Reduction roasting-magnetic separation method for iron ore

A technology of iron ore roasting, which is applied in reduction roasting-magnetic separation of iron ore and reduction roasting-magnetic separation of low-grade vanadium-titanium magnetite. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

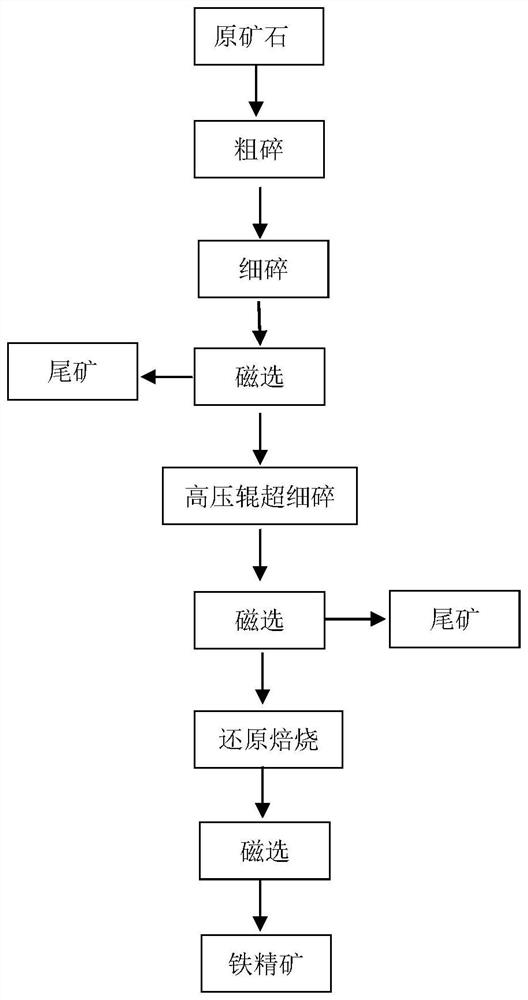

Image

Examples

Embodiment 1

[0049] A, the vanadium-titanium magnetite produced in Panzhihua, the iron grade is 23.74%, and the main impurity components contain titanium dioxide mass percentage content of 12.47%, vanadium pentoxide mass percentage content of 0.493%, magnesium oxide mass percentage content of 3.85%, 0.03% by mass of cobalt, 1.68% by mass of calcium oxide, 0.67% by mass of sulfur, 0.018% by mass of nickel, and 0.014% by mass of phosphorus; to the crushing workshop. Jaw crusher is used for coarse crushing, the designed coarse crusher feed capacity is Qh=3000.0t / h, feed particle size is 1200-0mm, discharge particle size is 250-0mm, and loose density is 2.28t / m 3 , Design the ore discharge port e=250mm, design and select the production capacity: Q=4300t / h, the obtained coarse crushing products 220-250mm account for 80%.

[0050] Then finely grind and design the ore outlet e=50mm, and finely crush to obtain finely crushed products of 30-50mm, accounting for 80%.

[0051] B. Pre-throw tail

...

Embodiment 2

[0059] A, a kind of magnetite with an iron grade of 27.45% produced in Sichuan, the impurity components containing titanium dioxide mass percentage is 11.59%, vanadium pentoxide mass percentage is 0.375%, magnesium oxide mass percentage is 4.93 %, 0.02% by mass of cobalt, 1.47% by mass of calcium oxide, 0.73% by mass of sulfur, 0.015% by mass of nickel, and 0.019% by mass of phosphorus. workshop. First use the jaw crusher to coarsely crush it to -230mm, design the ore discharge port e=230mm, and obtain coarse crushed products of 220-230mm accounting for 80%; then finely crush it to -30mm, design the ore discharge port e=30mm, Finely crushed products of 30-50mm in size account for 80%.

[0060] B. Pre-throw tail

[0061] The finely crushed products are separated by a dry magnetic separator at a magnetic field strength of 33KA / m to obtain iron concentrate and non-metallic waste rock. High-grade iron ore concentrate II was obtained by magnetic separation under a magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com