A wet cycle electromagnetic separator

An electromagnetic and machine selection technology, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of inconvenient management, large floor space, and long process, and achieve easy management, small floor space, and process flow short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

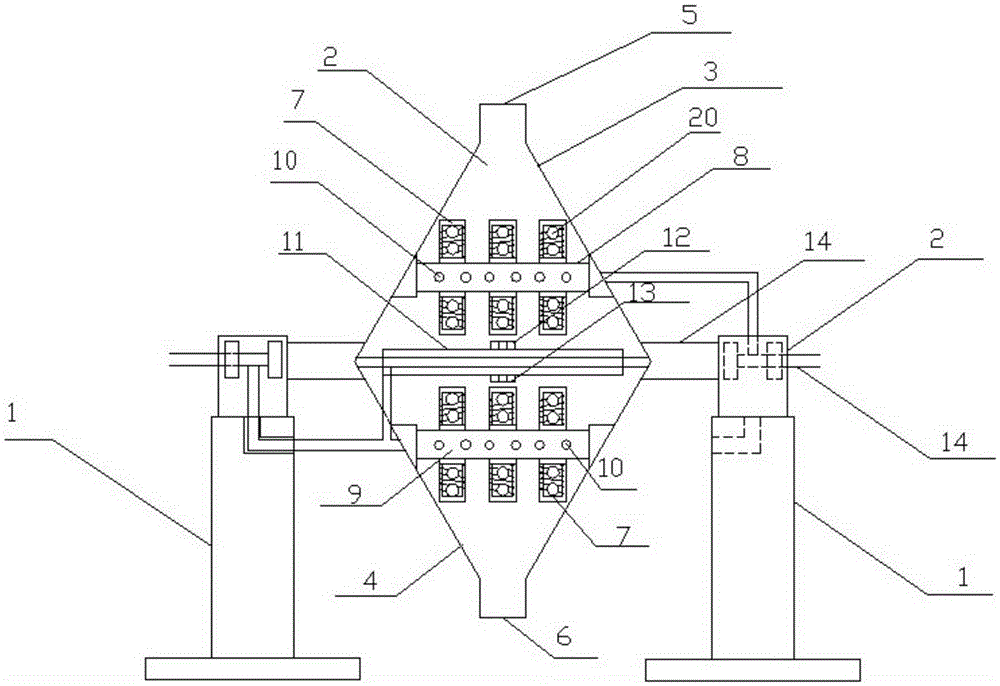

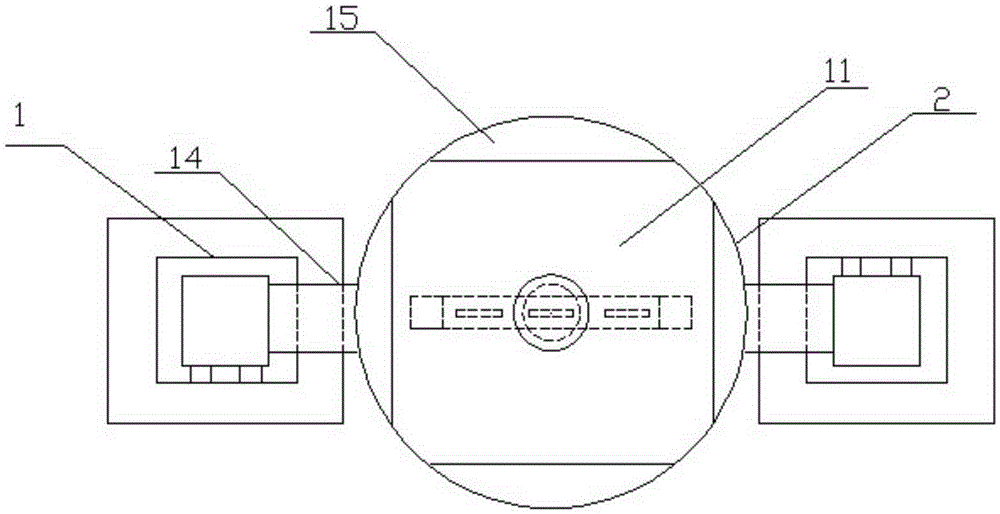

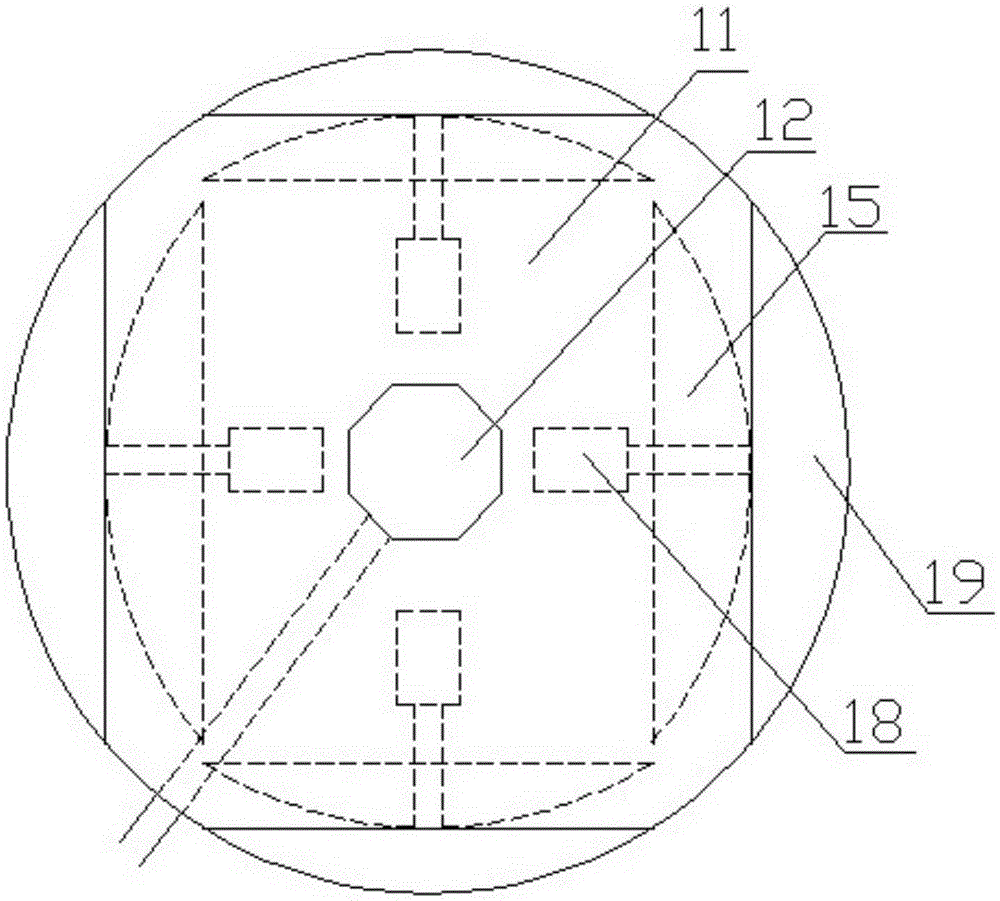

[0019] Referring to the accompanying drawings, a wet cycle electromagnetic separator includes a support 1, a magnetic separation cylinder 2 is set on the support 1 through a rotating shaft 14, and the magnetic separation cylinder 2 is composed of an upper conical cylinder 3 and a lower conical cylinder 4 connected to the bottom surface , the tops of the upper cone 3 and the lower cone 4 are the upper water inlet and outlet 5 and the lower water inlet and outlet 6 respectively, the upper cone 3 and the lower cone 4 are respectively rotated and provided with rotating shafts, and multiple rows of electromagnets are fixedly arranged on the rotating shafts 7. Leakage holes are distributed on the electromagnet 7. The upper conical cylinder 3 and the lower conical cylinder 4 are provided with an upper water spray pipe 8 and a lower water spray pipe 9 with covers placed outside the rotating shaft. Spray holes 10 are distributed on the water spray pipe 9, the upper water spray pipe 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com