Production method of albite

A production method and albite technology, applied in the field of albite production, can solve problems such as limiting product application range, reducing product quality, affecting raw ore and product whiteness, achieving excellent collection capacity, improving efficiency, removing rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

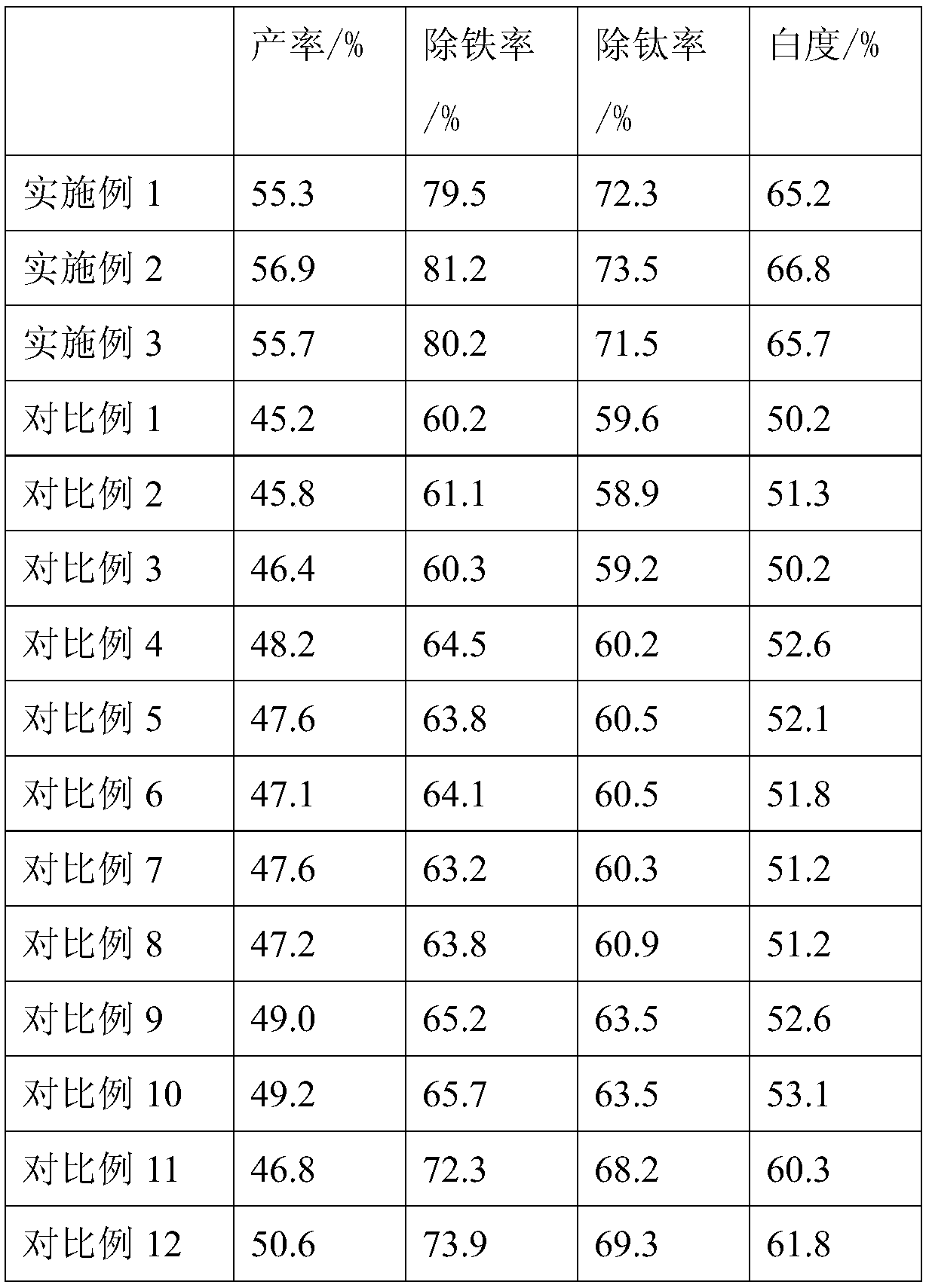

Examples

Embodiment 1

[0024] A kind of production method of albite, concrete steps are as follows:

[0025] S1. Desilting: excavate low-grade albite raw ore, and transfer the raw ore to the washing machine through a screw conveyor whose pitch ratio of the screw blades of the first half section and the screw blades of the second half section is 3:1. There is a spiral cleaning pipeline, and high-pressure nozzles are evenly arranged around the cleaning pipeline. The water outlet of the high-pressure nozzle faces the inside of the cleaning pipeline. The water inlet of the high-pressure nozzle is connected to the water pipe, and the water pipe is connected to the high-pressure pump. Turn on the high-pressure pump, and water is sprayed from the high-pressure nozzle to wash the raw ore in the cleaning pipeline to remove the sludge on the surface of the raw ore;

[0026] S2, ball milling: dehydrate the raw ore processed in step S1, and then send it into a ball mill for ball milling until the particle size ...

Embodiment 2

[0034] A kind of production method of albite, concrete steps are as follows:

[0035] S1. Desilting: excavate low-grade albite raw ore, and transfer the raw ore to the washing machine through a screw conveyor whose pitch ratio of the screw blades of the first half section and the screw blades of the second half section is 5:1. There is a spiral cleaning pipeline, and high-pressure nozzles are evenly arranged around the cleaning pipeline. The water outlet of the high-pressure nozzle faces the inside of the cleaning pipeline. The water inlet of the high-pressure nozzle is connected to the water pipe, and the water pipe is connected to the high-pressure pump. Turn on the high-pressure pump, and water is sprayed from the high-pressure nozzle to wash the raw ore in the cleaning pipeline to remove the sludge on the surface of the raw ore;

[0036] S2, ball milling: dehydrate the raw ore processed in step S1, and then send it into a ball mill for ball milling until the particle size ...

Embodiment 3

[0044] A kind of production method of albite, concrete steps are as follows:

[0045] S1. Desilting: excavate low-grade albite raw ore, and transfer the raw ore to the washing machine through a screw conveyor whose pitch ratio of the screw blades of the first half section and the screw blades of the second half section is 4:1. There is a spiral cleaning pipeline, and high-pressure nozzles are evenly arranged around the cleaning pipeline. The water outlet of the high-pressure nozzle faces the inside of the cleaning pipeline. The water inlet of the high-pressure nozzle is connected to the water pipe, and the water pipe is connected to the high-pressure pump. Turn on the high-pressure pump, and water is sprayed from the high-pressure nozzle to wash the raw ore in the cleaning pipeline to remove the sludge on the surface of the raw ore;

[0046] S2, ball milling: dehydrate the raw ore processed in step S1, and then send it into a ball mill for ball milling until the particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com