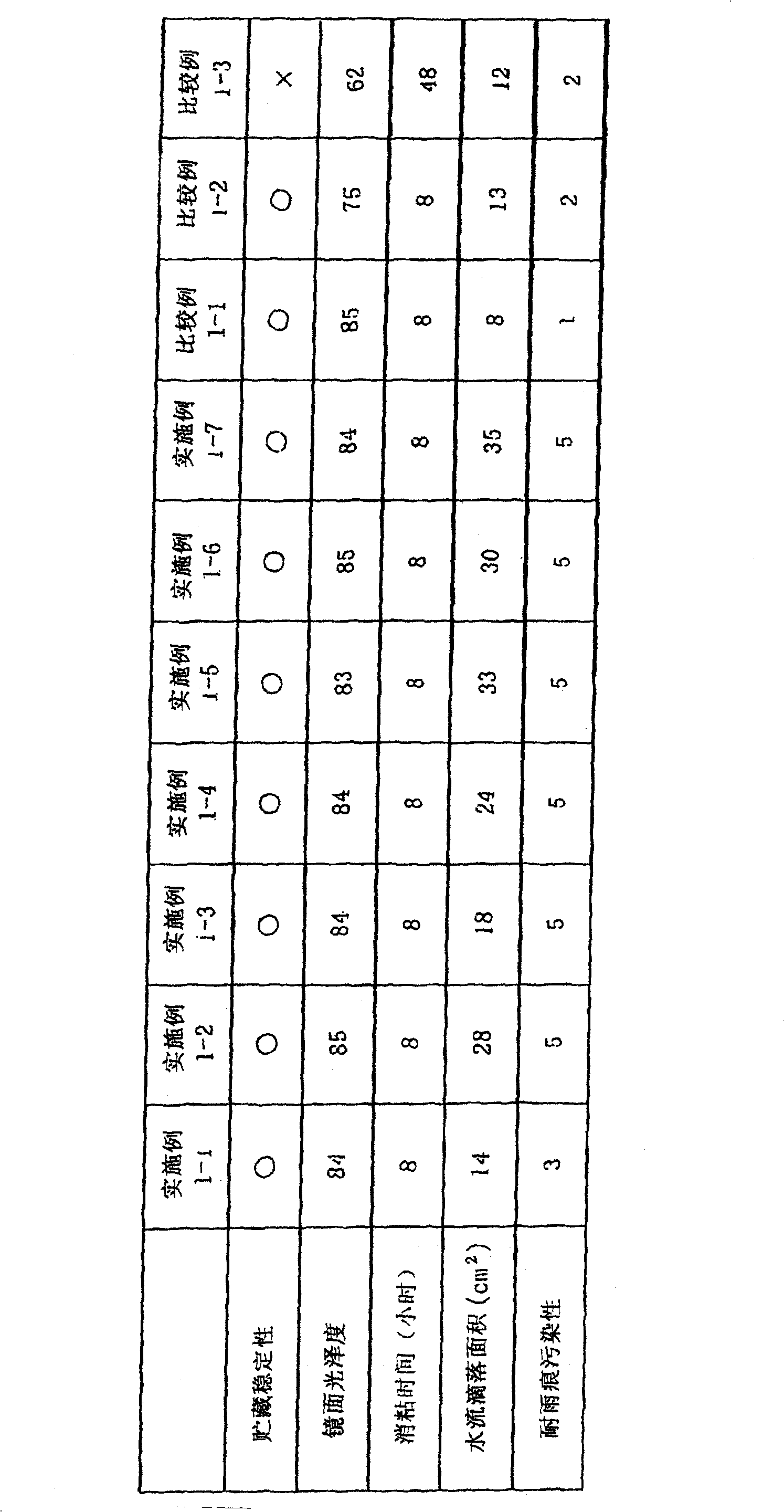

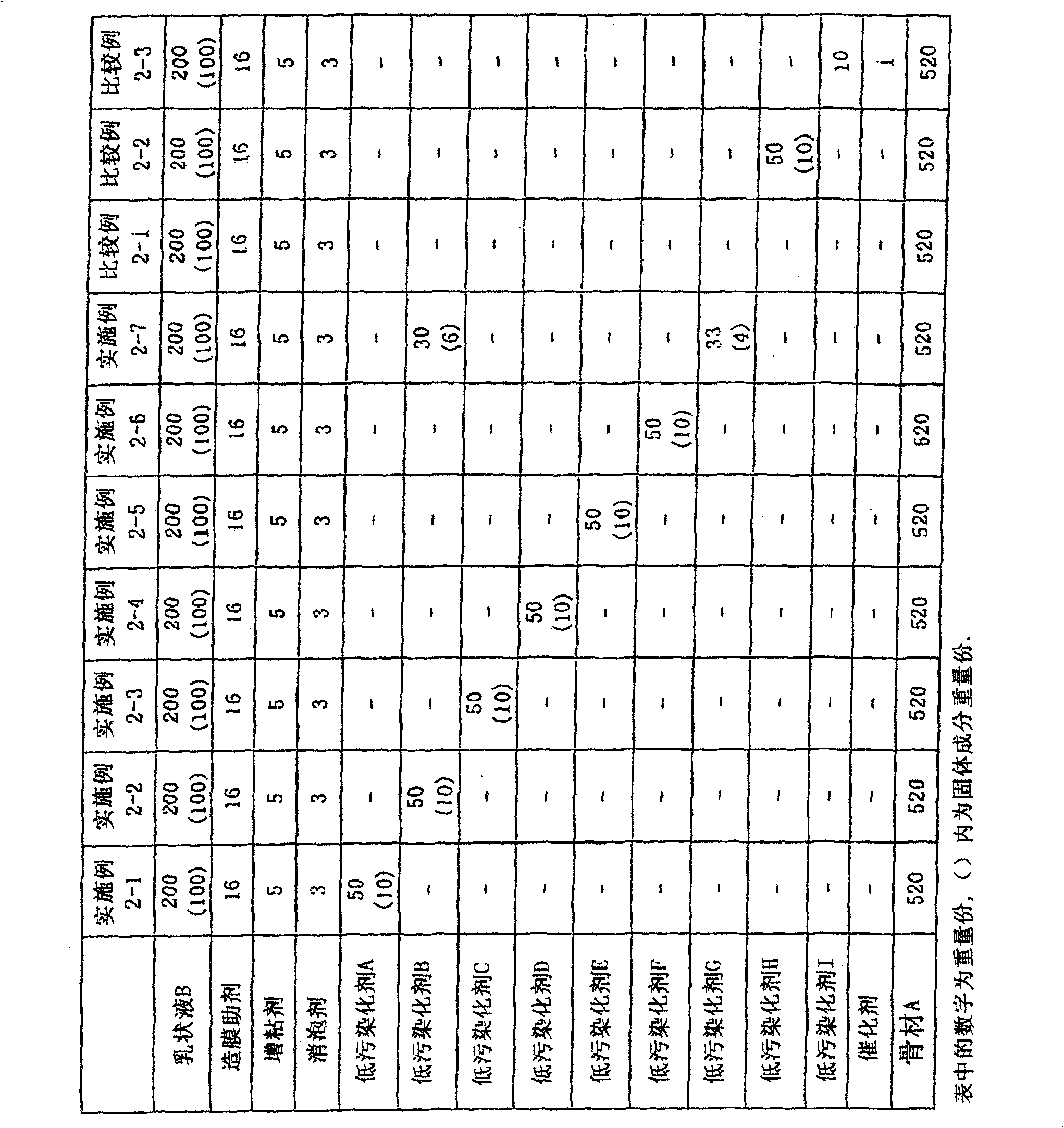

Aqueous coating composition

Disclosed is an aqueous coating composition which enables to simplify storage of an anti-staining agent. The aqueous coating composition is excellent in coating stability when the anti-staining agent is mixed with an emulsion resin coating material, and also excellent in anti-contamination properties. Specifically, the aqueous coating composition essentially contains a synthetic resin emulsion (A) having a pH of not less than 4.0 and not more than 10.0 and a neutral silica sol (B) having a particle diameter of 1-200 nm and a pH of not less than 5.0 and less than 8.5. The aqueous coating composition contains 0.1-50 parts by weight of the neutral silica sol (B) component per 100 parts by weight of the solid content of the synthetic resin emulsion (A) in terms of solid content.

Owner:SK KAKEN CO LTD

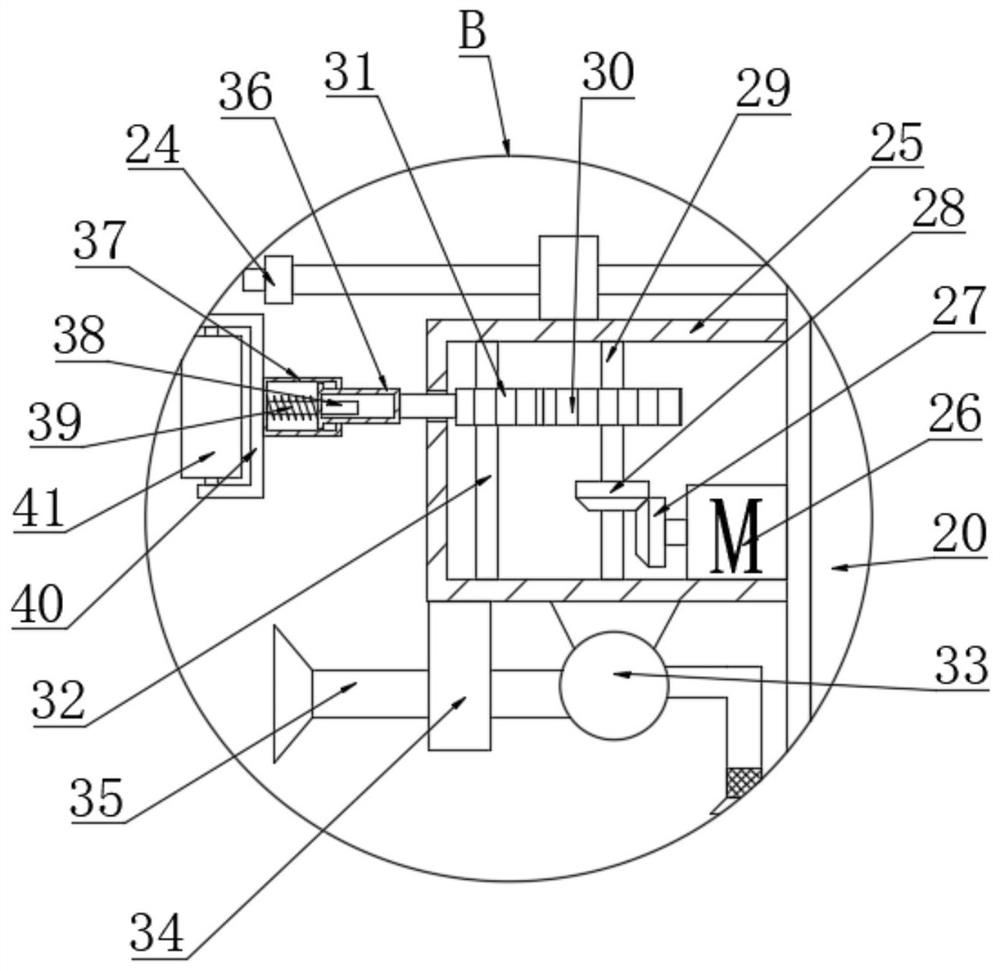

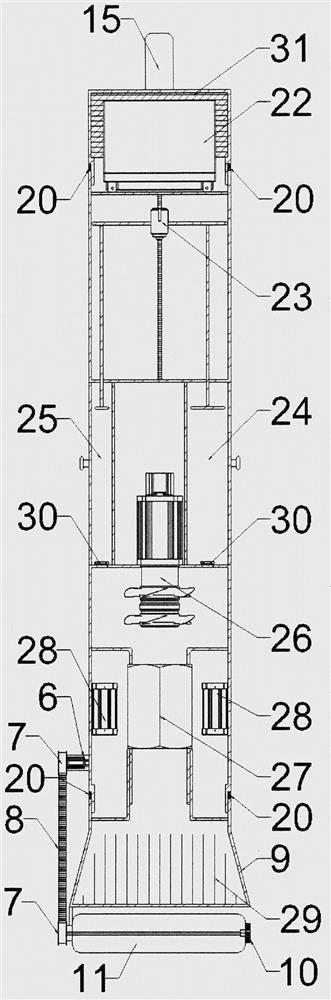

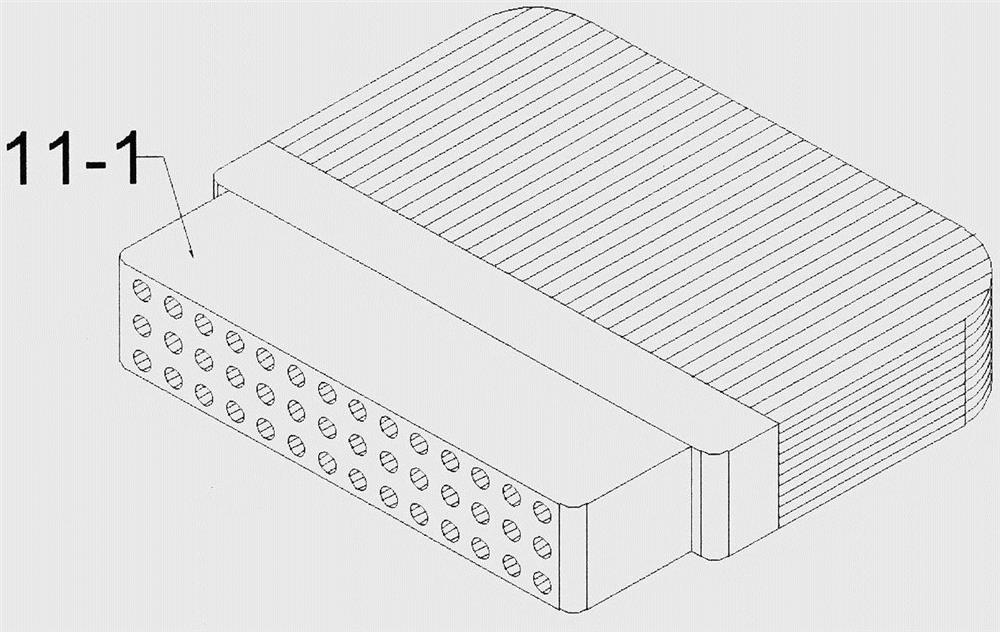

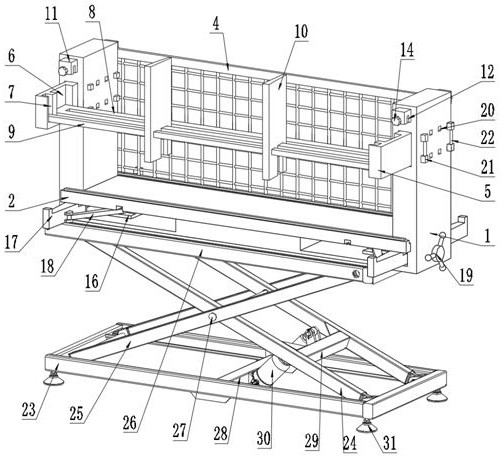

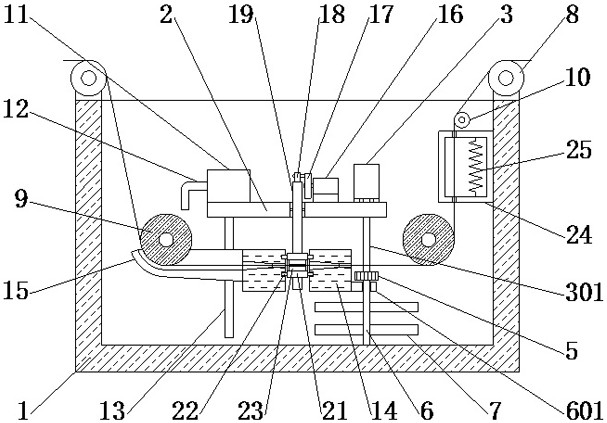

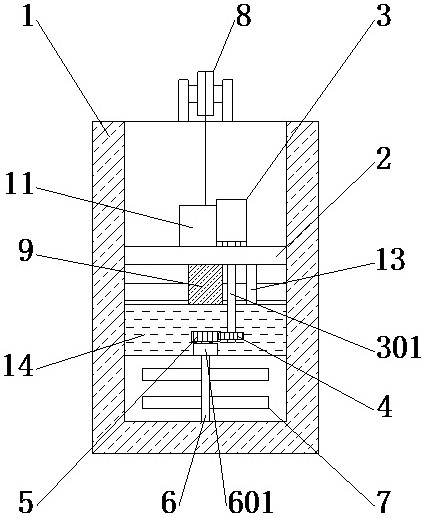

Underwater painting device

PendingCN111774261AReduce volumeEasy to operateLiquid surface applicatorsCoatingsMicroorganismUnderwater

The invention relates to the technical field of coating and painting, in particular to an underwater painting device. The underwater painting device comprises an external mechanism and an internal mechanism; the device is small in size, convenient to operate and capable of conducting painting underwater, and is provided with a material A stock bin and a material B stock bin independent from the material A stock bin, and a material A and a material B are proportionally supplied and mixed easily and practically; a material pushing mechanism adopts a motor to push the materials for feeding, and the feeding speed can be controlled manually and automatically; a roller brush driver is driven by the motor, a cog belt is connected with a roller brush driving gear to transmit a roller brush, a vibration device is arranged, operation is effortless, painting adhesion is improved, and according to different environments, a roller brush fixing device and a hairbrush special for roller brush replacement can be disassembled for usage. According to the underwater painting device, the problems that ocean equipment and ships are subjected to corrosion and microorganism parasitism because of being soaked into seawater, usage of the underwater equipment and the route speed of structure strength of ships are influenced, the underwater equipment and the ships need painting treatment and cannot leavethe water surface, and the cost for painting by leaving the water surface is too high are solved.

Owner:刘家超

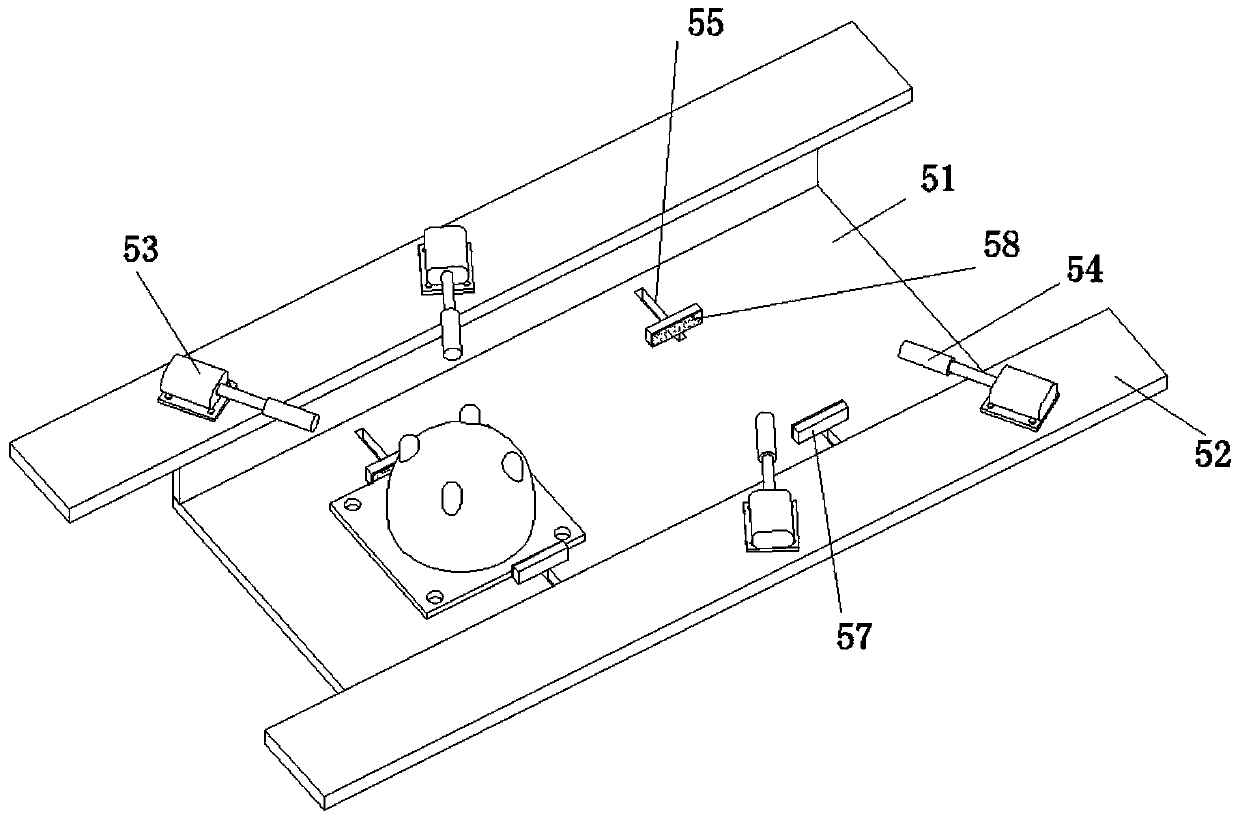

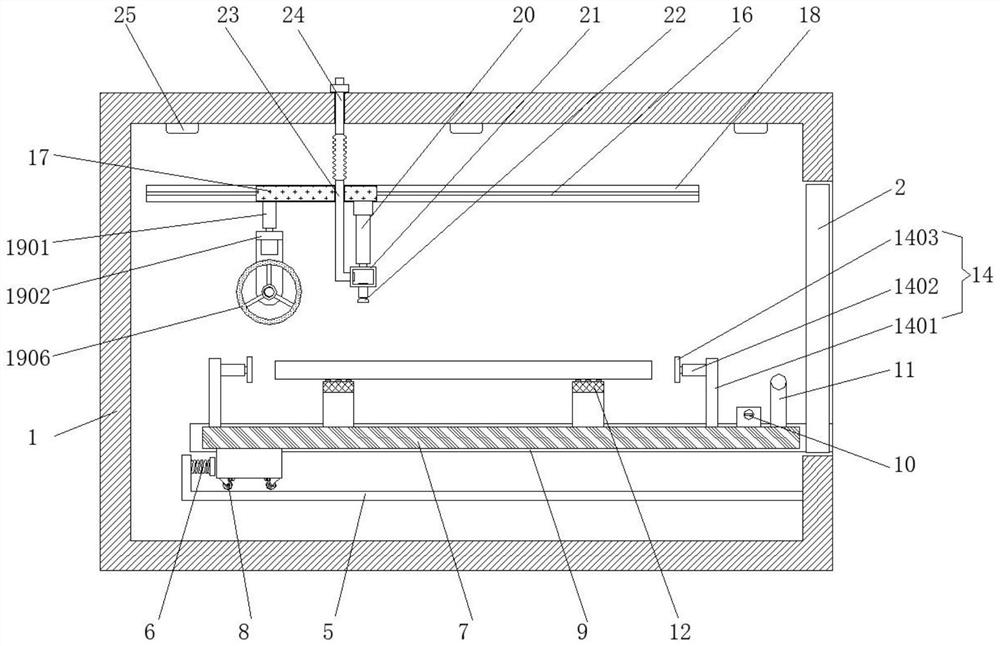

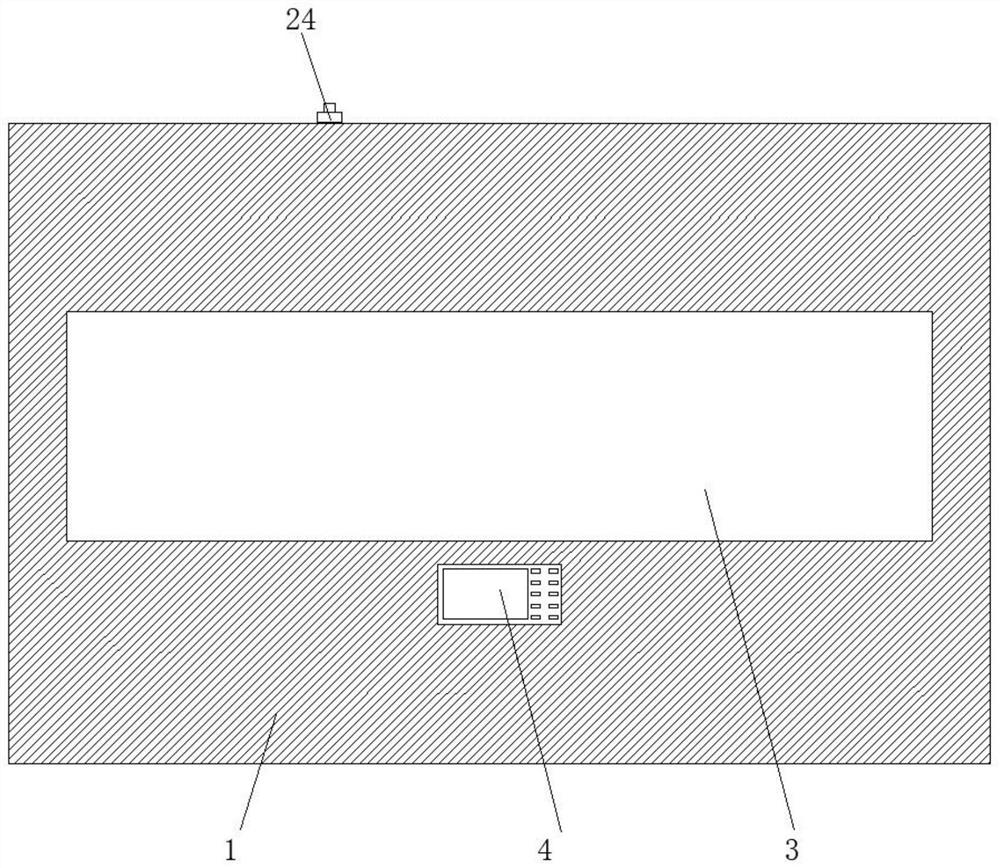

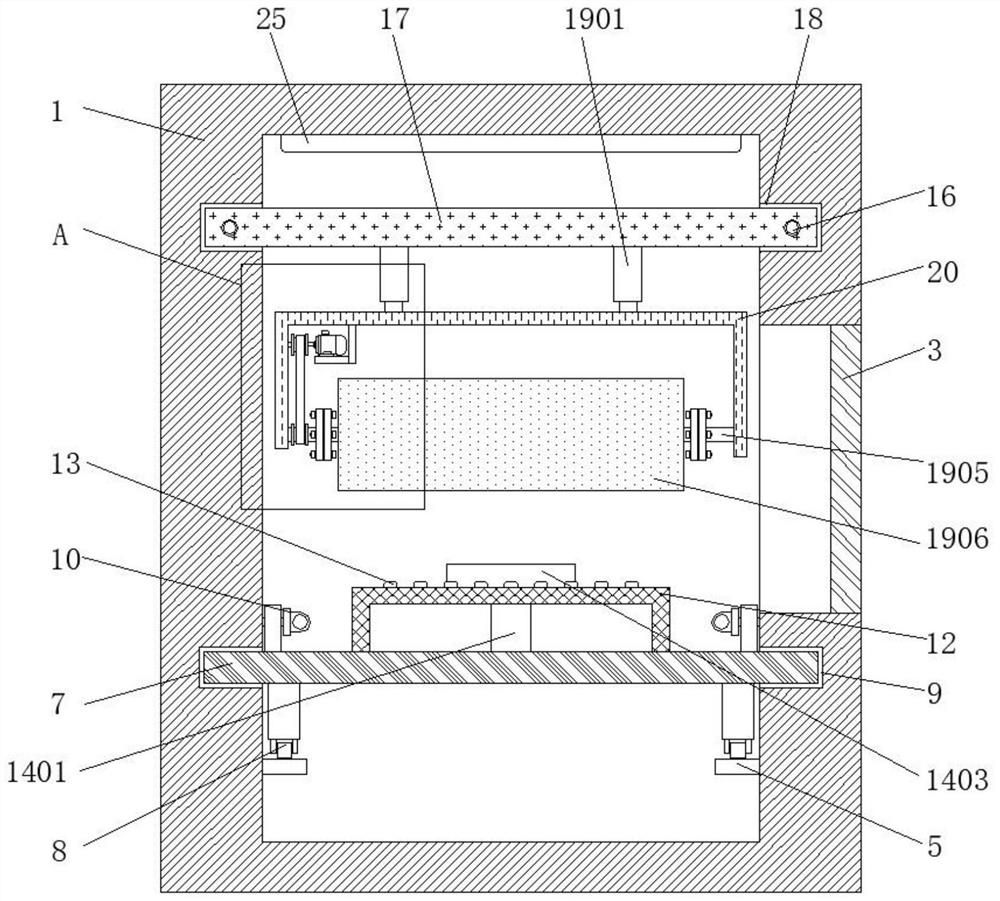

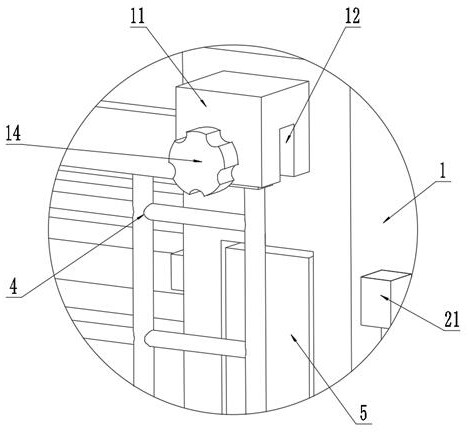

Coating device with dust removal mechanism for electromagnetic shielding door processing

InactiveCN113289823AEasy to clamp and fixEasy to place and takeLighting elementsCleaning using toolsLap jointDust control

The invention discloses a coating device with a dust removal mechanism for electromagnetic shielding door processing. The coating device comprises a bearing box, a bearing table, a clamping and fixing mechanism, a first motor, the dust removal mechanism and an electric feeding valve, wherein supporting plates are fixed on the front inner wall and the rear inner wall of the bearing box, the bearing table is arranged on the supporting plates in a lap joint mode, storage racks are fixed on the left side and the right side of the upper end surface of the bearing table, the clamping and fixing mechanism is fixed on the upper end surface of the bearing table, the dust removal mechanism is fixed on the left side of the lower end surface of a sliding plate, a second electric telescopic column is fixed on the right side of the lower end surface of the sliding plate, and the electric feeding valve penetrates through the top of the bearing box and is connected with a connecting pipeline. According to the coating device with the dust removal mechanism for electromagnetic shielding door processing, after a clamped material is placed and a box door is closed, a dust sticking cylinder moves downwards along with a bearing frame and is attached to the upper end surface of the material, then the sliding plate, the bearing frame and the dust sticking cylinder integrally move left and right, meanwhile, the dust sticking cylinder rotates, and dust on the surface of the material can be conveniently stuck and removed.

Owner:东台市苏宝电磁屏蔽设备有限公司

Safety lifting platform for exterior wall painting for building engineering construction

ActiveCN114837390AEasy to drawClearly smudge the edgesSustainable buildingsScaffold accessoriesArchitectural engineeringStructural engineering

The invention discloses a safety lifting platform for exterior wall painting for building engineering construction. The safety lifting platform comprises a lifting mechanism and a bearing mechanism. The bearing mechanism comprises a bearing frame and a widened treading structure arranged at the bottom of the bearing frame, and an extensible protection structure is arranged on the widened treading structure; the bearing frame is further provided with a material bearing structure and a windproof structure. The material bearing structure is used for containing paint, it is avoided that constructors bend down to pick up the painted paint frequently, and it is avoided that due to the large action range of continuous bending down, safety accidents are likely to happen; high-altitude constructors are protected through the protection structure, the phenomenon of step missing and falling is prevented, and the safety is improved; the protection structure is arranged in an extensible manner, so that the safety lifting platform can be used on both sides without dividing the front side and the back side; and by widening the treading structure, the treading area of workers and the placement area of painting tools are increased, and painting operation is more convenient. The safe lifting platform for painting is comprehensive in function and high in safety.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP

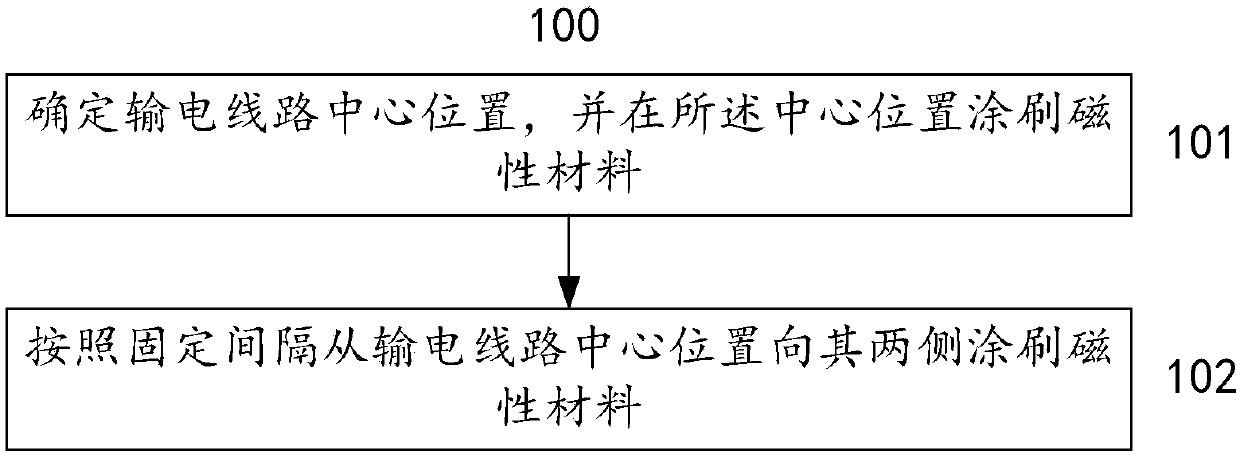

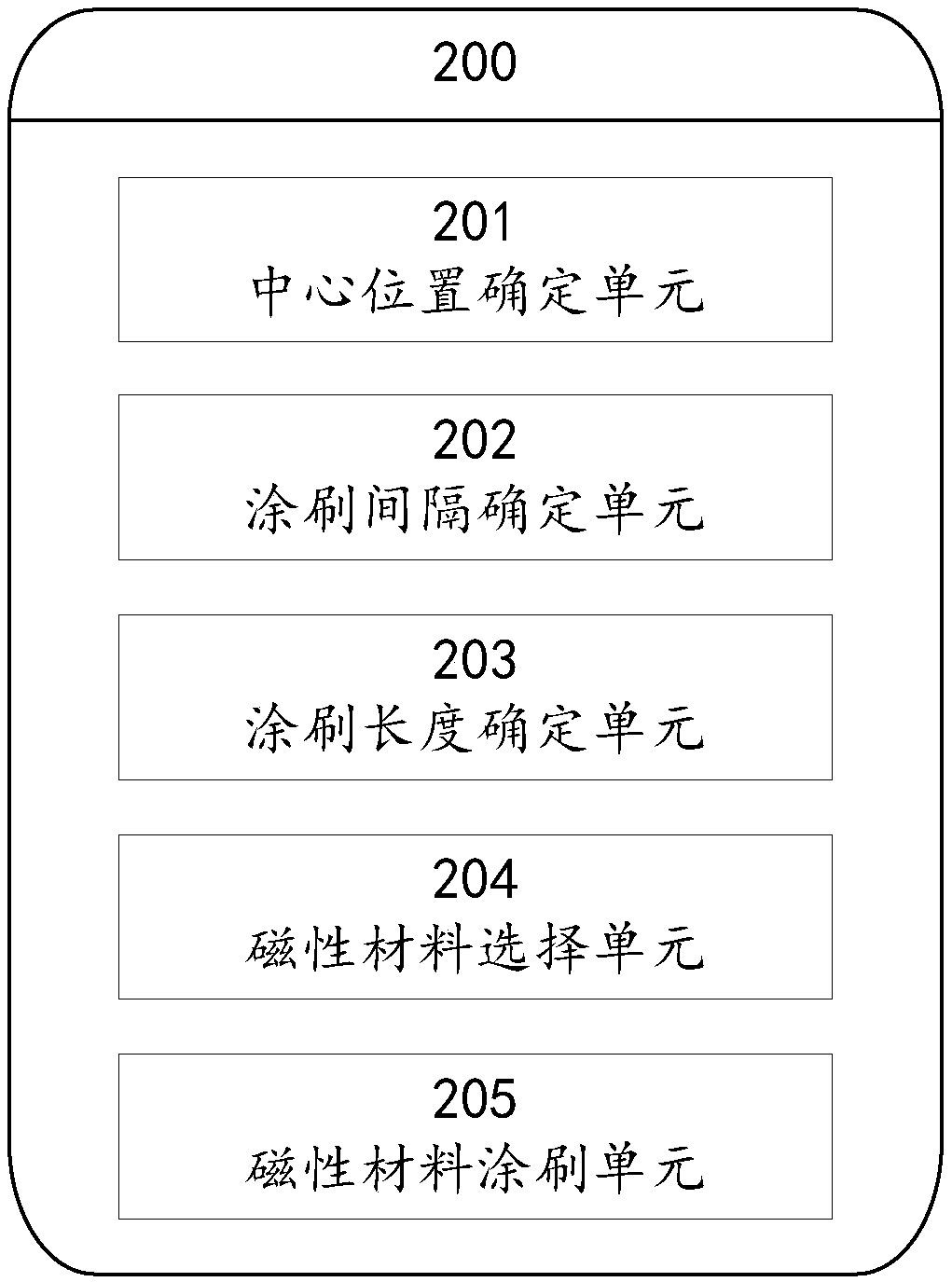

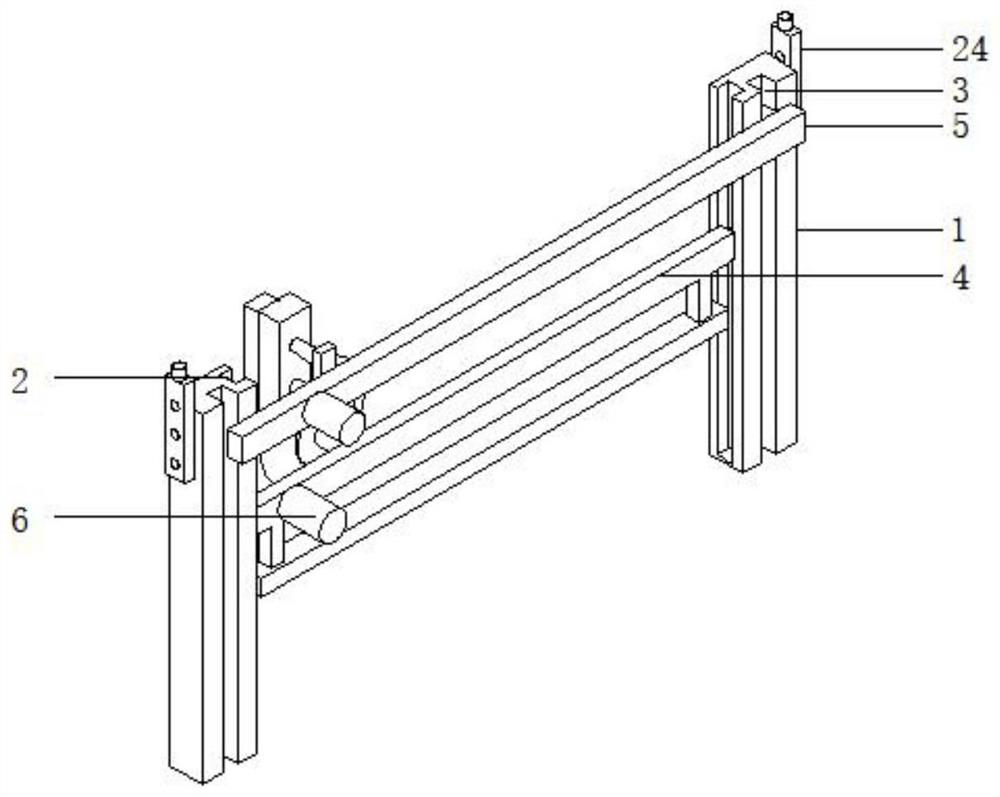

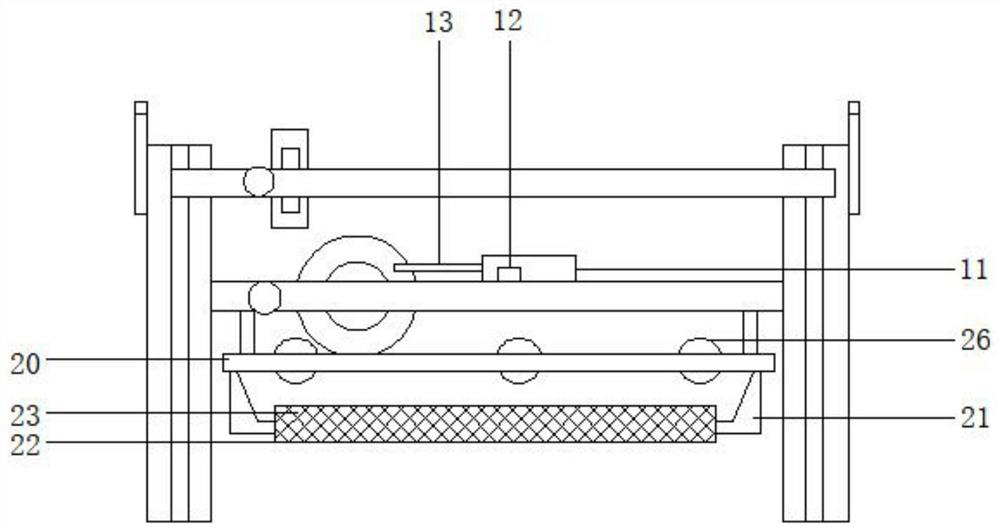

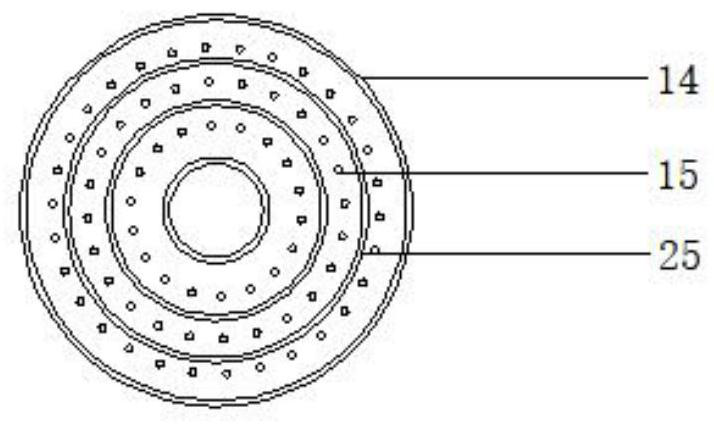

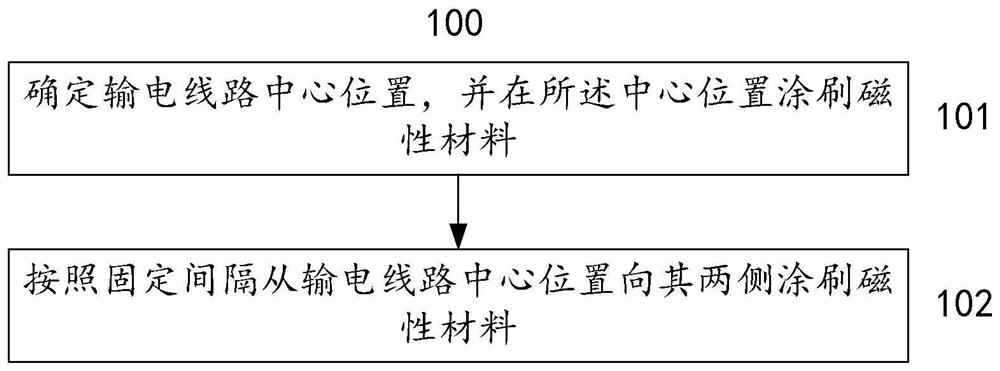

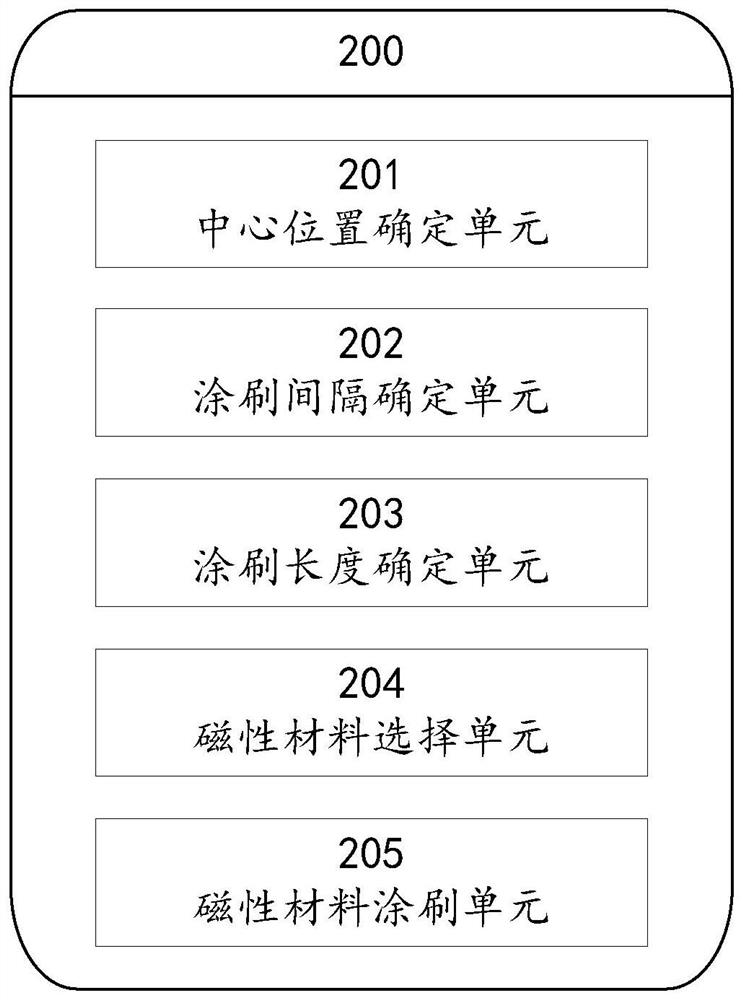

A method and a system for reducing loss of radar detection power caused by a power transmission line

ActiveCN107894582AEasy brushing operationReduce detection power lossWave based measurement systemsWave bandPeak value

The invention provides a method and a system for reducing loss of radar detection power caused by a power transmission line. The method comprises the steps of determining the center position of a power transmission line and painting the center position with a magnetic material; painting the two sides of the power transmission line with a magnetic material from the center position thereof at fixedintervals. Through cooperation of the technical solution provided by the invention and working frequency, the induced current peak position of a power transmission line is painted with a magnetic material with simple operation and low weight, so that the intensity of induced currents can be suppressed and the loss of detection power of meter wave band radar caused by the power transmission line can be reduced.

Owner:CHINA ELECTRIC POWER RES INST +2

Sanding method of fast-growing wood

ActiveCN107283271AThere will be no breakageHigh hardnessOther chemical processesBelt grinding machinesSanderAdhesive

The invention discloses a sanding method of fast-growing wood. The sanding method comprises the steps: (1) removing stains from the surface of the fast-growing wood, and then applying sanding auxiliaries to the surface of the fast-growing wood; (2) performing sanding treatment to the fast-growing wood with a disc sander, and the model of sanding materials is any one of 100#, 120# and 150#, wherein the substrate of the sanding materials is a fabric abrasive belt; abrasive materials comprise, by weight, 29-36 parts of brown corundum abrasives, 1-3 parts of magnesium borate, 4-7 parts of docosanamide and 1-2 parts of iodooctadecane; the abrasive materials are bonded with the substrate through adhesive. The sanding method of the fast-growing wood, provided by the invention, has the advantages of easy operation, low cost, and safety and environmental protection in the operation process, and the surface of the fast-growing wood sanded is free of burrs, and smooth and flat, so that convenience is provided for subsequent coating operation; and in the sanding process, the fast-growing wood is not broken, and the rate of finished products is high.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Environment-friendly paint for children furniture

InactiveCN108610692AImprove impermeabilityAdd new activation points to improve anti-seepage abilityAnti-corrosive paintsCyclohexanoneChemical reaction

The invention relates to environment-friendly paint for children furniture. The paint is prepared from, by weight, 80-85 parts of epoxy resin, 2-4 parts of titanium dioxide, 5-8 parts of talc powder,6-8 parts of methyl methacrylate, 3-5 parts of aluminum powder, 3-4 parts of titanium dioxide, 22-25 parts of fly ash, 4-6 parts of organism, 2-4 parts of calcium carbonate, 6-8 parts of defoaming agent, 10-14 parts of butyl acetate, 0.5-0.7 part of polydimethylsiloxane, 2-2.5 parts of inorganic silica sol, 1-1.4 parts of polyvinyl alcohol, 12-14 parts of styrene, 1.2-1.8 parts of leveling agent,10-14 parts of benzyl alcohol, 3-5 parts of cyclohexanone, 3-6 parts of dispersing agent and an appropriate amount of absolute ethanol. The dispersing agent and the talc powder are utilized, so that new activation points are increased, and the specific surface area is increased; grinding with the aluminum powder can reduce chemical reactions on the aluminum surface and improve the corrosion resistance and environmental protection effects; activation of an active agent is utilized to improve the impermeability of the active agent in the paint. The coating and brushing operation of the paint isconvenient, the drying speed is high, the coating surface is flat and smooth, and the paint has good wear resistance and excellent environmental protection capability.

Owner:QIANMUYE FURNITURE TIANJIN

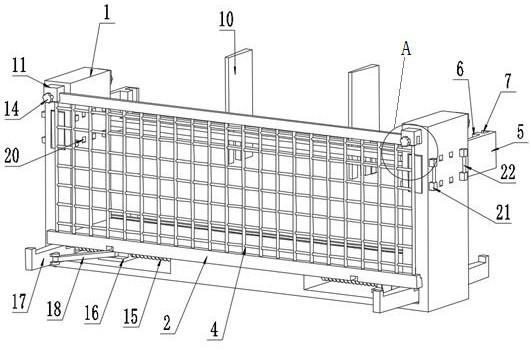

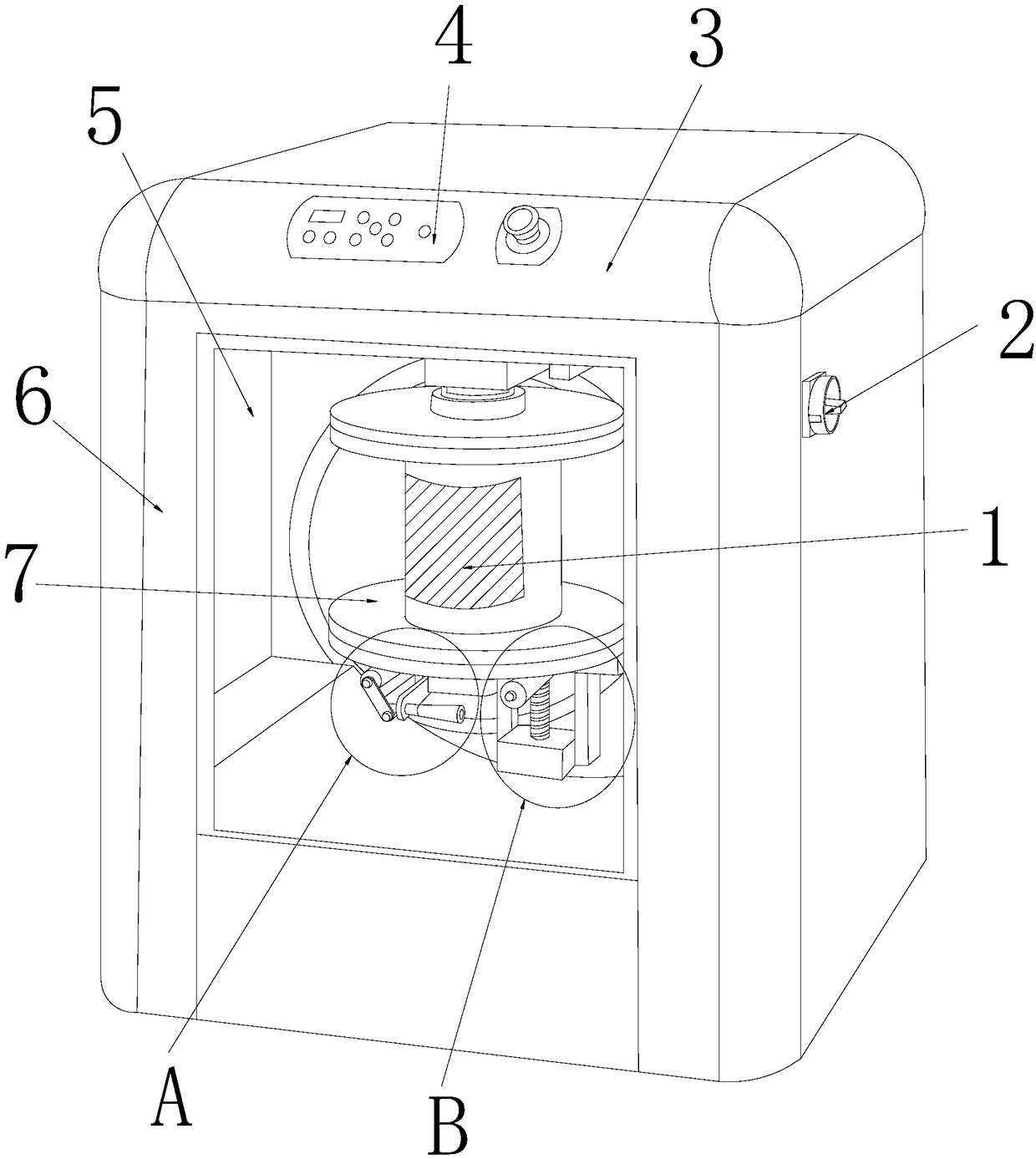

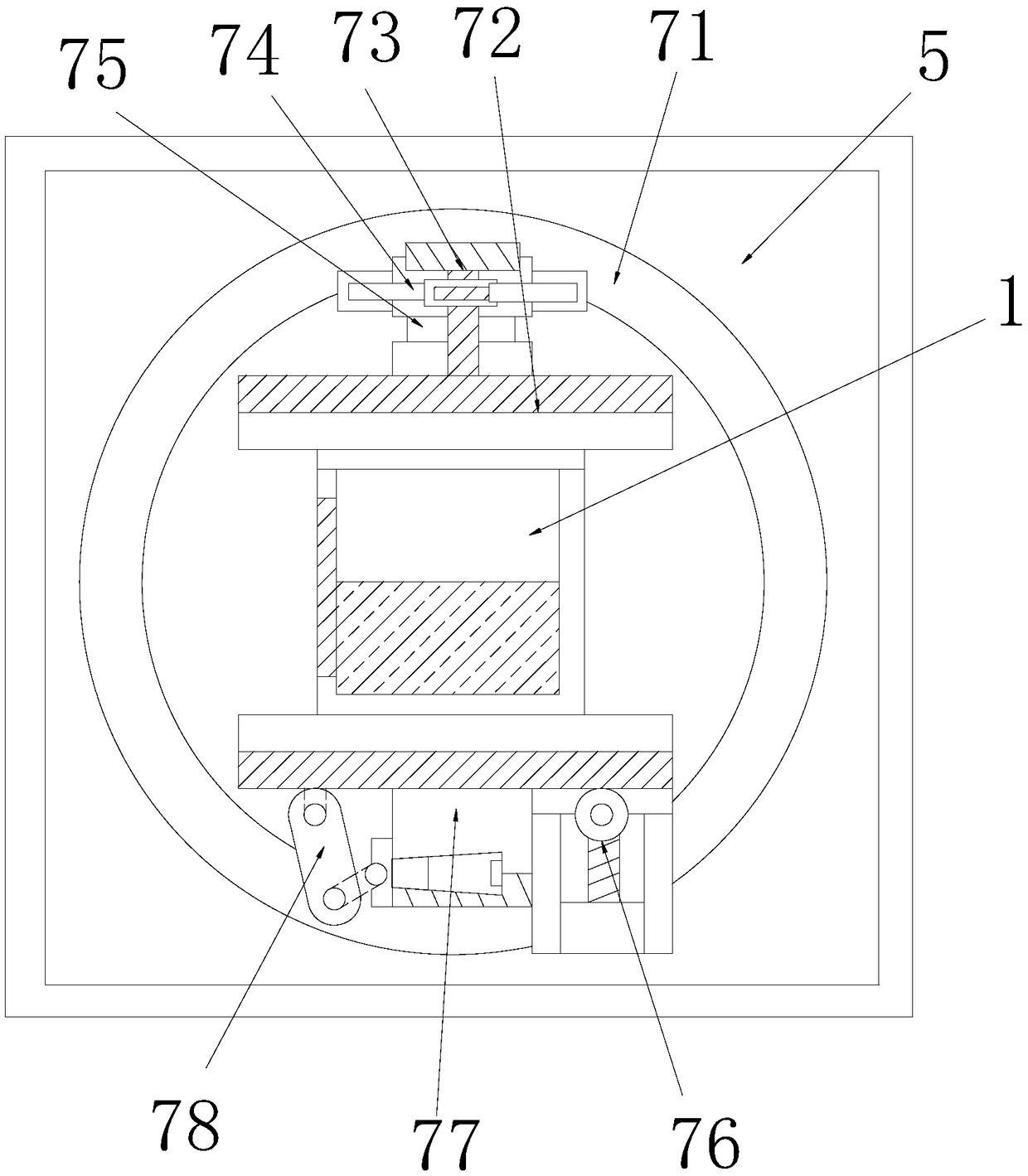

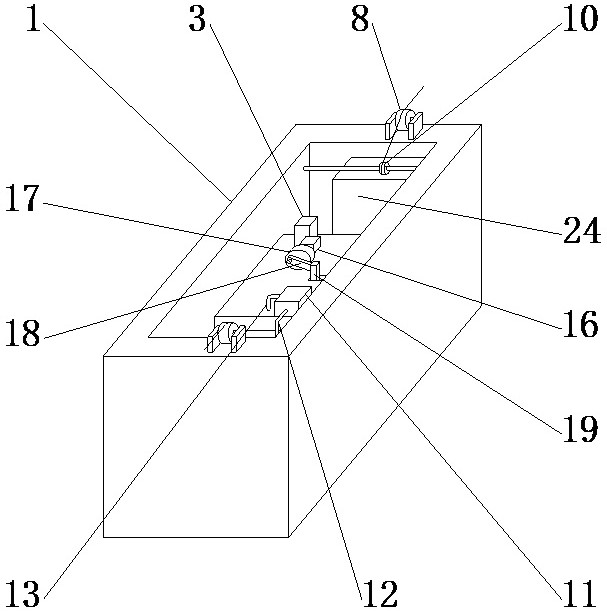

Vibratory paint stirring device for clamping-turning and hanging-rotation of printing ink paint bucket

InactiveCN109499453AImprove work efficiencyAdd quick liquidityRotating receptacle mixersTransportation and packagingPrinting inkEngineering

The invention discloses a vibratory paint stirring device for clamping-turning and hanging-rotation of a printing ink paint bucket. The paint stirring device structurally comprises a printing ink bucket, a shell frame dismounting button, an integrated top cover, an operation panel, an inner groove, a box shell and a chuck hanging-rotation mechanism. The paint stirring device has the advantages that the printing ink bucket is matched with the chuck hanging-rotation mechanism, printing ink fluid in the printing ink bucket is matched with the rotation angle of a gear shaft of a chuck body to reduce the internal viscosity and then matched with a batten connecting rod rest and ball-colliding couplers of an annular track frame to be integrally turned, the lubrication of the liquid flow rate is improved, oil films of printing ink are diluted, the rapid fluidity is increased, the multi-layer rotation effect of the hanging-rotation type clamping-turning is achieved, the paint does not directlycontact with an agitator, and uniform internal stirring and shaking without impurities can be realized; by an external stirring frame, contamination caused by paint adhesion is avoided, so that the equipment cleaning time is reduced, and the work efficiency is improved; the two-way stirring effect of a circular track matched with the rotation of the chuck is achieved, so that looseness of the printing ink is improved and the viscosity is reduced to facilitate painting.

Owner:郭逢金

Environment-friendly coating for children furniture

InactiveCN105802301AImprove impermeabilityReduce chemical reactionsAnti-corrosive paintsChemical reactionPolyvinyl alcohol

The invention discloses environment-friendly coating for children furniture.The environment-friendly coating comprises, by weight, 80 parts of epoxy resin, 2 parts of titanium dioxide, 5 parts of talcum powder, 6 parts of methyl methacrylate, 3 parts of aluminium powder, 3 parts of titanium dioxide, 22 parts of coal ash, 4 parts of organisms, 2 parts of calcium carbonate, 6 parts of deforming agent, 10 parts of butyl acetate, 0.5 part of polydimethylsiloxane, 2 parts of industry silicasol, 1 part of polyvinyl alcohol, 12 parts of styrene, 1.2 parts of leveling agent and 10 parts of benzyl alcohol.According to the environment-friendly coating for children furniture, dispensing agents and talcum powder are used, new activation sites are added to increase the specific surface area, the dispensing agents and talcum powder are ground with the aluminium powder to reduce chemical reactions on the surface of aluminium so as to improve corrosion resistance and environmental protection effects, and impermeability of the dispensing agents and talcum powder in the coating is enhanced through activity of activating agents.The environment-friendly coating for children furniture is convenient to brush, fast to dry, good in abrasion resistance with flat and smooth coating surface, and is highly environment-friendly.

Owner:HEFEI ZHONGLAN NEW MATERIAL TECH CO LTD

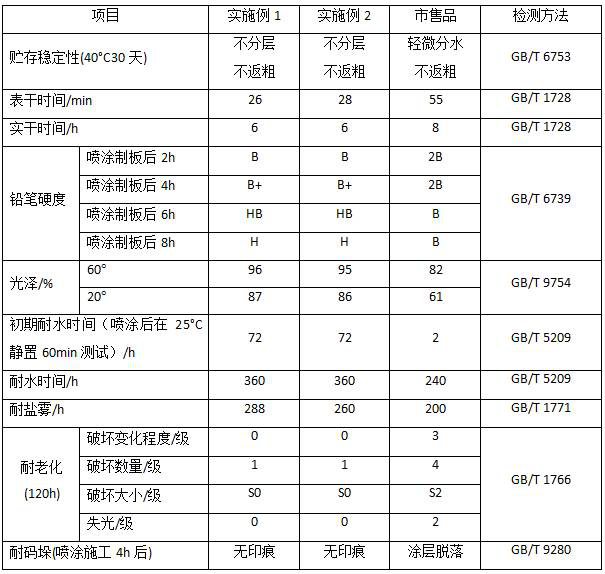

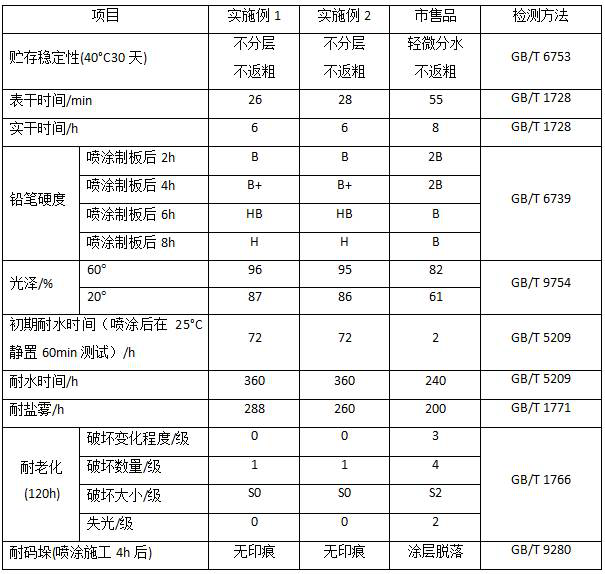

Bottom-surface-integrated water-based epoxy ester coating for tower crane standard parts and preparation method thereof

A bottom-surface-integrated water-based epoxy ester coating for tower crane standard parts and a preparation method thereof, the coating is composed of vinyl modified epoxy ester resin, environment-friendly pigment, hydrolysis-stable filler, dispersant, defoamer, Thickener, anti-sagging agent, leveling agent, wetting agent, drier, anti-flash rust agent, pH regulator, co-solvent and deionized water are mixed. The invention also includes the preparation method of the paint. The coating of the invention dries quickly, has tough paint film, high gloss, excellent initial water resistance, stacking resistance and weather resistance, convenient construction and simple preparation process.

Owner:湘江涂料科技有限公司

A kind of sanding method of fast-growing wood

ActiveCN107283271BThere will be no breakageHigh hardnessOther chemical processesBelt grinding machinesSanderAdhesive

The invention discloses a sanding method of fast-growing wood. The sanding method comprises the steps: (1) removing stains from the surface of the fast-growing wood, and then applying sanding auxiliaries to the surface of the fast-growing wood; (2) performing sanding treatment to the fast-growing wood with a disc sander, and the model of sanding materials is any one of 100#, 120# and 150#, wherein the substrate of the sanding materials is a fabric abrasive belt; abrasive materials comprise, by weight, 29-36 parts of brown corundum abrasives, 1-3 parts of magnesium borate, 4-7 parts of docosanamide and 1-2 parts of iodooctadecane; the abrasive materials are bonded with the substrate through adhesive. The sanding method of the fast-growing wood, provided by the invention, has the advantages of easy operation, low cost, and safety and environmental protection in the operation process, and the surface of the fast-growing wood sanded is free of burrs, and smooth and flat, so that convenience is provided for subsequent coating operation; and in the sanding process, the fast-growing wood is not broken, and the rate of finished products is high.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

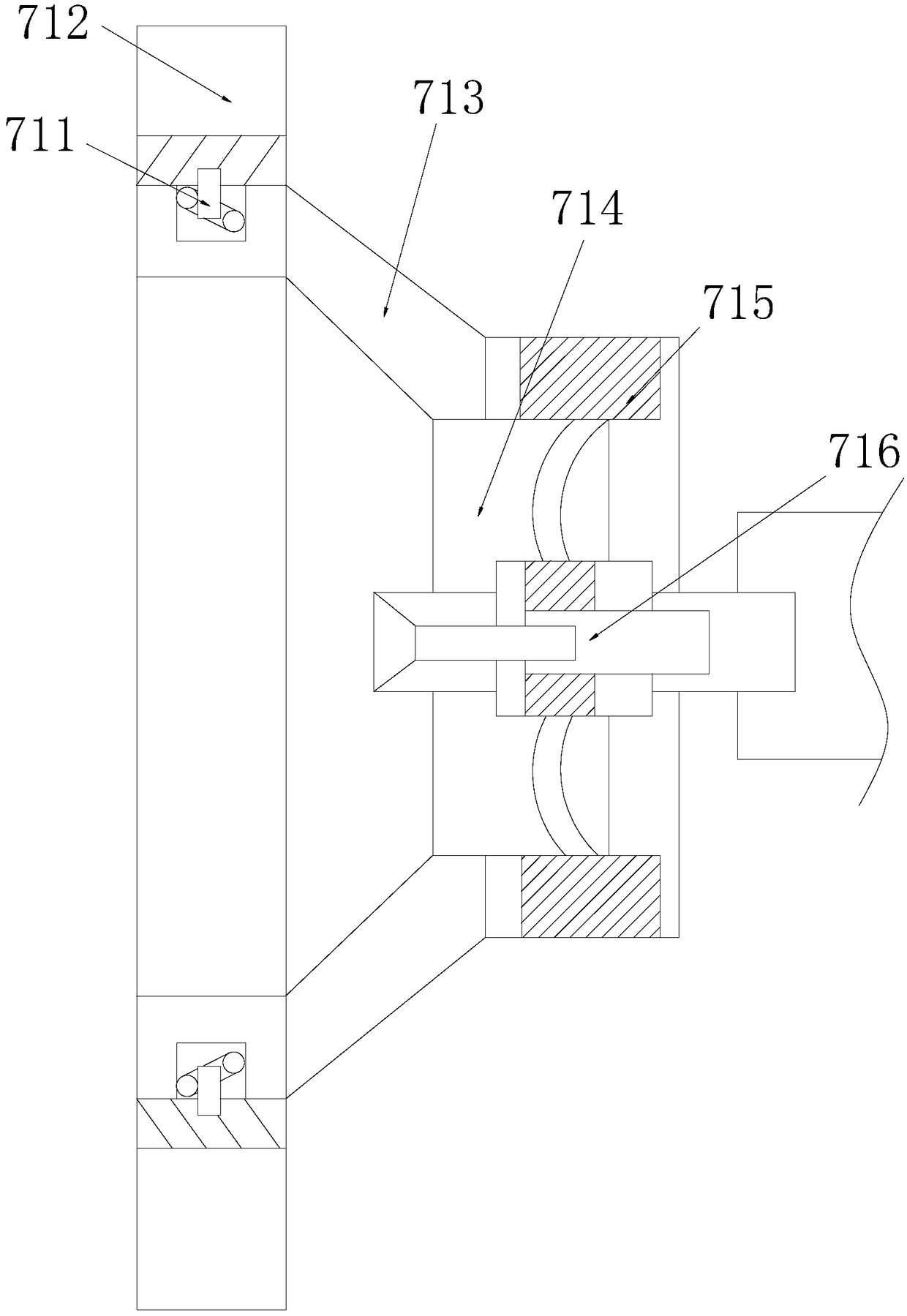

Intelligent spray oiling device for steel wire rope

The invention relates to the technical field of intelligent machining of steel wire ropes, and discloses a spray oiling device for a steel wire rope, and solves the problems of low oiling efficiency and poor oiling quality in the oiling process of the steel wire rope. The spray oiling device comprises a spraying box body; supporting columns are symmetrically arranged at the bottom end of the spraying box body; openings are symmetrically formed in the middles of the two sides of the spraying box body; a through hole located above the openings is formed in one side of the spraying box body; a supporting frame is arranged on one side of the top end of the spraying box body; a spraying pipe is arranged in the spraying box body; a connecting cover is connected to one side of the spraying pipe; a brushing unit is arranged on the connecting cover; and a spraying mechanism is arranged in the spraying pipe. By arranging the spraying pipe, the connecting cover, a fluid director, an oil conveying pipe, a containing groove, an oil storage groove, a communicating ring, a communicating opening, a spraying head, a third gear and a transmission mechanism, comprehensive oil spraying operation on the steel wire rope is achieved, the oiling comprehensiveness of the steel wire rope is improved, and the oiling efficiency of the steel wire rope is improved.

Owner:南通市宇翔特种钢丝钢绳有限公司

Wire rope intelligent spray oiling device

ActiveCN113564948BEasy to achieve rotationAchieve rotationRope making machinesSpray coatingProcess engineering

The invention relates to the technical field of steel wire rope intelligent processing, and discloses a steel wire rope spray oiling device, which solves the problems of low oiling efficiency and poor oiling quality of the steel wire rope during the oiling process, which includes a spraying box, the spraying box The bottom of the body is symmetrically provided with support columns, and the middle of both sides of the spraying box is symmetrically opened with openings, one side of the spraying box is provided with a through hole above the opening, and the top side of the spraying box is provided with a support frame. The inside of the spraying box is provided with a spraying pipe, one side of the spraying pipe is connected with a connecting cover, the connecting cover is provided with a brushing unit, and the inside of the spraying pipe is provided with a spraying mechanism; The device, oil delivery pipe, accommodation tank, oil storage tank, communication ring, communication port, nozzle, gear and transmission mechanism realize the comprehensive oil injection operation on the wire rope, thereby improving the comprehensiveness of wire rope oiling and the efficiency of wire rope oiling.

Owner:南通市宇翔特种钢丝钢绳有限公司

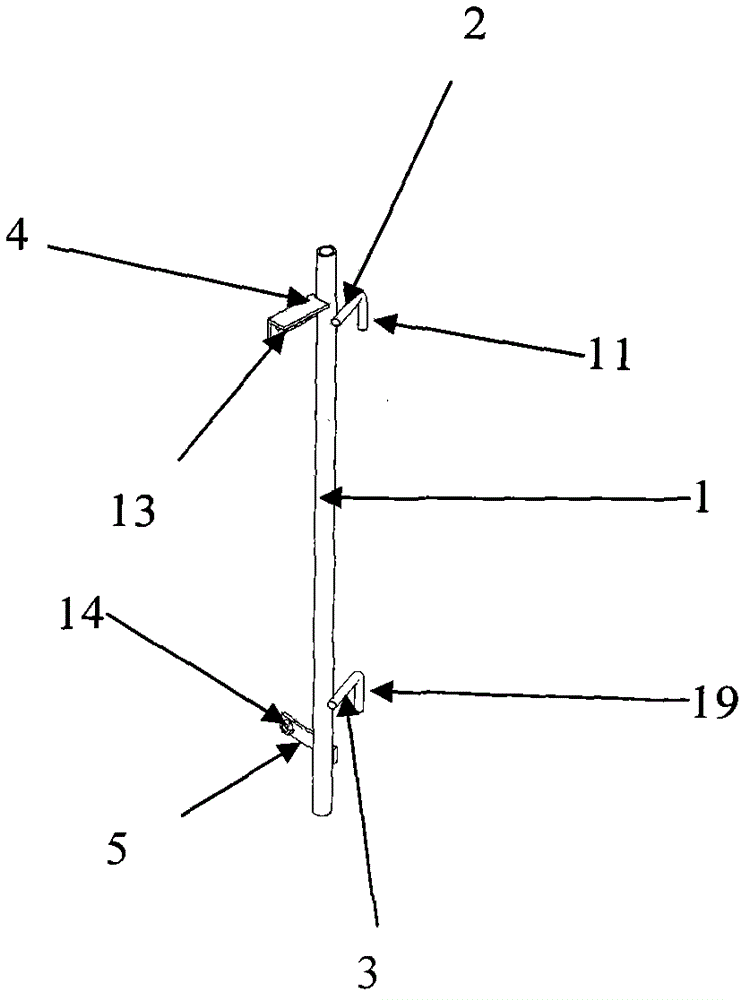

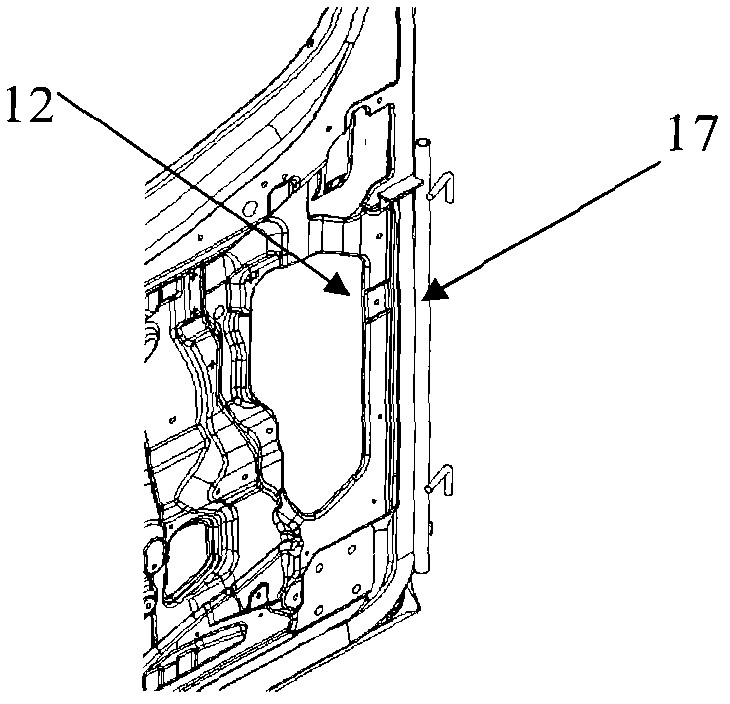

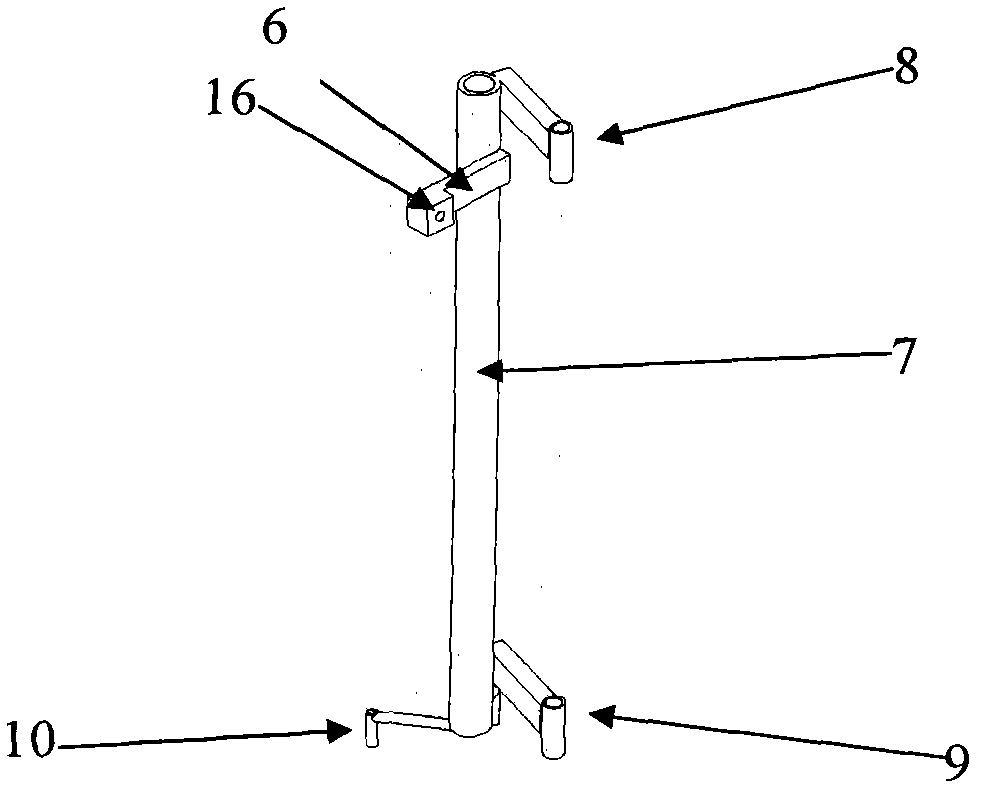

Assistant sliding door coating device

ActiveCN102513273BReasonable designEasy to disassemble and operateLiquid surface applicatorsCoatingsEngineeringCommercial vehicle

The invention provides an assistant sliding door coating device. The device comprises a first installation part and a second installation part, the first installation part is arranged on a sliding door, the second installation part is arranged on a vehicle body, and the first installation part is movably connected to the second installation part. The assistant sliding door coating device which has the advantages of simple structure, convenient realization and realization of repeated use is especially suitable for sliding door coating operations of large commercial vehicles.

Owner:CHERY AUTOMOBILE CO LTD

Primer-topcoat type waterborne epoxy ester coating for tower crane standard parts, and preparation method thereof

The invention relates to a primer-topcoat type waterborne epoxy ester coating for tower crane standard parts, and a preparation method thereof. The coating is prepared by mixing vinyl modified epoxy ester resin, an environment-friendly pigment, a hydrolytic stable filler, a dispersing agent, an antifoaming agent, a thickener, an anti-sagging agent, a leveling agent, a wetting agent, a drier, an anti-flash-rust agent, a pH regulator, a cosolvent and deionized water. The invention further discloses the preparation method of the coating. The coating disclosed by the invention is rapid to dry, tough in paint film, high in gloss, excellent in initial water resistance, stacking resistance and weather resistance, and convenient to construct; and the preparation process is simple.

Owner:湘江涂料科技有限公司

Wall spraying equipment for constructional engineering

ActiveCN113719081AIncrease the areaEvenly paintedSpraying apparatusBuilding constructionsClassical mechanicsStructural engineering

The invention discloses wall spraying equipment for constructional engineering. The wall spraying equipment comprises two vertical frame columns which are kept parallel and perpendicular, the vertical frame columns are cuboid, a first guide rail groove is formed in the inner side of each vertical frame column, a second guide rail groove is further formed in the front face of each vertical frame column, a first transverse rod is embedded in each first guide rail groove, a second transverse rod is embedded in the second guide rail groove, the first transverse rod is connected with the vertical frame columns in a sliding mode, and the second transverse rod is connected with the vertical frame columns in a sliding mode; servo motors are arranged on the outer side of the first transverse rod and the outer side of the second transverse rod, strip-shaped notches are formed in the inner side of the first transverse rod and the inner side of the second transverse rod, the output ends of the servo motors are connected with shaft rods, the outer sides of the shaft rods are wrapped with transmission chain belts, and linkage blocks are arranged on the transmission chain belts; and the outer side of the linkage block on the inner side of the first transverse rod is connected with a spraying assembly. According to the wall spraying equipment, rapid wall spraying of the regional area is facilitated, the efficiency is high, the use safety is high, and the equipment is practical.

Owner:江苏顺隆鸿泰电力设备有限公司

A method and system for reducing the power loss of transmission lines to radar detection

ActiveCN107894582BEasy brushing operationReduce detection power lossWave based measurement systemsRadar detectionWavelength band

The present invention provides a method and system for reducing the power loss of power transmission lines to radar detection. The method includes: determining the center position of the power transmission line, and painting magnetic materials on the center position; Brush both sides with magnetic material. The technical solution provided by the present invention combines the working frequency, and brushes the magnetic material with easy operation and small weight at the peak position of the induced current of the transmission line, which effectively suppresses the intensity of the induced current, thereby reducing the detection of the transmission line by the meter-band radar Power loss.

Owner:CHINA ELECTRIC POWER RES INST +2

A sun-resistant and water-resistant polyester resin and its production process

The invention discloses a sun-resistant and water-resistant polyester resin and its production process. The process is as follows: esterify purified terephthalic acid and neopentyl glycol → polycondense → vacuumize, dehydrate → capping → filter →Cooling→Crushing→Packing and warehousing, and then obtained. The characteristic parameters of the polyester resin are as follows: acid value 48-55mgKOH / g, softening point 100-115°C, viscosity 100-200 poise (165°C), curing condition 200°C / 10min, the mass ratio of polyester resin and epoxy resin in the finished product is 90:10; What the present invention produces is applicable to the polyester resin of outdoor furniture or outdoor wall, improves its anti-ultraviolet performance by adding isophthalic acid , because the product will be exposed to the outdoors for a long time, the use of isophthalic acid is relatively large. At the same time, the water resistance is increased by adding 2,2,4-trimethyl-1,3-pentanediol as its auxiliary additive. At the same time, it reduces the leveling of the product and the viscosity of the product is low. The forming effect of the paint is good, the paint film is plump, and it is convenient for the painting operation of the finished paint; at the same time, the waste produced by the whole production process is convenient to handle.

Owner:滁州市全丰物资有限公司

A painting device for cardboard strip processing

ActiveCN107931004BUniform treatmentEasy brushing operationLiquid surface applicatorsCoatingsPolymer sciencePaperboard

The invention discloses a painting device for cardboard strip processing, which includes a processing tank, a connecting column, a sliding device, a dryer, an adsorption pad, a collar, a painting board, a hydraulic rod, a hydraulic seat, an outlet pipe, a storage Grooves, sliders, rails, chutes, pulleys, paint channels, springs and mounts. The beneficial effect of the invention is: by installing a hydraulic rod and a hydraulic seat above the painted board, the painted board can be freely stretched up and down according to different painting steps. By arranging several collars under the painted board, and the diameter of the collars matches the diameter of the cardboard strips, the user can fix the cardboard strips on the collars according to the needs of painting. By arranging the spring and the adsorption pad above the base, the paint on the cardboard strips can be coated more evenly after being treated by the adsorption pad. By arranging a storage tank with a triangular structure on one side of the dryer, the treated cardboard strips can be further dried in the storage tank.

Owner:佛山市万良商贸有限公司

A polyimide enameled wire painting device and its control method

ActiveCN111161928BImprove uniformityPromote circulationInsulating conductors/cablesGear driveLiquid storage tank

Owner:江苏龙创新材料科技有限公司

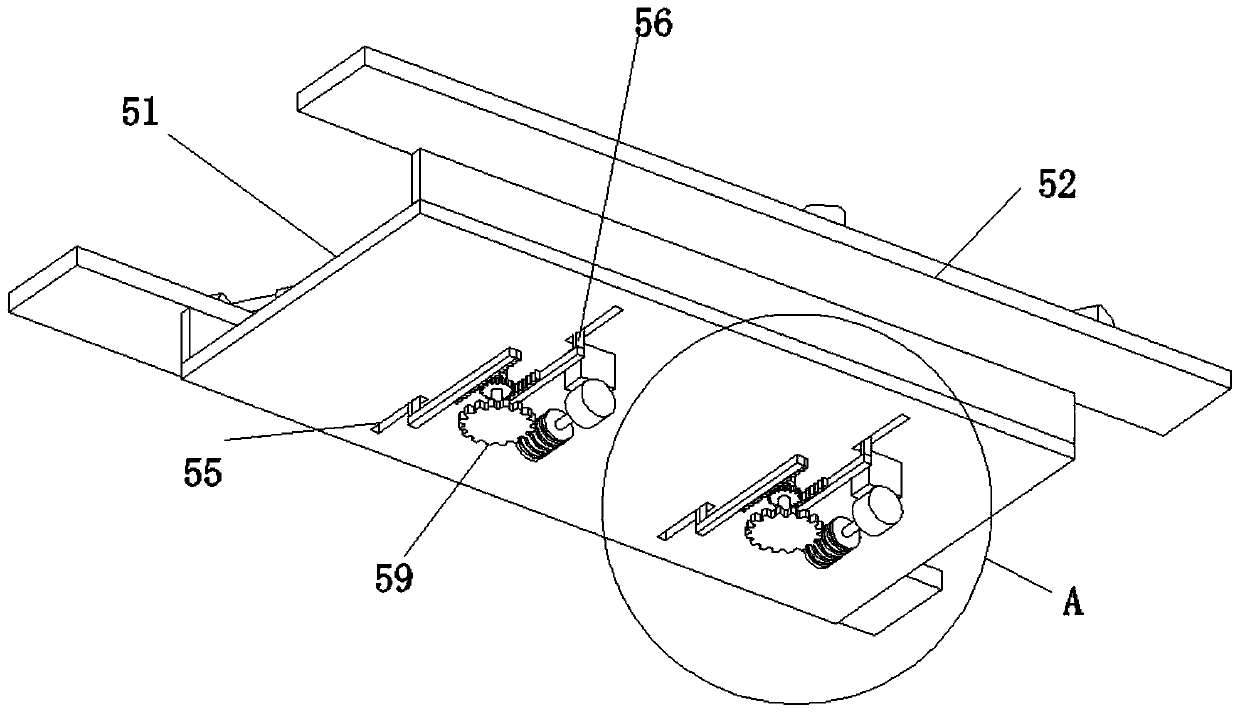

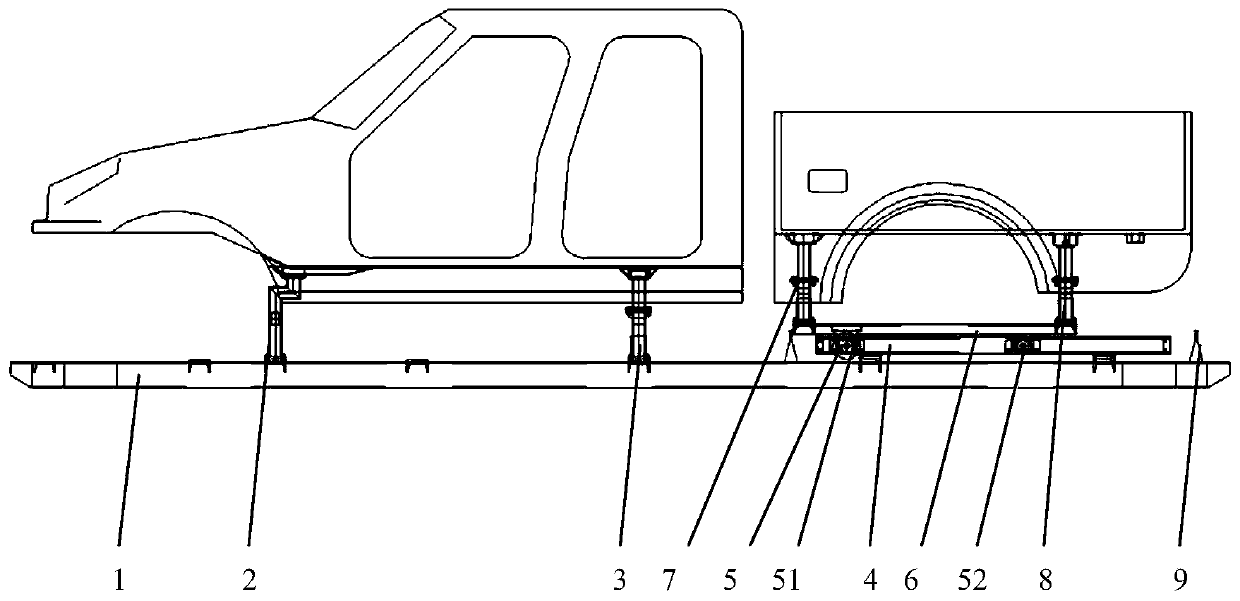

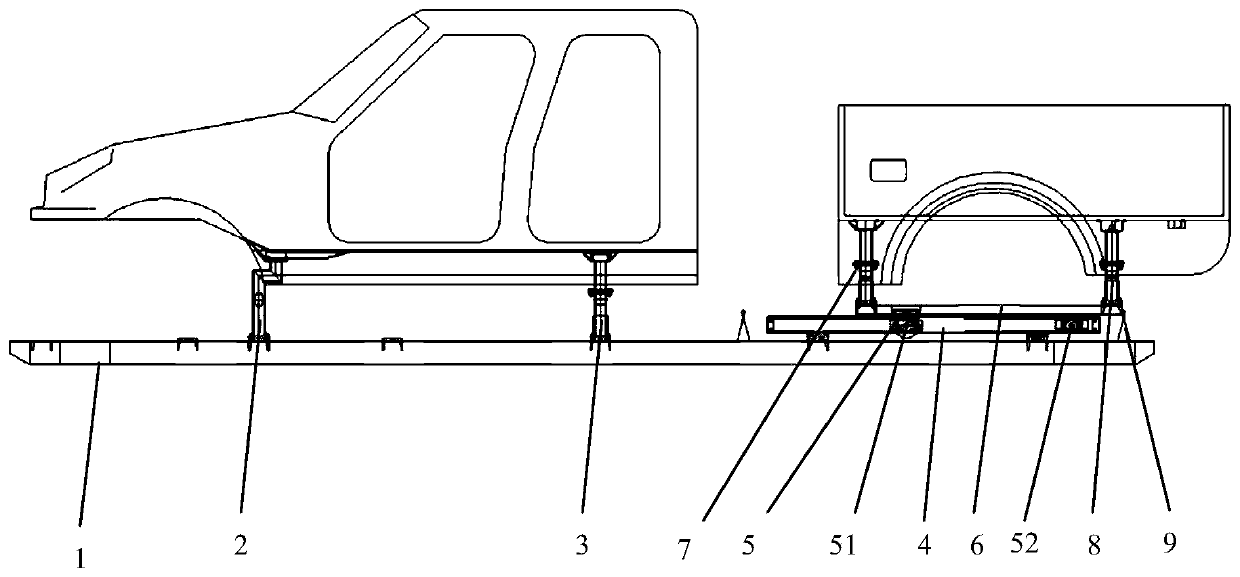

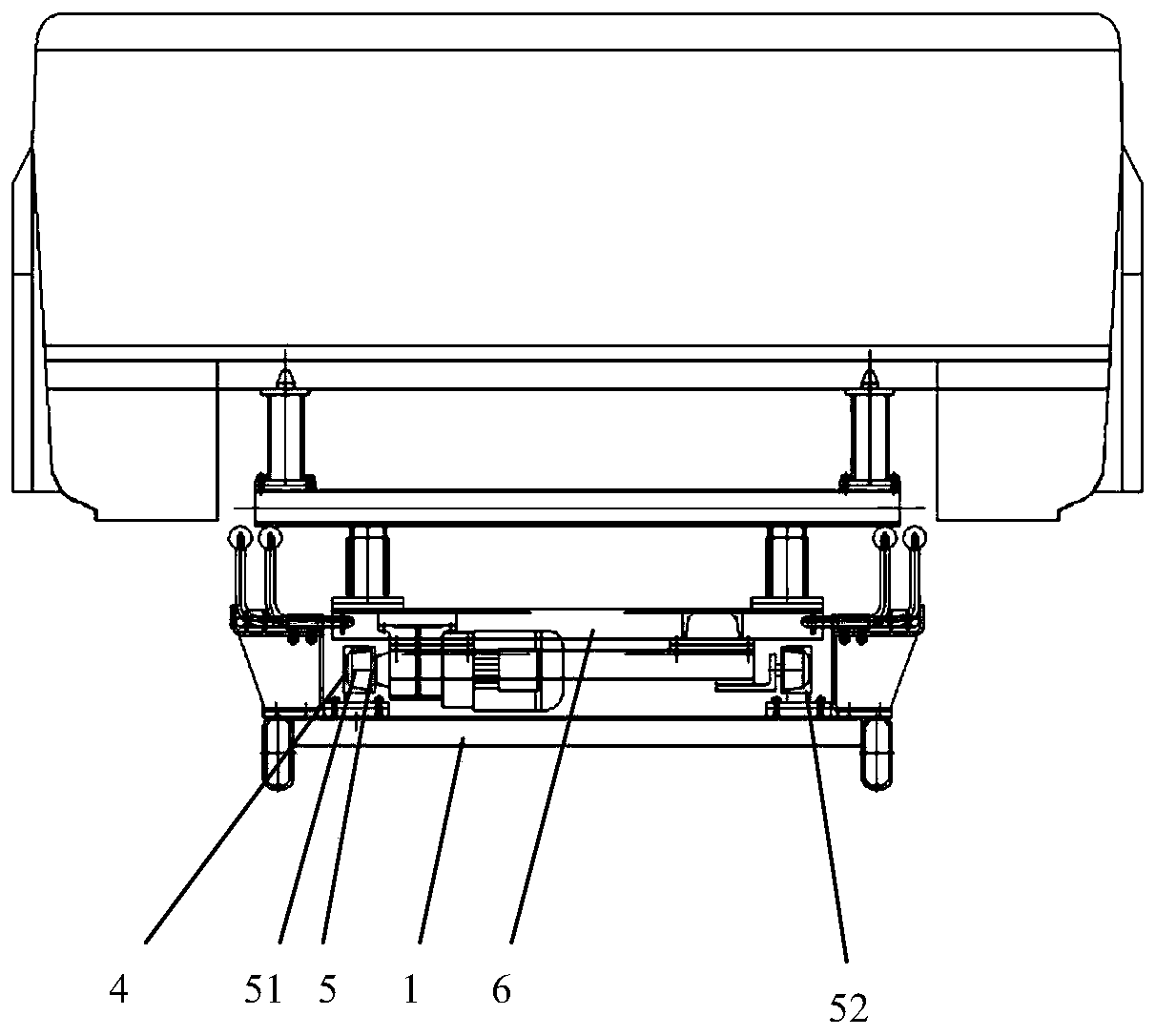

Device and method for automatically adjusting distance between cab and container for coating line

The invention discloses a device and a method for automatically adjusting the distance between a cab and a container for a coating line. The device comprises a skid, a track device, a rolling wheel moving device and a movable framework, wherein a cab front support and a cab rear support are arranged at the front end of the skid, the track device is arranged at the rear end of the skid, the rollingwheel moving device is arranged on the track device, and the movable framework is arranged on the rolling wheel moving device; and the movable framework is provided with a container front support anda container rear support. According to the device and the method, the distance between the cab and the container can be automatically adjusted, an coating operation is facilitated, the production pitch can be reduced, the operation is simple, the whole and local coating procedures of a truck can be ensured smoothly, the overall occupied space of a production line can be reduced as well, the early-stage cost investment and the later-stage energy loss are saved for enterprises.

Owner:NANTONG BEST MACHINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com