Intelligent spray oiling device for steel wire rope

An oiling device and wire rope technology are applied in the field of intelligent spraying and oiling devices for steel wire ropes, which can solve the problems of poor oiling quality and low oiling efficiency of steel wire ropes, so as to improve oiling quality, improve spraying and oiling efficiency, The effect of improving the uniformity of oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

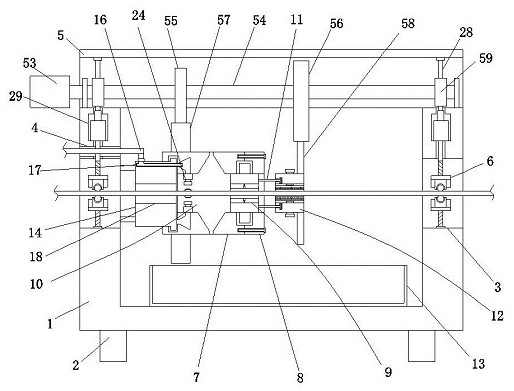

[0038] Embodiment one, by Figure 1 to Figure 8 Provided, the present invention includes a spraying box 1, the bottom of the spraying box 1 is symmetrically provided with a support column 2, the middle position of both sides of the spraying box 1 is symmetrically provided with an opening 3, and one side of the spraying box 1 is provided with a The through hole 4 above the opening 3, the top side of the spraying box 1 is provided with a support frame 5, the interior of the spraying box 1 is provided with a spraying pipe 7, and one side of the spraying pipe 7 is connected with a connecting cover 8, on which the connecting cover 8 A brushing unit is provided, and a spraying mechanism 10 is provided inside the spraying pipe 7. Through the design of the spraying mechanism 10, it is convenient to carry out oil spraying operation on the steel wire rope. The transmission mechanism, the interior of the opening 3 is equipped with a clamper 6 connected to the transmission mechanism, and ...

Embodiment 2

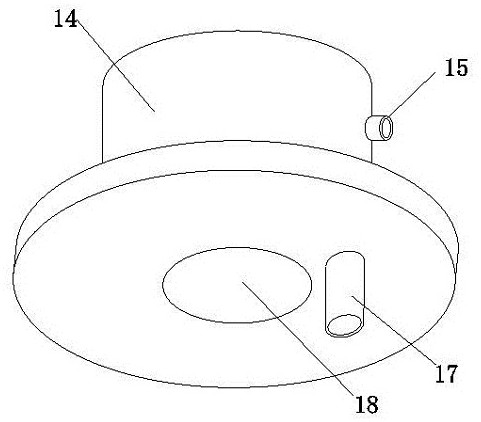

[0043] Embodiment two, on the basis of embodiment one, by figure 1 with figure 2 Given, the deflector includes an oil delivery tray 14, a connector 15, a guide pipe 17 and a through groove 18, the oil delivery tray 14 is installed on one side of the spraying pipe 7, and one end of the oil delivery tray 14 extends to the holding tank 20, the middle position of the oil delivery tray 14 is provided with a through groove one 18 connected with the second through groove 19, and the oil delivery tray 14 is provided with a flow guide that runs through the inside of the communication ring 22 and extends to the inside of the oil storage tank 21. Pipe 17, one side of the oil delivery tray 14 is provided with a connector 15 connected to the oil delivery pipe 16, and the connector 15 communicates with the flow guide tube 17;

[0044] The worker connects the connecting head 15 to one end of the oil delivery pipe 16, and then snaps one end of the oil delivery tray 14 into the interior of t...

Embodiment 3

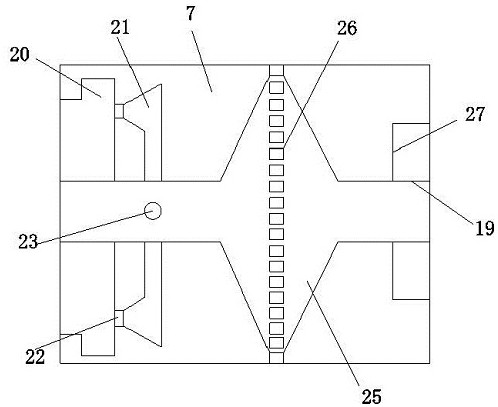

[0045] Embodiment three, on the basis of embodiment one, by figure 1 , image 3 with Figure 4 Given, the inner wall of the spraying pipe 7 is provided with a receiving groove 25, the inner wall of the receiving groove 25 is surrounded by a discharge hole 26, the receiving groove 25 is a diamond-shaped groove, and one side of the spraying pipe 7 and the connecting cover 8 is provided with a groove 27, The spraying box 1 is symmetrically provided with placement grooves 29, through the design of the storage groove 25 and the discharge hole 26, it is convenient to collect the oil dripped during the oiling process of the wire rope, and then the oil is discharged through the discharge hole 26, and the oil The collection is stored in the collection box 13, thereby realizing the saving of oil resources. At the same time, the operation of oiling the steel wire rope can be reused. The design of the placement groove 29 facilitates the work of the clamper 6 in the later stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com