Annular porous nano magnetic bead separator and mounting method thereof

A nano-magnetic bead and separator technology, applied in the preparation of test samples, etc., can solve the problems of low magnetic permeability, low separation efficiency, and weakened effect, and achieve the effect of less magnetic loss and high magnetic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

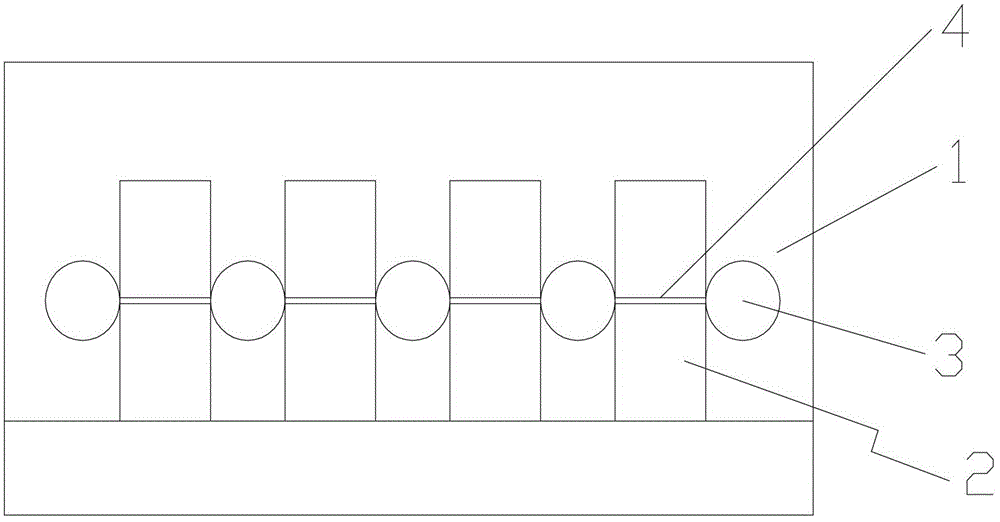

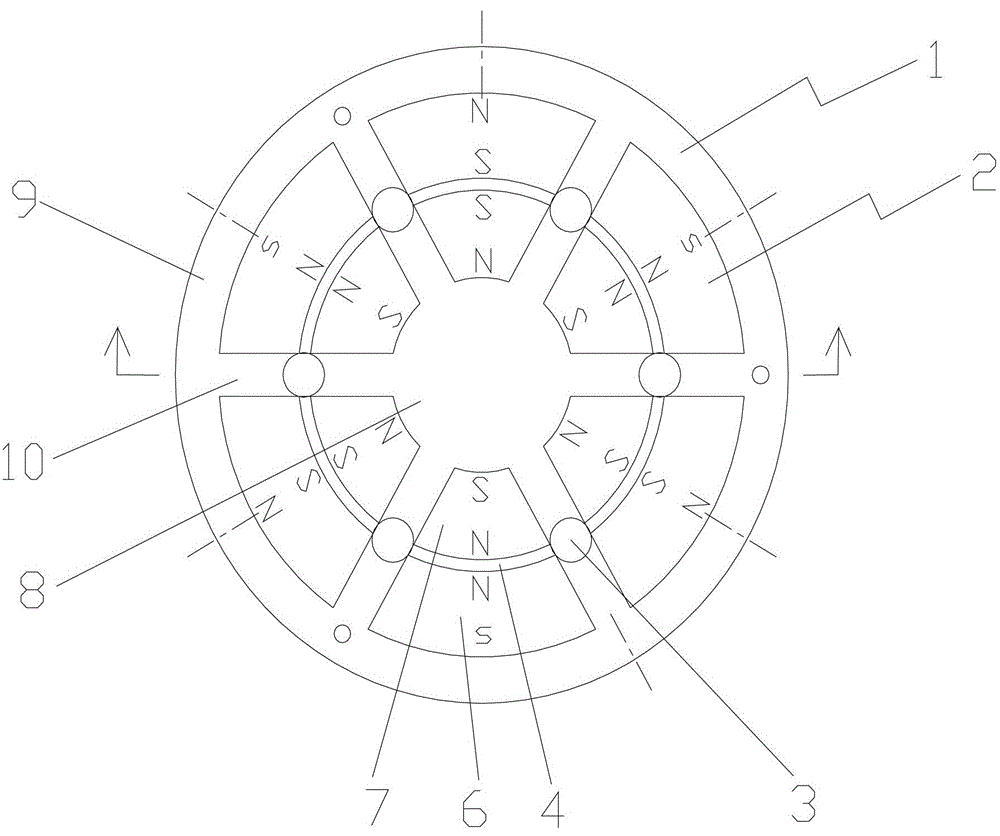

[0043] The annular porous nano-magnetic bead separator includes: a shell, six magnet groups, six metal sheets and two plexiglass plates.

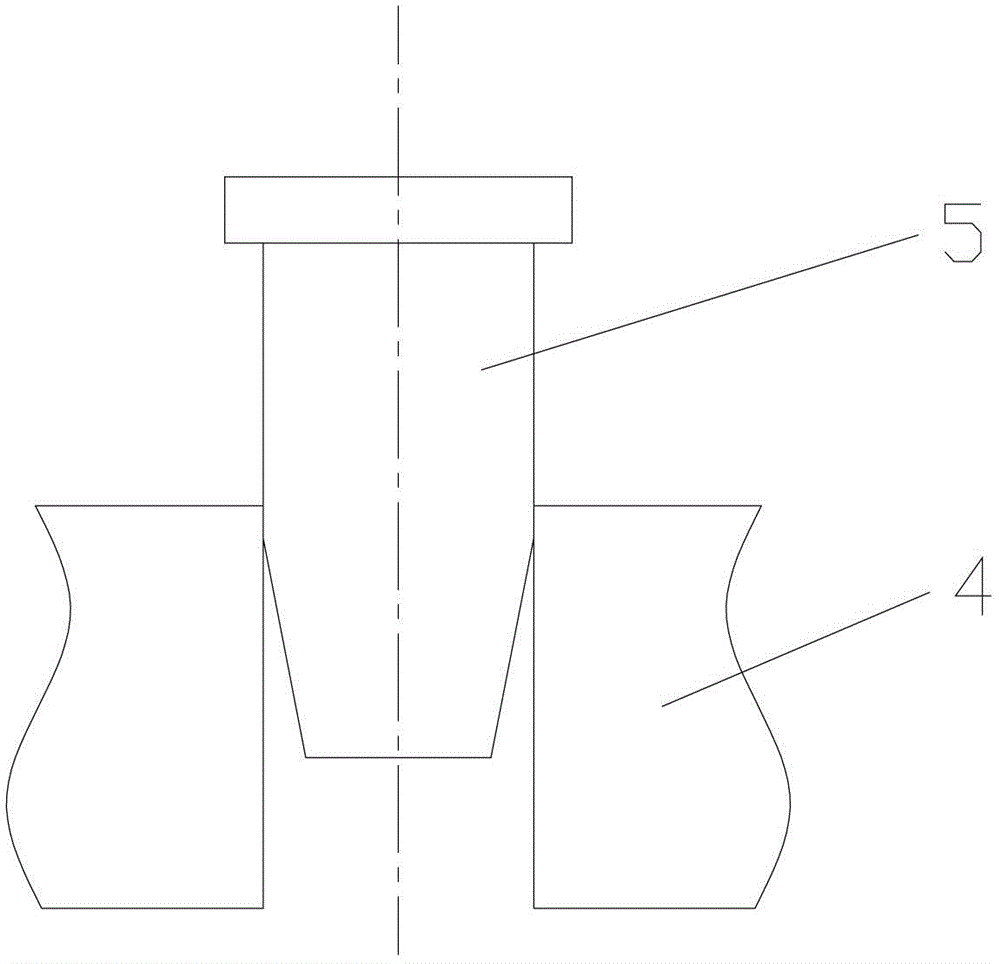

[0044] The shell includes: a circular part, a ring part and six partition parts, and the circular part, the ring part and the partition part are integrally formed. The circular portion is located at the center of the annular portion. The separator part is located between the circular part and the annular part, and its length direction is consistent with the radial direction, and the six separator parts are evenly distributed along the circumference. The circular part, the ring part and the partitions on both sides surround a tile-shaped cavity for accommodating the magnet group. Test tube holes for placing test tubes are arranged on the partition part.

[0045] The magnet group includes tile-shaped la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com