Patents

Literature

34results about How to "Improve the efficiency of magnetic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

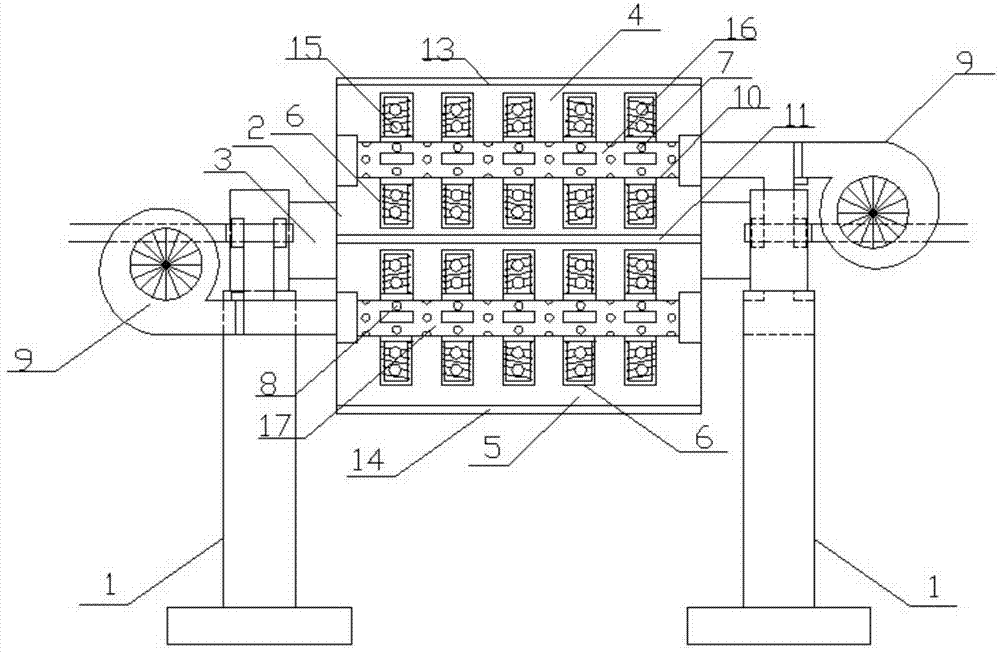

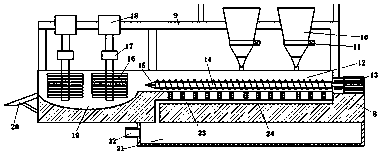

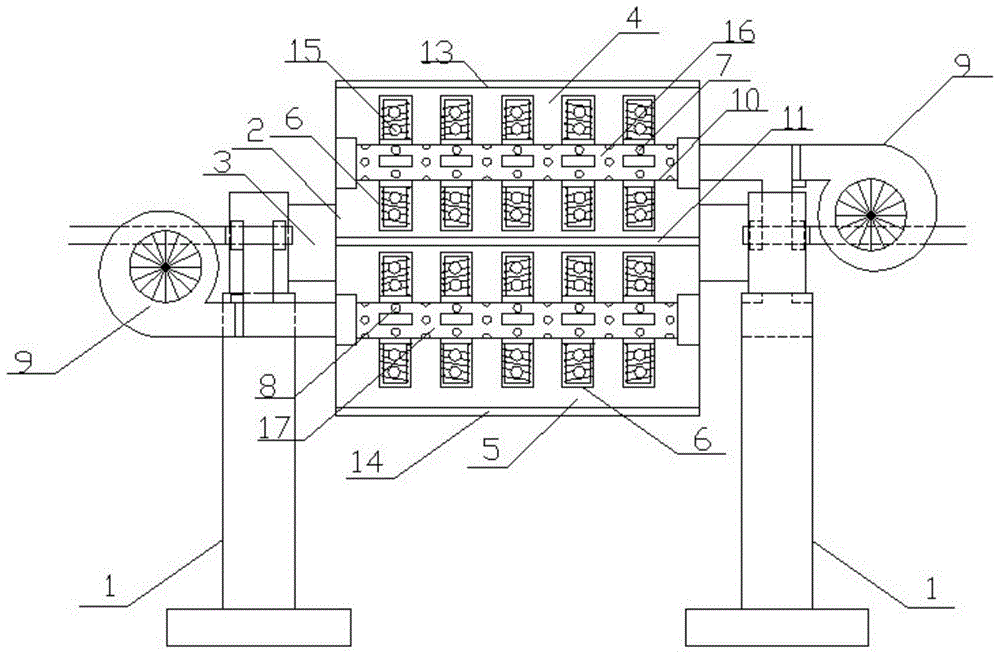

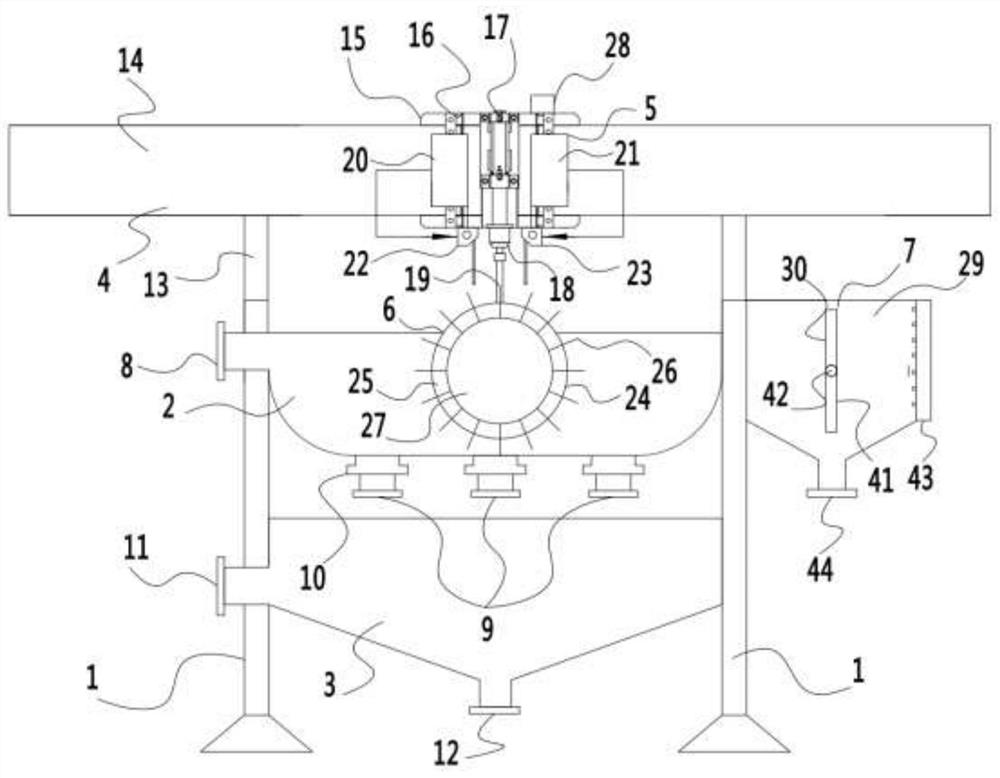

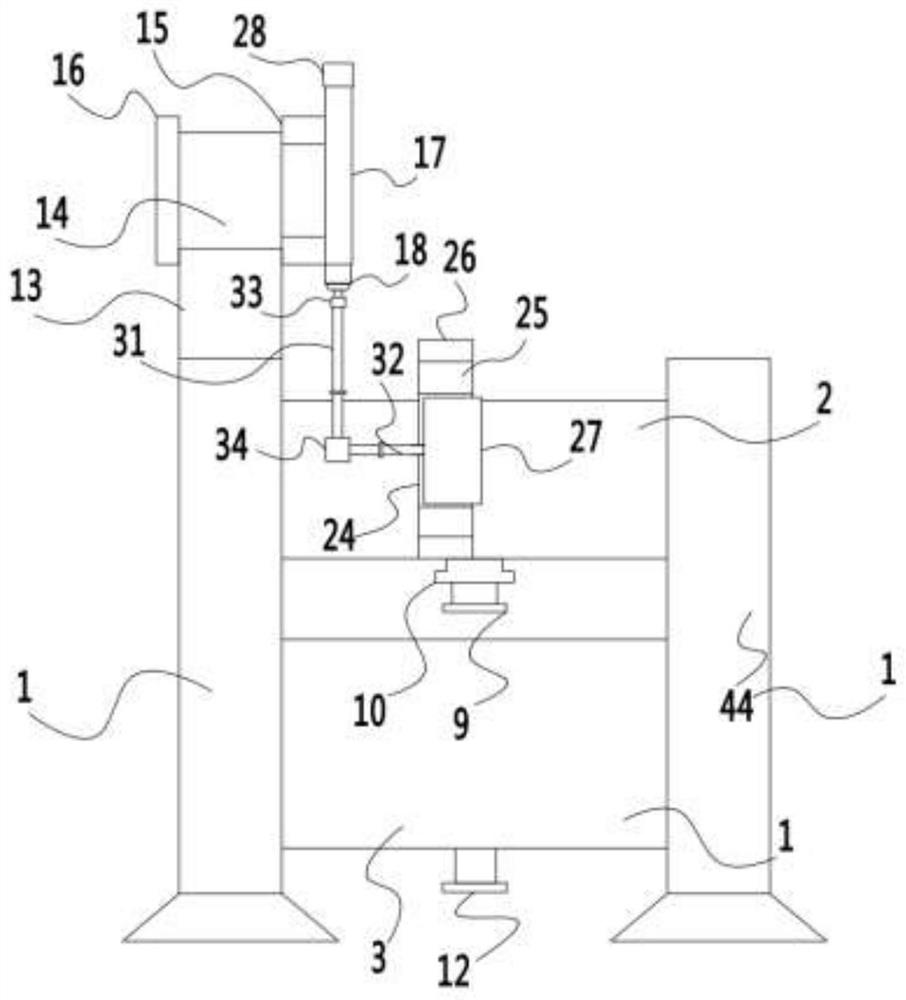

Wind dry type magnetic separator

ActiveCN105772219ACompact structureEasy to manufactureGas current separationMagnetic separationMagnetic separatorNon magnetic

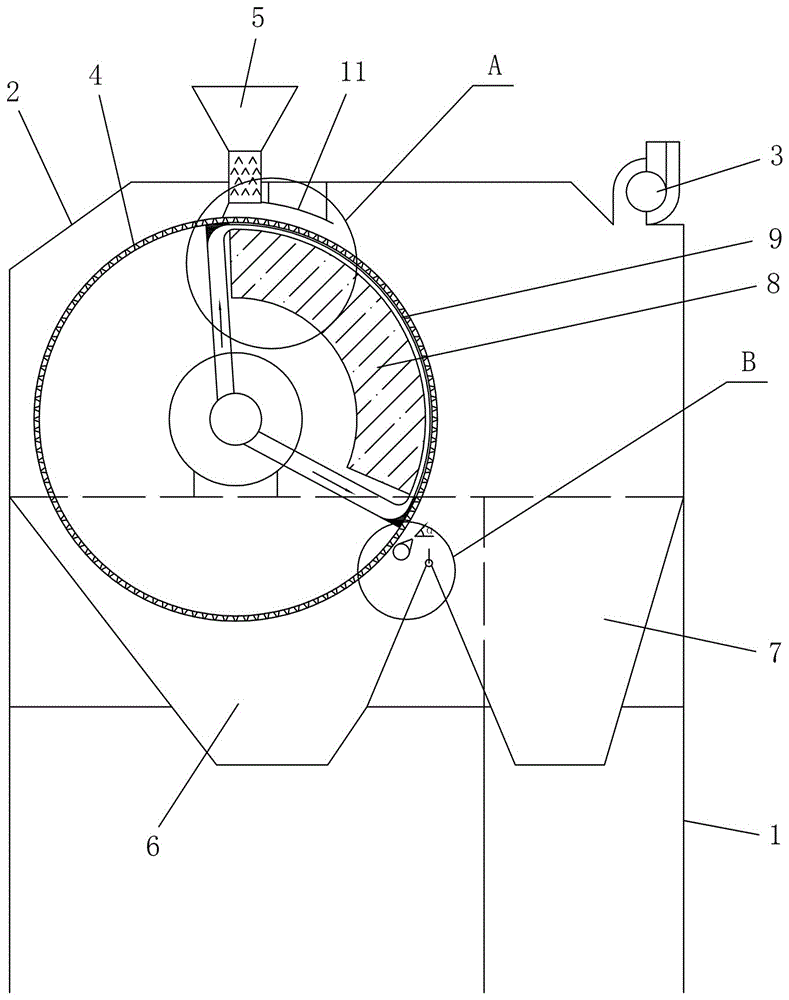

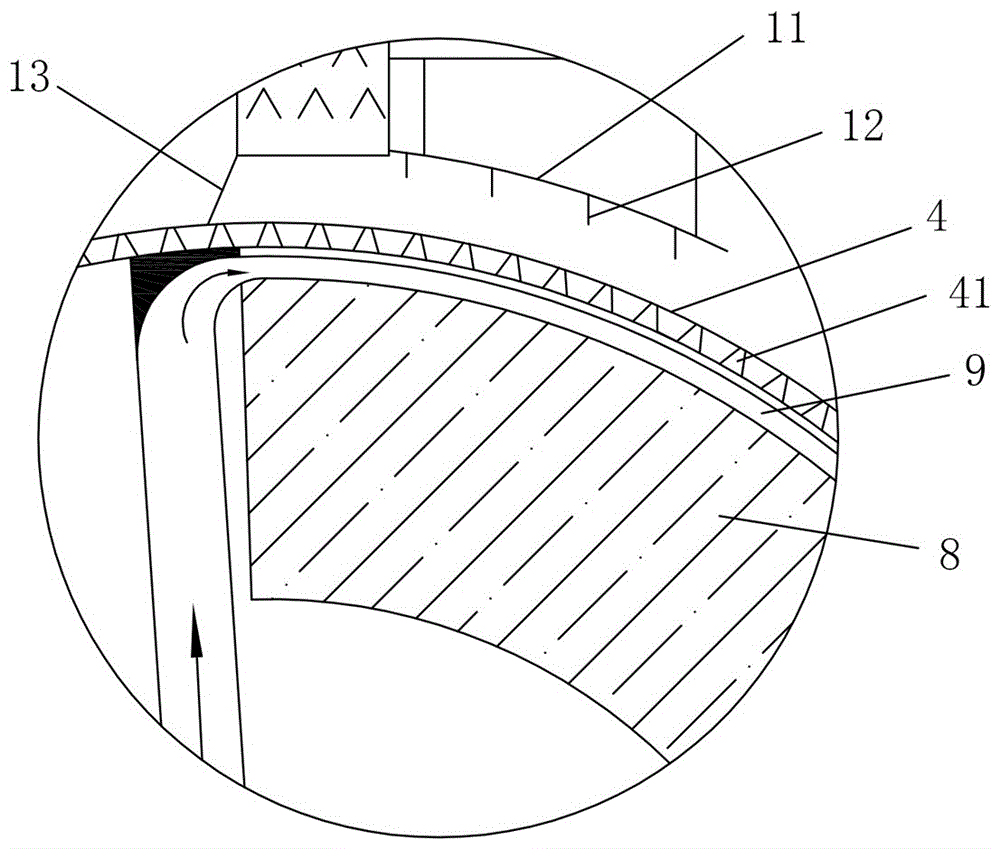

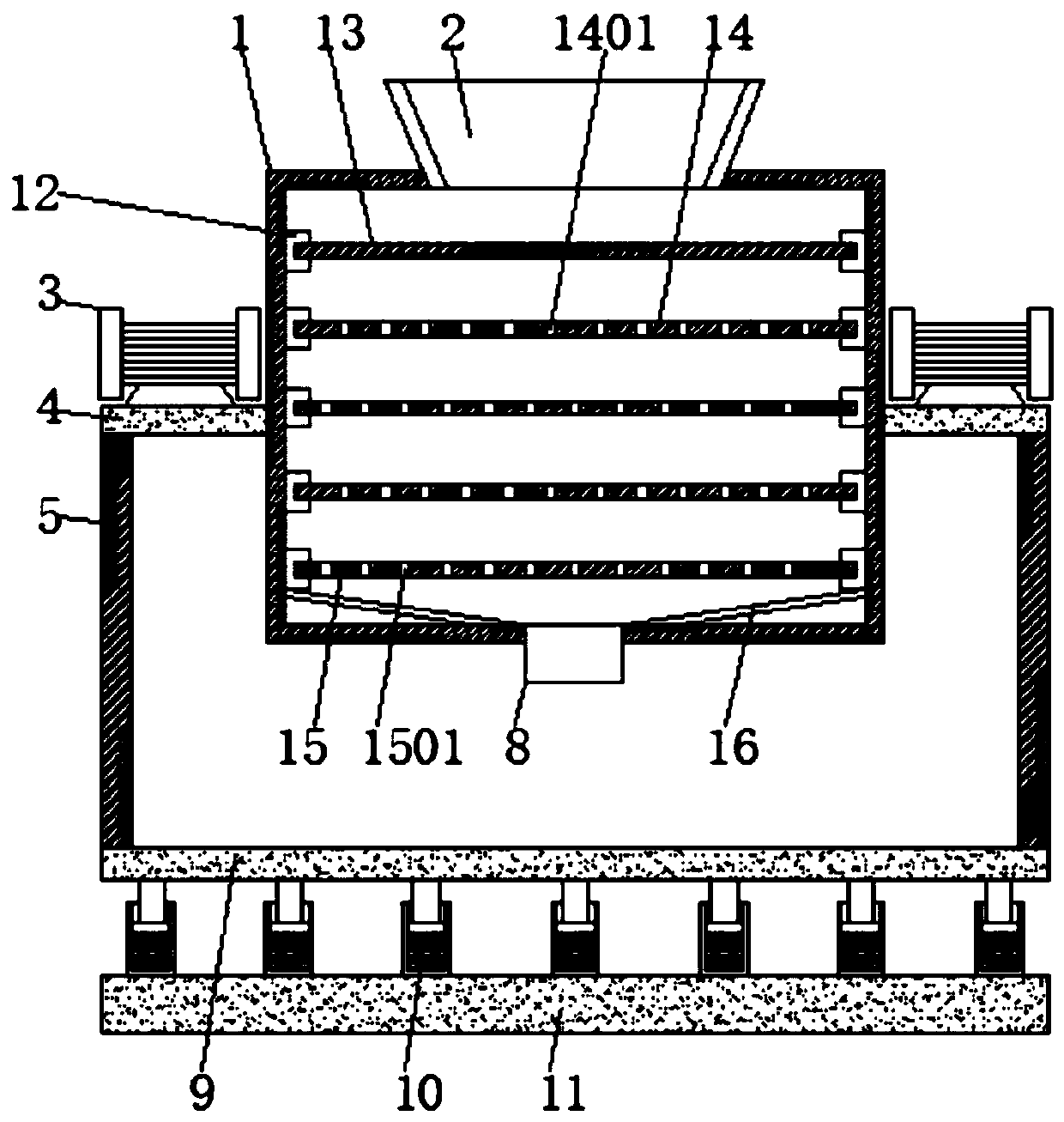

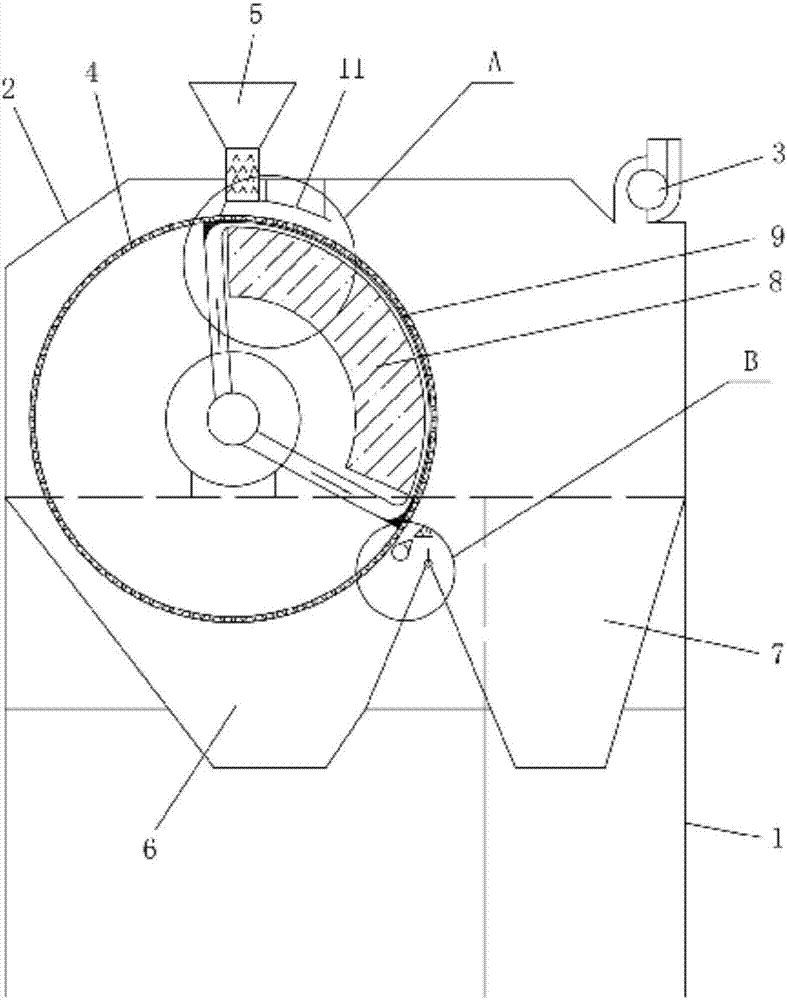

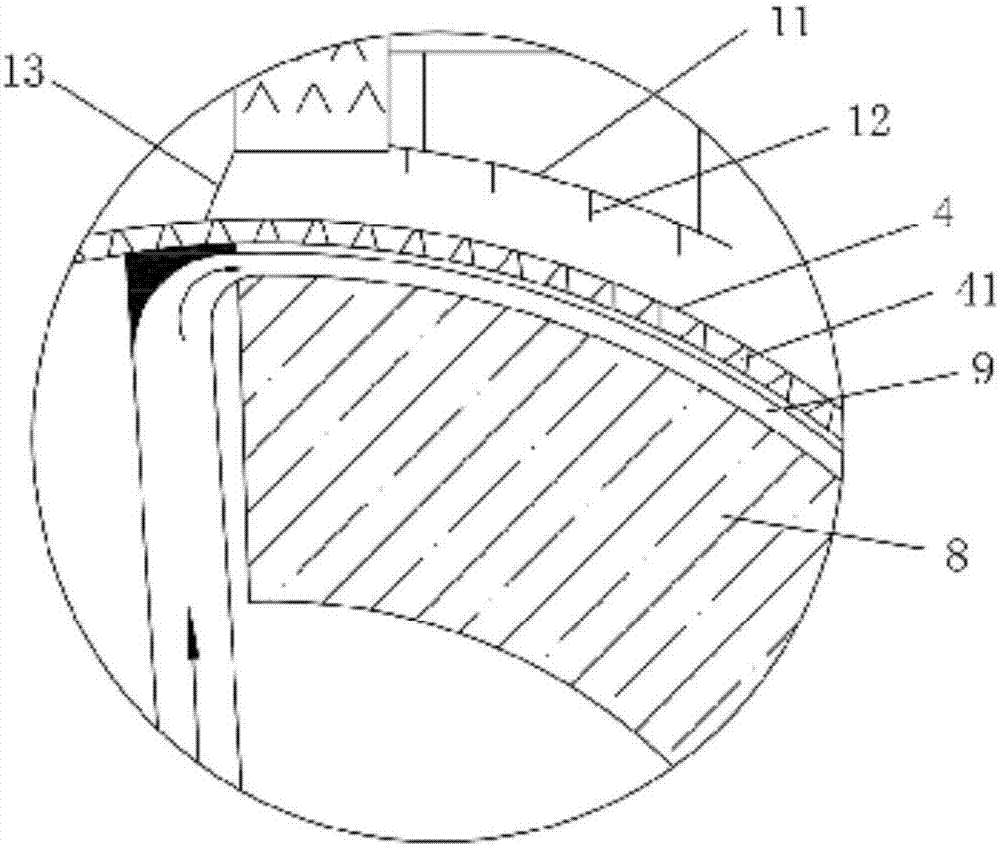

The invention discloses a wind dry type magnetic separator. The wind dry type magnetic separator comprises a rack, an enclosure, dust removing devices and a nonmagnetic cylinder screen roller, wherein the dust removing devices communicate with an inner cavity of the enclosure and are used for exhausting and removing dust; the nonmagnetic cylinder screen roller is arranged in the enclosure and is driven by a driving device to rotate; a feeding device is arranged above the nonmagnetic cylinder screen roller; a concentrate bin, a tailing bin and a discharging device are arranged below the nonmagnetic cylinder screen roller; a plurality of ventilation holes are formed in the roller surface of the nonmagnetic cylinder screen roller; a fixedly-arranged magnetic system is arranged inside the nonmagnetic cylinder screen roller; an air chamber communicating with the ventilation holes is also arranged in the nonmagnetic cylinder screen roller; the air chamber is connected with an air feeding device; a striker plate which is arranged along the rotating direction of the nonmagnetic cylinder screen roller in an extending manner from a discharge opening of the feeding device is arranged on the enclosure; and a space is reserved between the striker plate and the outer surface of the nonmagnetic cylinder screen roller. The wind dry type magnetic separator disclosed by the invention has the advantages that the structure is simple and compact, magnetic agglomeration and inclusion can be effectively reduced, the magnetic separation efficiency of materials is improved, and the like.

Owner:CENT SOUTH UNIV

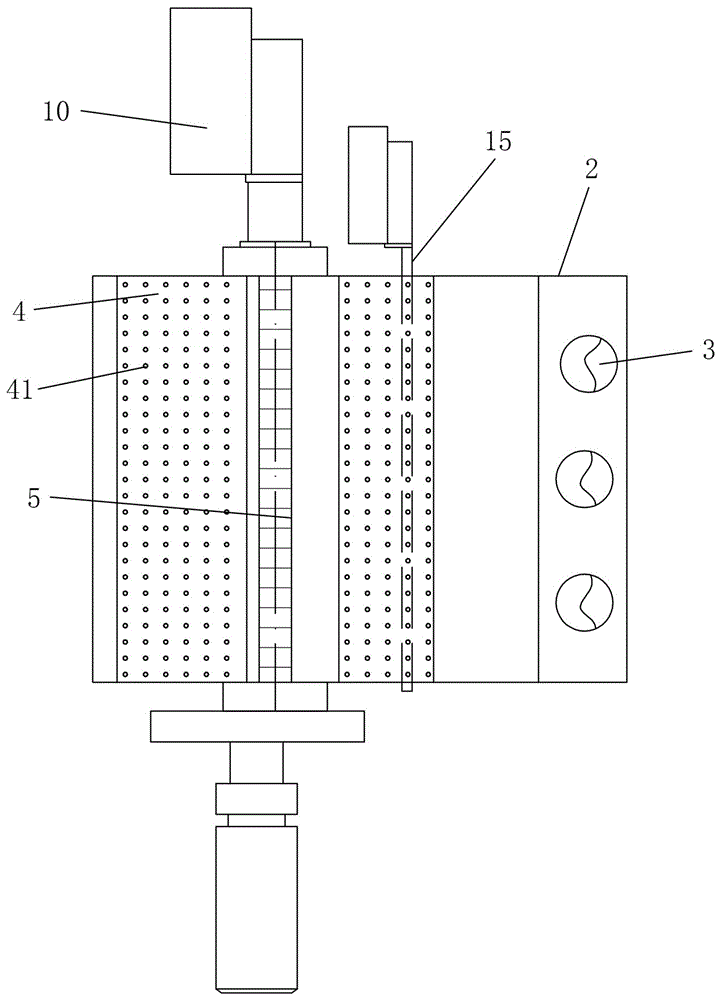

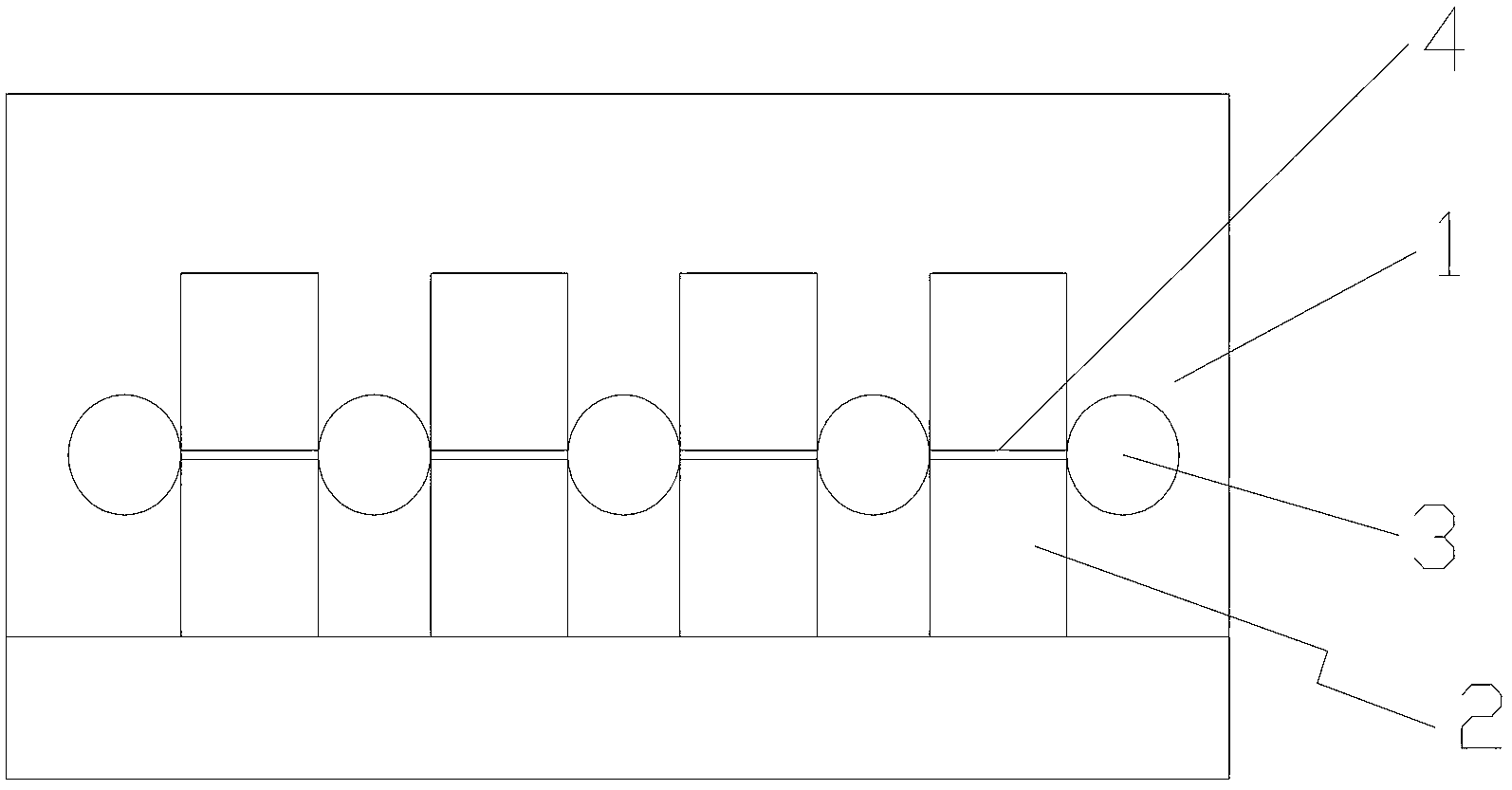

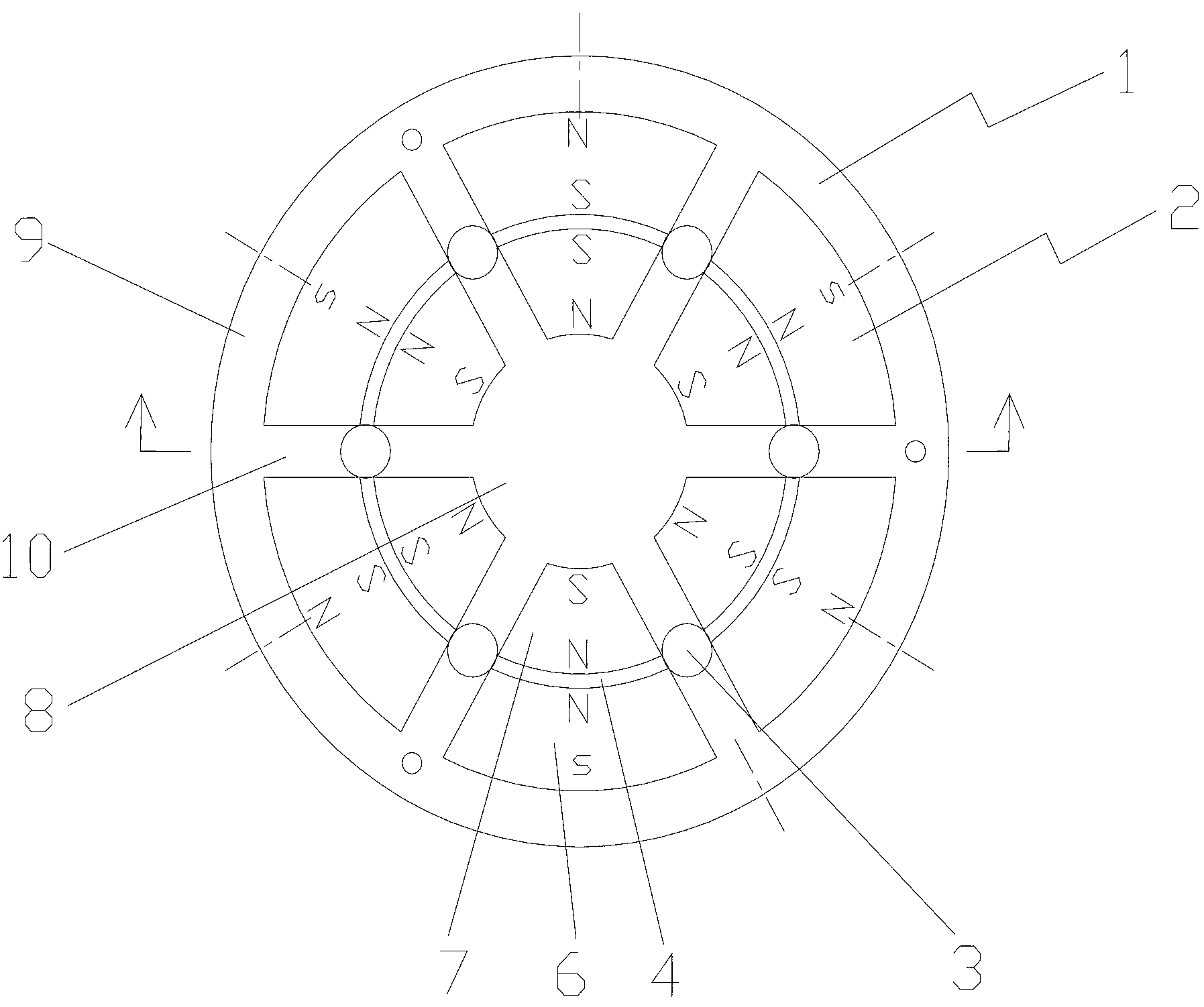

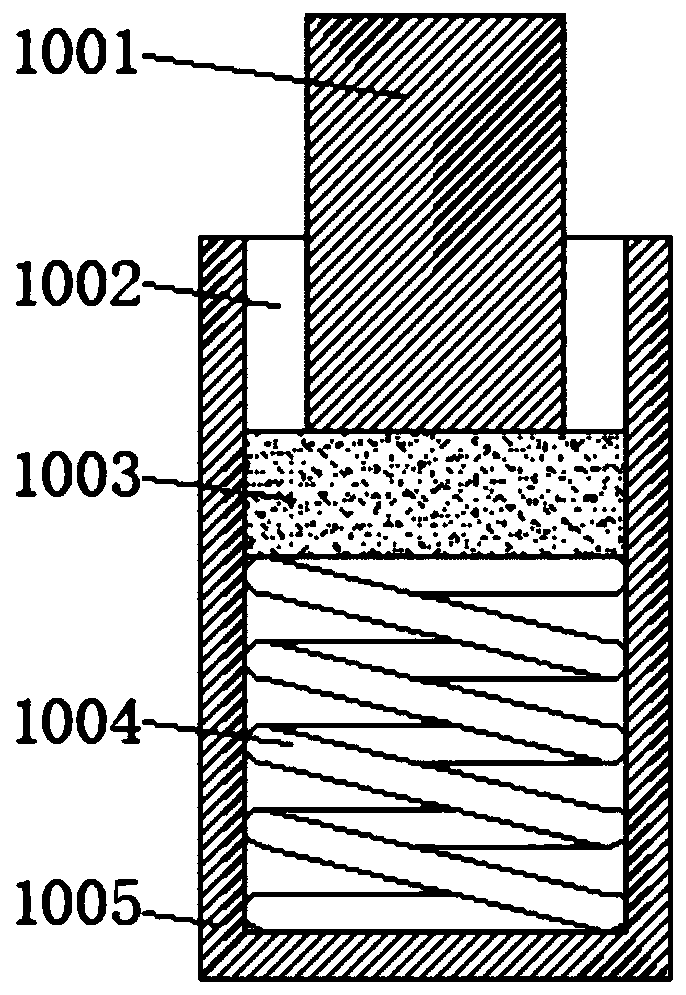

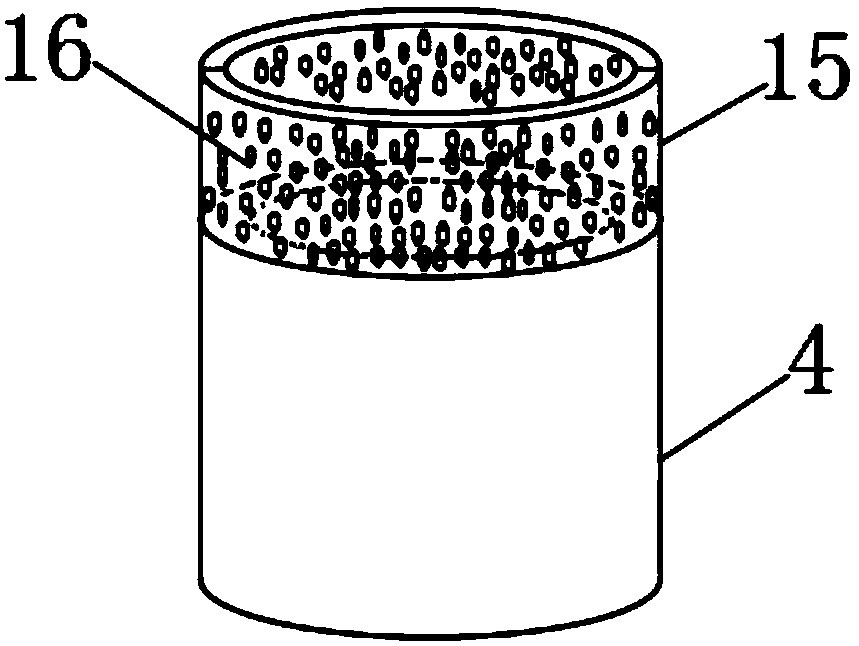

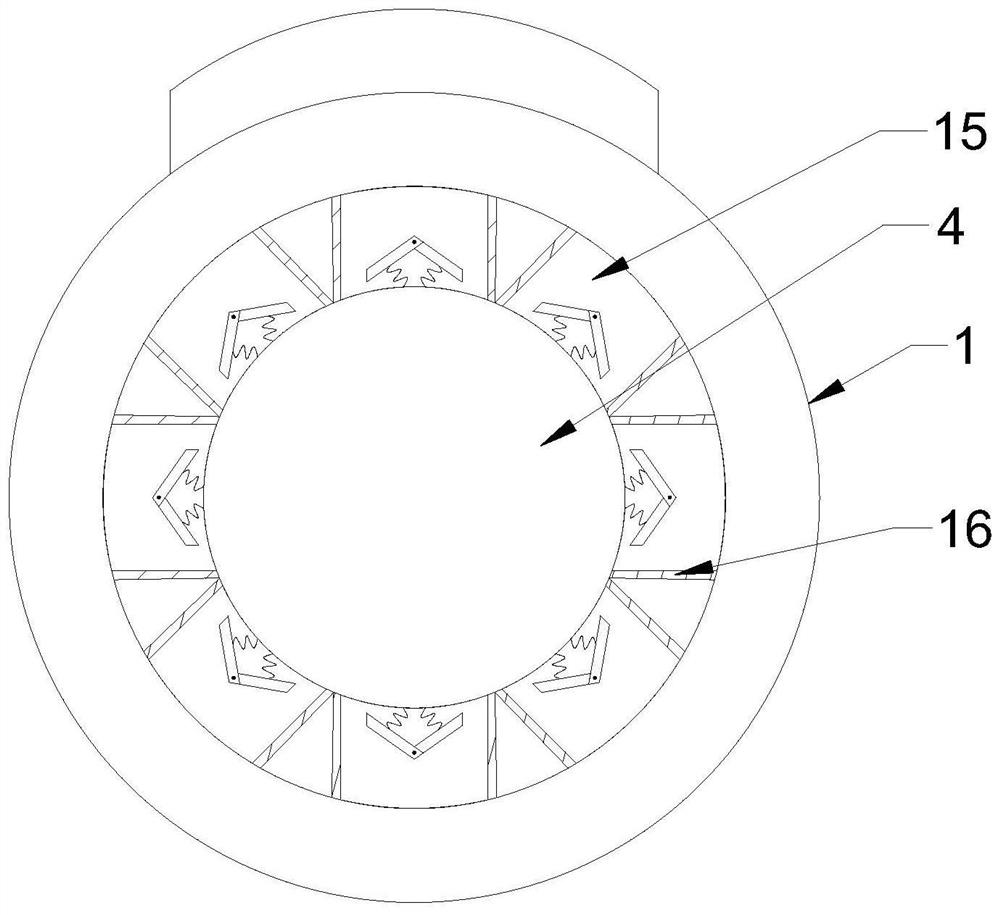

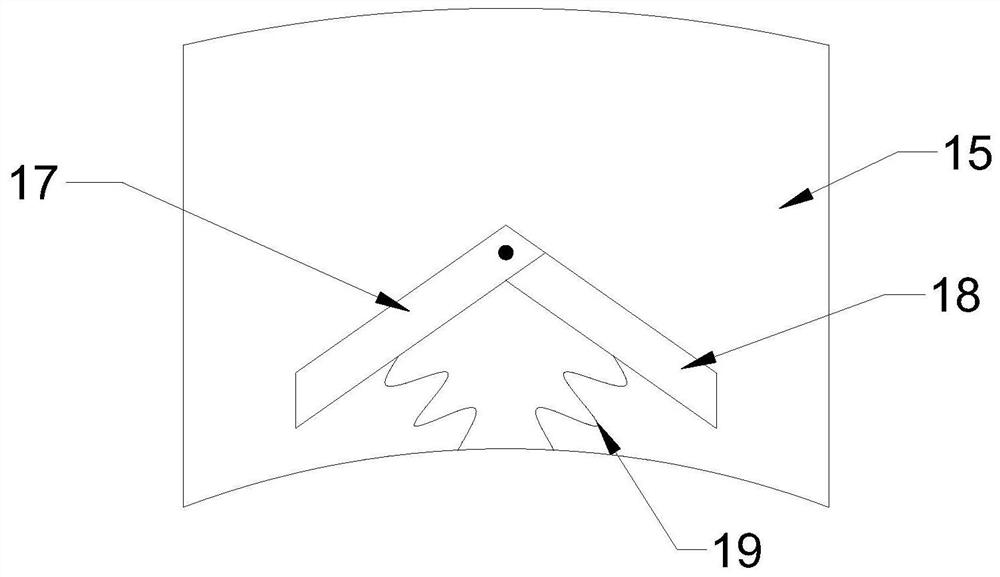

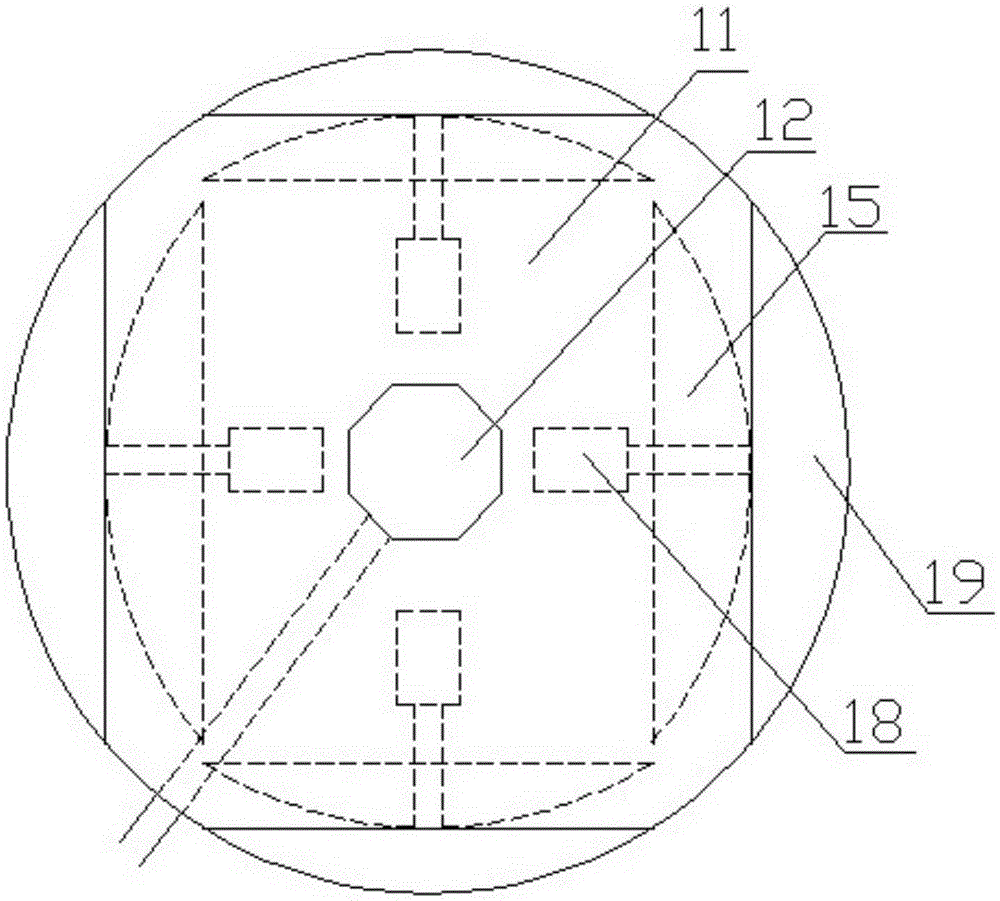

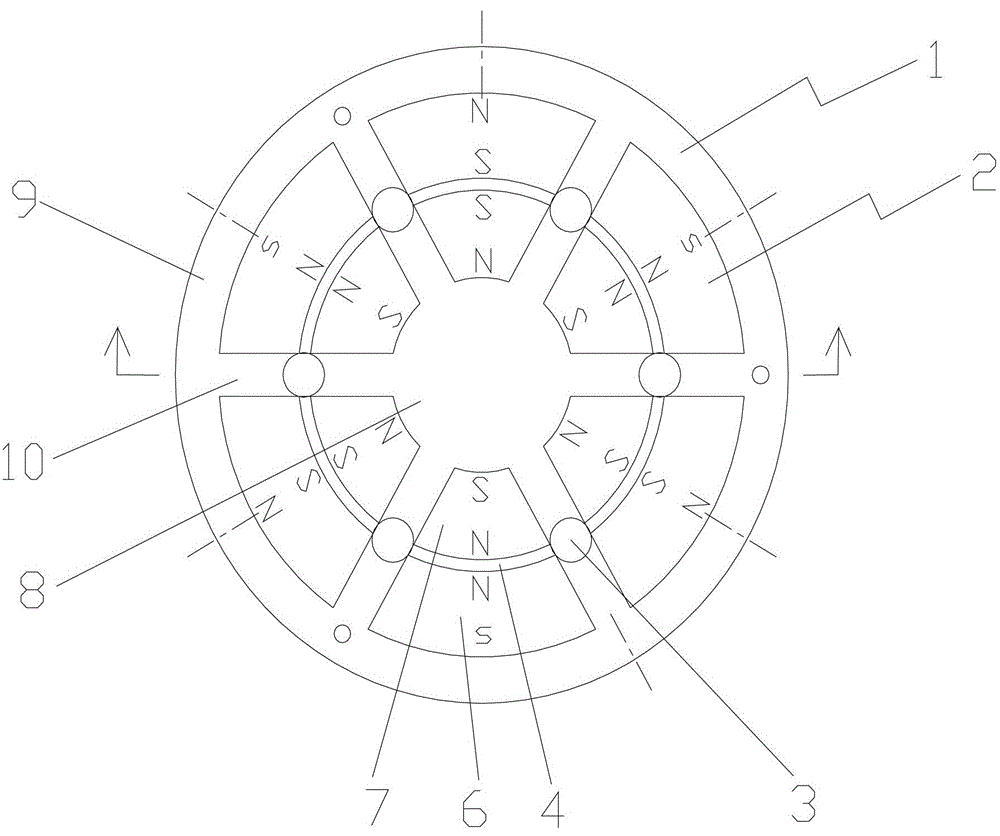

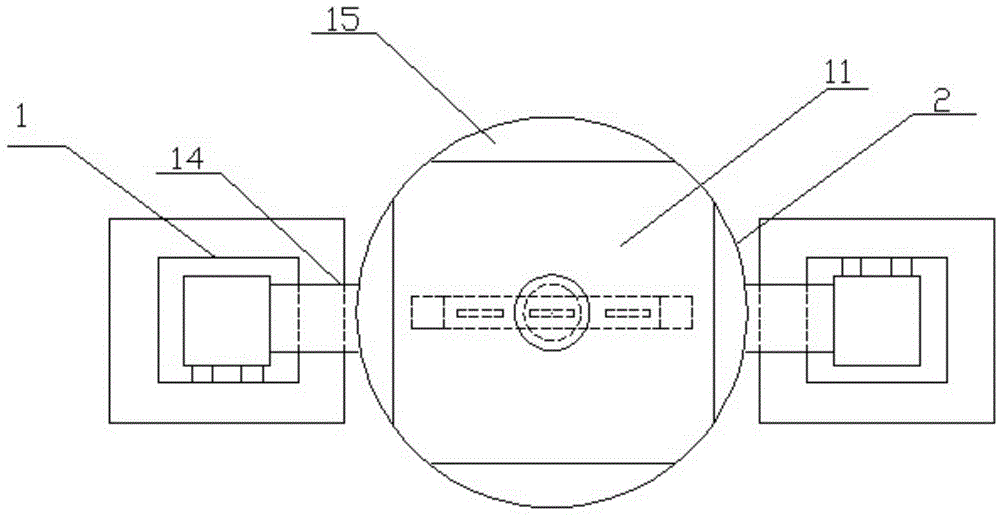

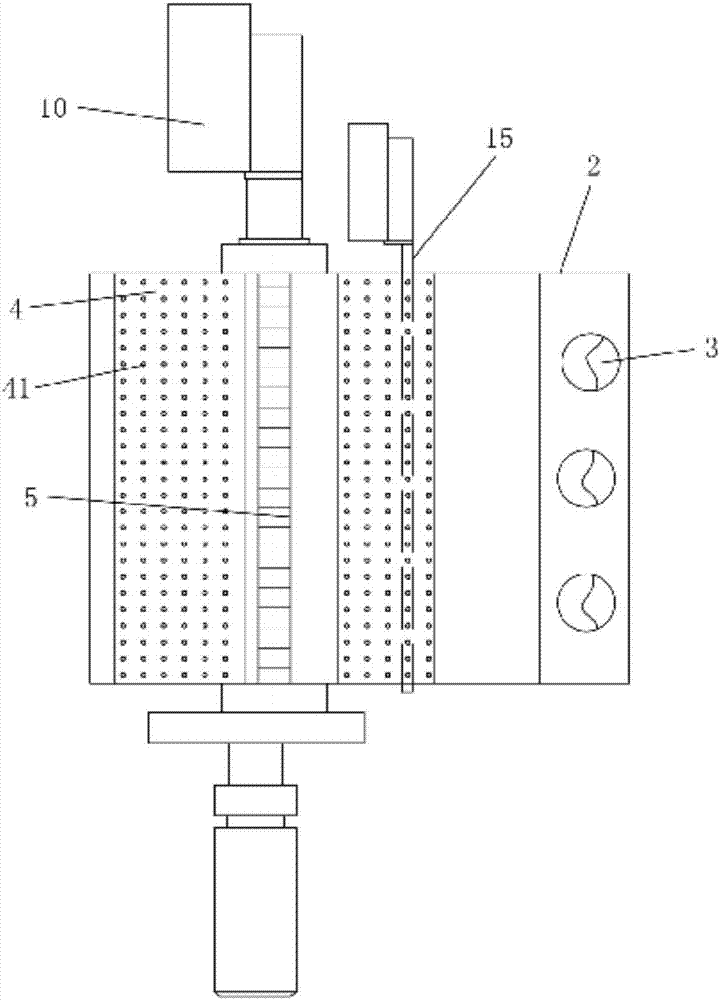

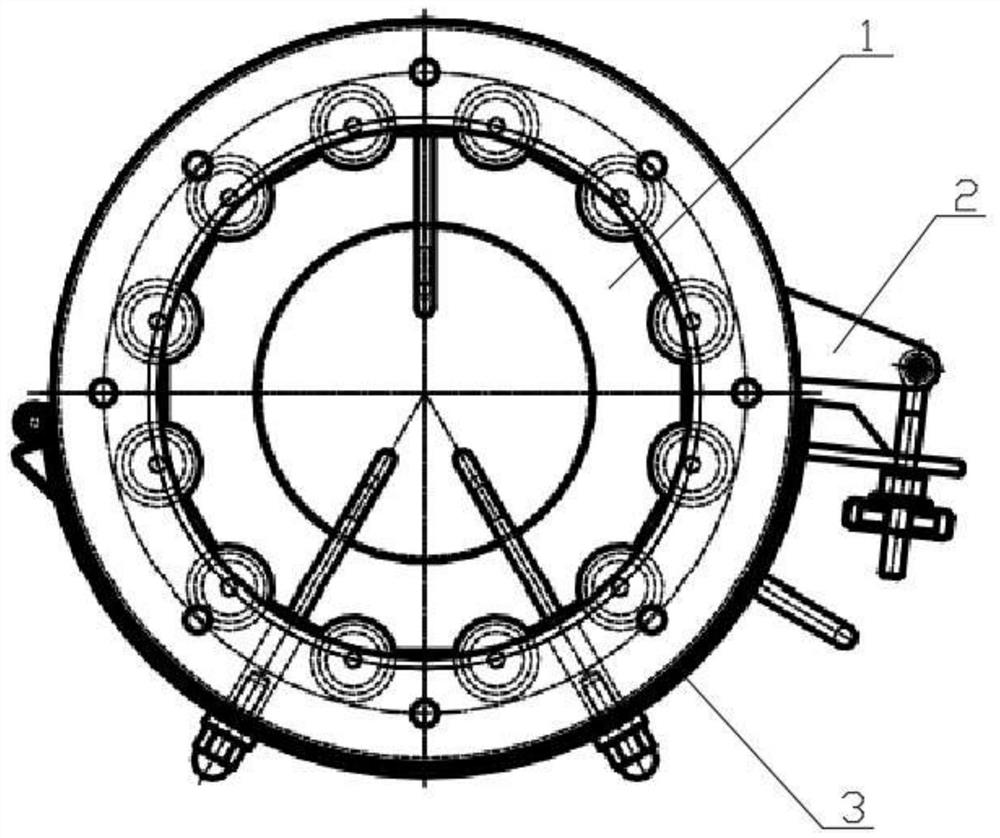

Annular porous nano magnetic bead separator and mounting method thereof

ActiveCN103185680AIncrease profitA large amountPreparing sample for investigationMagnetic beadEngineering

The invention relates to an annular porous nano magnetic bead separator which comprises a casing and magnet groups, wherein each magnet group adopts a tile shape, and the number of the magnet groups is an even number; the magnet groups are arranged in an accommodating cavity which corresponds to the shape of the magnet groups and is arranged in the casing in an annular manner; a tube hole for accommodating a tube is arranged on the casing between every two adjacent magnet groups; and the polarities of poles of every two magnet groups are contrary. The invention further relates to a mounting method of the annular porous nano magnetic bead separator. The annular porous nano magnetic bead separator and the mounting method thereof have the advantages that the utilization rate of magnets and the tube holes are effectively improved, the separation efficiency is improved, and the annular porous nano magnetic bead separator can be assembled easily. The annular porous nano magnetic bead separator belongs to the technical field of nano magnetic bead separation devices.

Owner:SOUTH CHINA AGRI UNIV

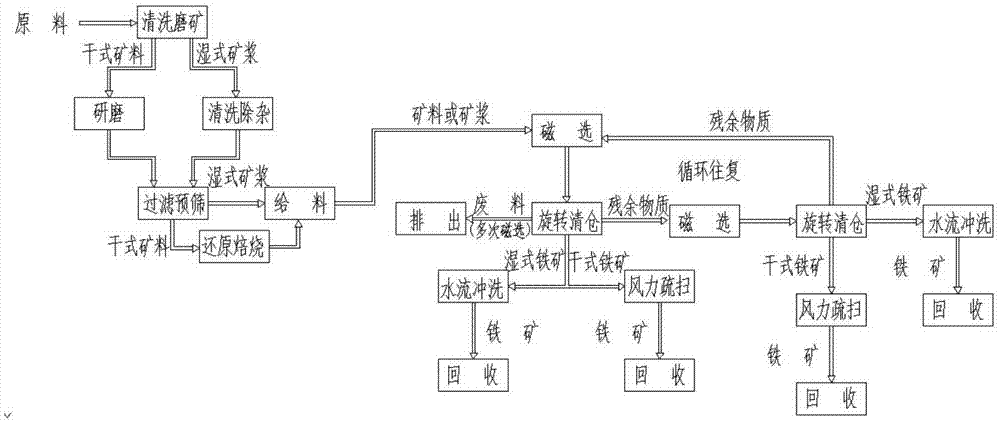

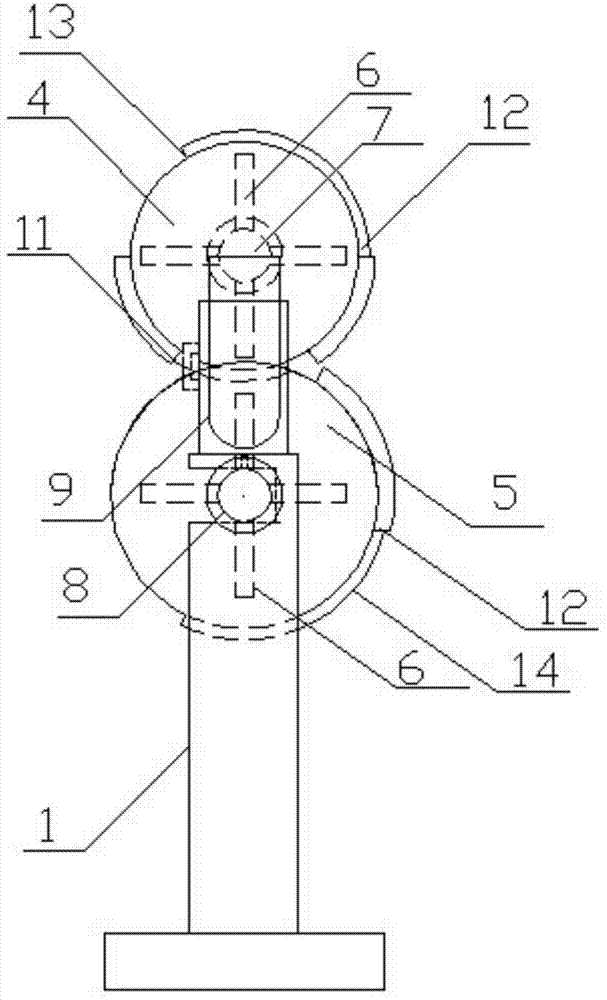

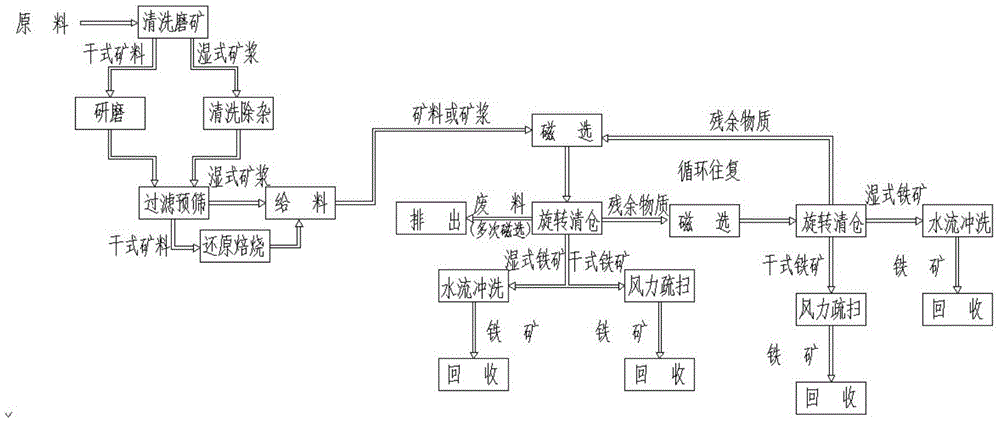

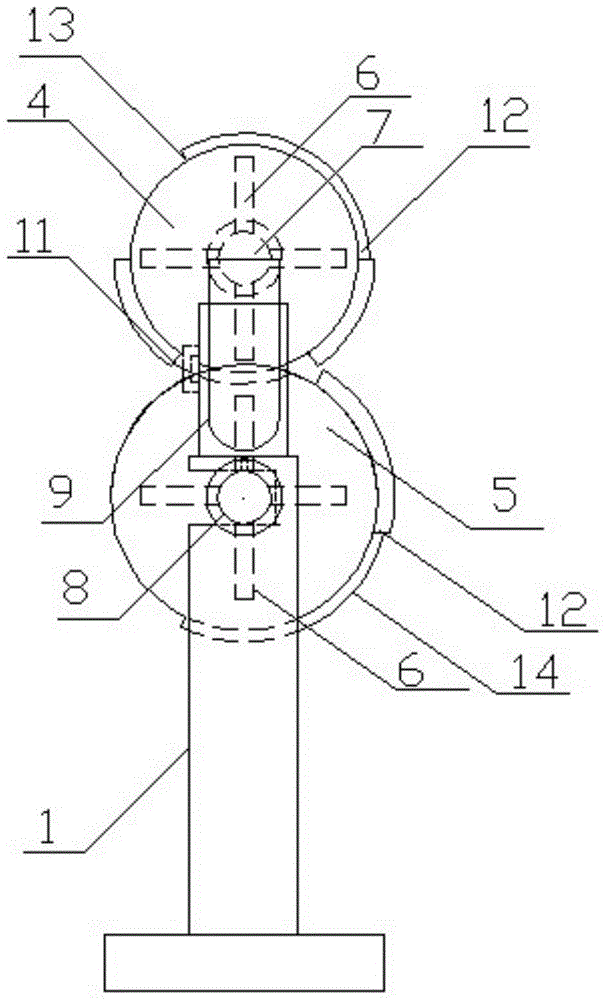

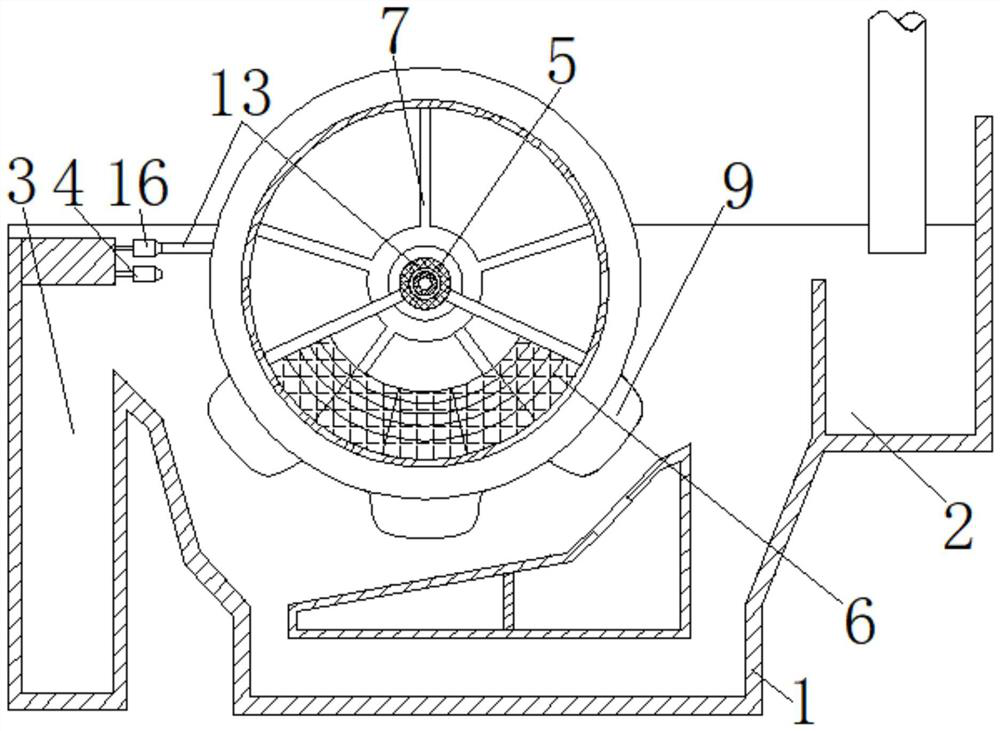

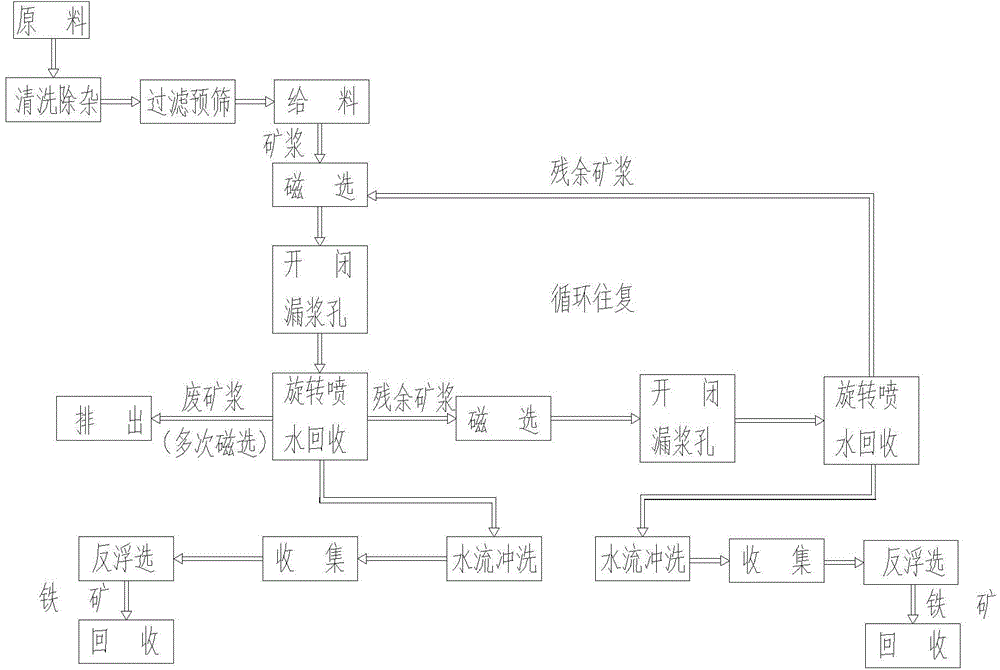

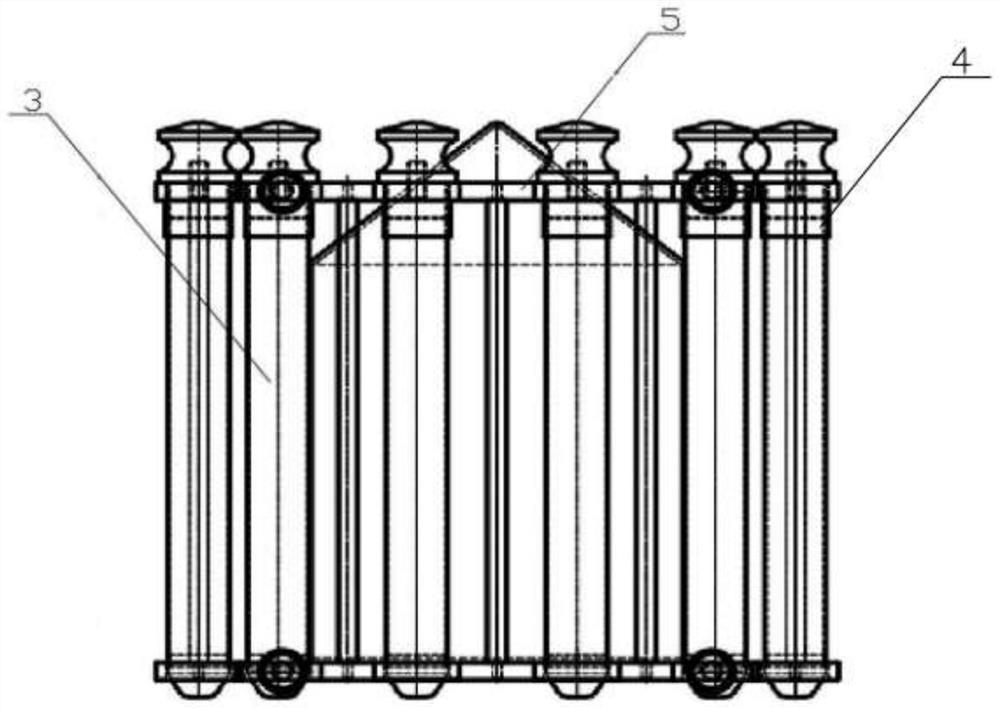

Dry and wet type cyclic magnetic separation method

ActiveCN103861730AAchieve alternationIncrease profitMagnetic separationGrain treatmentsSlagEngineering

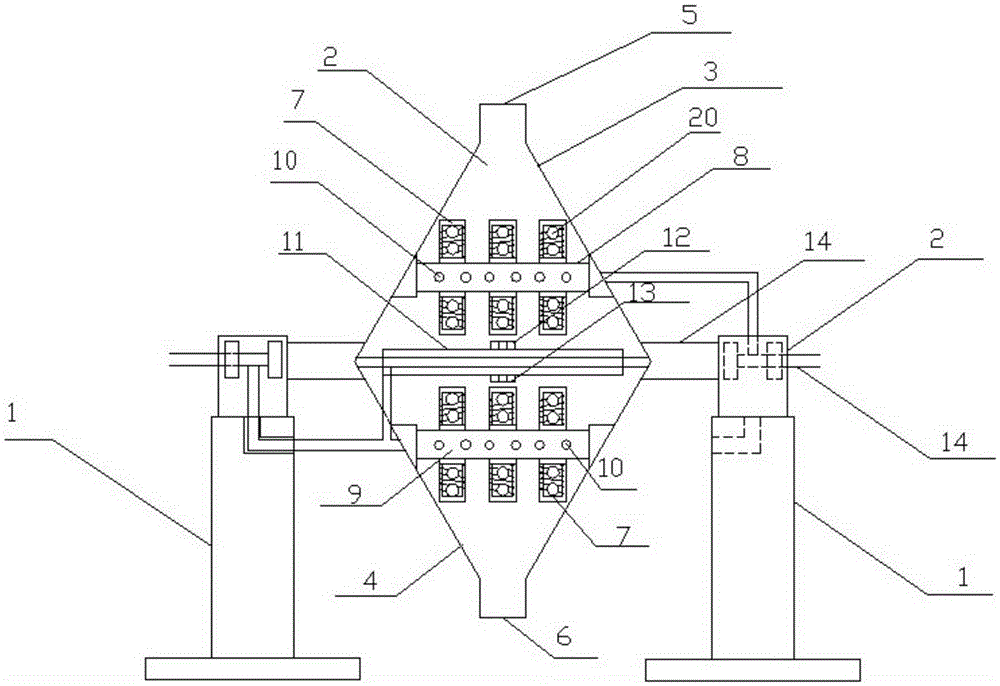

The invention discloses a dry and wet type cyclic magnetic separation method. A dry type magnetic separation method comprises the steps of a, grinding ores; b, performing pre-screening; c, performing reducing roasting; d, feeding materials; e, performing magnetic separation through an upper magnetic separation barrel; f, enabling the upper magnetic separation barrel to rotate to clean a storehouse; g, performing magnetic separation through a lower magnetic separation barrel; h, enabling the lower magnetic separation barrel to rotate to clean the storehouse; i, performing cyclic reciprocating magnetic separation; and j, rotating to discharge slag. A wet type magnetic separation method comprises the steps of a, cleaning impurities; b, performing filtering and pre-screening; c, feeding materials; d, performing magnetic separation through an upper magnetic separation barrel; e, enabling the upper magnetic separation barrel to rotate to clean a storehouse; f, performing magnetic separation through a lower magnetic separation barrel; g, enabling the lower magnetic separation barrel to rotate to clean the storehouse; h, performing cyclic reciprocating magnetic separation; and i, rotating to discharge slag. The device adopts a unique double-barrel circulating structure; when the circulating structure rotates to different positions under the driving of a driving device, river sand or metal mortar can be cyclically separated between the two hollow barrels. The whole process of the method is automatically controlled by a circuit, so that the waste of human resources is reduced, and the problems that a separation method is complicated, a separation process is long and the like are solved.

Owner:黄山市开发投资集团有限公司

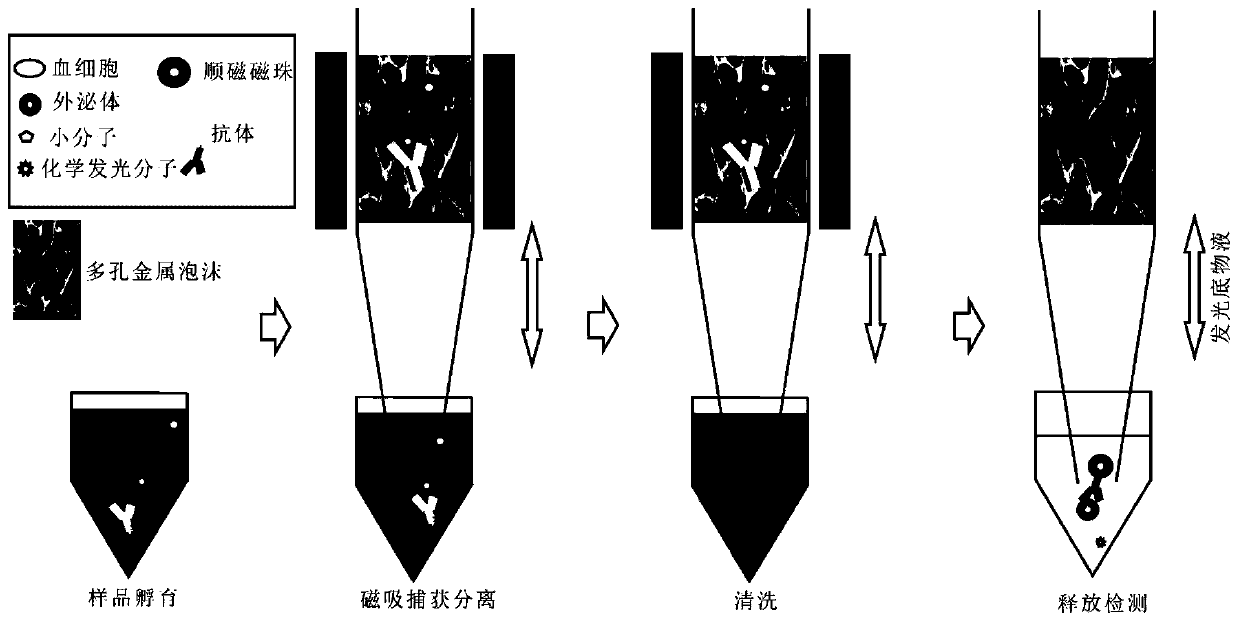

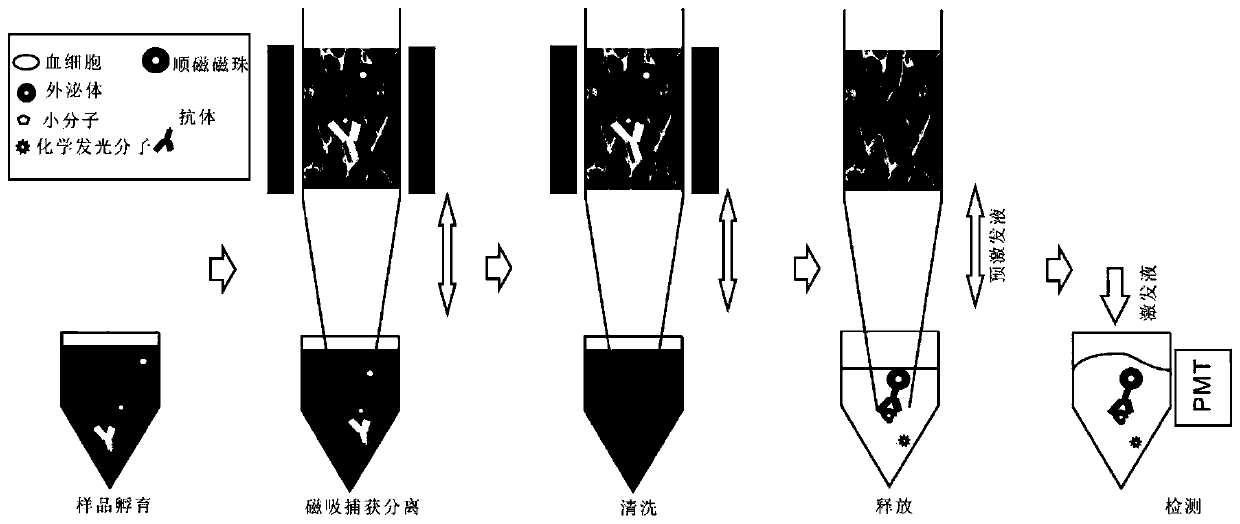

Magnetic immunochemiluminescence detection method for PD-L1 exosomes

InactiveCN109781999AIncreased chance of collisionStrong specificityChemiluminescene/bioluminescenceBiological testingMagnetic beadImpurity

The invention discloses a magnetic immunochemiluminescence detection method for PD-L1 exosomes and belongs to the technical field of rapid in-vitro detection. A kit used in detection contains an antibody A, an antibody B, a porous metal foam-filled hollow column, and a magnet; the antibody A is a chemiluminescent molecule exosomal antibody or an enzyme-labeled exosomal antibody which is capable ofmaking a substrate emit light; the antibody B is a magnetic bead-labeled exosomal antibody; at least one of the antibody A and antibody B is an exosome PD-L1 antibody. The detection method includes the following steps that: the antibody A, the antibody B and a sample are incubated; efficient capture and separation are realized by means of the porous metal foam magnet; and after impurities are cleaned, a magnetic field is removed, and a double-antibody sandwiched composite is collected and detected. The method integrates sample incubation, magnet efficient capture and separation, and rapid detection, and has the advantages of convenient operation, rapid detection, low cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

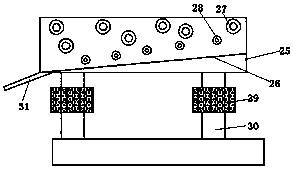

Magnetic separation device for high-purity quartz sand production and processing

The invention discloses a magnetic separation device for high-purity quartz sand production and processing. The device comprises a casing. Outer walls of two sides of the casing are equipped with mounting plates, upper surfaces of the mounting plates are equipped with vibration motors, a connecting plate is installed on one side of a lower surface of each mounting plate, the other end of each connecting plate is mounted on an upper surface of a supporting plate, a lower surface of the supporting plate is connected to an upper surface of a base by up-and-down vibration mechanisms, a flow equalizing plate is set at an upper part in the casing, two first plate-shaped electromagnets and two second plate-shaped electromagnets are disposed directly under the flow equalizing plate, and the two first plate-shaped electromagnets and two second plate-shaped electromagnets are misaligned with each other. The problem of a poor magnetic selection effect of an existing magnetic separation device forhigh-purity quartz sand production and processing is solved, and the magnetic separation device of the invention has the advantages of convenience in use, simple structure and high practicability.

Owner:新沂市引河石英材料有限公司

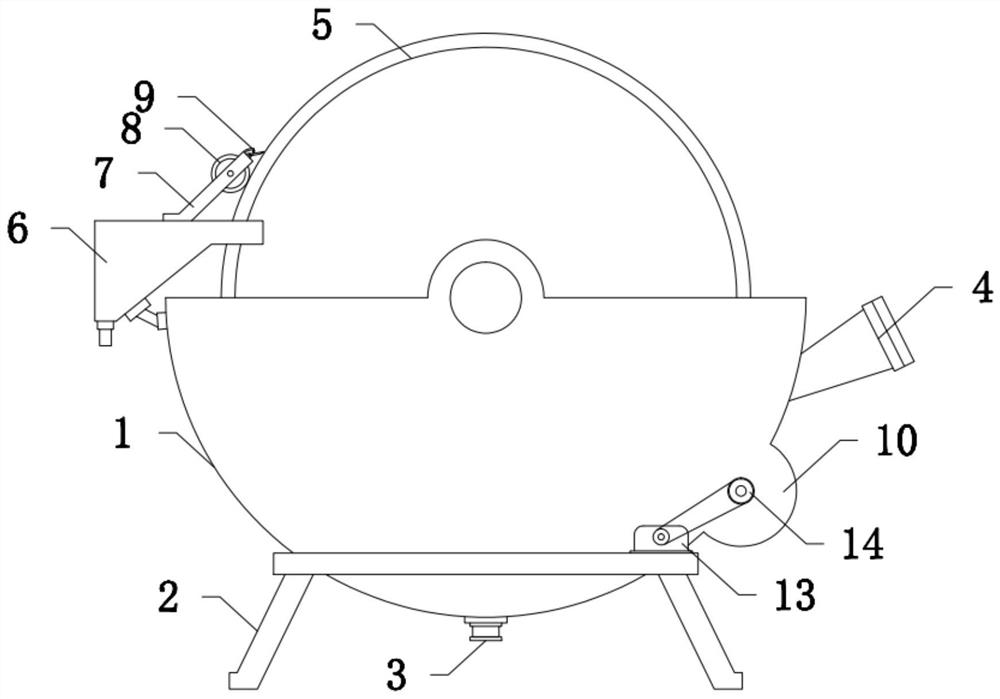

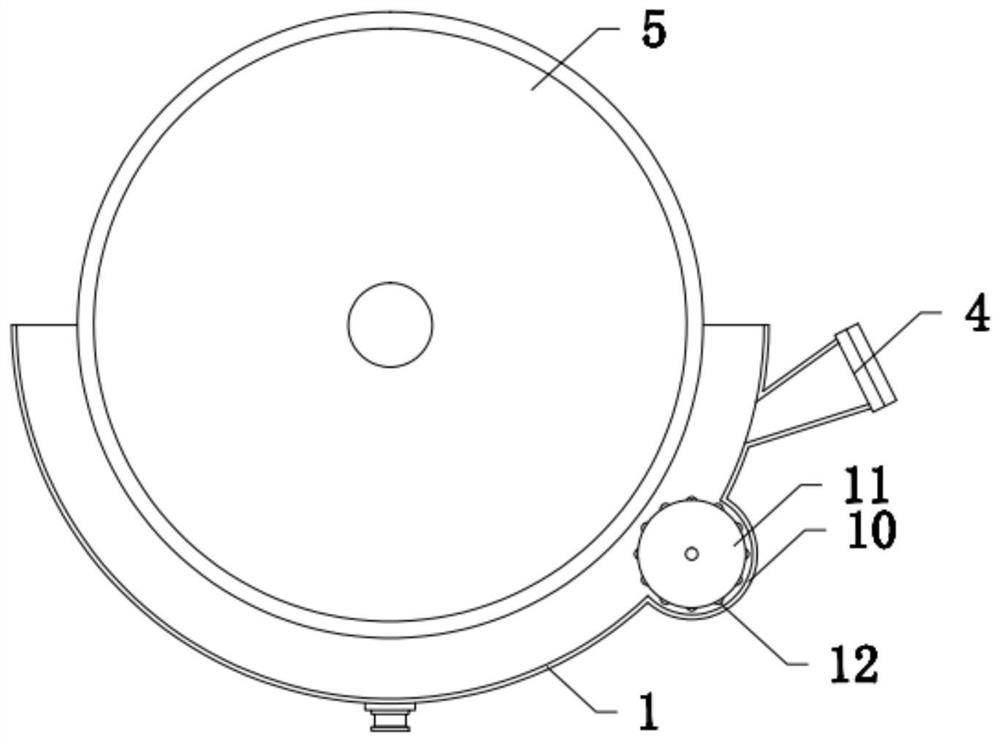

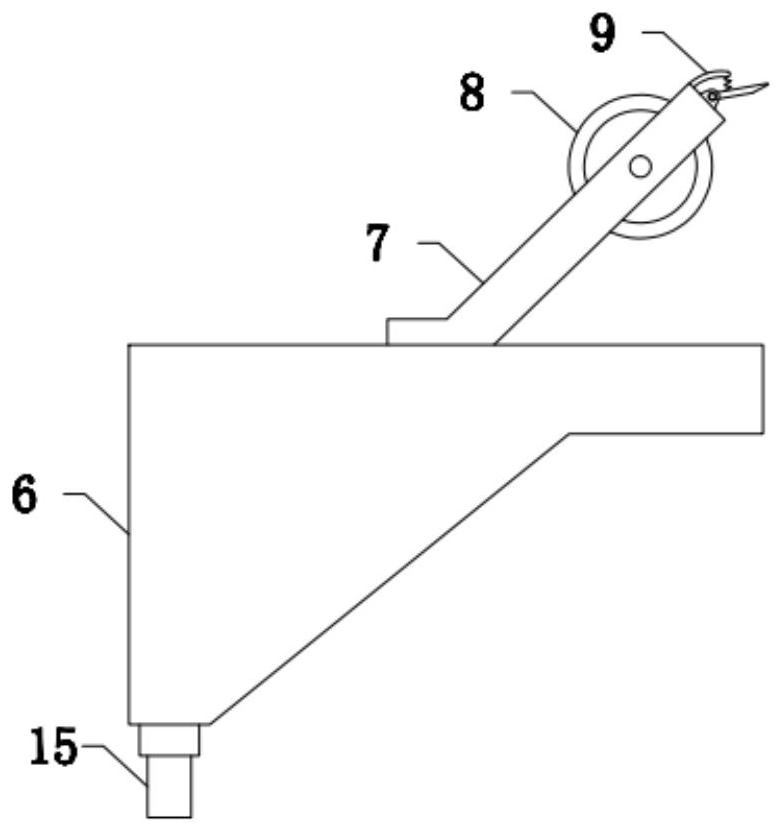

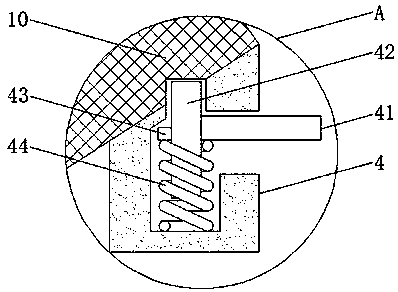

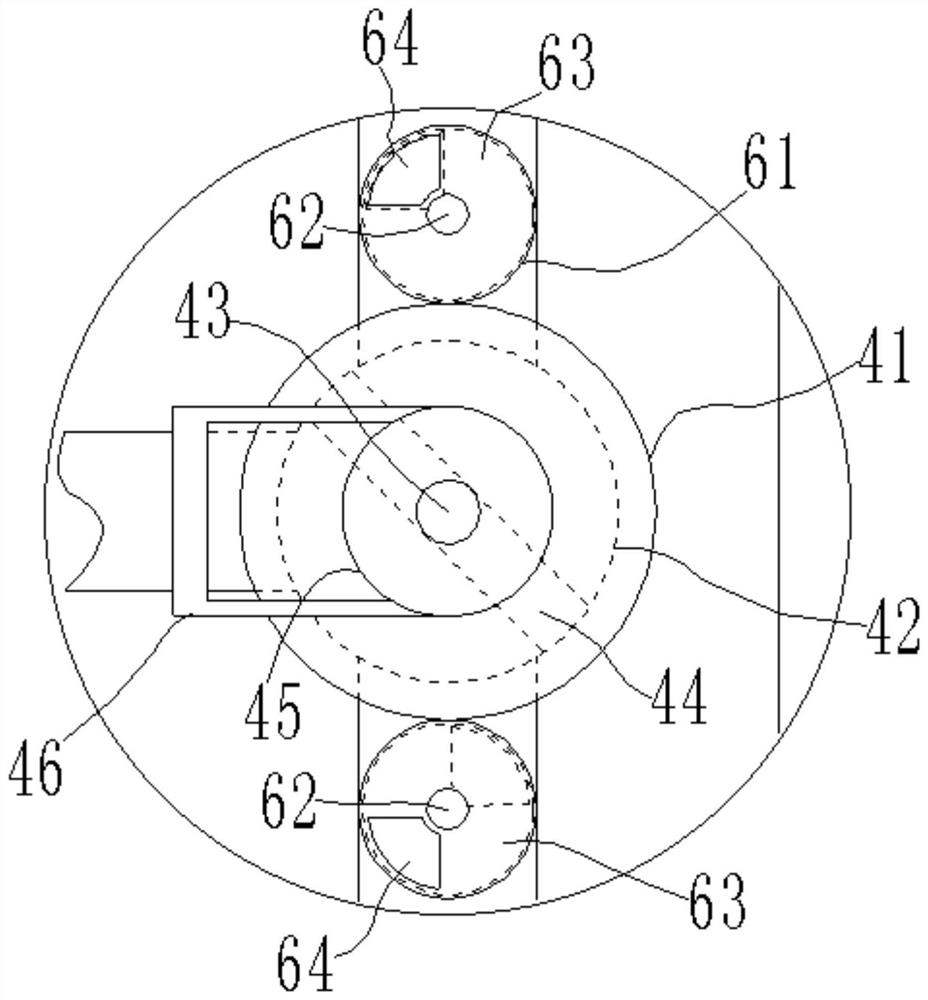

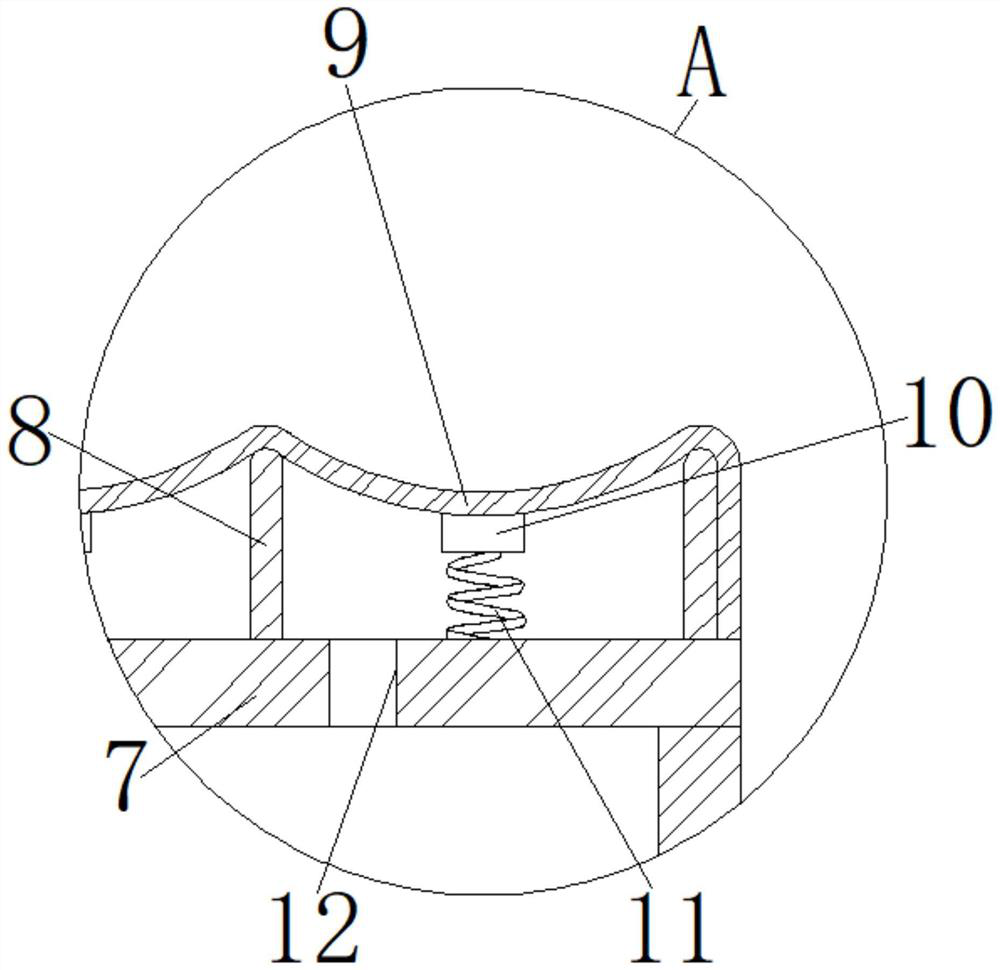

Raw material magnetic separation device for preparing rubber-plastic filler by taking lithium slag as raw material

InactiveCN111632759AEasy to separateImprove the efficiency of magnetic separationDirt cleaningCleaning using toolsElectric machineryDrive motor

The invention discloses the technical field of green resource utilization of industrial solid wastes, particularly to a raw material magnetic separation device for preparing a rubber-plastic filler bytaking lithium slag as a raw material. The device comprises a semicircular outer cylinder body, an inner cavity of the semicircular outer cylinder is connected with a magnetic separation roller through a rotating shaft; the magnetic separation roller is driven by a driving mechanism to rotate, and a support is arranged at the bottom of the semicircular outer cylinder; through the cooperation of asmashing bin, a smashing roller, a driving motor and a belt wheel mechanism, added lithium slag materials can be smashed in a grinding mode, so that magnetic particles in the materials are conveniently separated, and the magnetic separation efficiency is improved. Under the matching action of a limiting stop block, a scraper body and a supporting spring, a scraper body is elastically pressed on the outer wall of the magnetic separation roller, so that the scraper body is stably in contact with the outer wall of the magnetic separation roller, and materials on the outer wall of the magnetic separation roller are conveniently scraped off; and through the arrangement of a loosening brush roller, magnetic particles on the outer wall of the magnetic separation roller can be loosened and conveniently scraped off.

Owner:安徽齐鑫新材料科技有限公司

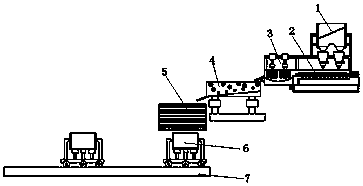

Quartz tailings recycling equipment

InactiveCN108097454AEasy to recycleGuaranteed Extraction PuritySolid separationMechanical material recoveryEngineeringQuartz

The invention discloses quartz tailings recycling equipment. The quartz tailings recycling equipment is simple in structure, and quartz tailings can be recycled well; the quartz tailings are screened,and then are subjected to washing and desliming, drying and scrubbing, primary magnetic separation, treatment through a flotation assembly and secondary magnetic separation; and the quartz tailings can be effectively utilized. Washing and desliming are implemented at first, soil in the tailings can be washed thoroughly, then the quartz tailings are slightly dried and then are scrubbed by a grinding disc, thus, iron oxide on the outer surface of quartz sand in the tailings is removed, follow-up magnetic separation is facilitated, during primary magnetic separation, the tailings are ground to one another while magnetic separation, the magnetic separation efficiency can be improved, and quartz stone can be separated from the quartz sand by the flotation assembly. During secondary magnetic separation, the iron oxide can be separated out well by strong magnetism, and the extracting purity of tailings quartz sand is greatly ensured.

Owner:韩恭超

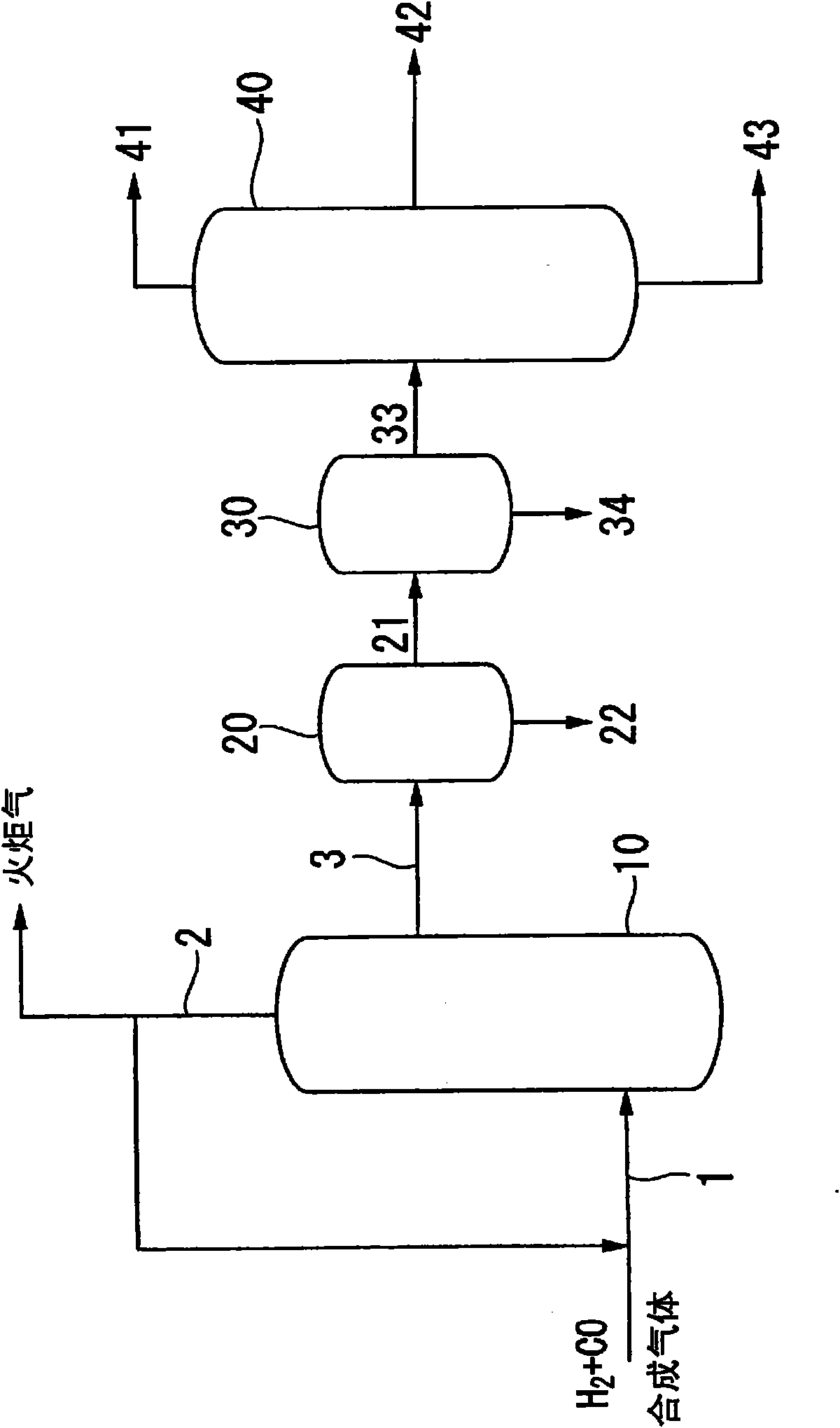

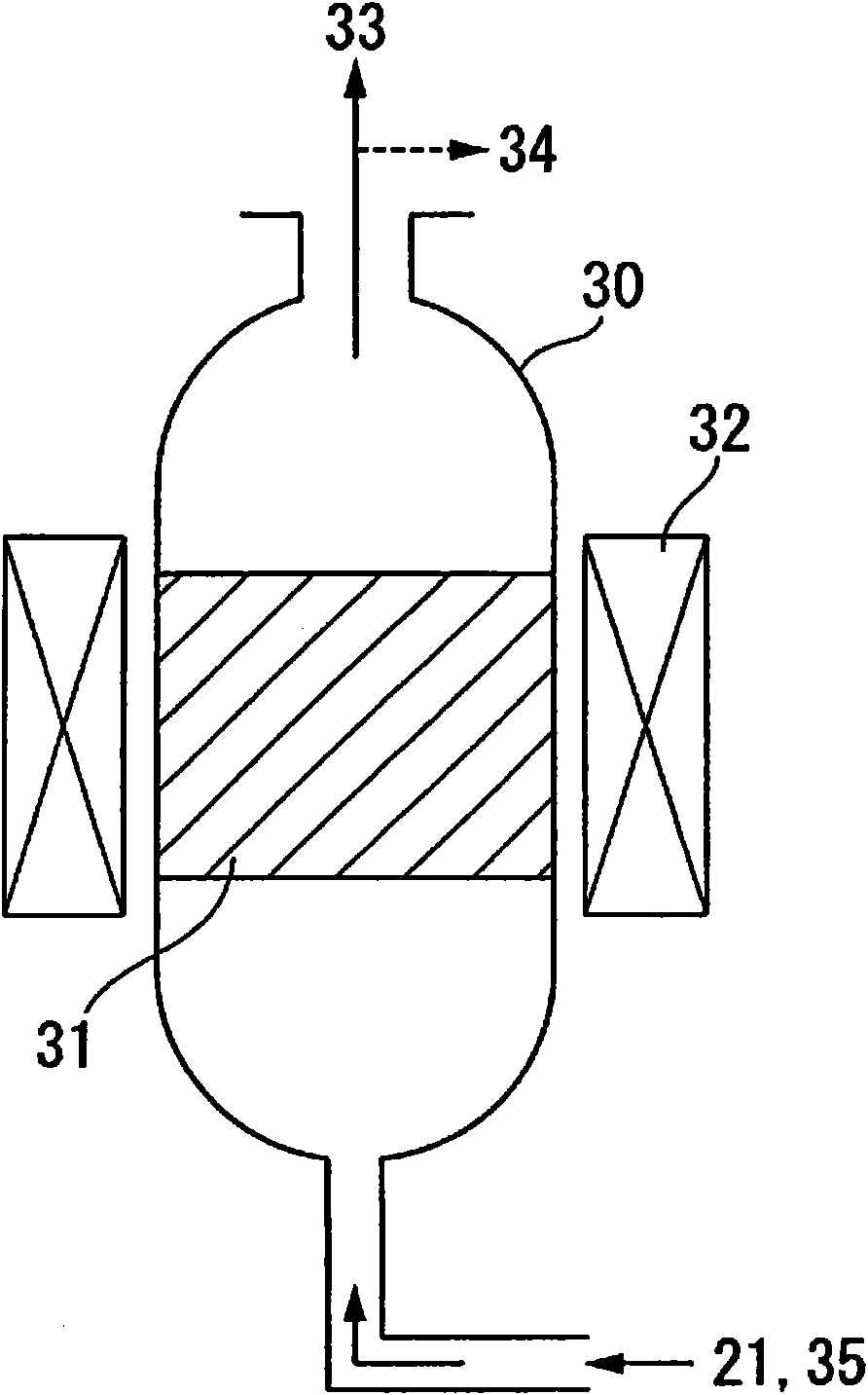

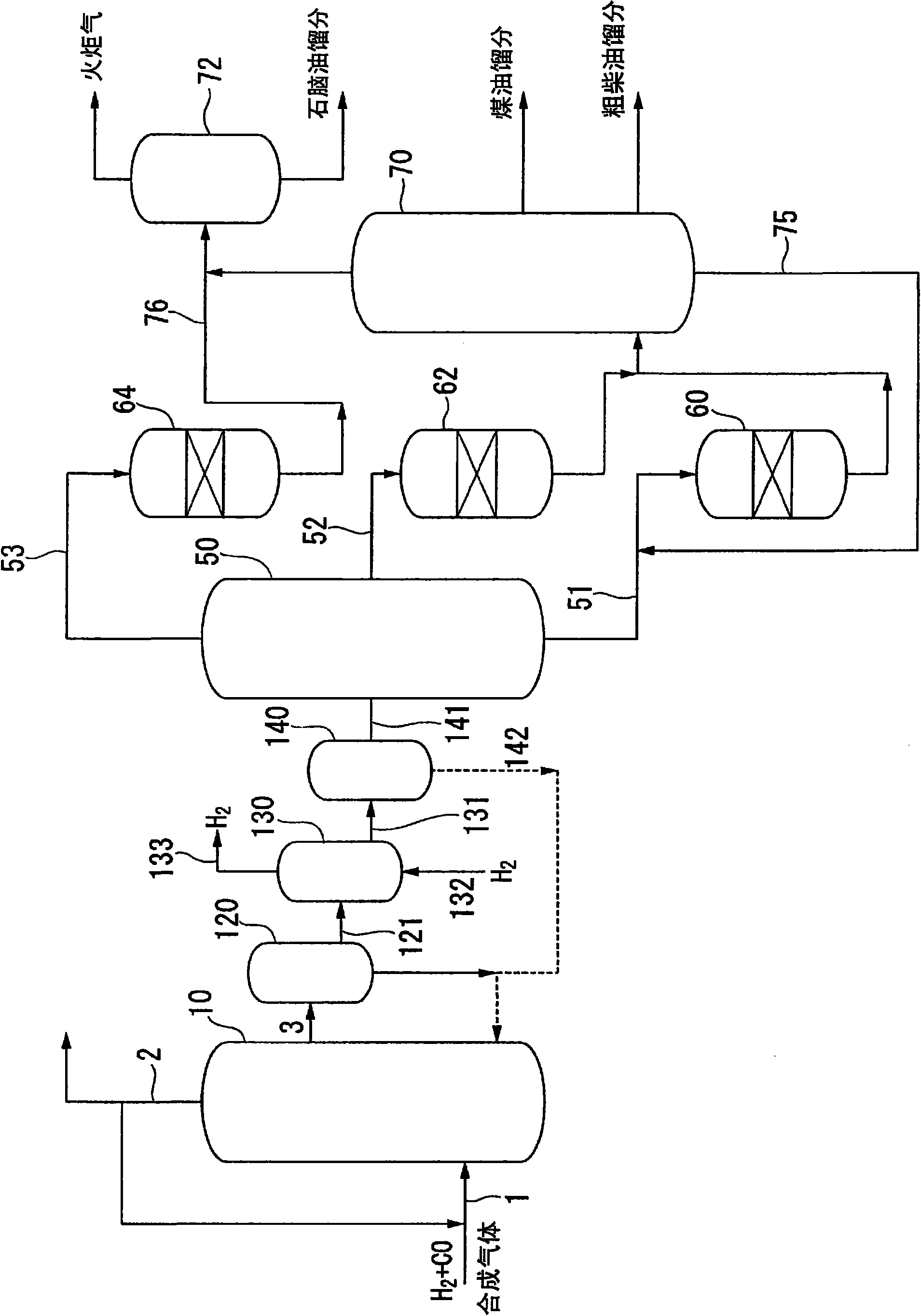

Method for removing magnetic particles from fischer-tropsch synthetic crude oil and method for manufacturing fischer-tropsch synthetic crude oil

InactiveCN101970604AReduce concentrationIncrease intervalCatalyst regeneration/reactivationRefining by water treatmentSolid componentChemical physics

Owner:JAPAN OIL GAS & METALS NAT CORP +5

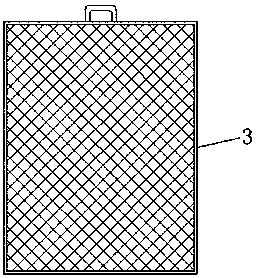

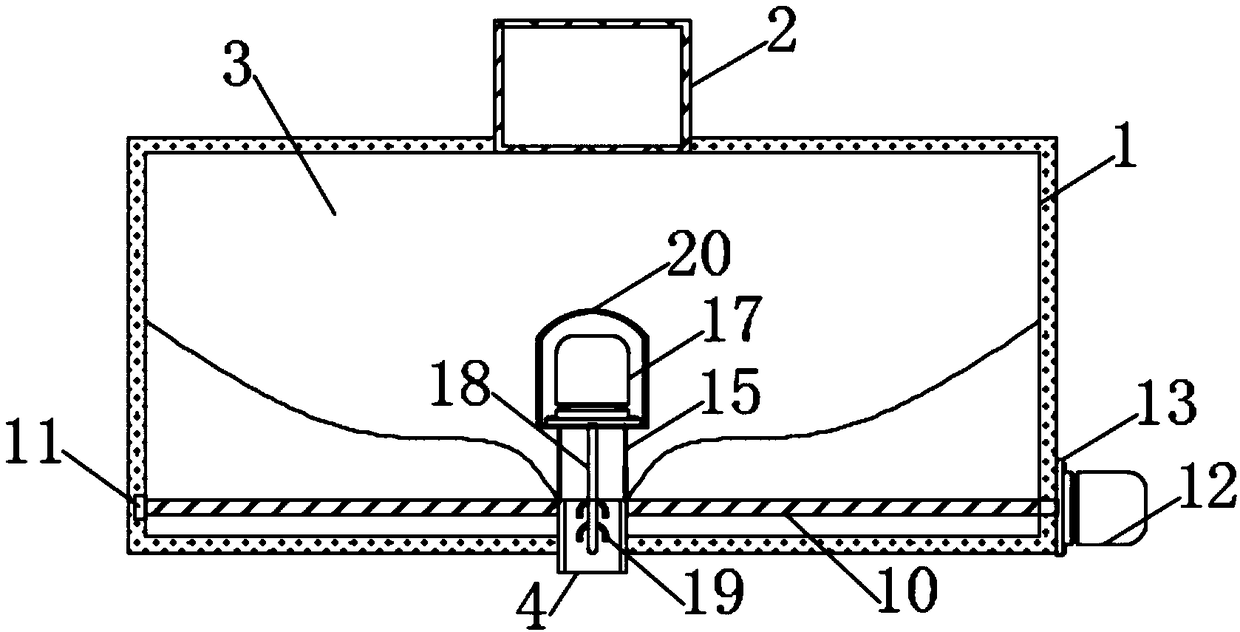

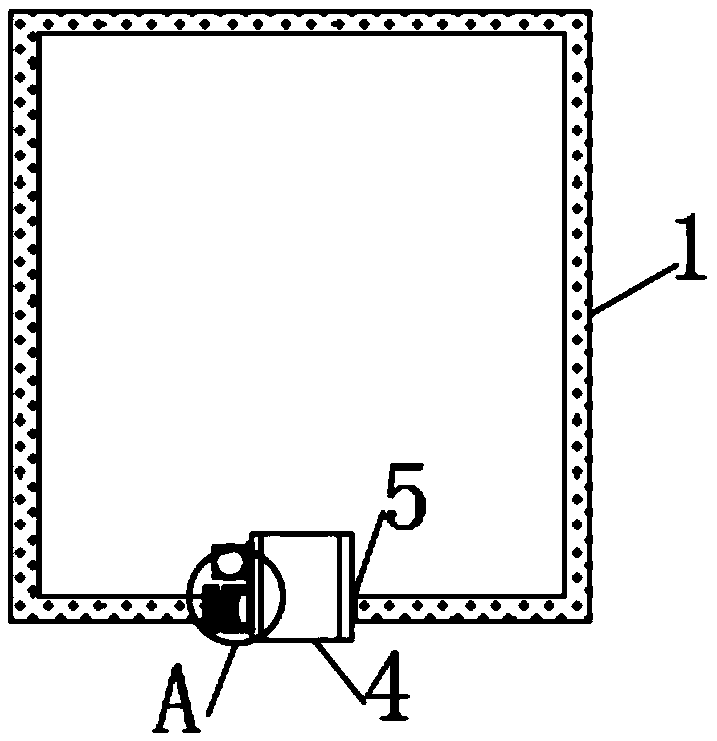

Graded screen mesh type big-lumpiness magnetic separator for producing potassium phosphate mineral substance

The invention discloses a graded screen mesh type big-lumpiness magnetic separator for producing a potassium phosphate mineral substance and relates to the technical field of potassium phosphate mineral substance screening devices. The graded screen mesh type big-lumpiness magnetic separator comprises a box body, wherein one side of the upper end in the box body is fixedly connected with a first screen mesh; one end, penetrating through the box body, of the first screen mesh is fixedly connected with a fixing device; the other end of the first screen mesh is fixedly connected with a crushing device; a washing device is fixedly connected with the lower end of the crushing device; a magnetic rotary barrel is fixedly connected with one side of the lower end of the washing device; the lower end of the magnetic rotary barrel is fixedly connected with a conveyor belt; one side of the lower end of the conveyor belt is fixedly connected with a second screen mesh; a clamping handle is fixedly connected with the middle part of one side of the fixing device; one end of the clamping handle is fixedly connected with a clamping strip; one side of the clamping strip is fixedly connected with a clamping block; a spring is sleeved with the lower end of the clamping strip. The graded screen mesh type big-lumpiness magnetic separator for producing the potassium phosphate mineral substance can beused for sufficiently sieving mineral aggregate; the magnetic concentration efficiency is improved and wastes of resources are avoided.

Owner:SUQIAN MODERN CHEM

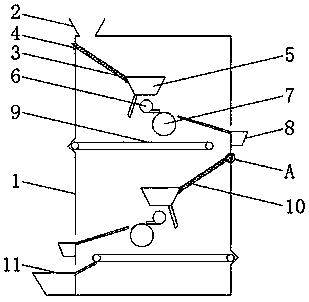

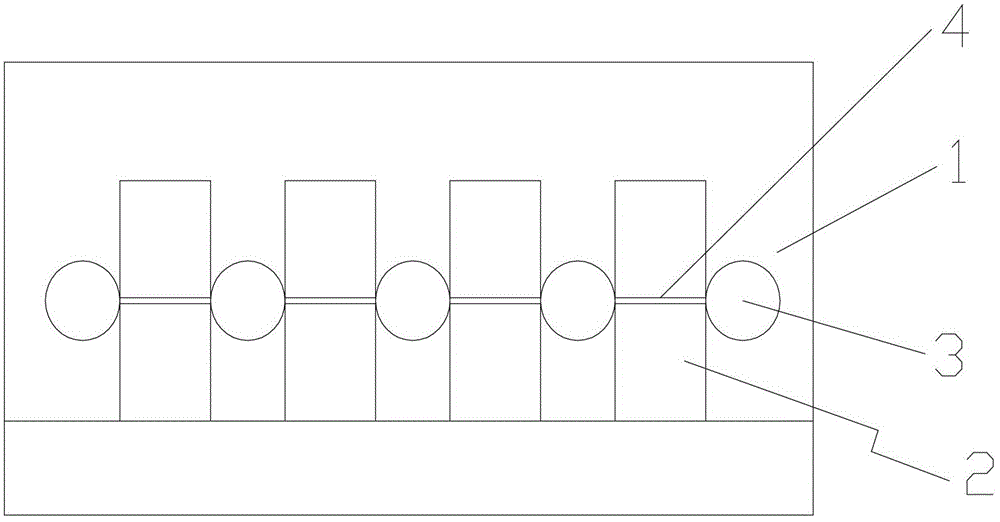

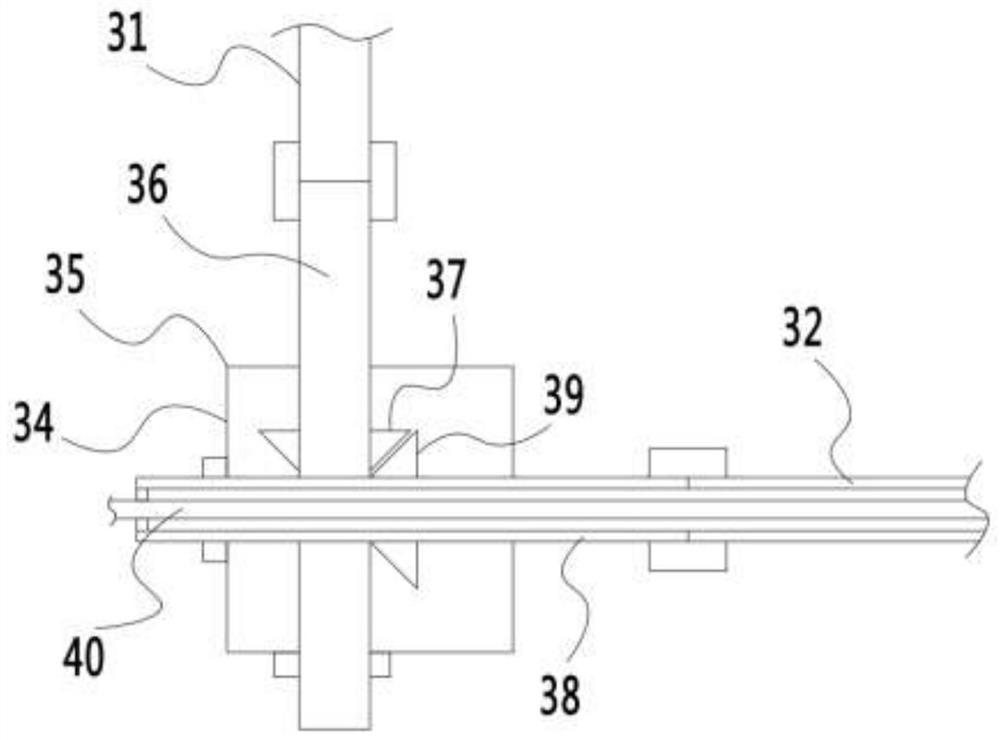

Feeding device of ceramic raw material magnetic separator

PendingCN109365124AEven and smooth feedingFeed smoothlyMagnetic separationMagnetic separatorMechanical engineering

The invention discloses a feeding device of a ceramic raw material magnetic separator. The feeding device comprises a material box; the top end of the material box is connected with a charging pipe; amaterial bag is arranged in the material box, and the bottom of the material bag is connected with a feeding pipe; the feeding pipe is arranged in a through groove formed in the bottom end of the material box; a slide rail is installed on the side wall of the through groove of the material box and provided with two concave grooves; a plurality of balls are uniformly distributed in the concave grooves and are in rolling connection with a slide seat; the slide seat is of a concave structure and arranged on the slide rail in a covering mode; a threaded rod is arranged in the position, below thematerial bag, of the interior of the material box and installed in a bearing seat located on the inner side wall of the material box in a penetrating mode; the end, penetrating through the side wall of the material box, of the threaded rod is connected with a spiral motor, and the spiral motor is fixedly installed on the outer wall of the material box through a motor seat; and the threaded rod isprovided with a moving block. According to the feeding device of the ceramic raw material magnetic separator, by arranging the material bag, the feeding pipe and a mechanism for driving the feeding pipe, uniform feeding is achieved, meanwhile, the feeding pipe is internally provided with a rotary shaft, and the problem that the interior of the feeding pipe is blocked during feeding is solved.

Owner:湖南醴陵复民瓷业机械制造有限公司

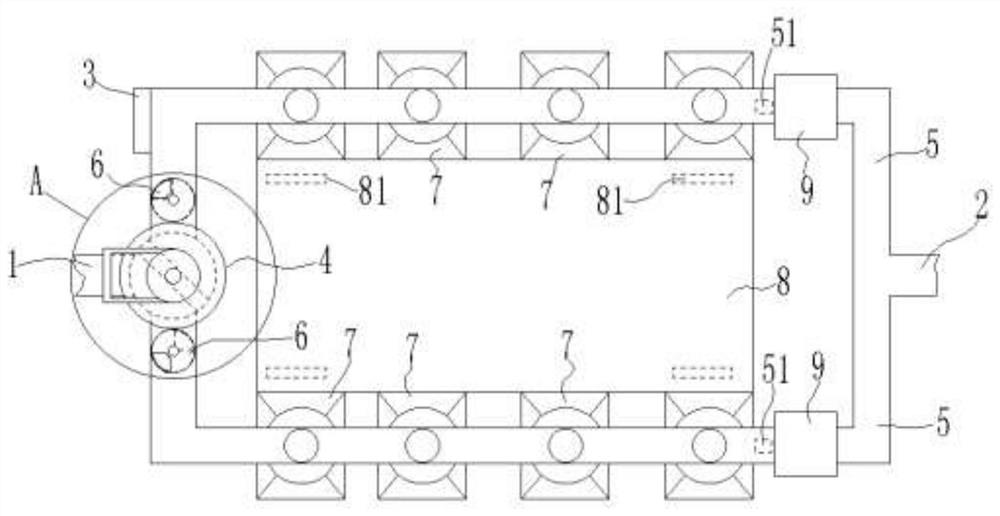

Tubular turbid wastewater suspended matter treatment device based on YC magnetic separation process

PendingCN113044939AImprove the efficiency of magnetic separationIncrease or decrease the number of magnetic purificationWater treatment parameter controlWater/sewage treatment by magnetic/electric fieldsWastewaterSewage

The invention discloses a tubular turbid wastewater suspended matter treatment device based on a YC magnetic separation process, and relates to the technical field of sewage treatment. The tubular turbid wastewater suspended matter treatment device based on the YC magnetic separation process comprises a water inlet pipe, a water outlet pipe and a PLC; a diversion valve is fixedly connected to the rear side of the water inlet pipe, the left side and the right side of the flow guide valve are fixedly connected with flow dividing pipes correspondingly, air valves are arranged at the front ends of the flow dividing pipes, a first gear is rotationally connected to the upper portion of each air valve, a second gear is rotationally connected to the upper portion of the flow guide valve, the first gears are in meshing transmission connection with the second gears, and a plurality of magnetic purification devices are arranged in the middle of each flow dividing pipe. The sewage in the water inlet pipe is continuously purified and separated through alternate work of the two flow dividing pipes, and the magnetic separation efficiency of the sewage can be effectively improved.

Owner:宜兴天鑫环保设备有限公司

A dry-wet circulation magnetic separation method

ActiveCN103861730BAchieve alternationIncrease profitMagnetic separationGrain treatmentsSlagEngineering

Owner:黄山市开发投资集团有限公司

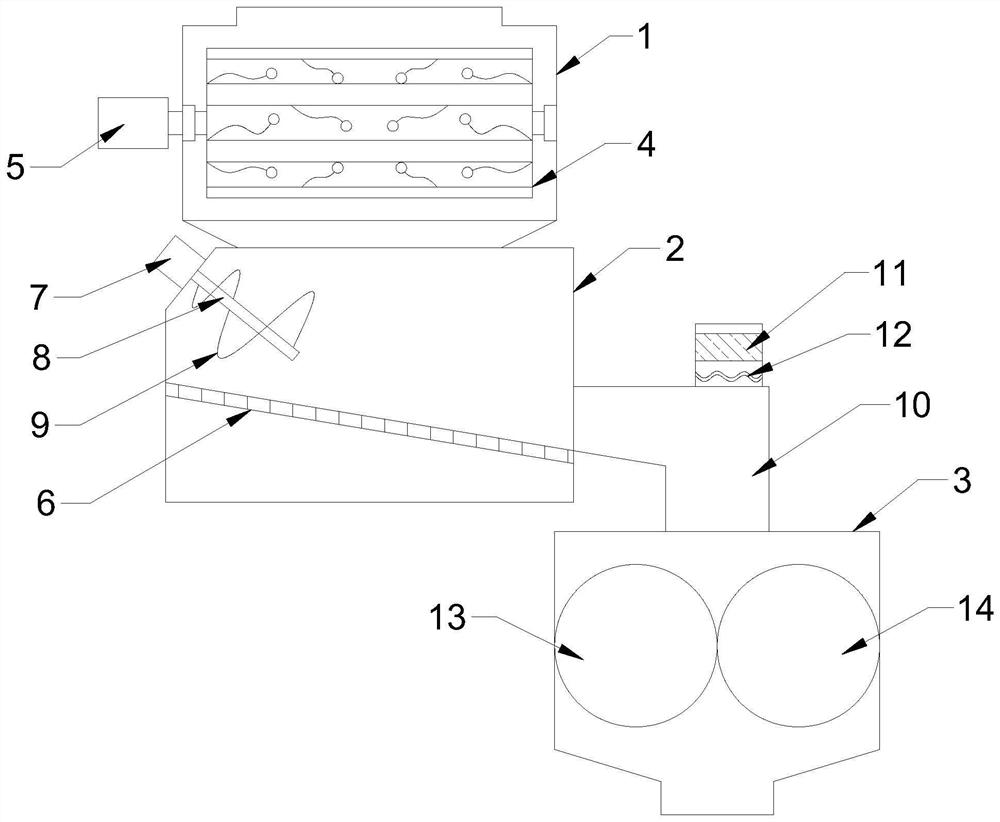

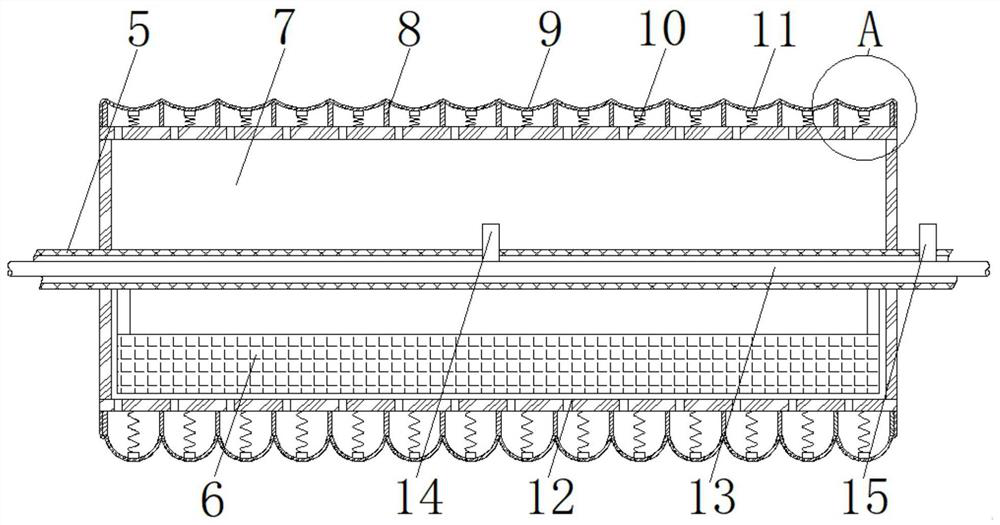

A product quality detection material recovery processing device

ActiveCN111068905BImprove the efficiency of magnetic separationGood decontamination effectDrying gas arrangementsMagnetic separationProcess engineeringHot blast

The invention discloses a material recovery and processing device for product quality testing. By setting a magnetic separation box, a magnetic separation groove is set on a magnetic separation roller inside the magnetic separation box, and then an elastic ball and a No. 1 plate are arranged in the magnetic separation box. , No. 2 plate and compression spring, and then set electromagnets on both sides of the magnetic separation box, which can absorb the iron metal through the electromagnet. At the same time, the bouncing of the elastic ball can drive the glass to shake, and the No. 1 plate and the Driven by the elastic force of the compression spring, the number plate can further drive the glass to shake, thereby improving the efficiency of magnetic separation; by setting a water tank and installing a spiral stirring blade in the water tank, it can be stirred by the spiral stirring blade, which can speed up the removal of unqualified glass. The effect of decontamination; by installing a fan on the top of the material guide pipe, and installing a heating wire at the outlet of the fan, hot air can be generated, and then the hot air can dry the unqualified glass, thereby dehumidifying. In addition, it can also Accelerate the speed at which unqualified glass enters the crushing box.

Owner:陕西众策网络科技发展有限公司

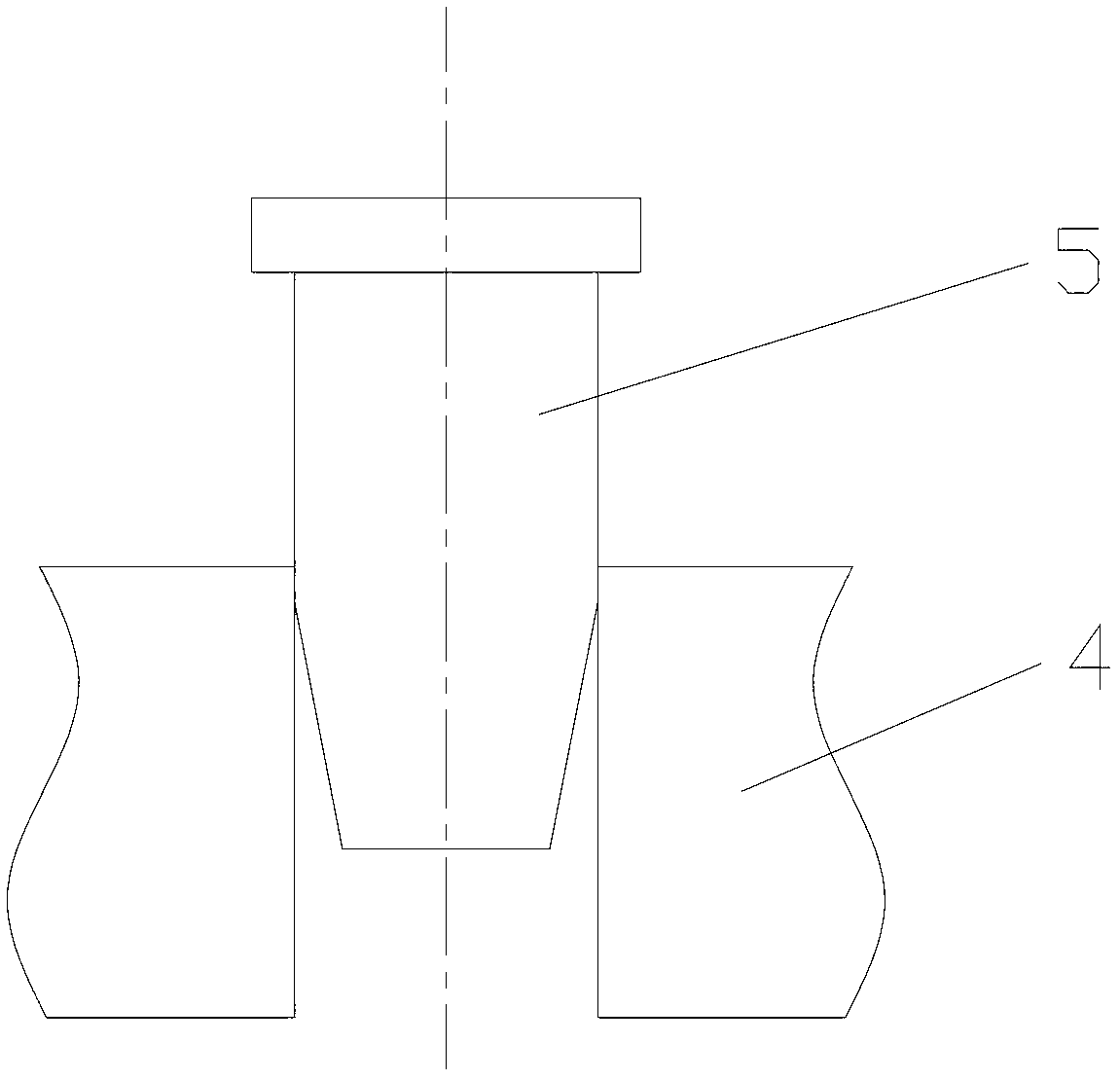

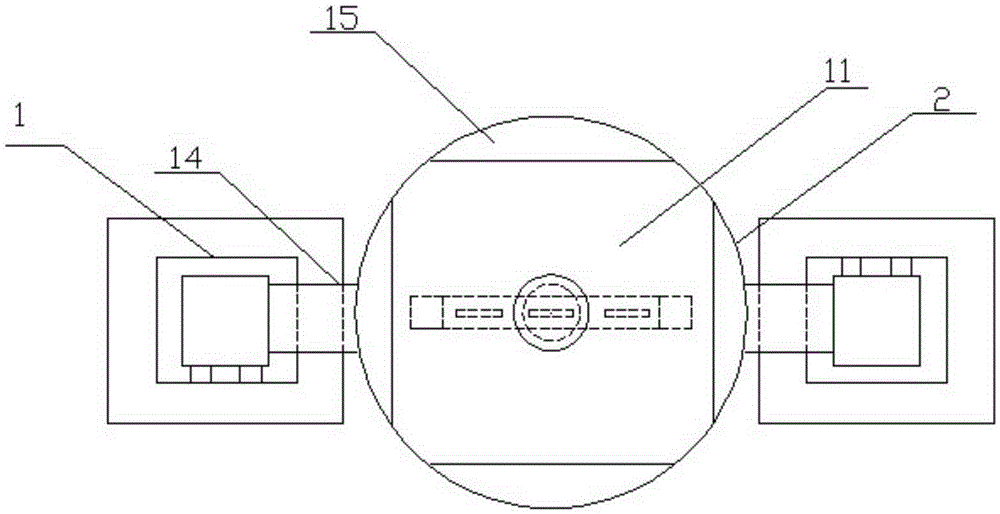

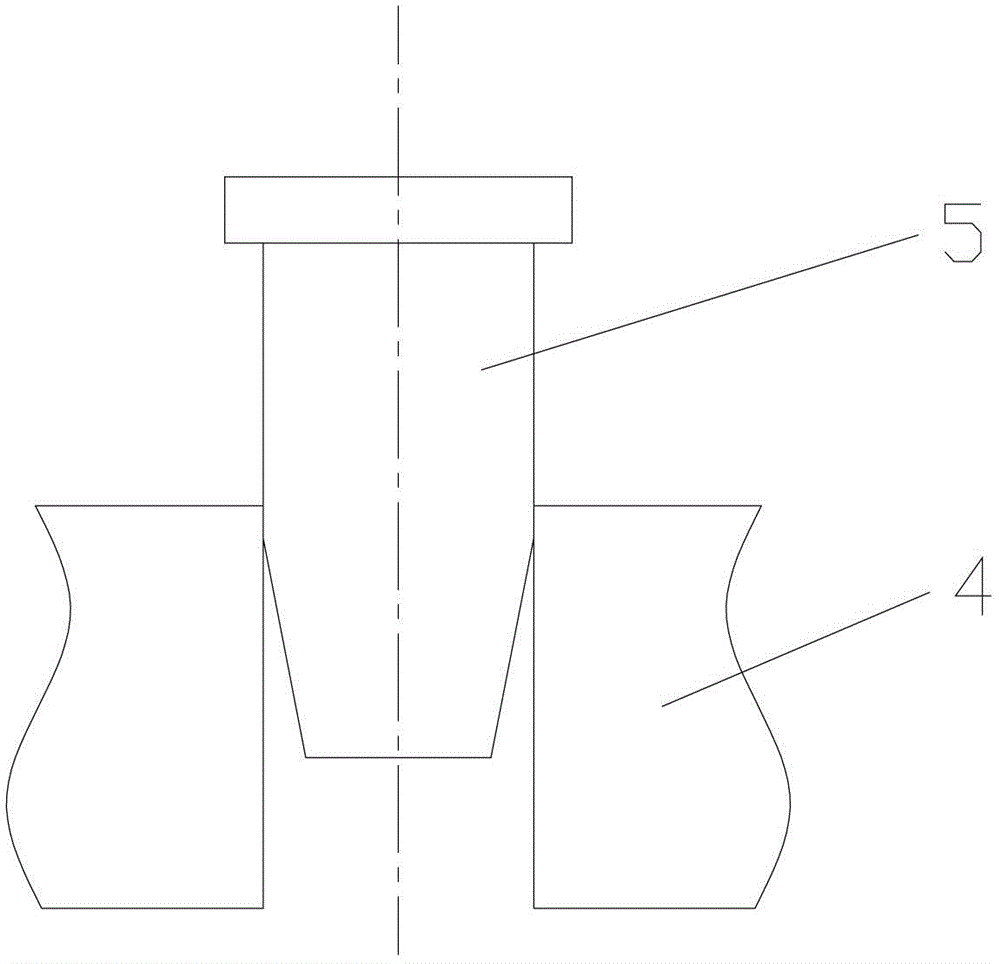

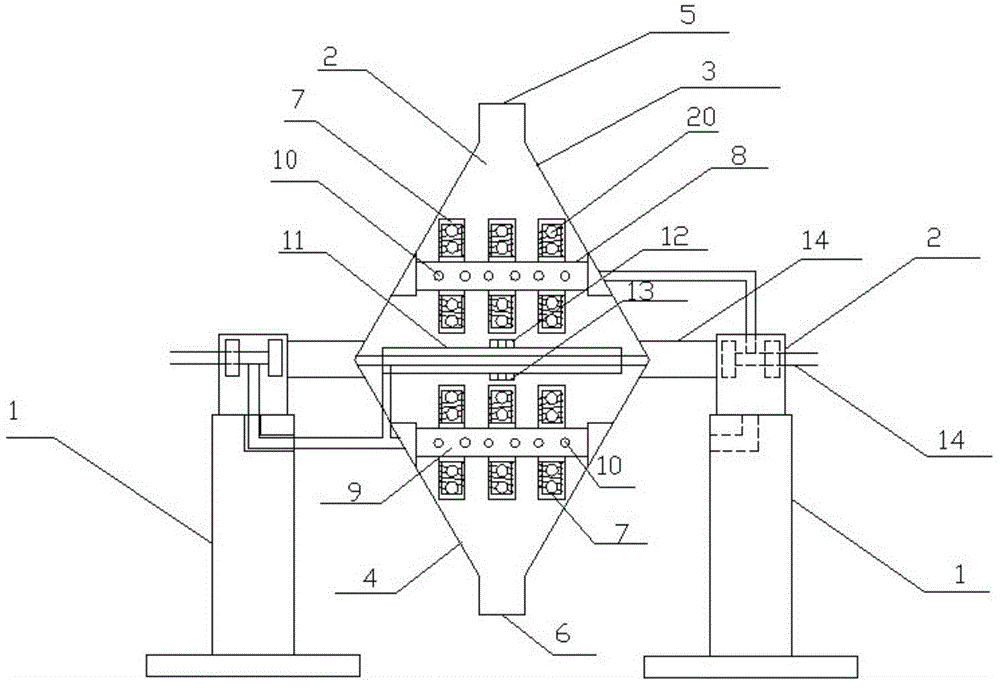

A wet cycle electromagnetic separator

The invention discloses a wet-type electromagnetic separator. The wet-type electromagnetic separator comprises a support seat, wherein an electromagnetic separation cylinder is arranged on the support seat through a rotating shaft. The wet-type electromagnetic separator is characterized in that the electromagnetic separation cylinder consists of an upper cone cylinder and a lower cone cylinder, wherein the bottom surfaces of the upper cone cylinder and the lower cone cylinder are connected, an upper water inlet / outlet and a lower water inlet / outlet are formed in the top ends of the upper cone cylinder and the lower cone cylinder, respectively, rotating shafts are respectively rotatably arranged in the upper cone cylinder and the lower cone cylinder, an upper group of electromagnets and a lower group of electromagnets are respectively fixedly arranged on the rotating shafts, an upper spray pipe and a lower spray pipe arranged outside the rotating shafts in a sleeved manner are arranged in the upper cone cylinder and the lower cone cylinder, and water spray holes are formed in the upper spray pipe and the lower spray pipe. According to the wet-type electromagnetic separator, by utilizing a specific dual-cone cycle structure, river sand or metal mortar can be circularly selected in two hollow cones when the cycle structure is driven to rotate to different positions by a driving device; the whole process is automatically controlled through circuits, so that the waste of manpower resources is reduced, the problems of complex separation method, long separation process and the like are solved, and the effectiveness of the electromagnetic separation is improved.

Owner:黄山市开发投资集团有限公司

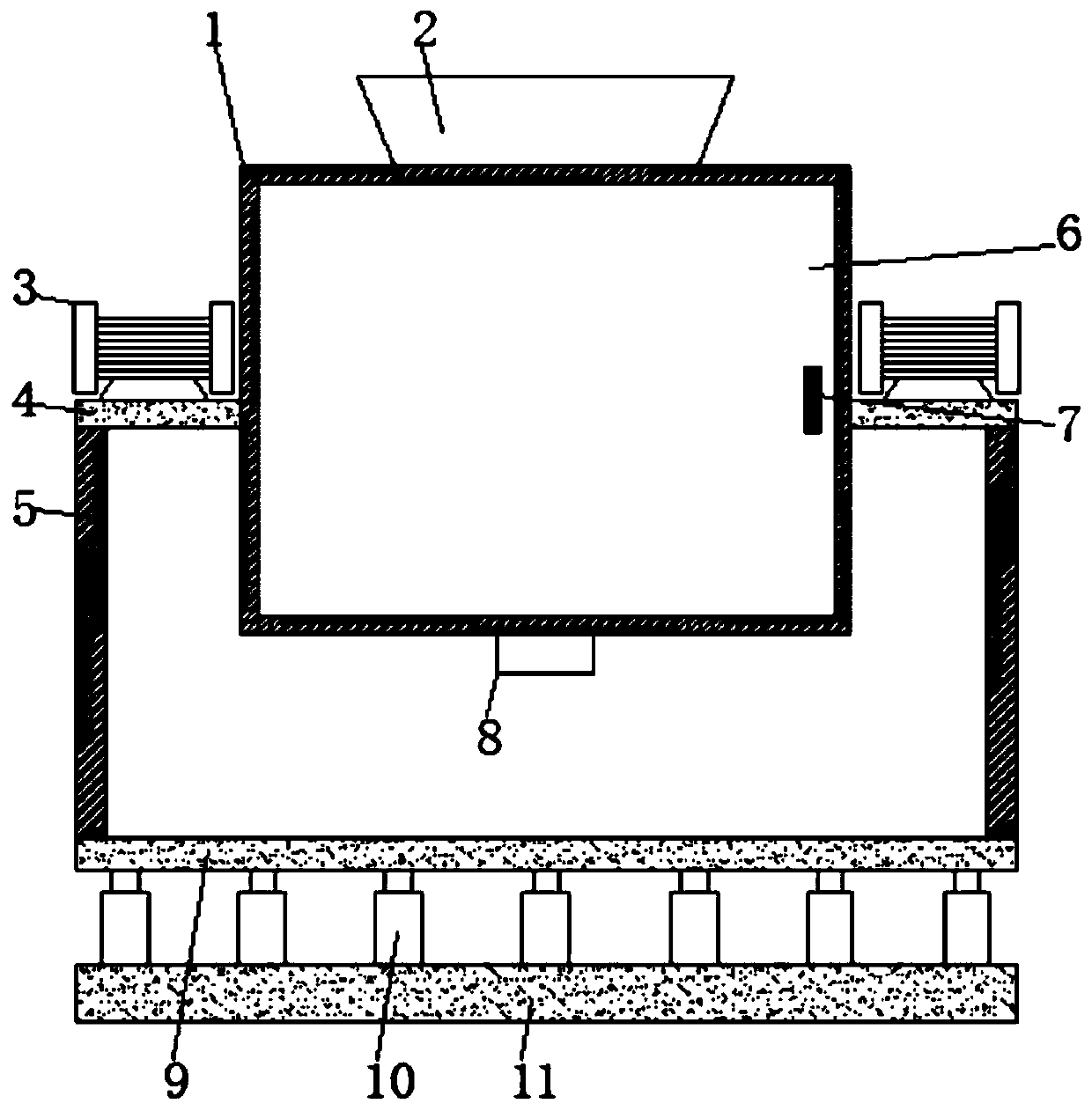

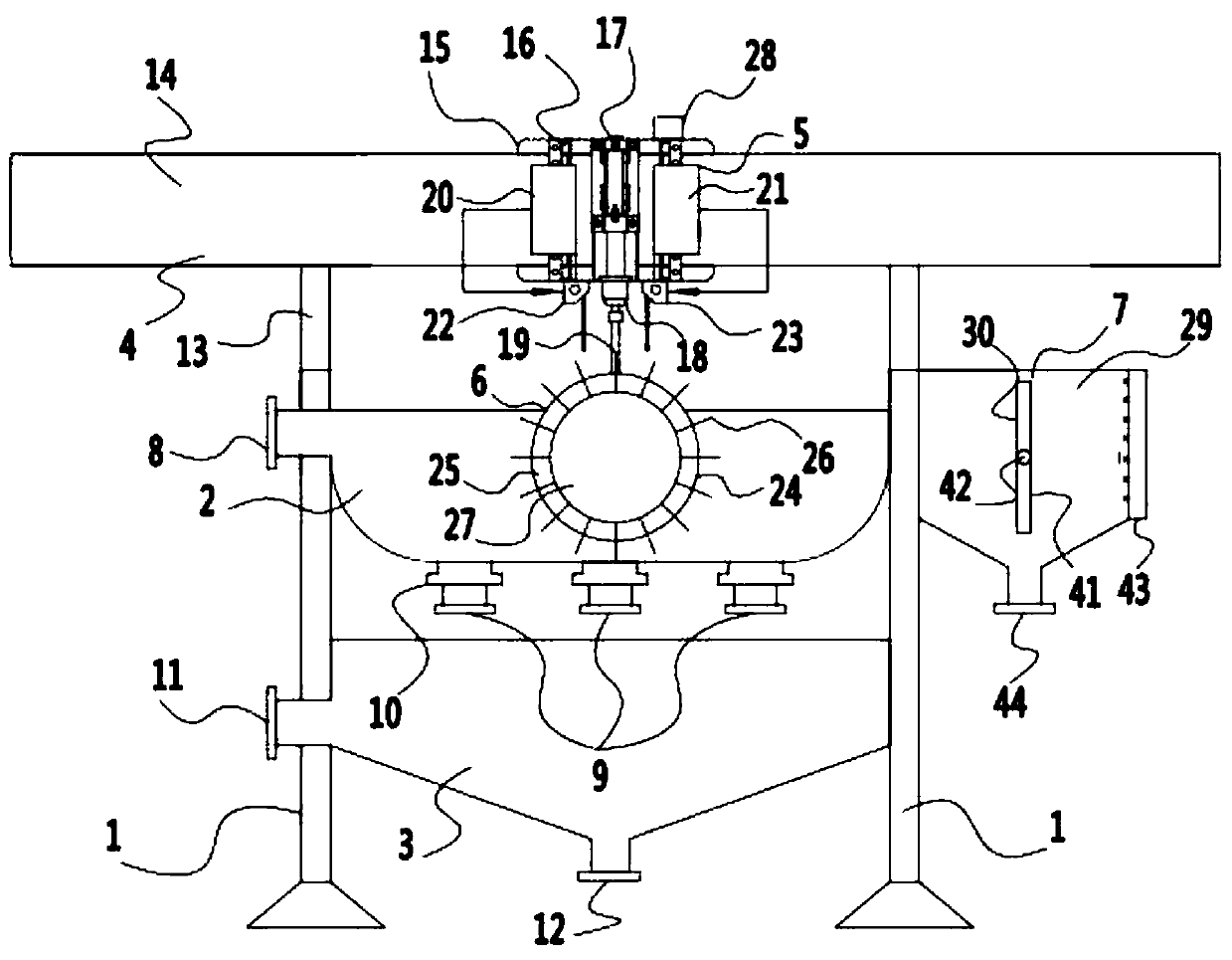

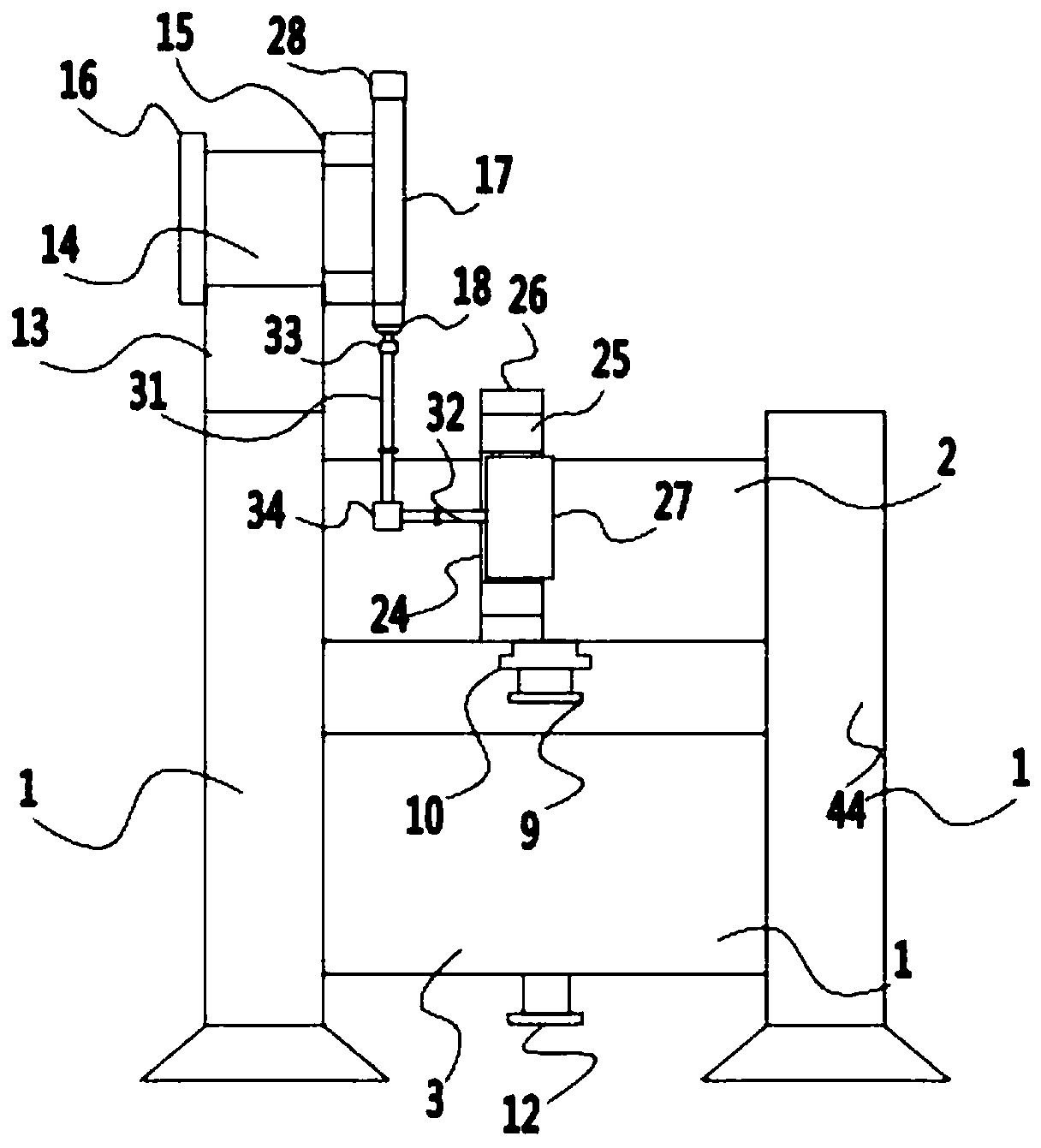

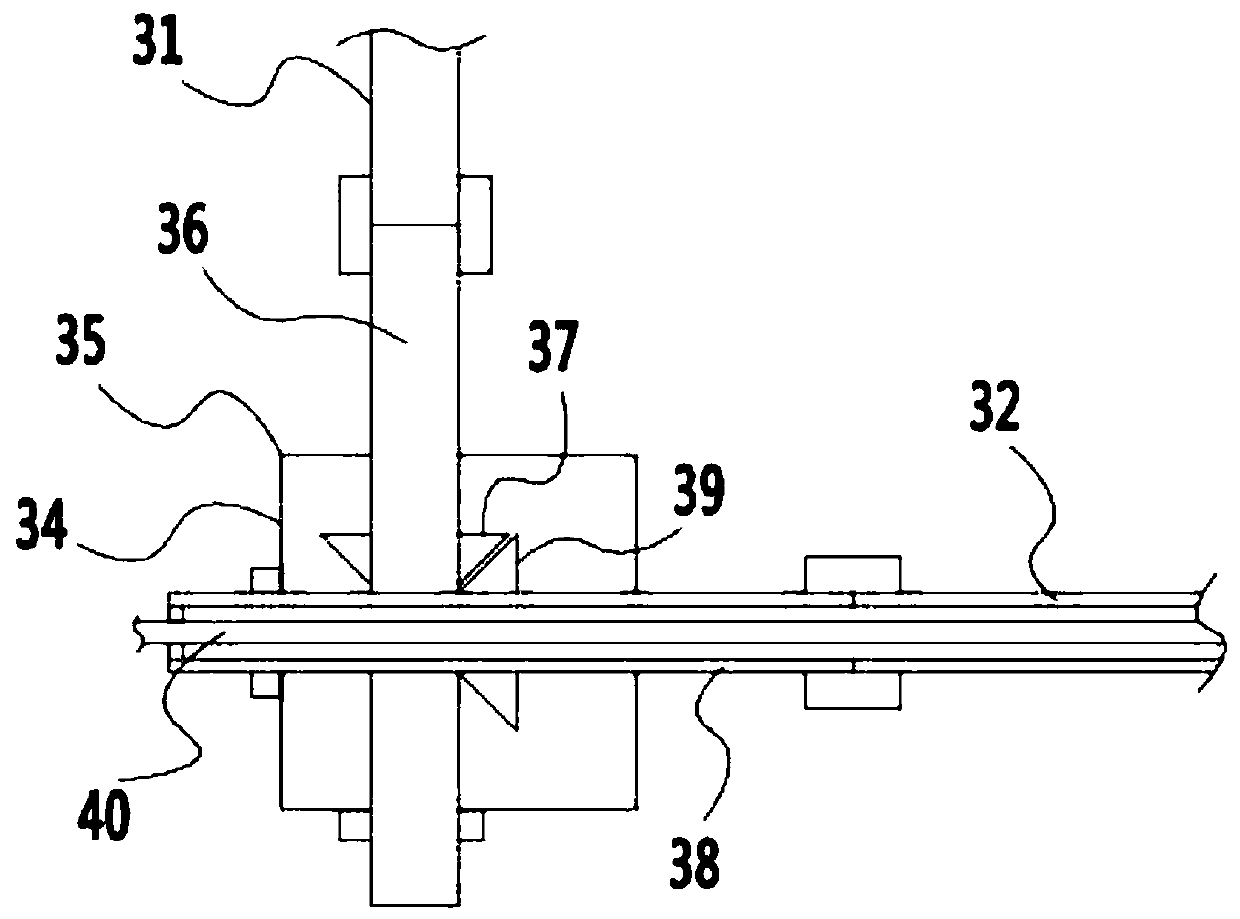

Multi-point dispensing well water coagulating sedimentation device based on micro-magnetic coagulation technology

ActiveCN110092525ASave medicineImprove the efficiency of magnetic separationWaste water treatment from quariesSpecific water treatment objectivesEngineeringSedimentation coefficient

The invention discloses a multi-point dispensing well water coagulating sedimentation device based on a micro-magnetic coagulation technology. The device comprises a frame, a water tank and a sedimentation tank which are arranged on the frame and a gantry frame arranged behind the frame, the crossbeam of the gantry frame is provided with a machine head capable of moving along the X-axis and the Z-axis, a coagulant metering pump and a magnetic suspension metering pump are arranged at the lower end of the machine head, a rotating motor is arranged below the machine head, the rotating motor rotates a rotating disc, connected to the rotating rotor, through the lower end of a steering transmission mechanism, the outer edge of the rotating disc is provided with a plurality of equally divided feeding grooves, the feeding grooves are connected with blades, and an electromagnetic disc, a residue discharge chamber located on the frame at one side of the end of the water tank, and a residue scraping mechanism located in the residue discharge chamber are arranged in front of the rotating disc. The device has the advantages of integration of stirring, reagent feeding and magnetic adsorption through magnetic separation mechanism, high integrity, and realization of rapid and efficient coagulating sedimentation and magnetic separation of mine water.

Owner:江苏凯勒奇环保设备有限公司

Annular porous nano magnetic bead separator and mounting method thereof

ActiveCN103185680BIncrease profitA large amountPreparing sample for investigationMagnetic beadEngineering

The invention relates to an annular porous nano magnetic bead separator which comprises a casing and magnet groups, wherein each magnet group adopts a tile shape, and the number of the magnet groups is an even number; the magnet groups are arranged in an accommodating cavity which corresponds to the shape of the magnet groups and is arranged in the casing in an annular manner; a tube hole for accommodating a tube is arranged on the casing between every two adjacent magnet groups; and the polarities of poles of every two magnet groups are contrary. The invention further relates to a mounting method of the annular porous nano magnetic bead separator. The annular porous nano magnetic bead separator and the mounting method thereof have the advantages that the utilization rate of magnets and the tube holes are effectively improved, the separation efficiency is improved, and the annular porous nano magnetic bead separator can be assembled easily. The annular porous nano magnetic bead separator belongs to the technical field of nano magnetic bead separation devices.

Owner:SOUTH CHINA AGRI UNIV

Wet-type roller magnetic separator

ActiveCN113522523AImprove efficiencyIncreased surface areaMagnetic separationCleaning using liquidsMagnetic separatorOre concentrate

The invention relates to the technical field of screening equipment, and discloses a wet-type roller magnetic separator which comprises a magnetic separator shell, an ore feeding box is arranged in the area on one side of the magnetic separator shell, a concentrate tank is arranged in the area in the other side of the magnetic separator shell, and an ore discharging water pipe head is fixedly installed on one side of the top end of the concentrate tank. The front face and the back face in the magnetic separator shell are movably connected with rotating shafts. When a rubber sleeve is in common magnetic attraction and repulsion of the magnetic blocks and the magnetic pole sets, the surface of the rubber sleeve partially protrudes out of or is sunken into the rubber sleeve, the rubber sleeve is arranged at the bottom end of the interior of the magnetic separator shell, and the surface of the rubber sleeve alternately protrudes out of or is sunken into the magnetic separator shell under the effect of the magnetic blocks in the rubber sleeve, and therefore, ore pulp at the bottom end in the magnetic separator shell shakes and is stirred along with the change of the surface state of the rubber sleeve, the ore pulp is more uniform in an ore dressing area in the magnetic separator shell, and the magnetic separation efficiency is improved.

Owner:江西嘉圆磁电科技有限公司

A kind of circulating wet magnetic separation method

Owner:黄山市开发投资集团有限公司

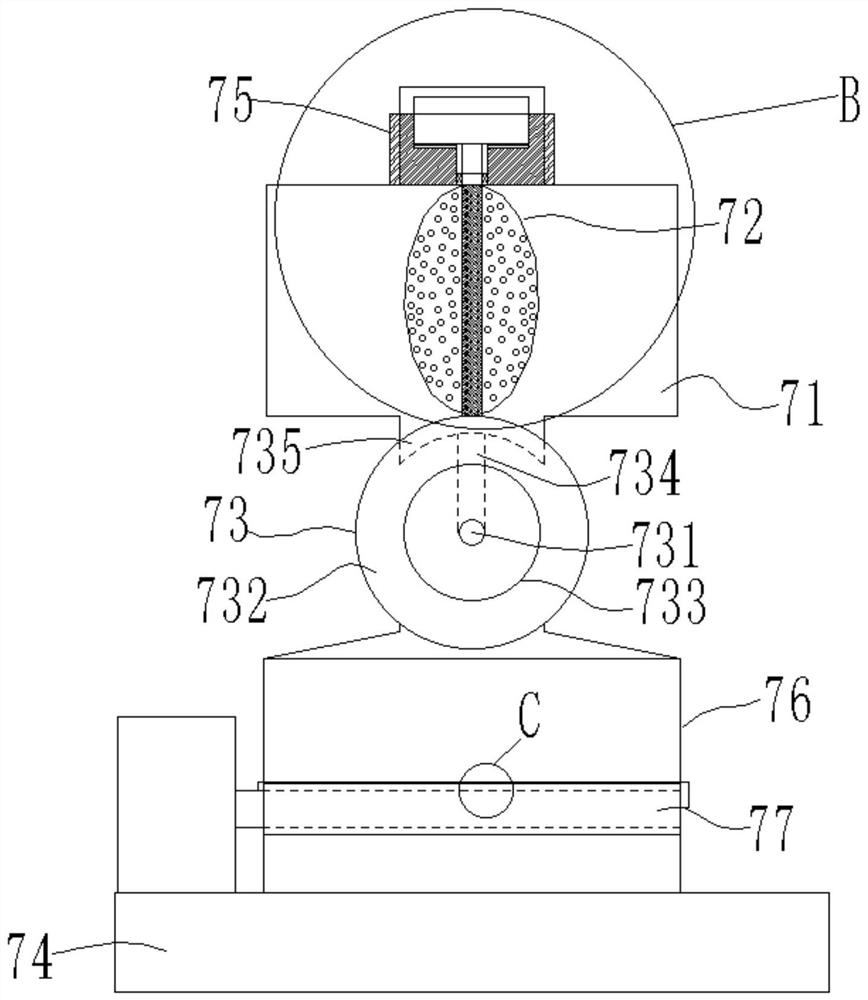

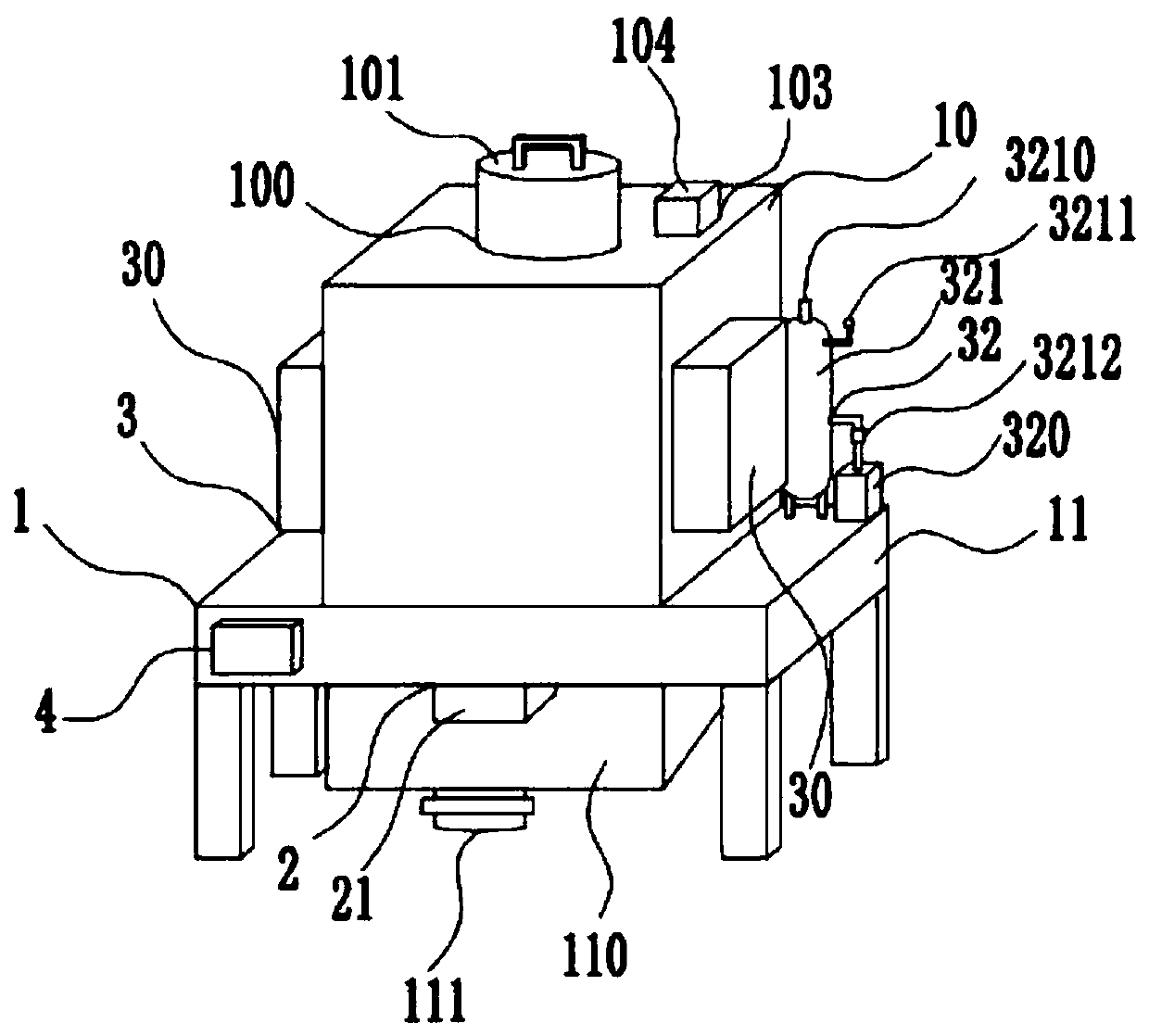

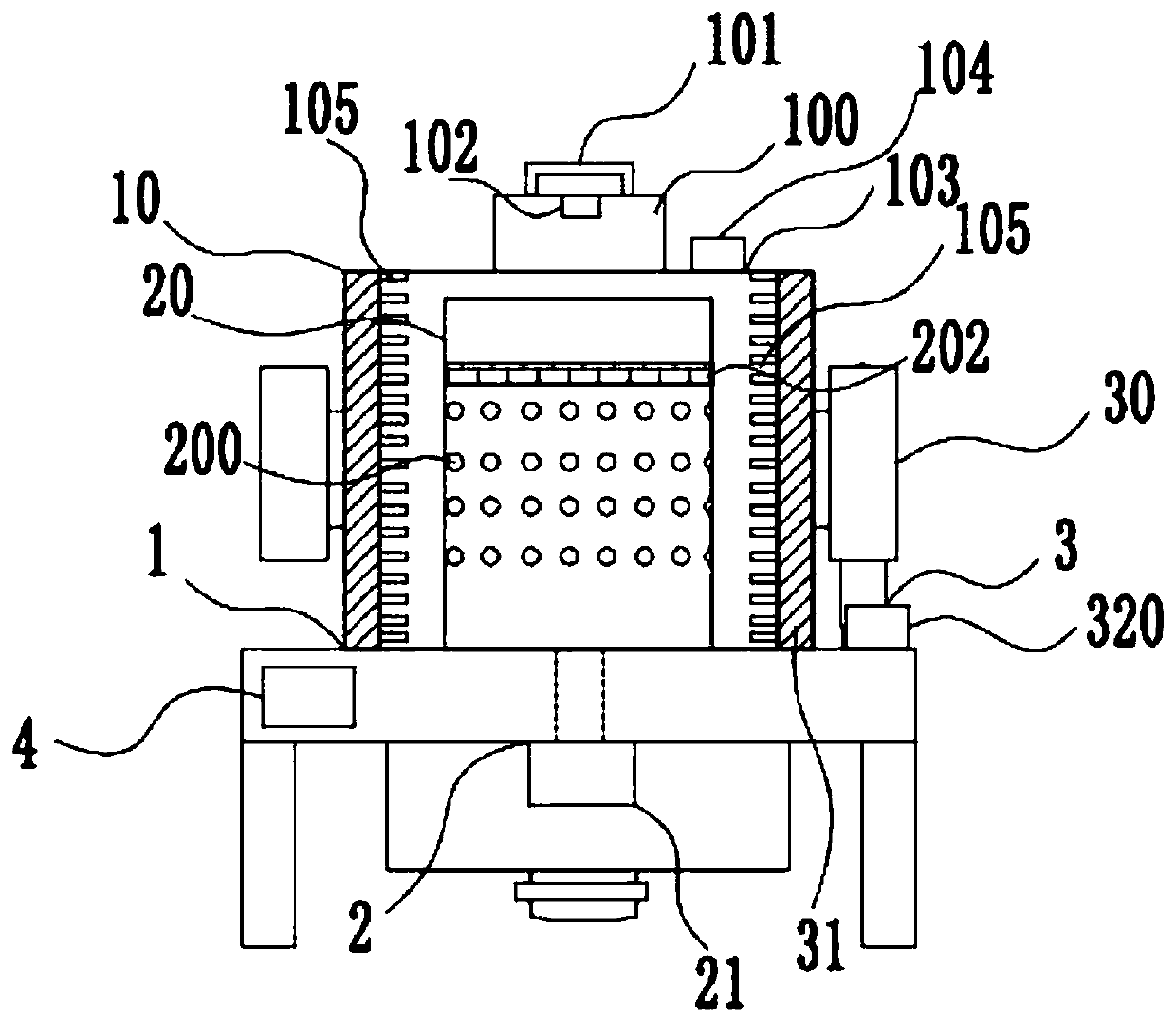

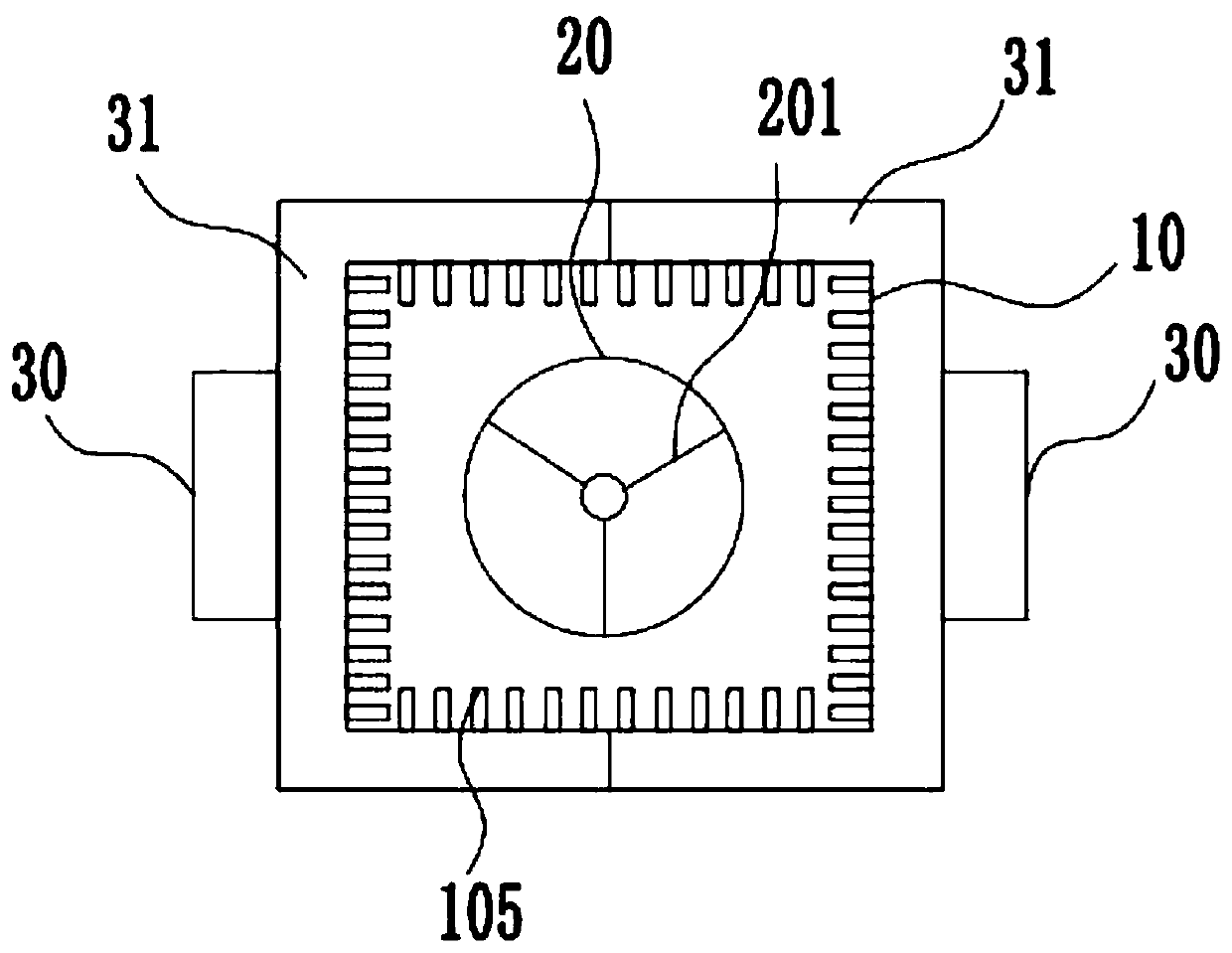

A dry-wet dual-purpose compound high-gradient intelligent magnetic separation device

ActiveCN110180675BLarge adsorption capacityIncrease centrifugation timeSievingScreeningElectric machineryEngineering

The invention discloses a dry and wet dual-purpose composite high-gradient intelligent magnetic separation device, and belongs to the technical field of magnetic separation equipment. The magnetic separation device mainly comprises a magnetic separation main body, a driving element, a magnetic separation element, an integrated motor control box and a power supply device. The driving element comprises a centrifugal rotating cylinder and a driving motor. A Y-shaped baffle plate is arranged in the centrifugal rotating cylinder. The Y-shaped baffle plate is used for uniformly dividing the centrifugal rotating cylinder into three independent spaces. Through the arrangement of the three independent spaces, the centrifugal time of materials in the centrifugal rotating cylinder can be prolonged, so that the magnetic separation effect is improved, dry type and wet type magnetic separation operation can be carried out, gradient setting of the magnetic field intensity can be completed by settingdifferent current values, and the magnetic separation efficiency is improved. The magnetic separation device has the advantages of high separation efficiency, convenience in operation and intelligentintegration, and is suitable for large-scale popularization.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Wind Dry Magnetic Separator

ActiveCN105772219BCompact structureEasy to manufactureGas current separationMagnetic separationMagnetic separatorWind force

The invention discloses a wind dry type magnetic separator. The wind dry type magnetic separator comprises a rack, an enclosure, dust removing devices and a nonmagnetic cylinder screen roller, wherein the dust removing devices communicate with an inner cavity of the enclosure and are used for exhausting and removing dust; the nonmagnetic cylinder screen roller is arranged in the enclosure and is driven by a driving device to rotate; a feeding device is arranged above the nonmagnetic cylinder screen roller; a concentrate bin, a tailing bin and a discharging device are arranged below the nonmagnetic cylinder screen roller; a plurality of ventilation holes are formed in the roller surface of the nonmagnetic cylinder screen roller; a fixedly-arranged magnetic system is arranged inside the nonmagnetic cylinder screen roller; an air chamber communicating with the ventilation holes is also arranged in the nonmagnetic cylinder screen roller; the air chamber is connected with an air feeding device; a striker plate which is arranged along the rotating direction of the nonmagnetic cylinder screen roller in an extending manner from a discharge opening of the feeding device is arranged on the enclosure; and a space is reserved between the striker plate and the outer surface of the nonmagnetic cylinder screen roller. The wind dry type magnetic separator disclosed by the invention has the advantages that the structure is simple and compact, magnetic agglomeration and inclusion can be effectively reduced, the magnetic separation efficiency of materials is improved, and the like.

Owner:CENT SOUTH UNIV

Potassium feldspar production method

ActiveCN109133075AStrong harvesting abilityImprove adsorption capacityAluminium silicatesWet separationAdditive ingredientPotassium

The invention belongs to the technical field of mineral dressing and particularly discloses a potassium feldspar production method, comprising the specific steps of S1, removing mud; S2, ball milling;S3, magnetically removing impurities; S4, drying, to be specific, adding concentrate pulp into a drying furnace, and drying to obtain solid concentrate; S5, calcining, to be specific, transferring the solid concentrate to a calcining furnace for calcining at 1300-1500 DEG C, and adding a mixed gas of nitrogen and argon in a volume ratio of 1:2 to fill the calcining furnace during calcining; S6, removing impurities, to be specific, subjecting the calcined mineral to ball milling to the particle size of 0.5 cm so as to obtain pulp; S7, carrying out floatation, to be specific, adding sulfuric acid solution, adjusting pH of the pulp to 6.2-6.8, adding a collecting agent and a foaming agent, and collecting finished foam to obtain concentrate pulp II; S8, removing oil. The method herein helps extract main effective ingredients of potassium feldspar and also helps effectively remove the impurities that affect the color of potassium feldspar powder.

Owner:贺州市骏鑫矿产品有限责任公司

A kind of production method of albite

ActiveCN108906314BStrong harvesting abilityImprove adsorption capacityWet separationFoaming agentImpurity

The invention belongs to the technical field of ore dressing, and particularly discloses a production method of albite. The production method comprises the following specific steps of S1, desilting; S2, ball grinding; S3, magnetic separation impurity removal; S4, drying, wherein concentrate pulp is added into a drying furnace to be dried to obtain solid concentrates; S5, calcining, the solid concentrates are transferred into a calcining furnace to be calcined, and the calcining temperature ranges from 1200 DEG C to 1350 DEG C; S6, impurity removal, wherein calcined ore is subjected to ball grinding, ball grinding is carried out till the particle size is smaller than 0.5 cm, and ore pulp is obtained; S7, flotation, wherein a sulfuric acid solution is added, the pH value of the ore pulp is adjusted to range from 6.0 to 6.5, then a collecting agent and a foaming agent are added, foam products are collected, and concentrate pulp B is obtained; and S8, oil removal. By means of the treatmentmethod, the main effective components of the albite can be purified, and impurities influencing the color of the albite can be effectively removed.

Owner:贺州市骏鑫矿产品有限责任公司

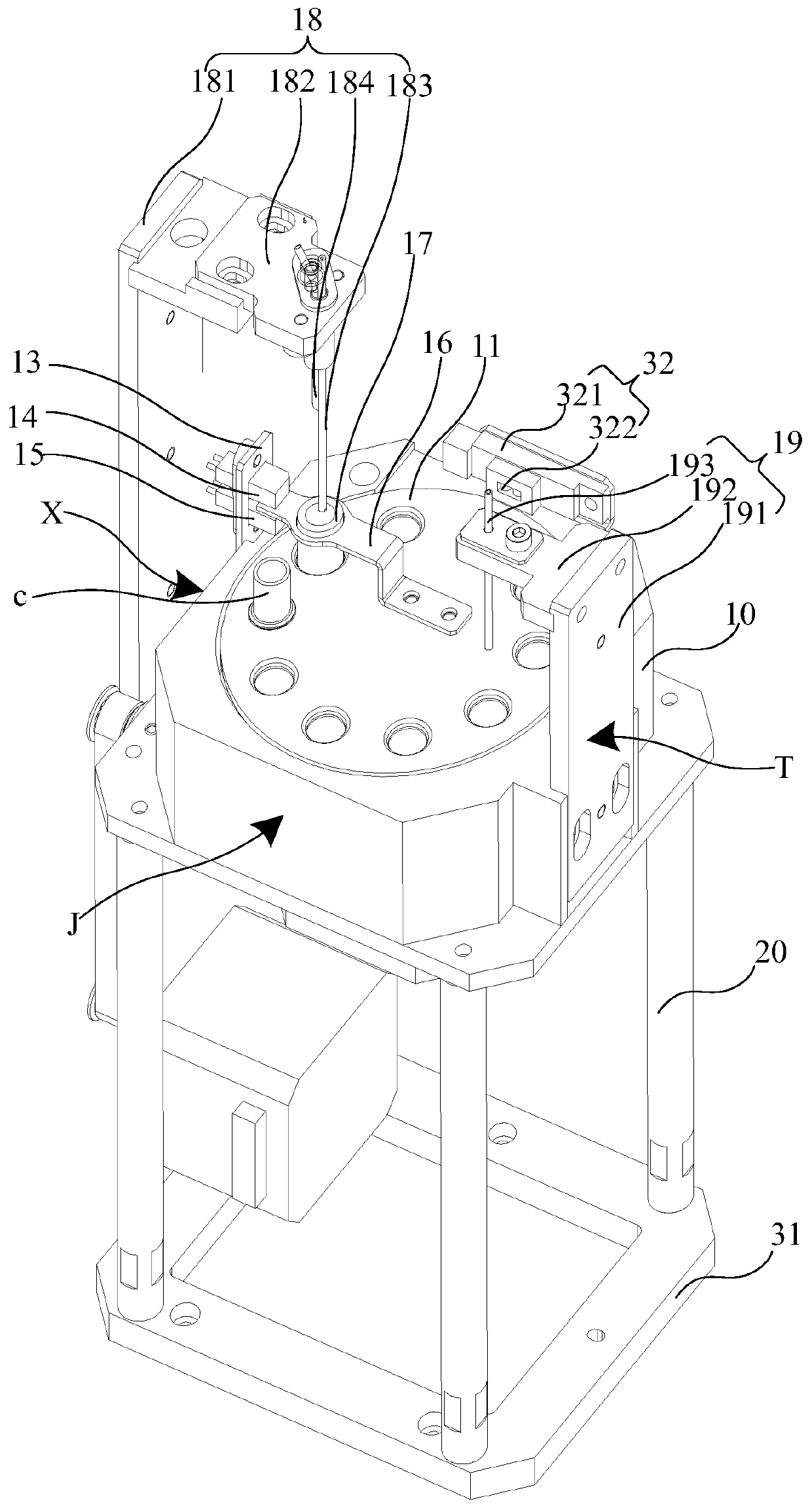

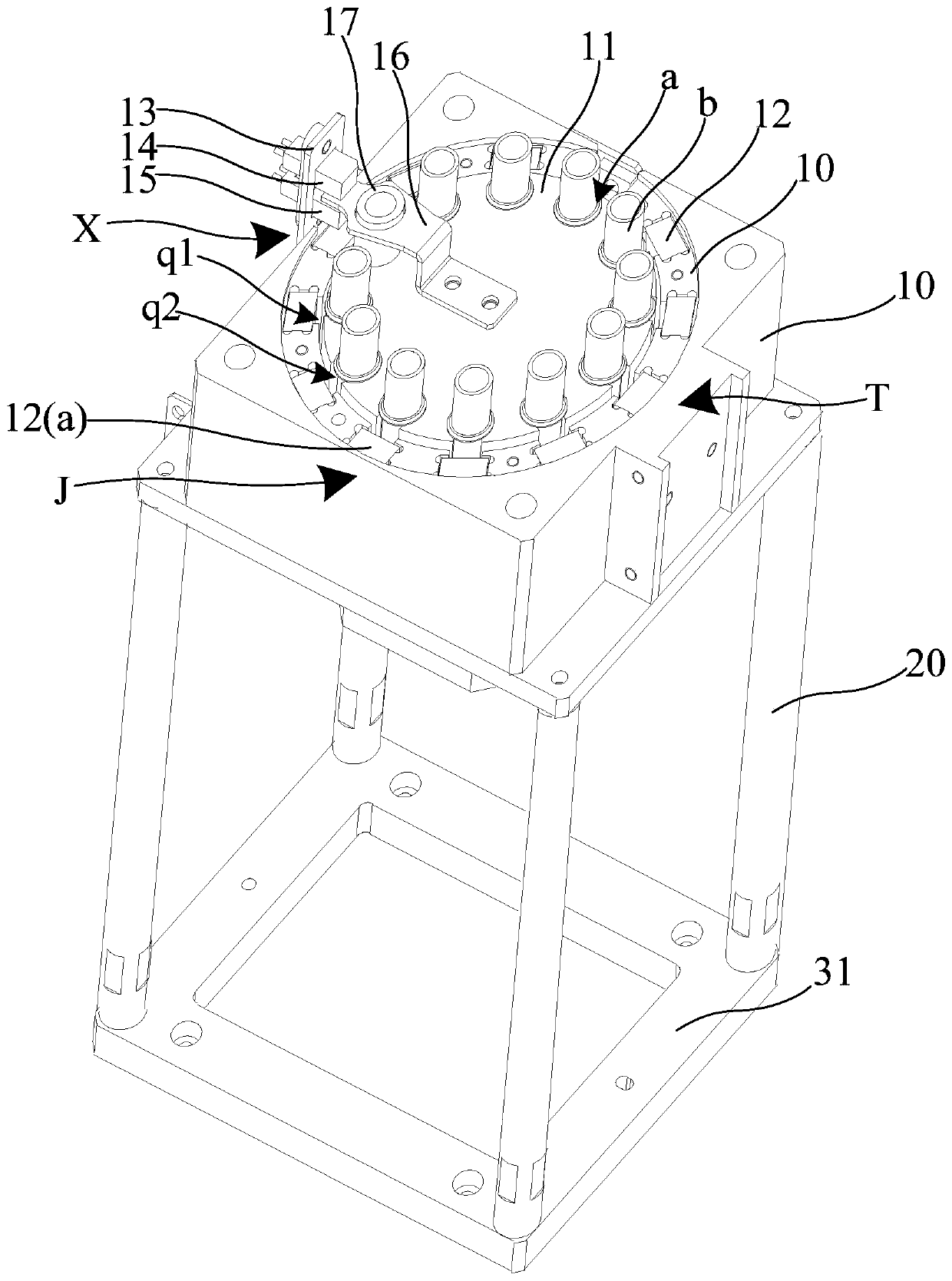

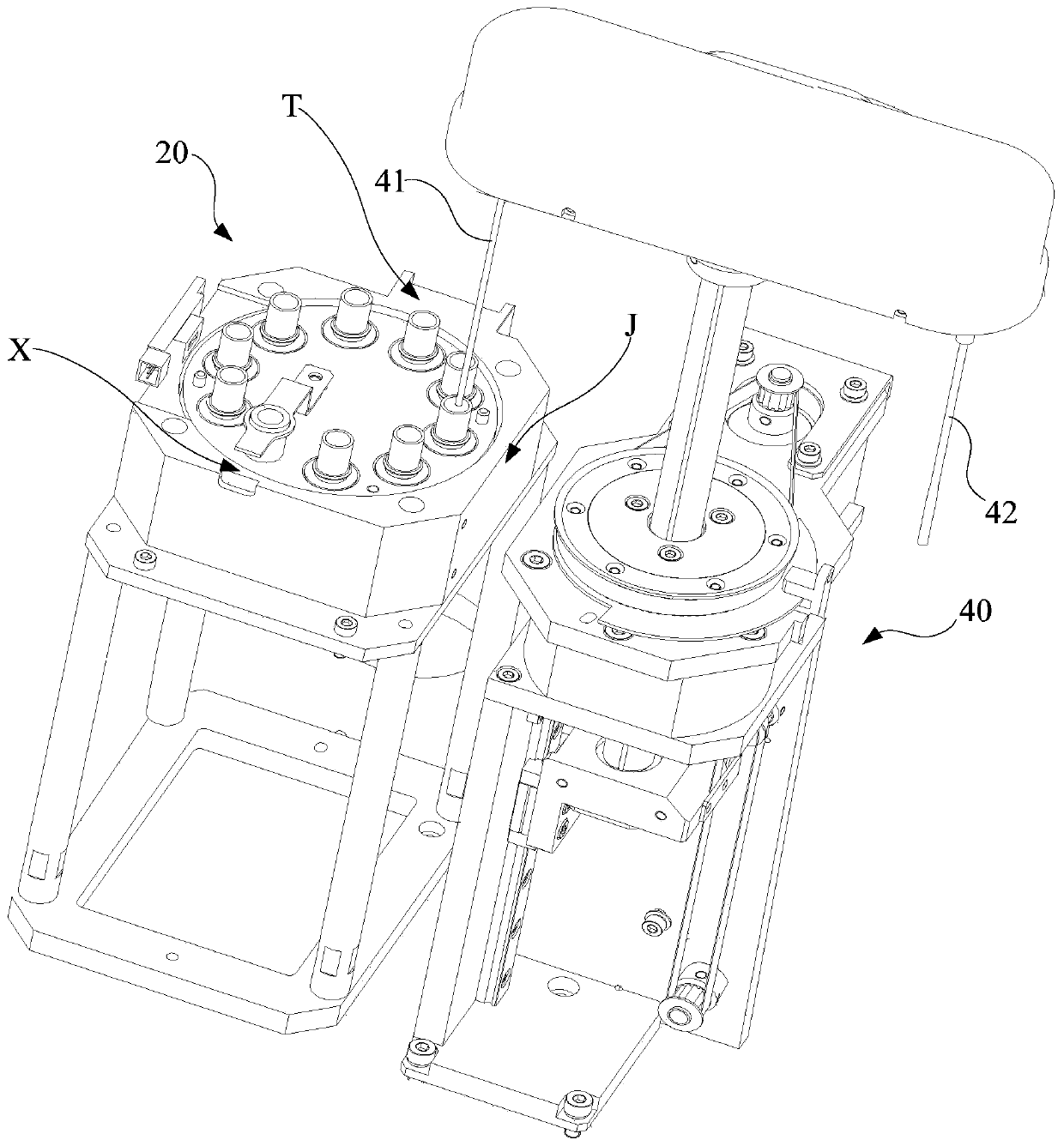

Magnetic separation device, sample analyzer, and flow fluorescence immunoassay analyzer

PendingCN111381058AReduce loadIncrease rotation ratePreparing sample for investigationFluorescence/phosphorescencePhysical chemistryFluorescence immunoassay analyzer

The invention discloses a magnetic separation device, a sample analyzer and a flow fluorescence immunoassay analyzer. The invention discloses a magnetic separation device, which comprises: a base provided with an accommodating groove; the turntable that is rotatably arranged in the accommodating groove, at least one accommodating hole is formed in the turntable, and the accommodating hole is usedfor accommodating a sample container filled with a sample and / or a magnetic compound; and the magnetic part that is arranged on the base and is used for adsorbing the magnetic compound in the sample container onto the inner wall of the sample container. The invention also discloses an immunoassay analyzer and a flow fluorescence immunoassay analyzer. The adsorption effect of the magnetic compoundcan be improved, the load of the turntable is reduced, and the magnetic separation efficiency is improved.

Owner:SHENZHEN DYMIND BIOTECH

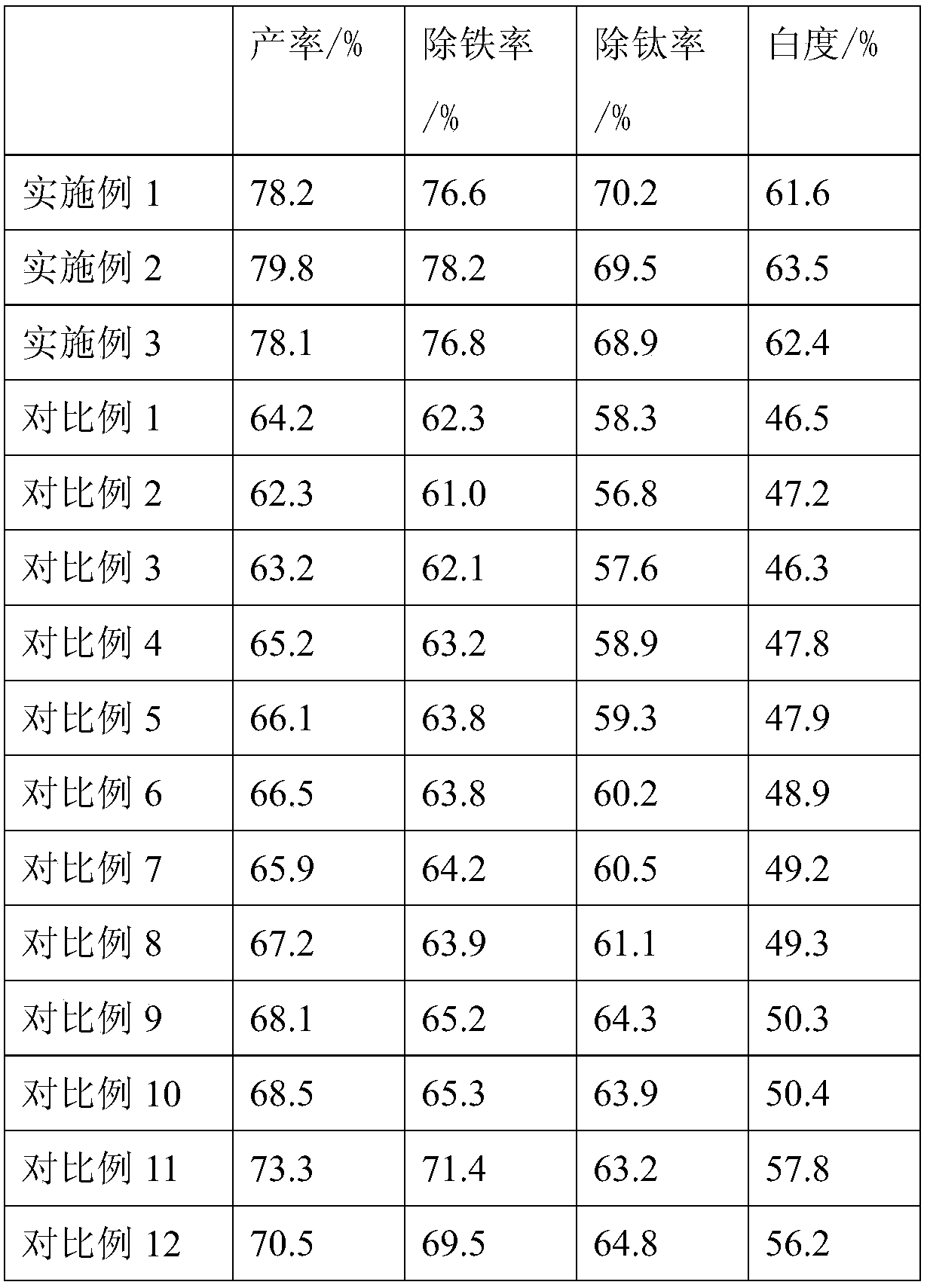

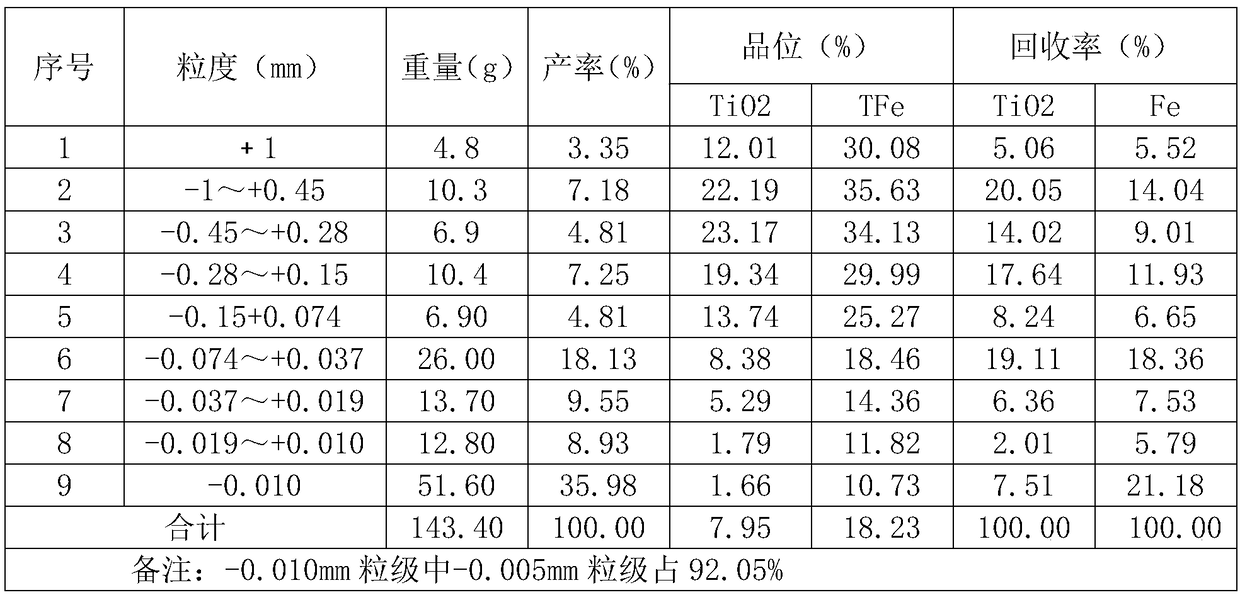

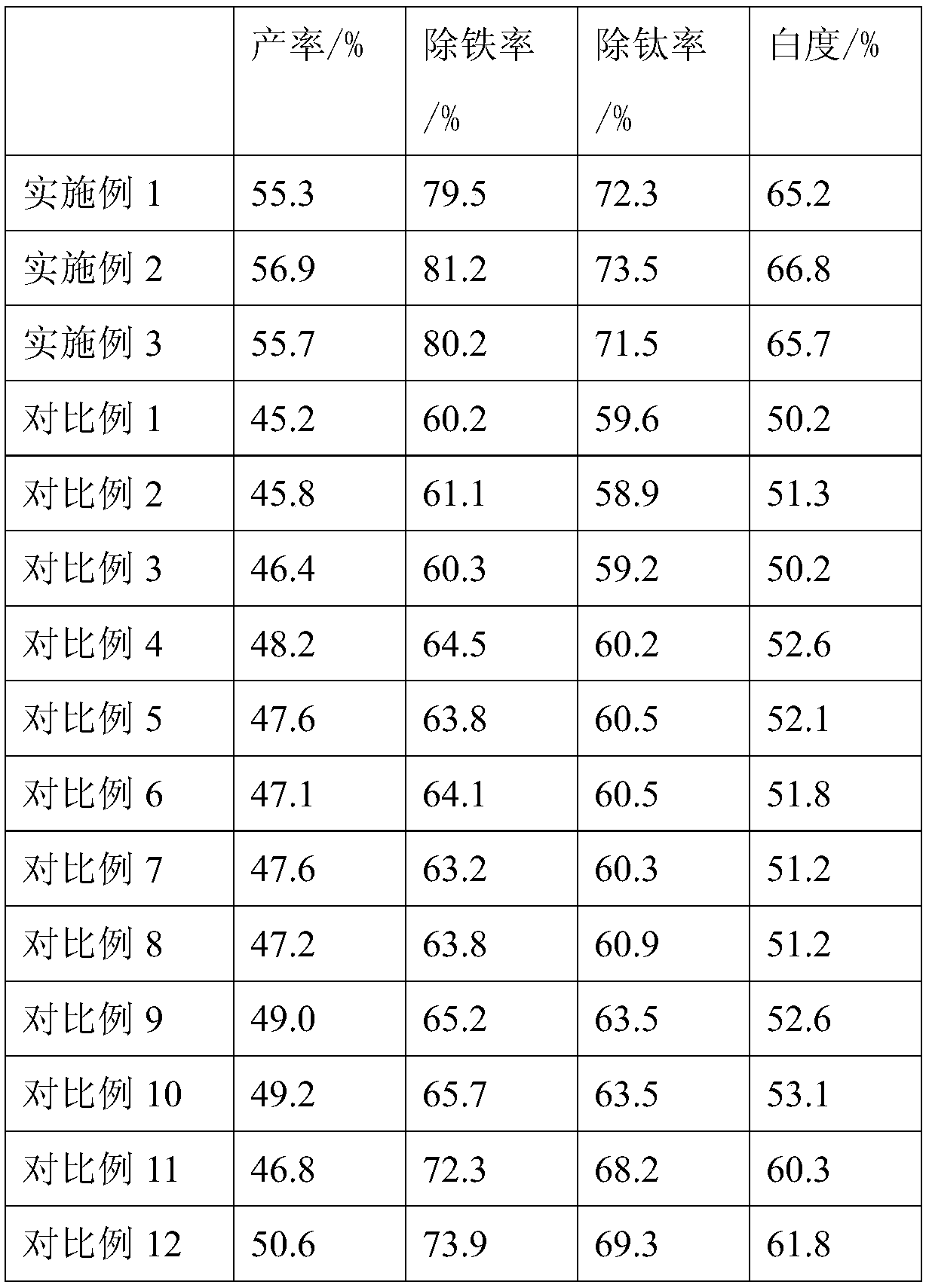

Method for improving grade of ultra-lean ore

The invention relates to a method for improving the grade of ultra-lean ore. The method comprises the following steps: 1) raw ore is subjected to open-circuit rubbing and washing by using a ball mill,and the obtained ore pulp is deslimed to obtain deslimed ore pulp; 2) the deslimed ore pulp is ground to obtain first-grade deslimed ore pulp; 3) the first-grade deslimed ore pulp is subjected to first-stage magnetic separation to obtain rough concentrate, and the tailings are discarded; 4) the rough concentrate is ground to obtain second-grade deslimed ore pulp; 5) the second-grade deslimed orepulp is subjected to second-stage magnetic separation to obtain iron rough concentrate and tailings of second-stage magnetic separation; 6) the iron rough concentrate is ground and subjected to third-stage magnetic separation to obtain iron concentrate and tailings of third-stage magnetic separation; and 7) the tailings of second-stage magnetic separation and the tailings of third-stage magnetic separation are ground and subjected to fourth-stage magnetic separation to obtain titanium concentrate, and the tailings are discarded. The method utilizes a depreciated resource and uses the ball millto deslime ilmenite with high mud content firstly; and compared with the existing traditional desliming device, the ball mill has better effect and can avoid blocking.

Owner:会理秀水河矿业有限公司

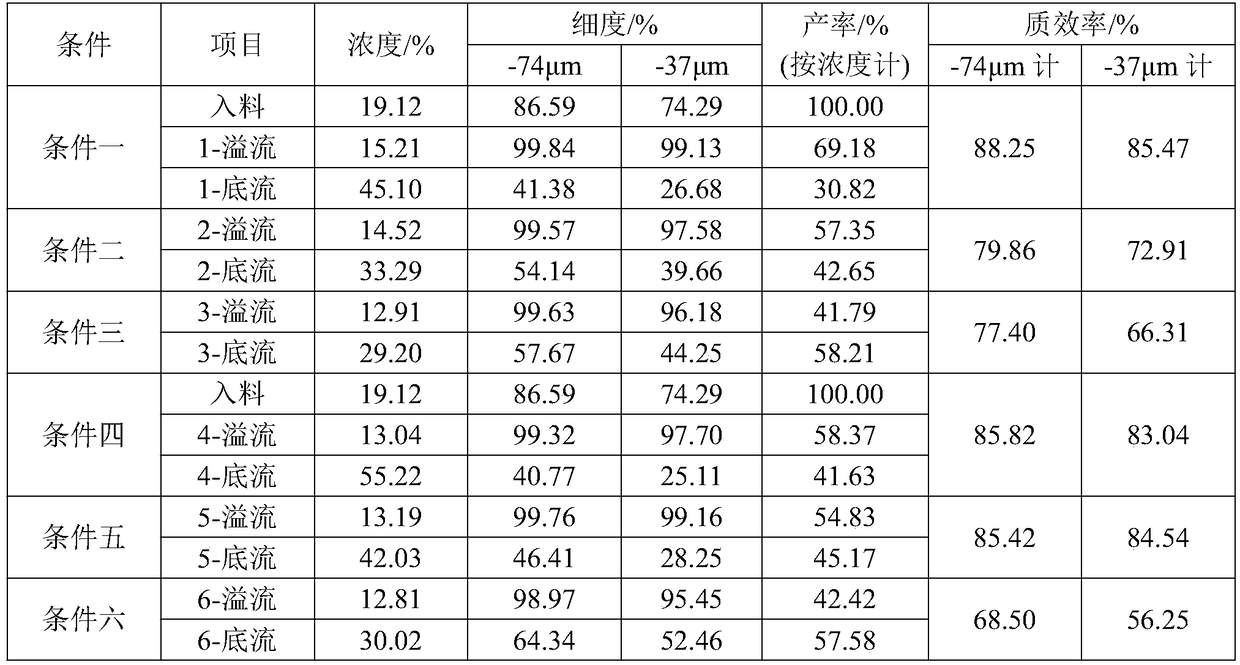

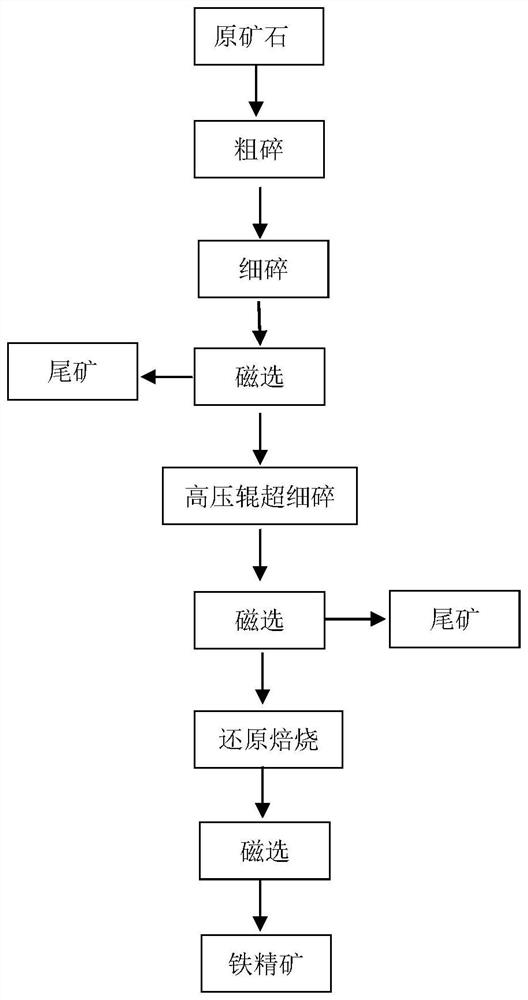

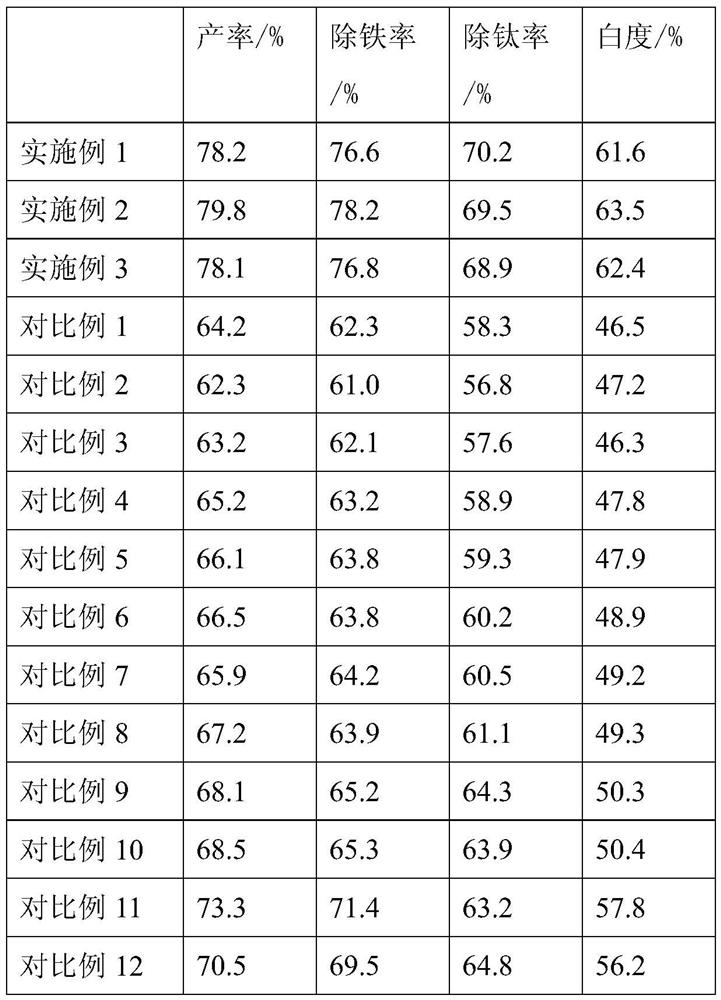

Reduction roasting-magnetic separation method for iron ore

ActiveCN113245054AImprove the efficiency of magnetic separationHigh recovery rateMagnetic separationIronstoneMagnetite

The invention relates to a reduction roasting-magnetic separation method for iron ore, in particular to a reduction roasting-magnetic separation method for low-grade vanadium titano-magnetite, which belongs to the technical field of mineral separation. The method comprises the steps that raw ore with the iron grade being 17.43%-28.59% is subjected to coarse crushing till the raw ore with the iron grade being 220-250 mm accounts for 80% or above, and then fine crushing till the raw ore with the iron grade being 30-50 mm accounts for 80% or above; waste rock and first concentrate are obtained through separation at the speed of 30-35 KA / m, the first concentrate is crushed to be 1-3 mm and accounts for 90% or above, magnetic separation is conducted at the speed of 115-125 KA / m, tailings are discarded, and second concentrate is obtained; the second concentrate, a reducing agent and a fluxing agent are mixed, roasted at 600-800 DEG C for 10-15 minutes, and cooled; and magnetic separation at 170-190 KA / m is then conducted to obtain iron ore concentrate. The magnetic separation efficiency is high, the iron recovery rate is high, the grade is greatly improved, and the resource value is maximized.

Owner:PANZHIHUA UNIV

A multi-point well water coagulation and settlement device based on micro-magnetic coagulation technology

ActiveCN110092525BUniform adsorptionEven doseWaste water treatment from quariesSpecific water treatment objectivesElectric machineryEngineering

Owner:江苏凯勒奇环保设备有限公司

A kind of production method of potassium feldspar

ActiveCN109133075BStrong harvesting abilityImprove adsorption capacityAluminium silicatesWet separationFoaming agentPotassium feldspar

The invention belongs to the technical field of mineral dressing and particularly discloses a potassium feldspar production method, comprising the specific steps of S1, removing mud; S2, ball milling;S3, magnetically removing impurities; S4, drying, to be specific, adding concentrate pulp into a drying furnace, and drying to obtain solid concentrate; S5, calcining, to be specific, transferring the solid concentrate to a calcining furnace for calcining at 1300-1500 DEG C, and adding a mixed gas of nitrogen and argon in a volume ratio of 1:2 to fill the calcining furnace during calcining; S6, removing impurities, to be specific, subjecting the calcined mineral to ball milling to the particle size of 0.5 cm so as to obtain pulp; S7, carrying out floatation, to be specific, adding sulfuric acid solution, adjusting pH of the pulp to 6.2-6.8, adding a collecting agent and a foaming agent, and collecting finished foam to obtain concentrate pulp II; S8, removing oil. The method herein helps extract main effective ingredients of potassium feldspar and also helps effectively remove the impurities that affect the color of potassium feldspar powder.

Owner:贺州市骏鑫矿产品有限责任公司

Magnetic conductive metal powder cleaning and sorting roller

PendingCN114713366AIncrease the magnetic field strengthImprove the efficiency of magnetic separationPlastic recyclingMagnetic separationMagnetic separatorLocked plate

The invention discloses a magnetic conductive metal powder cleaning and separating roller, and belongs to the technical field of magnetic separators. Comprising a shell, a door opening assembly and a magnetic core frame, a fixing frame is vertically arranged on the side wall of the shell, a sliding groove is formed in the side wall of the shell, the door opening assembly is arranged in the sliding groove, the door opening assembly comprises a locking hand wheel, a handle and a sliding door, the bottom of the sliding door is arranged in the sliding groove to form a sliding structure, and a locking plate is vertically arranged on the side wall of the sliding door. The locking plate is fixed through the locking hand wheel and the fixing frame, the magnetic core frame is arranged in the shell and comprises an upper frame, a lower frame and a guide sleeve, the upper frame and the lower frame are coaxial, the magnetic field intensity is high, the magnetic separation efficiency is improved, a magnetic bar is of a completely-closed structure, and the magnetic bar is smooth and labor-saving to insert back; and a gap between the external diameter of the magnetic rod and the internal diameter of the sleeve is large.

Owner:BEIJING SAINIGE MAGNETOELECTRICITY TECH

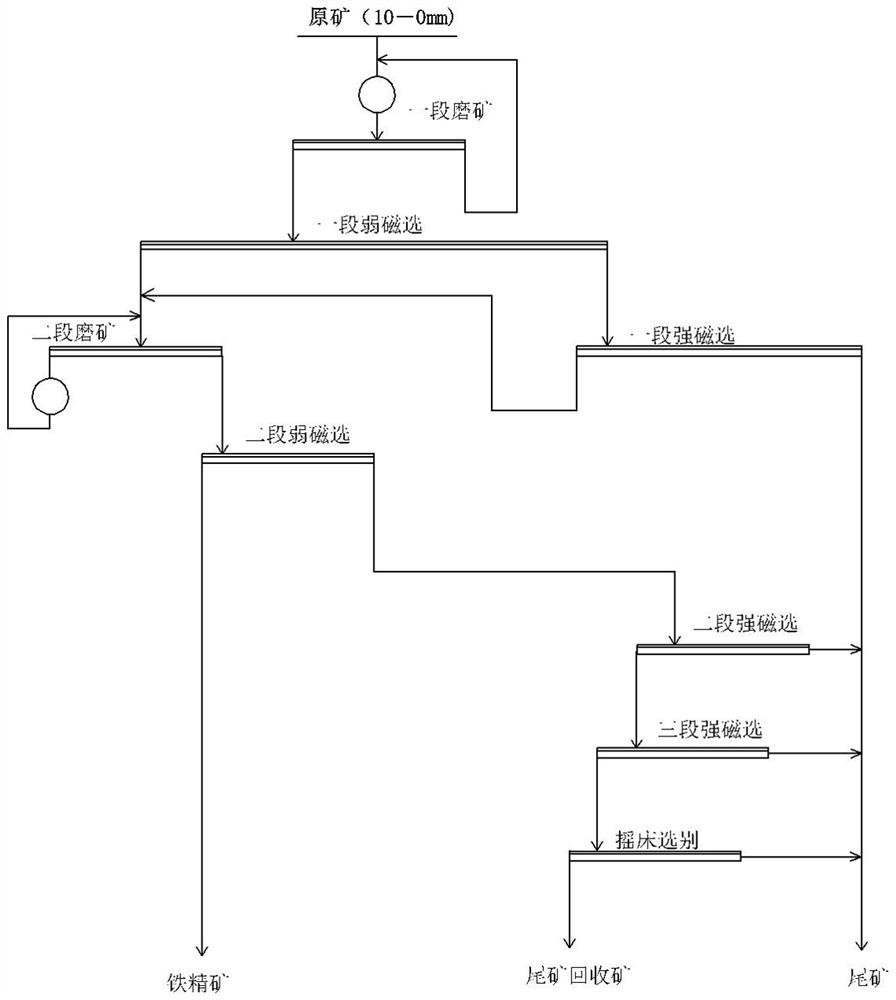

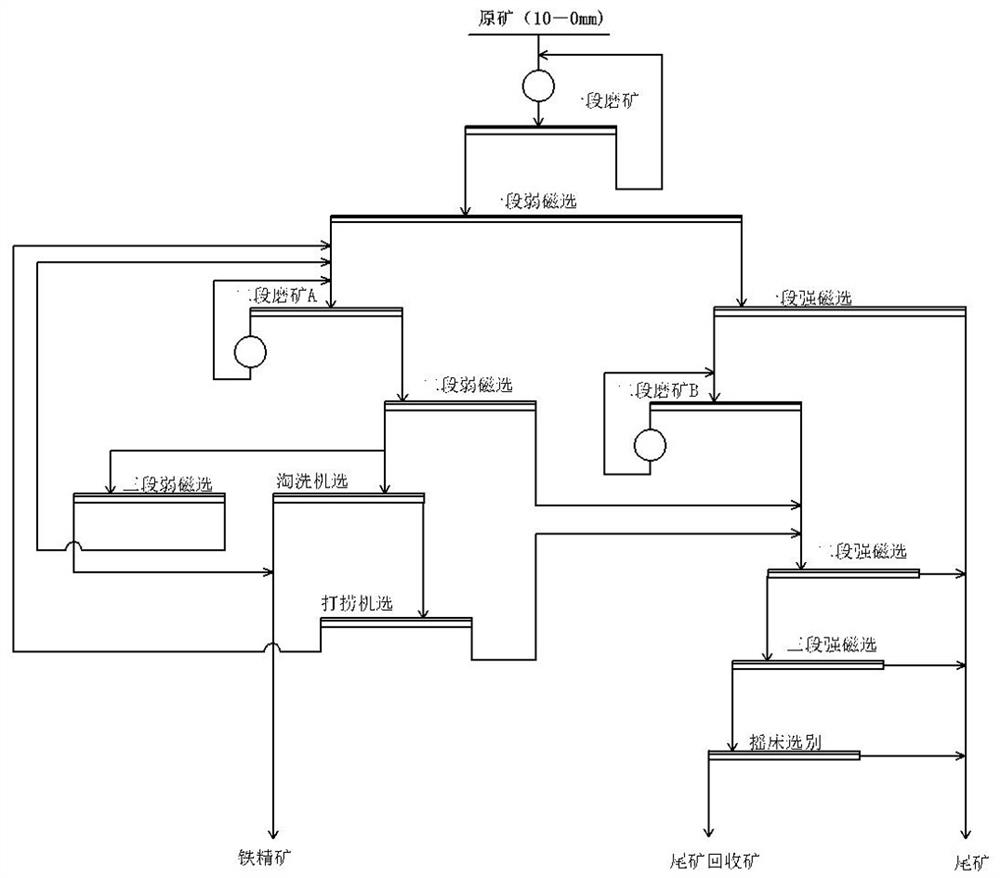

A beneficiation process for lava ore separation, grinding, separation, quality improvement and tail reduction

ActiveCN111013809BReduce in quantityRaise the gradeMagnetic separationWet separationMagnetiteEngineering

The invention discloses a lava ore beneficiation process for grinding, sorting, improving quality and reducing tail, including one-stage grinding, one-stage weak magnetic separation, second-stage grinding A, second-stage weak magnetic separation, elutriation machine separation, three-stage weak magnetic separation Magnetic separation, salvage machine separation, one-stage strong magnetic separation, two-stage grinding B, two-stage strong magnetic separation, three-stage strong magnetic separation, gravity separation. The invention realizes separate grinding and separation of magnetite and hematite, reduces the contradiction between over-grinding and under-grinding, improves the efficiency of magnetic separation, improves the grade of final iron concentrate, reduces the grade of recovered ore from tailings, and increases production efficiency .

Owner:YUXI DAHONGSHAN MINING

Production method of albite

ActiveCN108906314AStrong harvesting abilityImprove adsorption capacityWet separationFoaming agentAlkali feldspar

The invention belongs to the technical field of ore dressing, and particularly discloses a production method of albite. The production method comprises the following specific steps of S1, desilting; S2, ball grinding; S3, magnetic separation impurity removal; S4, drying, wherein concentrate pulp is added into a drying furnace to be dried to obtain solid concentrates; S5, calcining, the solid concentrates are transferred into a calcining furnace to be calcined, and the calcining temperature ranges from 1200 DEG C to 1350 DEG C; S6, impurity removal, wherein calcined ore is subjected to ball grinding, ball grinding is carried out till the particle size is smaller than 0.5 cm, and ore pulp is obtained; S7, flotation, wherein a sulfuric acid solution is added, the pH value of the ore pulp is adjusted to range from 6.0 to 6.5, then a collecting agent and a foaming agent are added, foam products are collected, and concentrate pulp B is obtained; and S8, oil removal. By means of the treatmentmethod, the main effective components of the albite can be purified, and impurities influencing the color of the albite can be effectively removed.

Owner:贺州市骏鑫矿产品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com