Vibratory paint stirring device for clamping-turning and hanging-rotation of printing ink paint bucket

A stirring device and ink technology, applied to mixer accessories, mixers with rotating containers, transportation and packaging, etc., can solve the problems of increasing friction loss, rotating shaft rod and bearing seat, difficult cleaning of agitator, and precipitation of gel blocks, etc. , to achieve the effect of increasing slack, saving cleaning equipment time, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

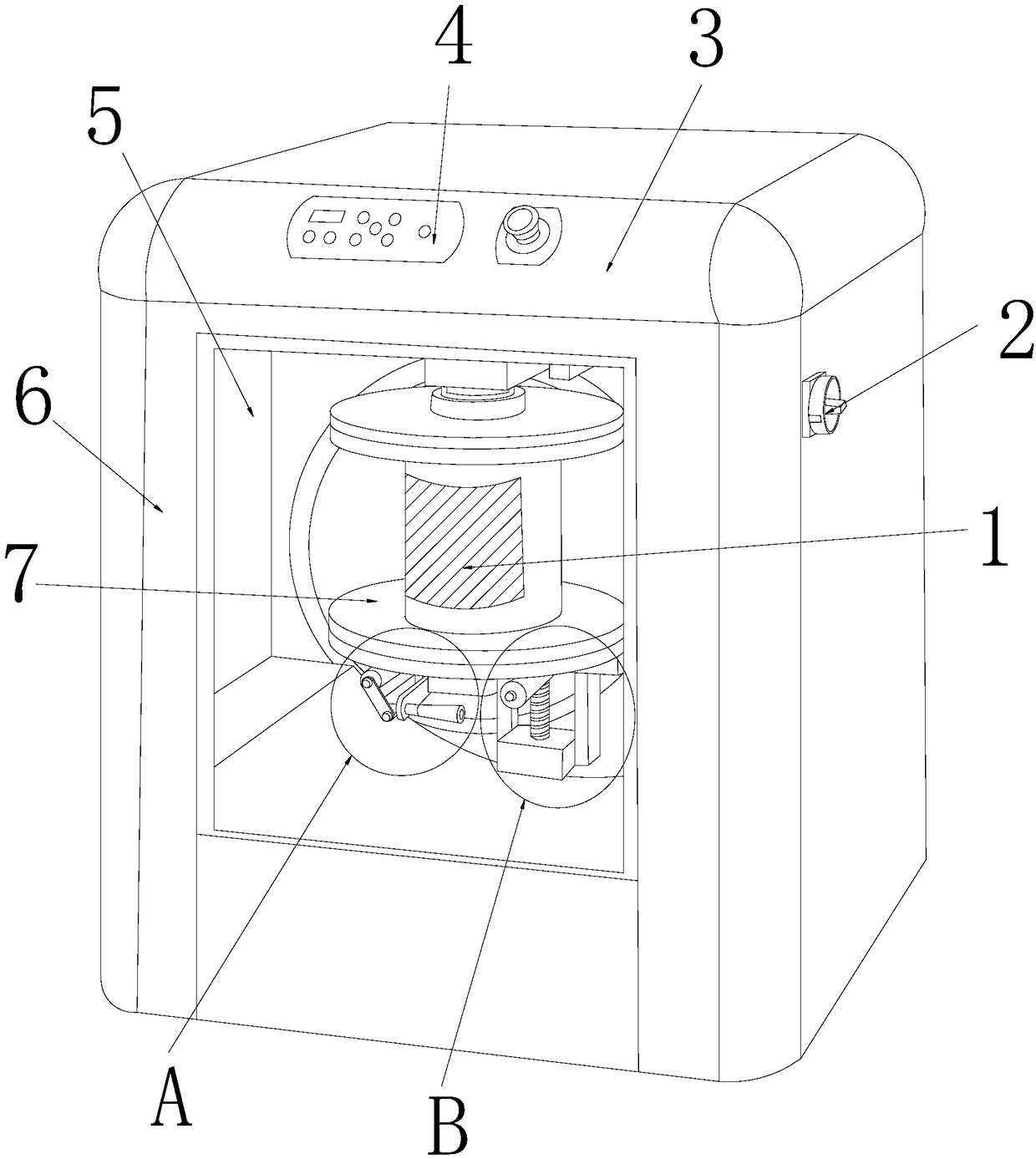

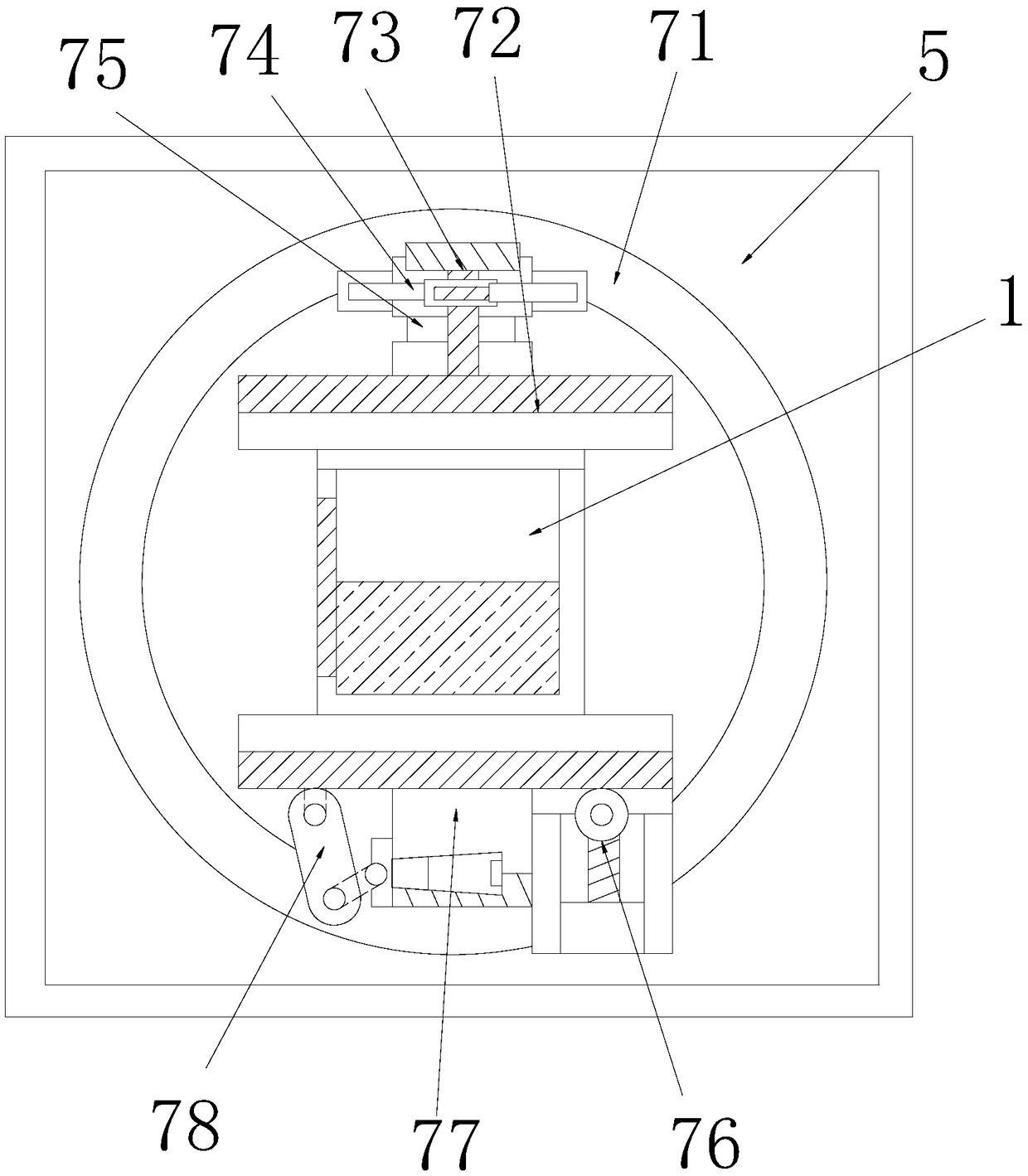

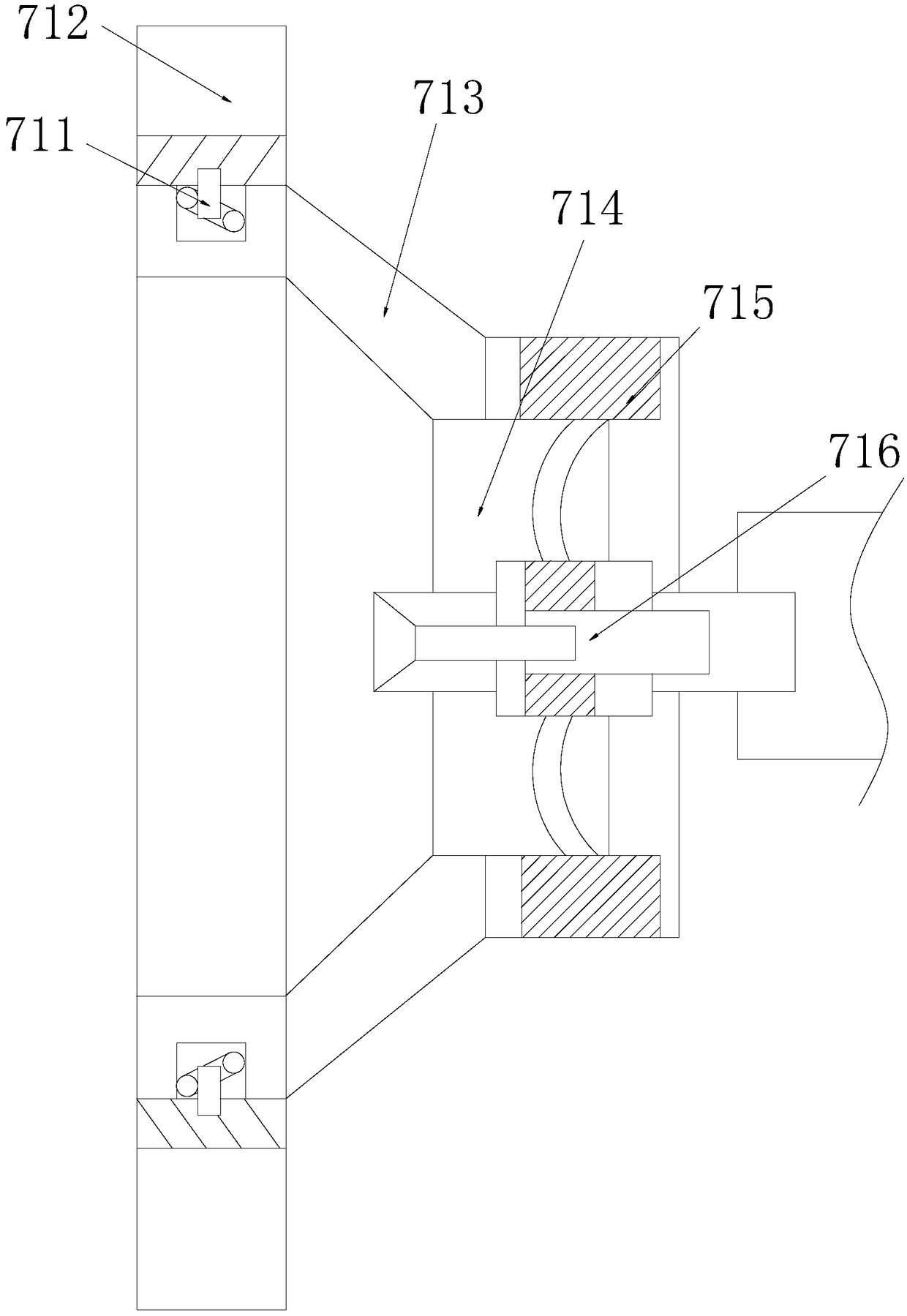

[0029] see Figure 1-Figure 7, the present invention provides a vibrating pinch-rotating paint mixing device for hanging ink paint buckets. Housing 6, chuck suspension mechanism 7, described ink barrel 1 and chuck suspension mechanism 7 are fastened together, and the motor inside described box housing 6 is mechanically connected with the rotor of chuck suspension mechanism 7, so The operation panel 4 is installed on the front side of the integrated top cover 3, the integrated top cover 3 is electrically connected to the pins of the operation panel 4 through wires, and the shell disassembly button 2 is nested on the right side of the box shell 6. On the side, the inner groove 5 is integrated with the box shell 6, the integrated top cover 3 is nest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com