A beneficiation process for lava ore separation, grinding, separation, quality improvement and tail reduction

A separate grinding and sorting technology, which is applied in the field of mineral processing, can solve the problems of increasing the number of second-stage weak magnetic separation equipment, difficulty in meeting the requirements of iron concentrate grade, and high grade of tailings recovery ore, so as to achieve perfect tailings recovery ore and tailings Ore indicators, improving the efficiency of magnetic separation, reducing the effect of tailings grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

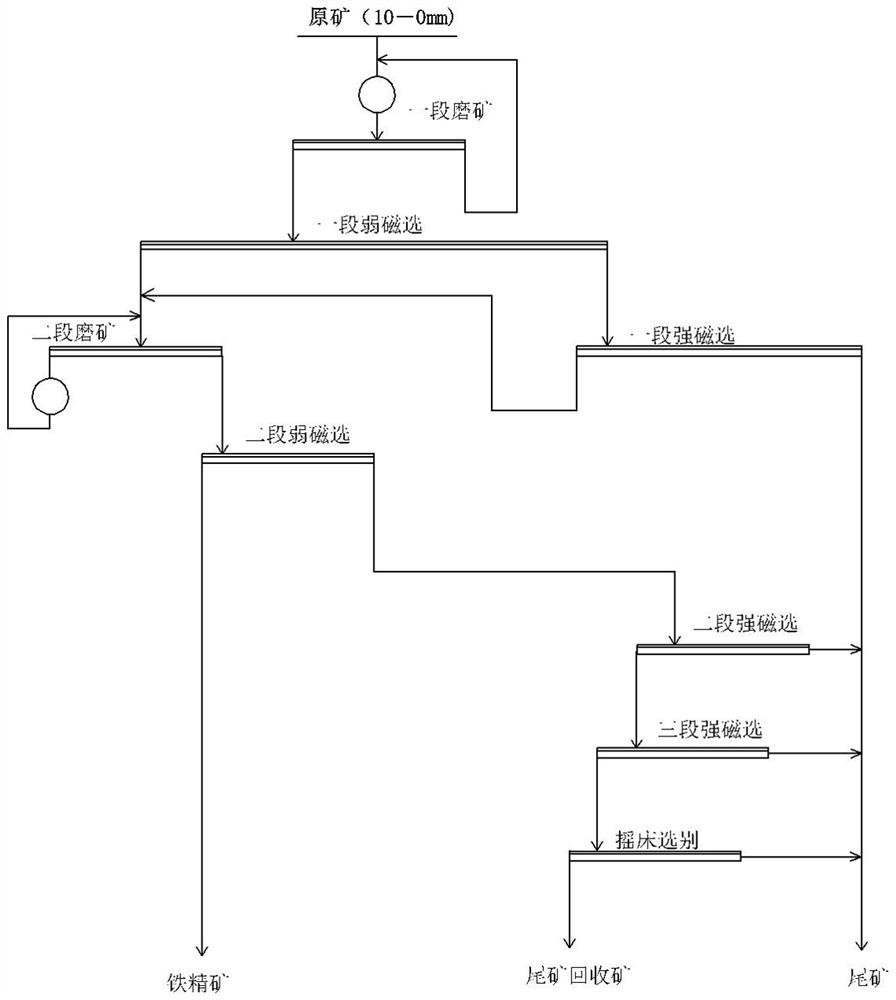

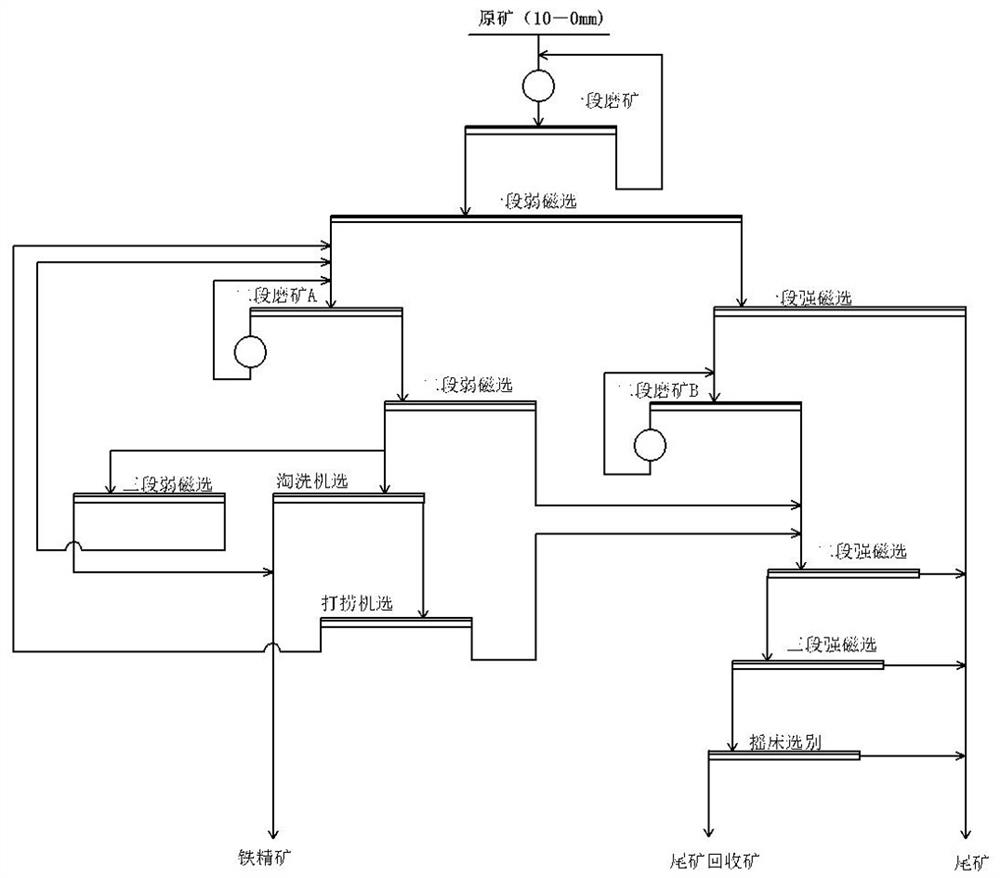

[0012] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

[0013] as attached Figure 1~2 The present invention shown includes one-stage grinding, one-stage weak magnetic separation, two-stage grinding A, two-stage weak magnetic separation, elutriation machine separation, three-stage weak magnetic separation, salvage machine separation, one-stage strong magnetic separation, and two-stage grinding B. Two-stage strong magnetic separation, three-stage strong magnetic separation, and re-election, specifically including:

[0014] 1) One-stage grinding: Grinding the lava ore, the grinding fineness -200 mesh content is 73% to 78%;

[0015] 2) One stage of weak magnetic separation: the above-mentioned products after one stage of grinding are fed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com