Wind Dry Magnetic Separator

A magnetic separation and dry-type technology, which is applied in the direction of magnetic separation, solid separation, and separation of solids from solids with airflow, can solve the problems of difficult to balance grade and recovery rate at the same time, poor primary roller effect, fluidization High bed design requirements, to achieve the effect of solving the problem of fine-grained magnetic agglomeration inclusions, improving efficiency, and reducing magnetic agglomeration inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

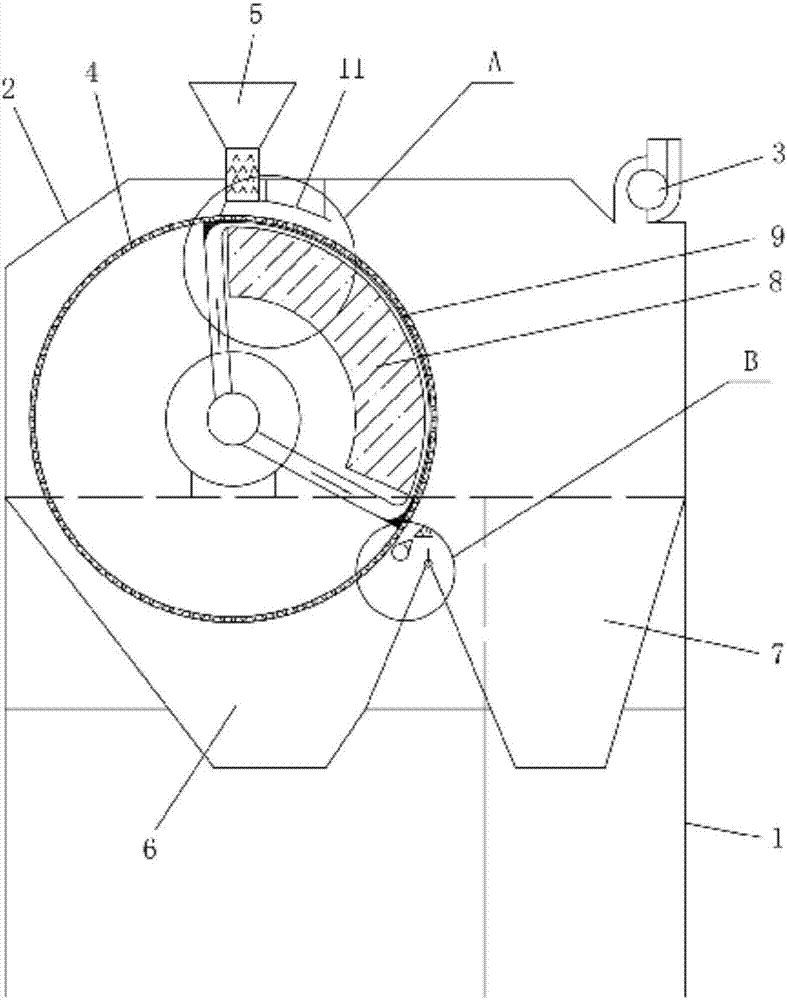

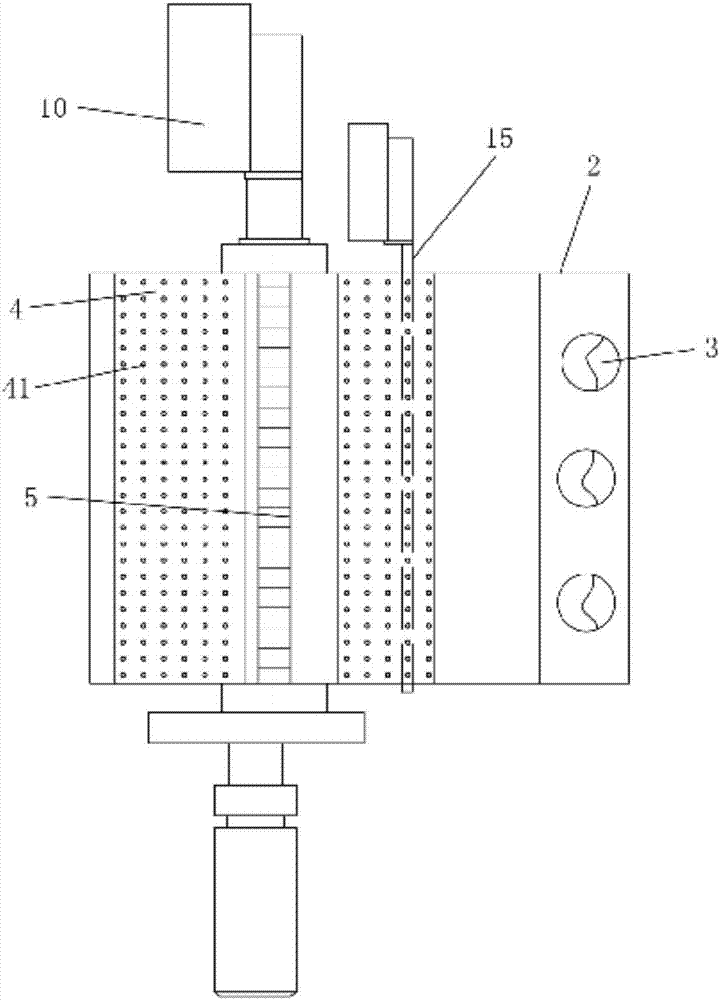

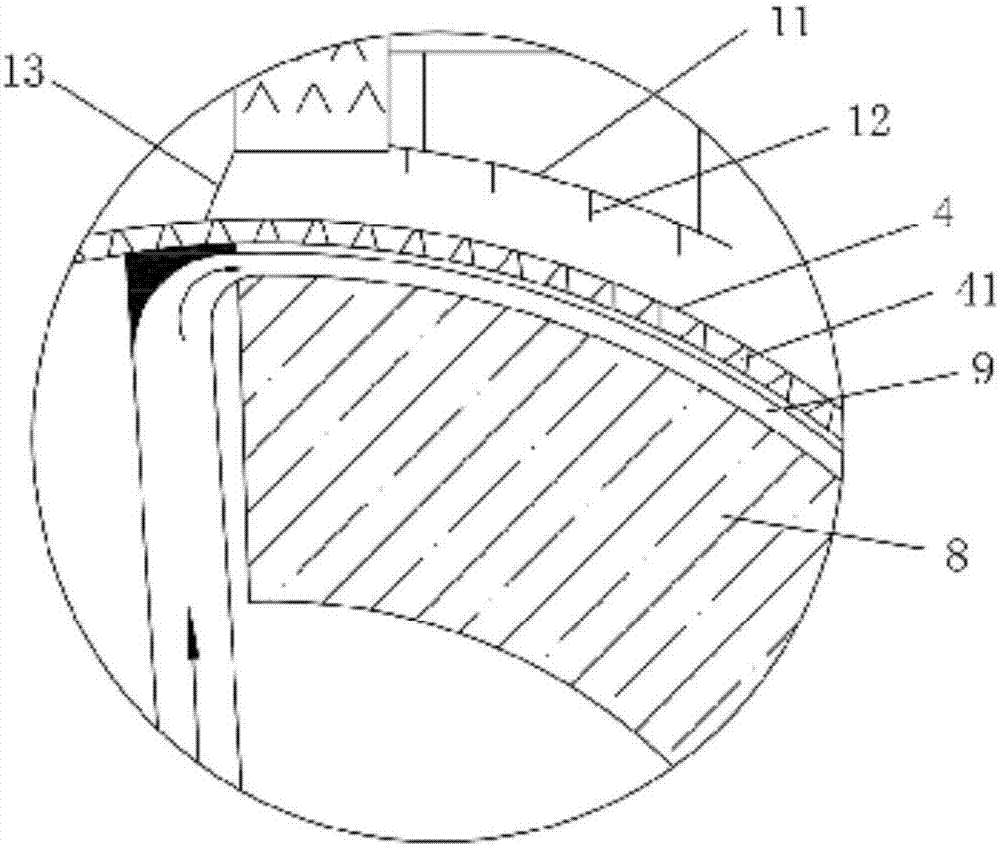

[0035] Such as Figure 1 to Figure 4As shown, the air dry magnetic separator of the present embodiment includes a frame 1, a casing 2, a dust removal device 3 that communicates with the inner cavity of the casing 2 for exhausting and dust removal, and is installed in the casing 2 and driven by a driving device. The rotating non-magnetic cylindrical screen roller 4, the casing 2 is installed on the frame 1, the dust removal device 3 adopts the combination of the exhaust fan and the exhaust pipe, the driving device adopts the combination of the existing motor and the reducer, and the driving device drives the non-magnetic circular The rotation speed of the cylinder screen roller 4 is adjustable to suit different sorting conditions. A feeding device 5 is installed above the non-magnetic cylinder screen roller 4. The feeding device 5 is a feeding hopper, and the outlet of the feeding hopper is located in the non-magnetic Directly above the cylinder sieve roller 4 and below the non...

Embodiment 2

[0048] The air dry type magnetic separator of the present embodiment is basically the same as Embodiment 1, the difference is: as Figure 8 and Figure 9 As shown, the wind chamber 9 in this embodiment includes an annular chamber arranged along the circumference of the entire inner surface of the non-magnetic cylindrical screen roller 4, and the annular chamber is divided into 6 to 90 ring-shaped chambers around the non-magnetic cylindrical screen roller 4 by partitions. The third small chambers 104 arranged in the circumferential direction, each of the third small chambers 104 are provided with an air guide channel at both ends, and the rotating shaft of the non-magnetic cylindrical sieve roller 4 is provided with a The hollow air supply pipe 105, each air guide channel extends to the hollow air supply pipe 105 along the radial direction of the non-magnetic cylindrical screen roller 4 and is in contact with the outer surface of the hollow air supply pipe 105, and the hollow a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com